Method for preparing two-component vitrified brick backing glue

A vitrified back, two-component technology, applied in the direction of adhesives, polymer adhesive additives, non-polymer adhesive additives, etc. Difficult pasting, low water absorption of vitrified tiles, etc., to achieve the effect of increased contact area, easy pasting, and improved roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

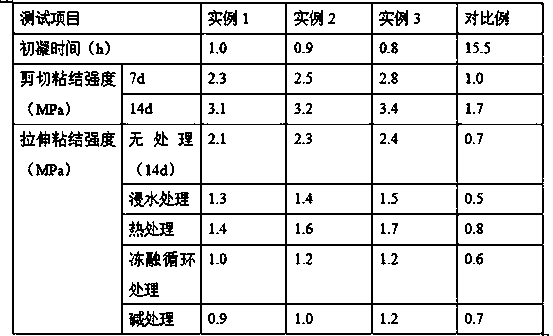

Examples

example 1

[0027] Take sugarcane, extract sugarcane juice with a sugarcane juicer to obtain bagasse, weigh 30g of bagasse and place it in a mortar, grind for 20min, pass through a 100-mesh sieve to obtain sugarcane powder, add the sugarcane powder to the conical flask, Add 100mL of sodium hydroxide solution with a mass fraction of 40% into the shaped bottle, heat up to 120°C, cook for 1h, filter and remove the filtrate to obtain the filter residue, put the filter residue in an oven, heat up to 100°C, and dry for 2h to obtain pretreatment Sugarcane powder: Weigh 20g of pretreated sugarcane powder and add it to a beaker, add 10mL of acrylic acid to the beaker, adjust the pH to neutral with a 10% sodium hydroxide solution to obtain a suspension, and mix the suspension with kaolin according to the mass ratio 3:1 mixing, placed in a high-speed disperser, dispersed for 12 minutes at a speed of 2000r / min, to obtain a pre-dispersed suspension; in parts by weight, 70 parts of a pre-dispersed suspe...

example 2

[0029] Take sugarcane, extract the sugarcane juice with a sugarcane juicer to obtain bagasse, weigh 33g of bagasse and place it in a mortar, grind for 23min, pass through a 100-mesh sieve to obtain sugarcane powder, add the sugarcane powder to the Erlenmeyer flask, Add 110mL of sodium hydroxide solution with a mass fraction of 40% into the shaped bottle, heat up to 125°C, cook for 1.5h, filter and remove the filtrate to obtain the filter residue, put the filter residue in an oven, heat up to 105°C, and dry for 2.5h to obtain Pretreatment sugarcane powder: Weigh 23g pretreatment sugarcane powder and add it to a beaker, add 13mL acrylic acid to the beaker, adjust the pH to be neutral with a 10% sodium hydroxide solution to obtain a suspension, and mix the suspension with kaolin according to The mass ratio is 3: 1 and mixed, placed in a high-speed disperser, dispersed at a speed of 2500r / min for 13 minutes, to obtain a pre-dispersed suspension; in parts by weight, 75 parts of the ...

example 3

[0031] Take sugarcane, extract the sugarcane juice with a sugarcane juicer to obtain bagasse, weigh 35g of bagasse and place it in a mortar, grind for 25min, pass through a 100-mesh sieve to obtain sugarcane powder, add the sugarcane powder to the conical flask, Add 100-120mL of sodium hydroxide solution with a mass fraction of 40% in the shaped bottle, heat up to 130°C, cook for 2h, filter and remove the filtrate to obtain the filter residue, put the filter residue in an oven, heat up to 110°C, and dry for 3h to obtain Pretreated sugarcane powder; weigh 20-25g of pretreated sugarcane powder and add it to a beaker, add 15mL of acrylic acid to the beaker, adjust the pH to neutral with a 10% sodium hydroxide solution to obtain a suspension, and mix the suspension with Kaolin is mixed in a mass ratio of 3:1, placed in a high-speed disperser, and dispersed at a speed of 3000r / min for 15 minutes to obtain a pre-dispersed suspension; in parts by weight, 80 parts of the pre-dispersed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com