Method and system for reducing operation of clean circulating water system

A ring water purification and reduction technology, applied in the water supply pipeline system, water supply equipment, water supply equipment, etc., can solve the problem of increasing the water treatment of the pipe network and environmental protection load, the high circulating water volume of the system, and the uneconomical operation mode, etc. problems, to achieve the effect of reducing energy consumption and water consumption, reducing the cost of purchasing water, and reducing the cost of circulating water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

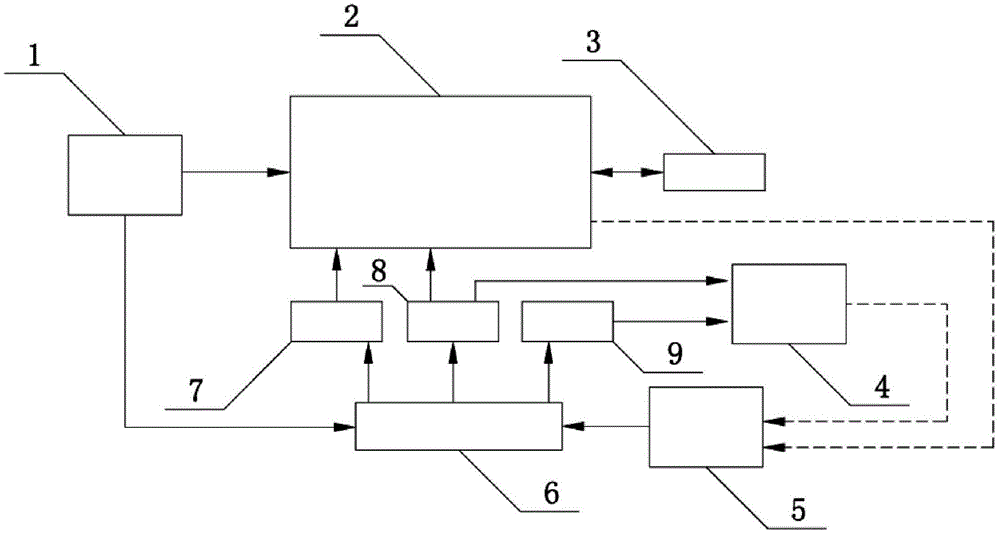

Image

Examples

Embodiment 1

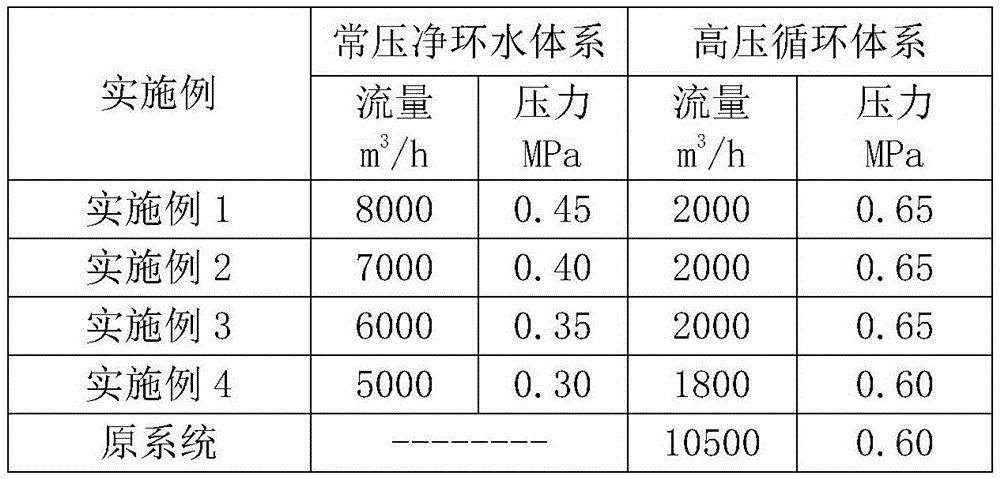

[0032] The treated water production capacity of sewage treatment station 1 is 6000m 3 / h, the supply of normal pressure ring water system 2 is 4000m 3 / h, transported to the large-capacity storage tank 6 is 2000m 3 / h; Atmospheric pressure ring water system 2 replenishment water volume 8000m 3 / h, pressure 0.45MPa, high pressure circulation system 4 supplementary water volume 2000m 3 / h, pressure 0.65MPa, circulation system backwater 5 flow rate 4000m 3 / h.

Embodiment 2

[0034] The treated water production capacity of sewage treatment station 1 is 6000m 3 / h, the supply of normal pressure ring water system 2 is 3000m 3 / h, transported to the large-capacity storage tank 6 is 3000m 3 / h; Atmospheric pressure ring water system 2 replenishment water volume 7000m 3 / h, system pressure 0.40MPa, high pressure circulation system 4 supplementary water volume 2000m 3 / h, system pressure 0.65MPa, circulation system backwater 5 flow rate 3500m 3 / h.

Embodiment 3

[0036] The treated water production capacity of sewage treatment station 1 is 6000m 3 / h, the supply of normal pressure ring water system 2 is 2500m 3 / h, transported to the large-capacity storage tank 6 is 3500m 3 / h; Atmospheric pressure ring water system 2 replenishment water volume 6000m 3 / h, system pressure 0.35MPa, high pressure circulation system 4 supplementary water volume 2000m 3 / h, system pressure 0.65MPa, circulation system backwater 5 flow rate 3000m 3 / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com