Manufacturing method of colored panel and products produced thereby

A manufacturing method and panel technology, applied in layered products, chemical instruments and methods, glass/slag layered products, etc., can solve problems affecting product quality, glass fiber scrapping, unit cost increase, etc., to achieve not easy to fall off, control cost, attractiveness-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

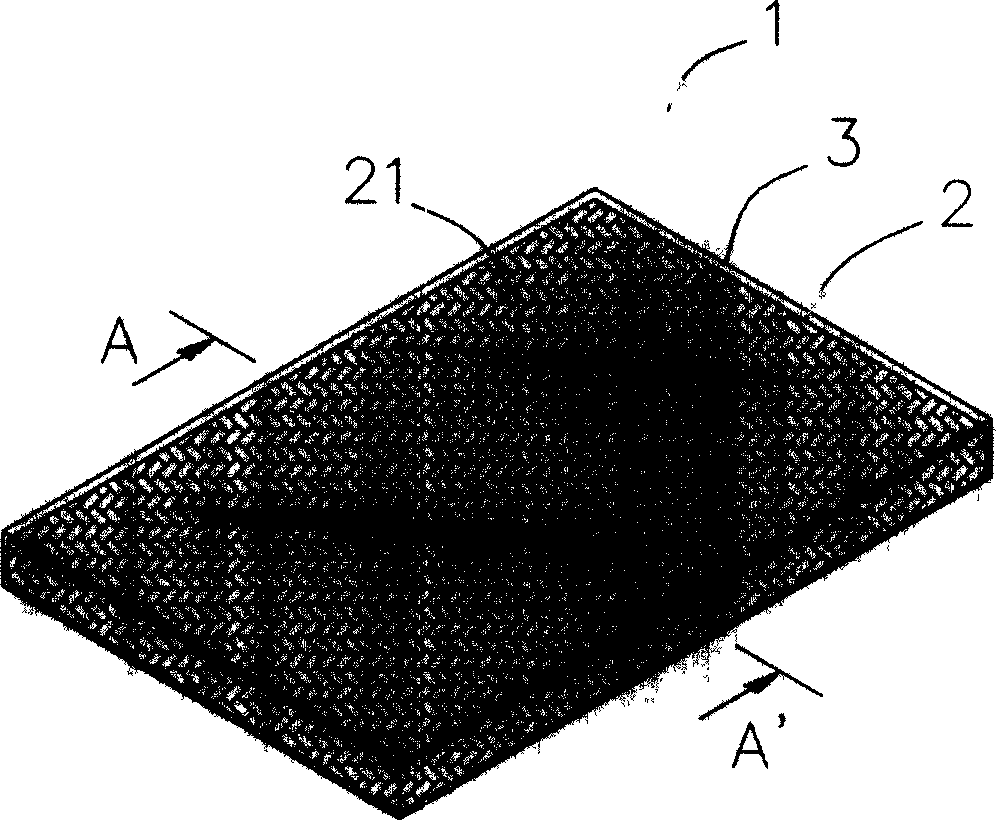

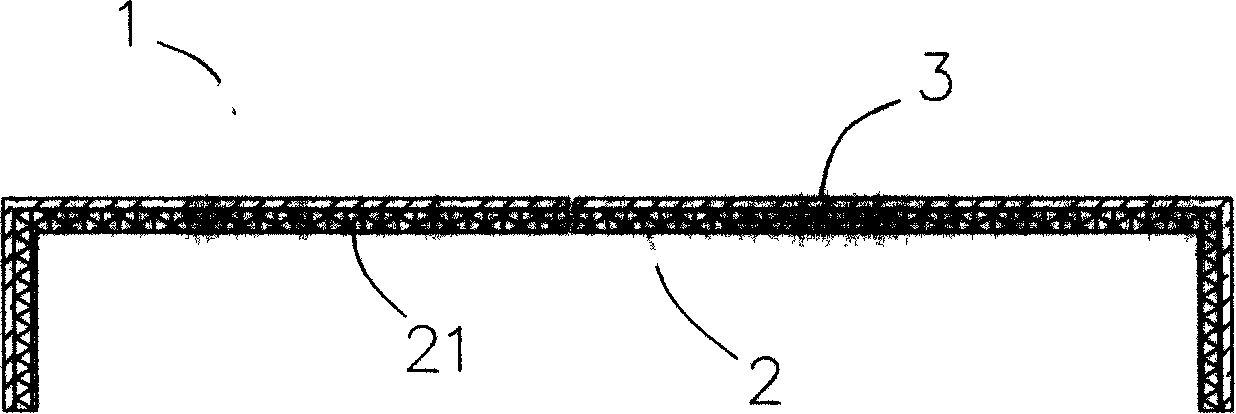

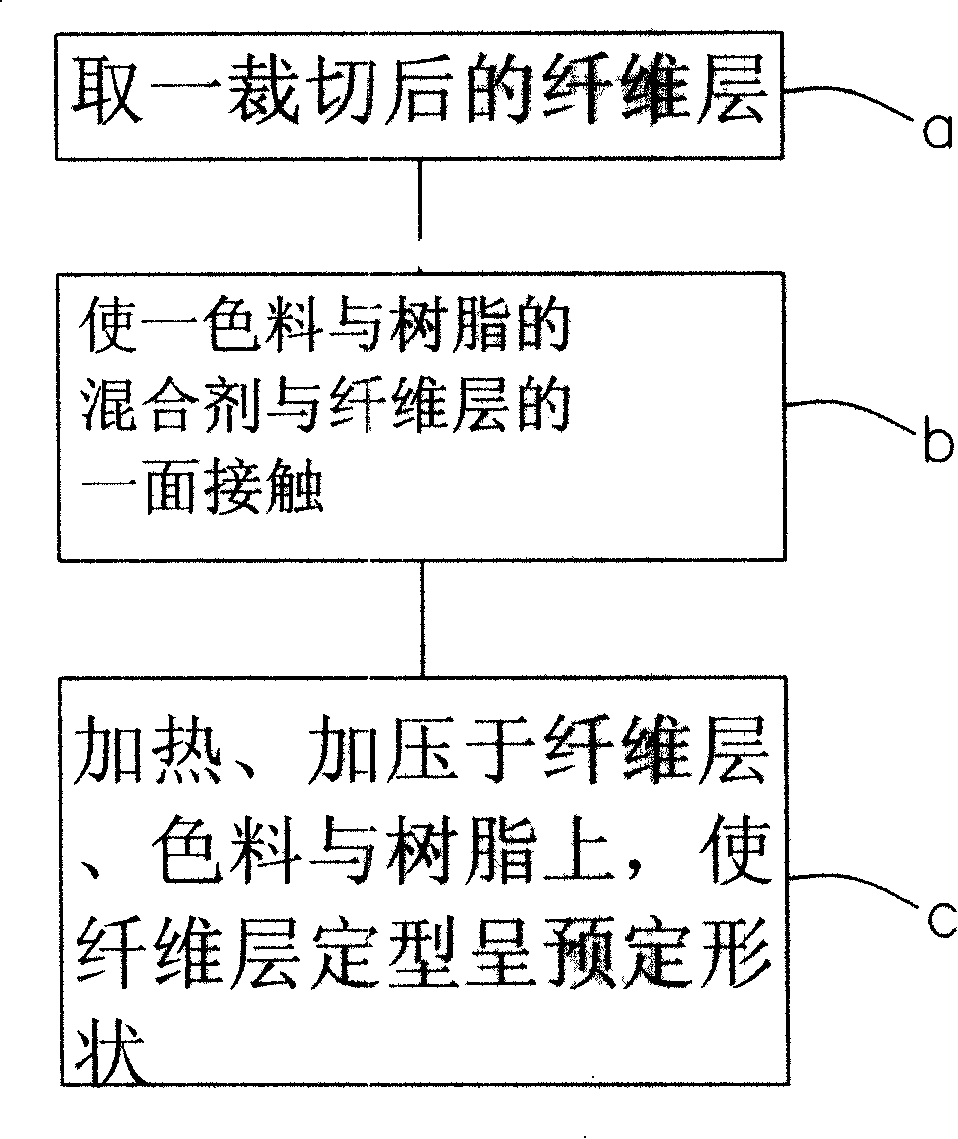

[0028] see figure 1 , 2 As shown, it is a preferred embodiment of the colored panel 1 of the present invention, which includes a cut fiber layer 2 and a mixture 3 .

[0029] The fiber layer 2 is woven with a plurality of glass fibers 21, which may be pre-impregnated with resin or not. After the fiber layer 2 is woven with glass fibers 21, interlaced three-dimensional lines are formed on the surface.

[0030] The mixture 3 includes colorant and resin (note: there is no specific ratio between the colorant and resin, and the user can prepare it according to the needs of the use, but it cannot completely cover the three-dimensional lines on the surface of the fiber layer), the color of the colorant It can be changed according to different needs of users or products. The mixture 3 is adhered on the top of the fiber layer 2 by coating, spraying or painting, so as to form colors and interlaced three-dimensional lines on the surface of the fiber layer 2 .

[0031] When the above-me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com