A method and system for configuring fresh industrial water

A configuration method and new water technology, applied in industrial water supply conservation, water supply installations, water supply installations, etc., to achieve the effects of reducing water purchase costs, alleviating tension, and reducing energy consumption for water intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

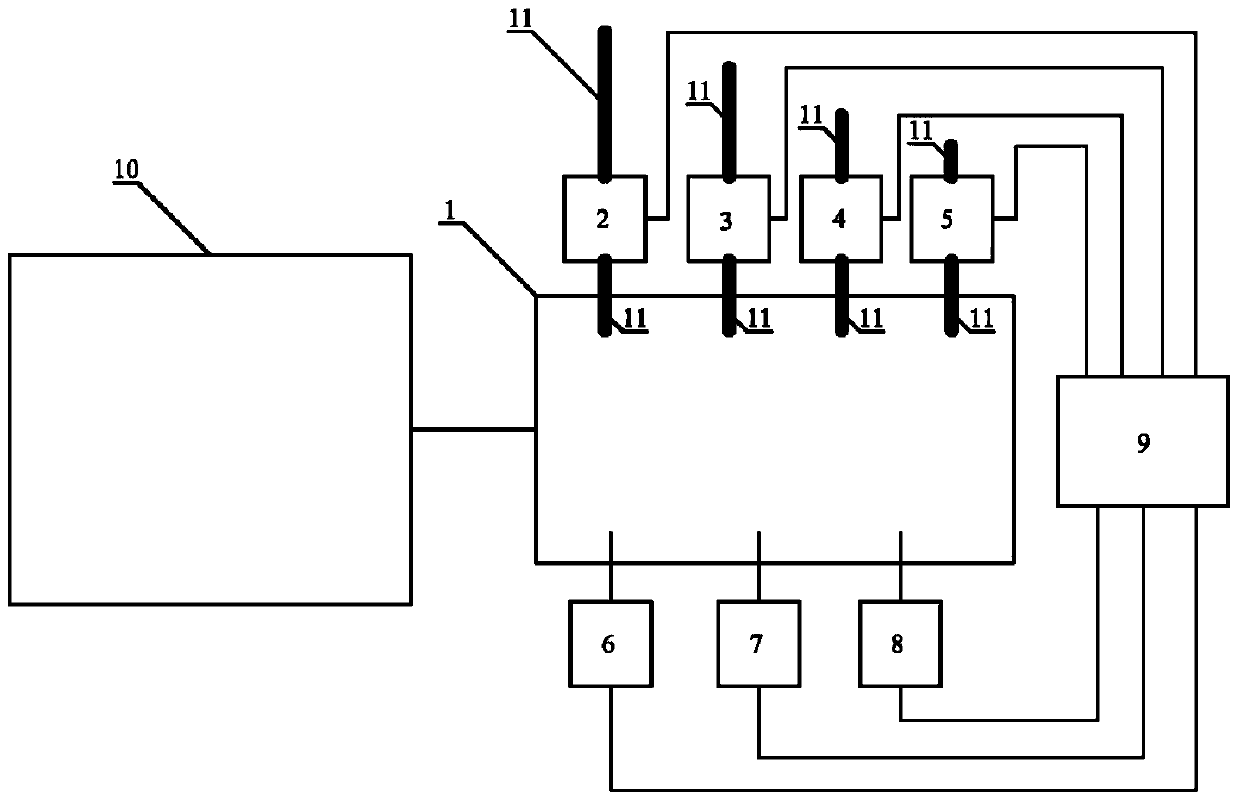

Image

Examples

Embodiment 1

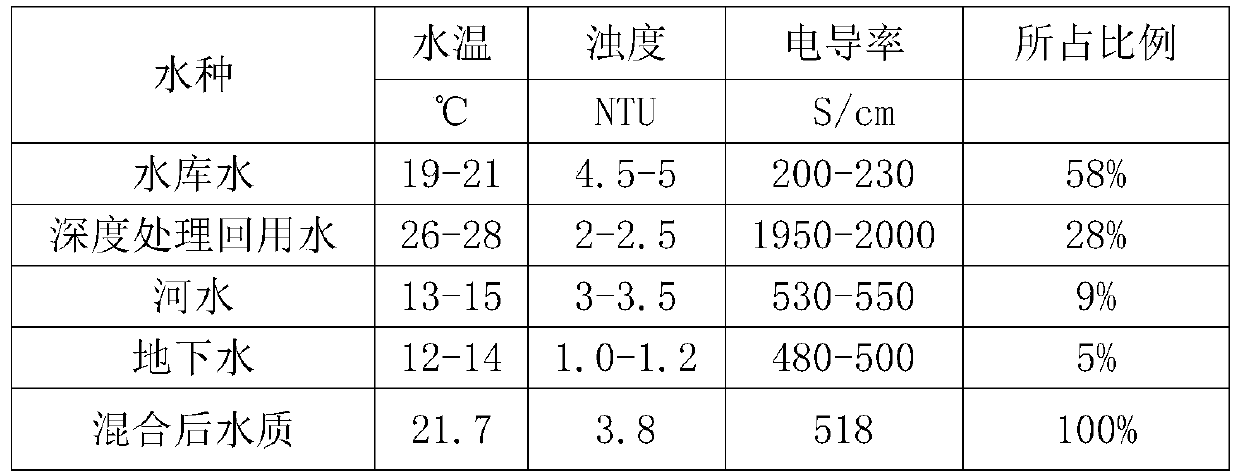

[0036] The use standard of industrial fresh water mainly includes three aspects: water temperature, turbidity and electrical conductivity, in which temperature determines the cooling effect, and turbidity and electrical conductivity have an important impact on corrosion and scaling. Reservoir water, advanced treatment reuse water, river water, groundwater, and water quality mixed in a certain proportion are shown in Table 1:

[0037] Table 1

[0038]

Embodiment 2

