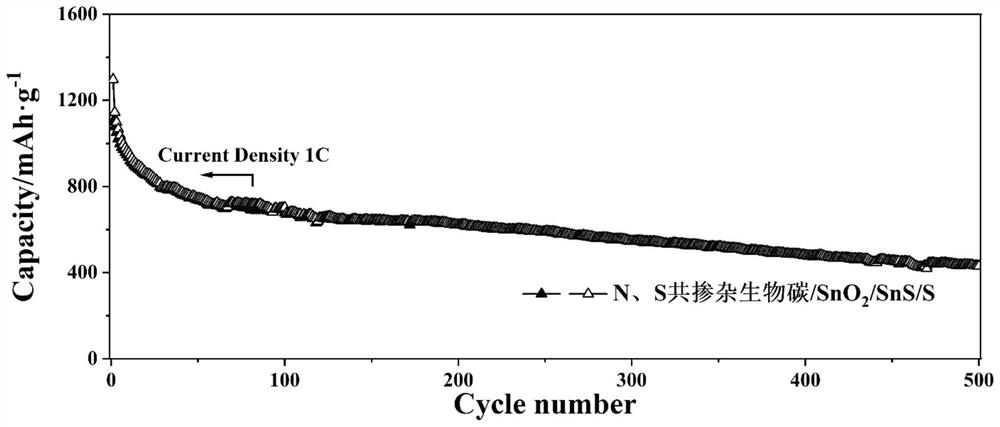

Nitrogen and sulfur co-doped biocarbon/SnO2/SnS/S composite material, preparation method and application

A composite material and bio-carbon technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of composite structure damage, failure to alleviate volume expansion, capacity loss, etc., to prevent oxidation, improve capture, and improve utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

