Desulfurization and denitrification agent with pickling waste residues from steel and iron plants as main materials and removal method

A pickling waste slag, desulfurization and denitrification technology, applied in the fields of electric power, steel, energy, chemical industry and environmental protection, can solve the problems of large equipment, large quantities, high operating costs, etc., achieve simple preparation and removal methods, low cost, and realize boiler The effect of flue gas dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

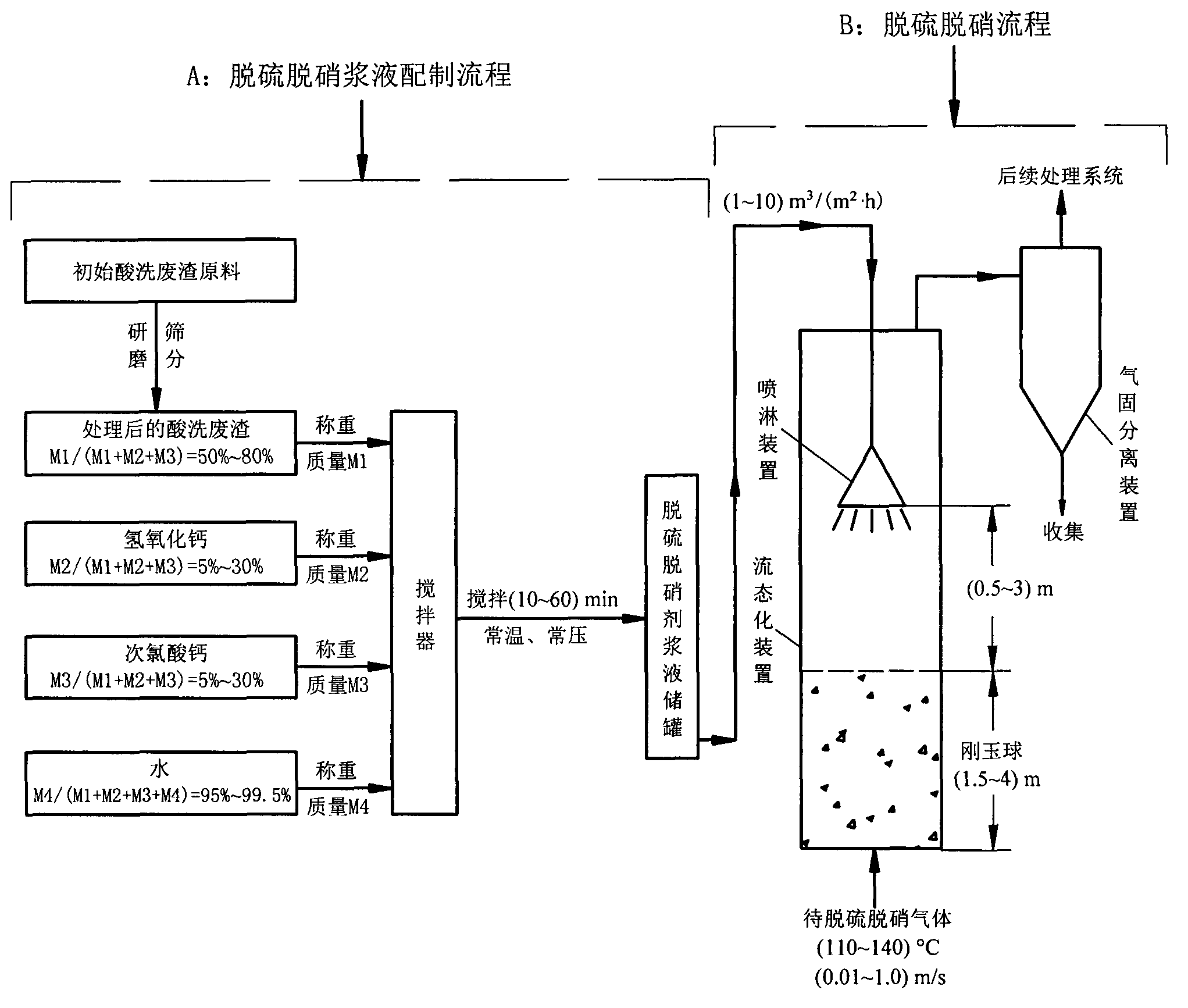

[0014] The present invention will be described in detail below through specific embodiments and in conjunction with the accompanying drawings.

[0015] A: Desulfurization and denitrification slurry preparation process

[0016] Referring to the attached figure, crush, grind, and sieve the pickling waste residue from a steel factory in Bazhou, Hebei, weigh the mass M1=18kg of the fine powder with a particle size of less than 200 μm, and then weigh the powder with a purity of 95% and a particle size of All less than 100 μm, quality is respectively calcium hydroxide and calcium hypochlorite of M2=M3=6kg, then take by weighing the water that quality is M4=3000kg, pickling waste residue, calcium hydroxide, calcium hypochlorite, Add water into the mixer, stir at normal temperature and pressure for 30 minutes, and then put it into the storage tank for later use.

[0017] B: Desulfurization and denitrification process

[0018] Referring to the attached figure, the fluidized device fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com