Carbon dioxide thickening fracturing system and technological method thereof

A technology of carbon dioxide and liquid carbon dioxide, which is applied in chemical instruments and methods, earthwork drilling, mining fluids, etc., can solve the problems that liquid carbon dioxide cannot create fractures, and achieve the effects of increasing single well production, increasing flowback rate, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

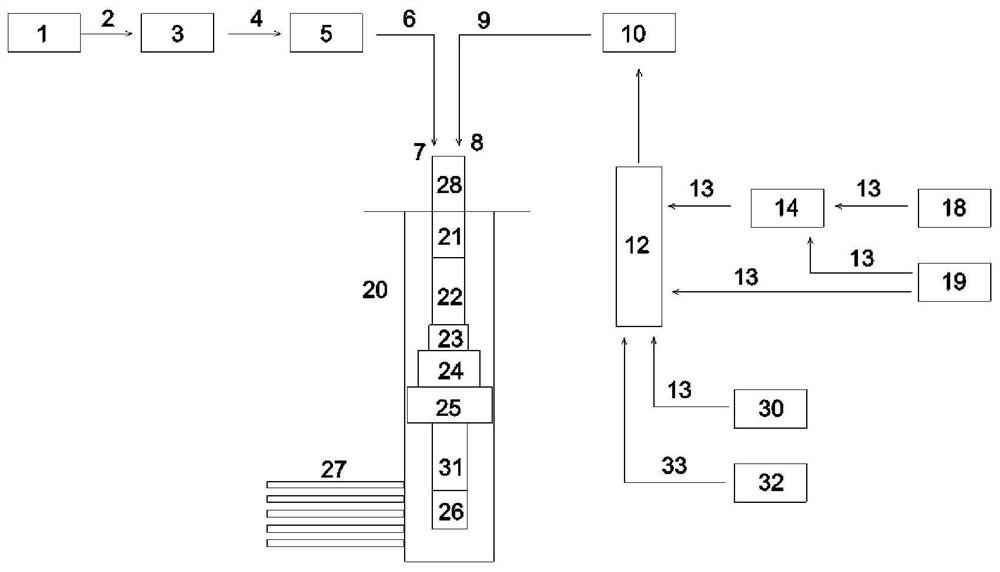

[0031] Embodiment 1, a carbon dioxide thickening fracturing process, comprising the following steps:

[0032] 1) Telescoping shorts 21, safety joints 23, low-temperature, high-pressure gas-sealed hydraulic anchors 24, low-temperature, high-pressure gas-sealed anchor packers 25, sandblasting nozzles 26 and fracturing completion tubing 22 are lowered into the well through workover machinery, The low-temperature, high-pressure air-tight anchored packer 25 is set and started by rotating the fracturing completion tubing 22, and the anchoring machine contacts and anchors with the inner wall of the production casing 20;

[0033] The seal is attached to the inner wall of the 20 production casing to play a sealing role. The low-temperature and high-pressure gas-sealed hydraulic anchor will enter the high-pressure fracturing fluid and liquid CO2 into the tubing 24. 2 start at the same time, contact and anchor with the inner wall of the production casing 20, when the cryogenic liquid CO ...

Embodiment 2

[0041] Embodiment 2, a carbon dioxide thickening fracturing process, comprising the following steps:

[0042] 1) Telescoping shorts 21, safety joints 23, low-temperature, high-pressure gas-sealed hydraulic anchors 24, low-temperature, high-pressure gas-sealed anchor packers 25, sandblasting nozzles 26 and fracturing completion tubing 22 are lowered into the well through workover machinery, The low-temperature, high-pressure air-tight anchored packer 25 is set and started by rotating the fracturing completion tubing 22, and the anchoring machine contacts and anchors with the inner wall of the production casing 20;

[0043] The seal is attached to the inner wall of the 20 production casing to play a sealing role. The low-temperature and high-pressure gas-sealed hydraulic anchor will enter the high-pressure fracturing fluid and liquid CO2 into the tubing 24. 2 start at the same time, contact and anchor with the inner wall of the production casing 20, when the cryogenic liquid CO ...

Embodiment 3

[0051] Embodiment 3, a carbon dioxide thickening fracturing process, comprising the following steps:

[0052] 1) Telescoping shorts 21, safety joints 23, low-temperature, high-pressure gas-sealed hydraulic anchors 24, low-temperature, high-pressure gas-sealed anchor packers 25, sandblasting nozzles 26 and fracturing completion tubing 22 are lowered into the well through workover machinery, The low-temperature, high-pressure air-tight anchored packer 25 is set and started by rotating the fracturing completion tubing 22, and the anchoring machine contacts and anchors with the inner wall of the production casing 20;

[0053] The seal is attached to the inner wall of the 20 production casing to play a sealing role. The low-temperature and high-pressure gas-sealed hydraulic anchor will enter the high-pressure fracturing fluid and liquid CO2 into the tubing 24. 2 start at the same time, contact and anchor with the inner wall of the production casing 20, when the cryogenic liquid CO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com