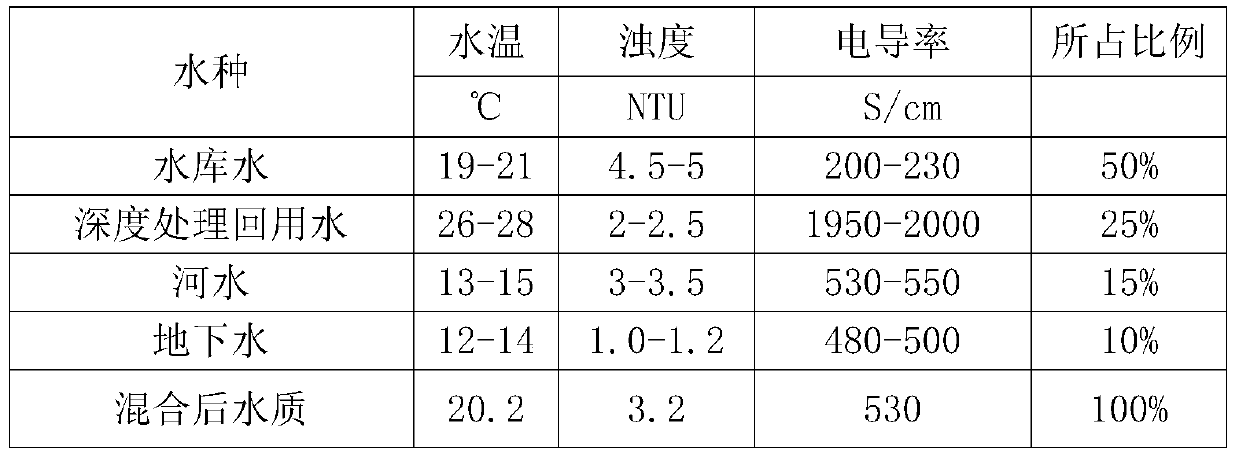

[0040] The use standard of industrial fresh water mainly includes three aspects: water temperature, turbidity and electrical conductivity, in which temperature determines the cooling effect, and turbidity and electrical conductivity have an important impact on corrosion and scaling. Reservoir water, advanced treatment reuse water, river water, groundwater, and water quality mixed in a certain proportion are shown in Table 2:

[0041] Table 2

[0042]

Embodiment 3

[0044] The use standard of industrial fresh water mainly includes three aspects: water temperature, turbidity and electrical conductivity, in which temperature determines the cooling effect, and turbidity and electrical conductivity have an important impact on corrosion and scaling. Reservoir water, advanced treatment reuse water, river water, groundwater, and water quality mixed in a certain proportion are shown in Table 3:

[0045] table 3

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com