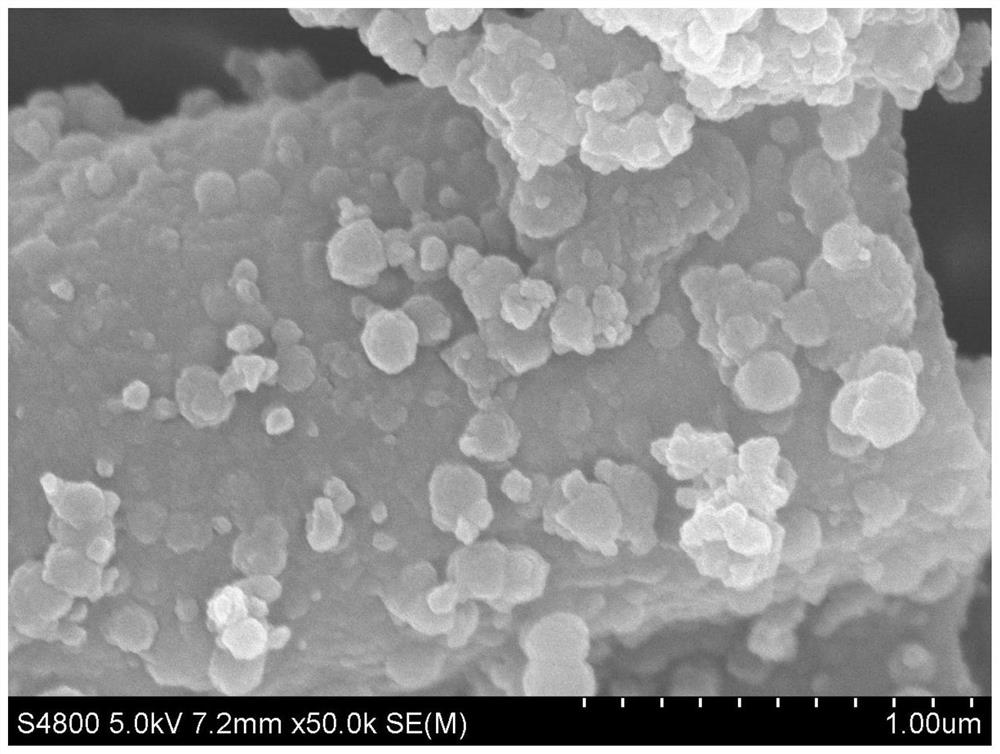

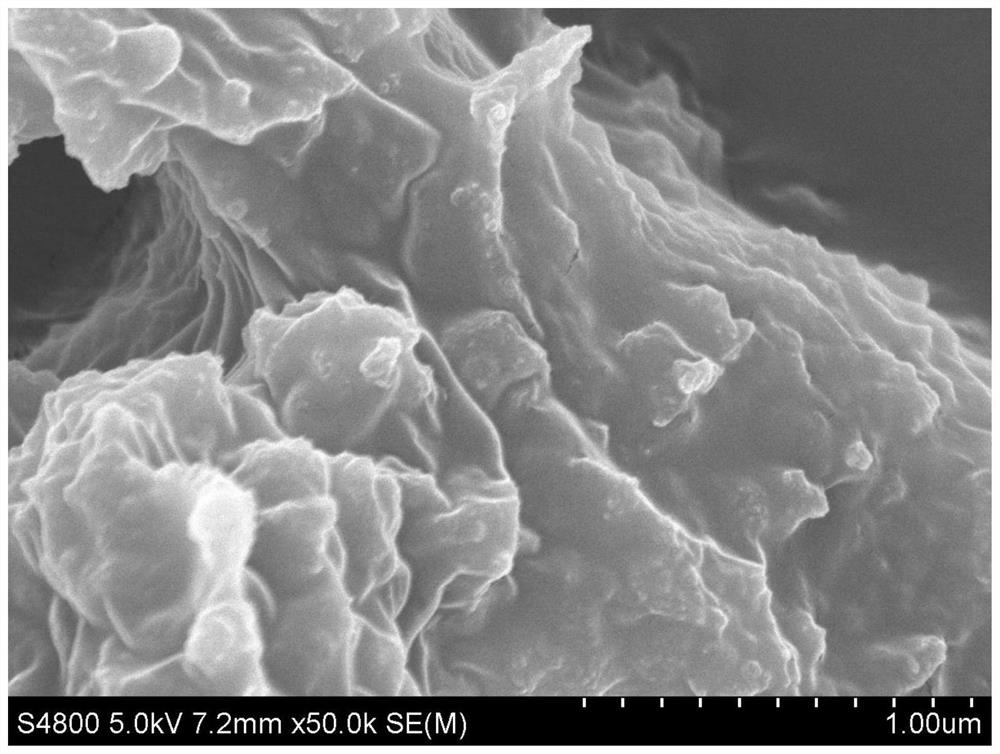

[0032] Nitrogen and sulfur co-doped biocarbon / SnO 2 The preparation method of / SnS / S composite material comprises the following steps:

[0033] Step 1: After grinding the dried tubular structure biomass, transfer to a low temperature tube furnace, in N 2 Under the atmosphere, the temperature is raised to 500°C to 600°C at a heating rate of 20°C / min to 30°C / min, maintained for 5min to 10min, and naturally cooled to room temperature to obtain biochar.

[0034] Wherein, the tubular structure biomass includes one or more of green onion, Spirogyra, water hyacinth, hyacinth moss, water moss, Jieji grass, and water peanut. When the tubular structure biomass is a mixture, any three of the above-mentioned tubular structure biomass are preferably mixed in a mass ratio of (1-3):(2-4):(3-6).

[0035]In this step, biomass with a slender tube structure is used as the carbon source, which has abundant reserves and wide sources. Using it as the carbon source effectively improves the utiliza...

Embodiment 1

[0061] Nitrogen and sulfur co-doped biocarbon / SnO 2 The preparation method of / SnS / S composite material comprises the following steps:

[0062] (1) Take 6.0g of dry water hyacinth in a mortar, grind for two minutes, put it into a white alumina porcelain boat, and heat up from room temperature to 500°C at a heating rate of 20°C / min in a low-temperature tube furnace. Incubate for 5 min under nitrogen protection to obtain biochar.

[0063] (2) 50 mL of a mixed solution of citric acid and tartaric acid with a molar ratio of 8 mol / L of 0.4:0.7 was added to the beaker, stirred uniformly, placed in a hydrothermal reactor after being placed for 10 min, and uniformly reacted at 160 ° C for 3 h to obtain Mixed acid solution.

[0064](3) Take 4g of biochar and put it in 10mL of mixed acid solution, stir the mixed acid solution evenly by hand for 20s and leave it for 0.5h, then put it in a tube furnace at 150℃ for 8h and take it out to get a mixed solution After the resulting mixed sol...

Embodiment 2

[0070] Nitrogen and sulfur co-doped biocarbon / SnO 2 The preparation method of / SnS / S composite material comprises the following steps:

[0071] (1) Take 6.0g of dry green onion and put it in a mortar, grind it for 3 minutes, put it into a white alumina porcelain boat, and heat it up from room temperature to 520°C at a temperature rise rate of 22°C / min in a low temperature tube furnace. Incubate for 7 min to obtain biochar.

[0072] (2) Add 45mL of a mixed solution of citric acid and tartaric acid with a molar ratio of 8.5moL / L of 0.2:0.5 into the beaker, stir evenly, place it for 15min and place it in a hydrothermal reactor, and react uniformly at 165°C for 3.5h , to obtain a mixed acid solution.

[0073] (3) Take 4.4g of biochar and put it in 12mL of mixed acid solution, stir the solution by hand for 20s and then leave it for 1h, then put it in a tube furnace at 165°C for 10h of uniform reaction, and then take it out to obtain a mixed solution, After the obtained mixed sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com