Graphene non-woven fabric and manufacturing method thereof

A technology of non-woven fabrics and manufacturing methods, applied in the direction of non-woven fabrics, rayon manufacturing, textiles and papermaking, etc., can solve the problems of poor strength and single function of non-woven fabrics, achieve uniform heating, easy separation, and ensure product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

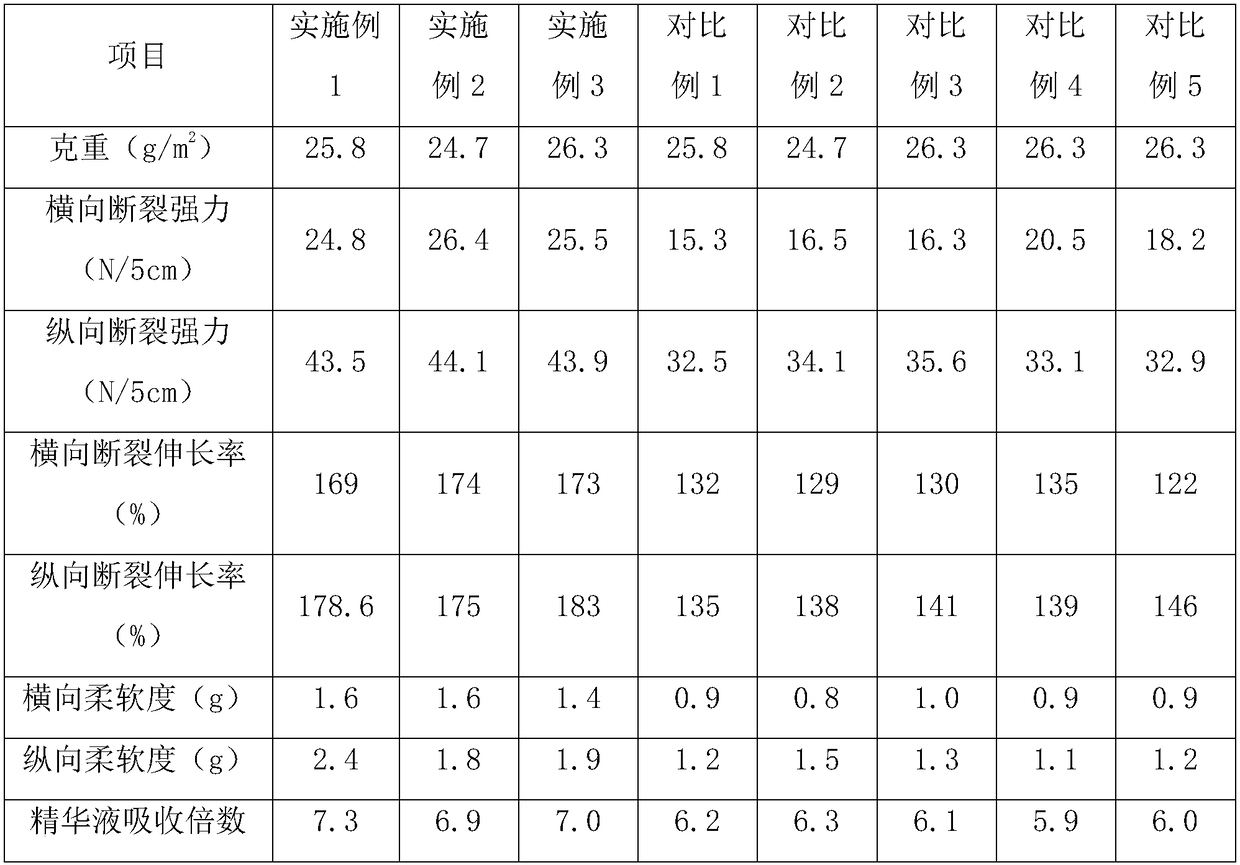

Examples

Embodiment 1

[0041] The present embodiment provides a graphene nonwoven fabric and a manufacturing method thereof, which are prepared according to the following steps:

[0042]S01: Mix elastomer VM6202, spunbond raw material PP3155E5, smooth masterbatch HS560, hydrophilic masterbatch RPSH~03, and graphene masterbatch according to the mass ratio of 72:20:3:4:1, and place in vacuum condition Under heating and melting, the melting temperature is 180°C to obtain a hot melt. The heating method of heating and melting is infrared heating.

[0043] S02: The hot melt is sprayed through a 0.3mm aperture at a temperature of 230°C and a pressure of 10MPa, and then cooled by a cooling bellows. The temperature of the cooling bellows is 10°C, and the cooling wind speed is 1.5m / s, and the silk is cooled to obtain Primary filaments.

[0044] S03: Drafting the primary growth filaments to obtain fibers: the method of drafting the primary growth filaments to obtain fibers is: passing the primary growth fila...

Embodiment 2

[0054] The present embodiment provides a graphene nonwoven fabric and a manufacturing method thereof, which are prepared according to the following steps:

[0055] S01: Mix elastomer VM6202: 60 parts, spunbond raw material PP3155E5: 10 parts, smooth masterbatch HS560: 2 parts, hydrophilic masterbatch RPSH-03: 3 parts, and graphene masterbatch 1 part. Heating and melting under conditions, the melting temperature is 270 ° C, to obtain a hot melt. The heating method of heating and melting is infrared heating.

[0056] S02: The hot melt is sprayed through a 0.8mm aperture at a temperature of 250°C and a pressure of 5MPa, and then cooled by a cooling bellows. The temperature of the cooling bellows is 20°C, and the cooling wind speed is 0.2m / s, and the silk is cooled to obtain Primary filaments.

[0057] S03: Drafting the primary growth filaments to obtain fibers: the method of drafting the primary growth filaments to obtain fibers is: passing the primary growth filaments through ...

Embodiment 3

[0067] The present embodiment provides a graphene nonwoven fabric and a manufacturing method thereof, which are prepared according to the following steps:

[0068] S01: Mix elastomer VM6202, spunbond raw material PP3155E5, smooth masterbatch HS560, hydrophilic masterbatch RPSH~03, and graphene masterbatch according to the mass ratio of 72:20:3:4:1, and place in vacuum condition Under heating and melting, the melting temperature is 220°C to obtain a hot melt. The heating method of heating and melting is infrared heating.

[0069] S02: The hot melt is sprayed through a 0.5mm aperture at a temperature of 240°C and a pressure of 8 MPa, and then cooled by a cooling bellows. The temperature of the cooling bellows is 15°C, and the cooling wind speed is 0.7m / s, and the silk is cooled to obtain Primary filaments.

[0070] S03: Drafting the primary growth filaments to obtain fibers: the method of drafting the primary growth filaments to obtain fibers is: passing the primary growth fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com