Preparation method of lithium ion battery anode composite material and special device thereof

A technology for lithium ion batteries and composite materials is applied in the field of preparation of positive electrode composite materials for lithium ion batteries, which can solve problems such as affecting battery performance, reducing filling amount, poor mixing uniformity, etc. The effect of increasing the bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

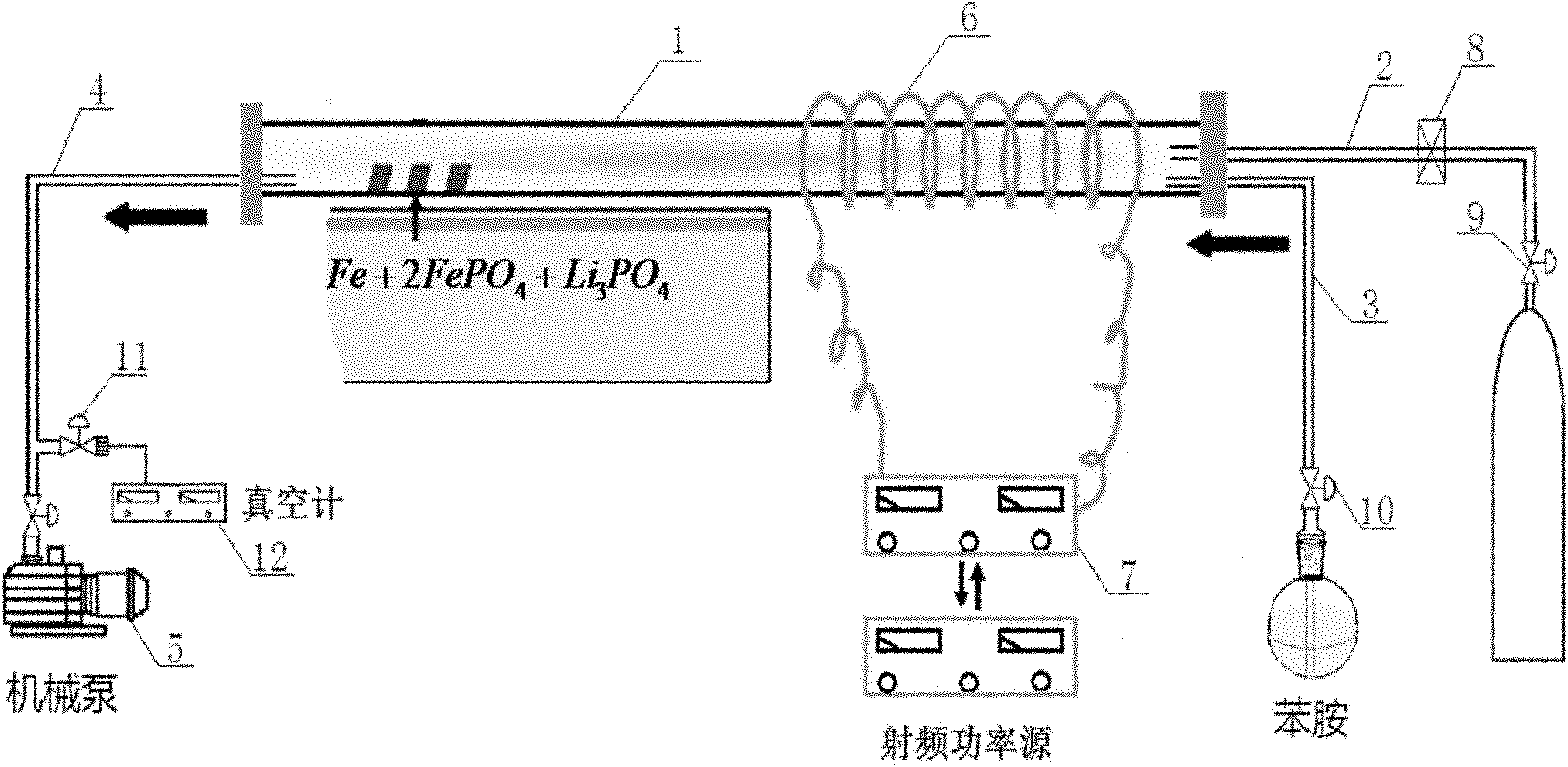

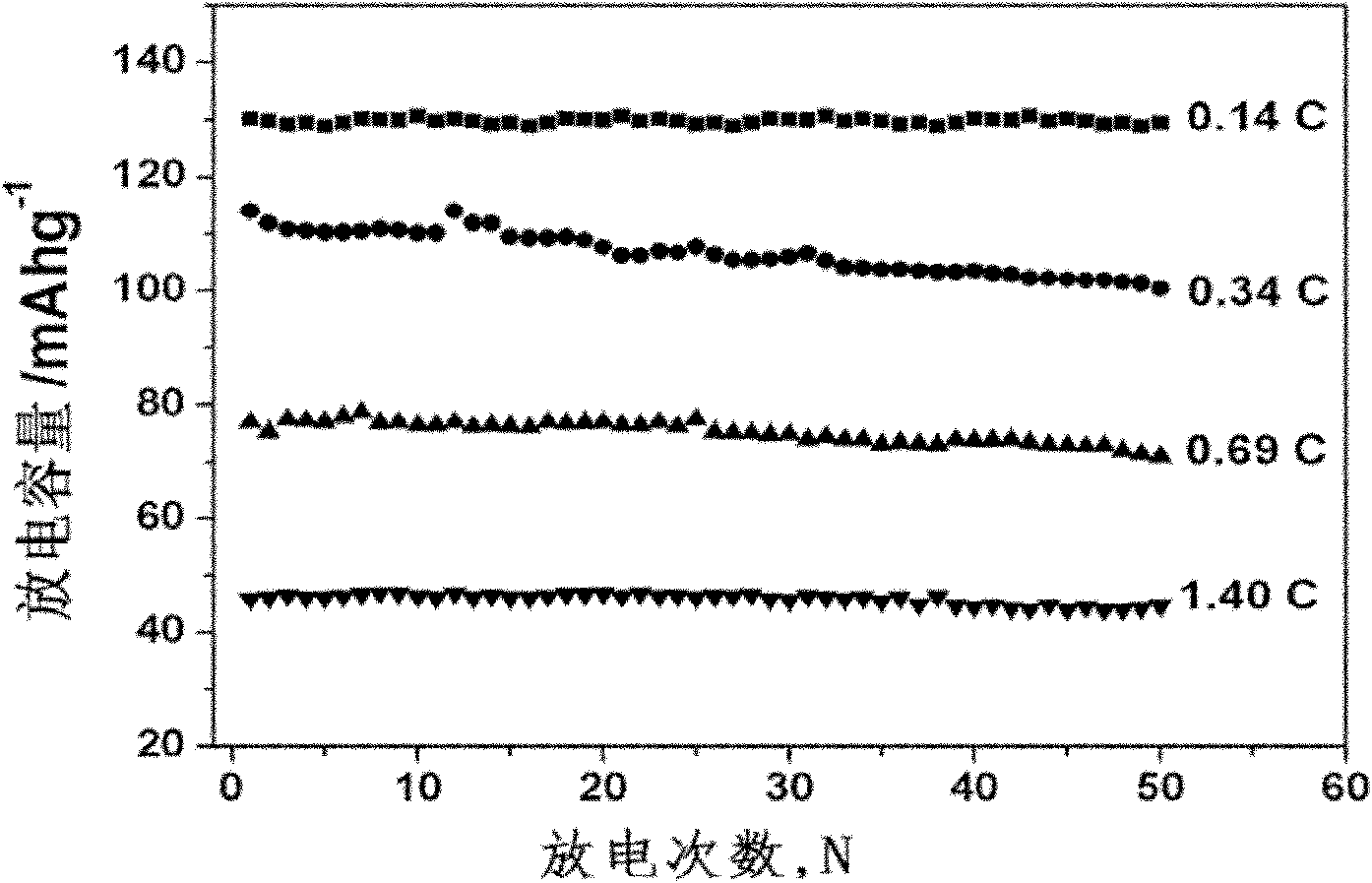

[0040] The invention discloses a method for preparing a lithium-ion battery cathode composite material, which utilizes a plasma-enhanced chemical vapor deposition method to synthesize in-situ grown carbon nanotube-coated lithium-ion battery cathode material LiFePO 4 , including the following steps:

[0041] (1) Mix 2.86 grams (0.05 moles) of metal iron powder, 15.1 grams (0.1 moles) of iron phosphate, and 6.37 grams (0.05 moles) of lithium phosphate, and put the above mixture into a ball mill container filled with argon atmosphere, and ball mill for 48 h, place the ball milled product in a plasma reaction device, use a mechanical pump to vacuumize the reaction chamber to remove impurities and water vapor, and when the pressure of the reaction chamber is less than 5 Pa, introduce reducing gas H 2 until the pressure is 100 Pa, the ball mill product is heated to 300 oC , constant temperature treatment for 10 min, remove the oxide on the surface of the ball milled product, and o...

Embodiment 2

[0045] The invention discloses a method for preparing a lithium-ion battery cathode composite material, which utilizes plasma-enhanced chemical vapor deposition to synthesize in-situ grown carbon nanosheet-coated lithium-ion battery cathode material LiFePO 4 , including the following steps:

[0046] (1) Mix 2.86 grams (0.05 moles) of metal iron powder, 15.1 grams (0.1 moles) of iron phosphate, and 6.37 grams (0.05 moles) of lithium phosphate, and put the above mixture into a ball milling container filled with argon atmosphere, and ball mill for 36 hours , the ball milled product is placed in the plasma reaction device, and the reaction chamber is evacuated by a mechanical pump to remove impurities and water vapor, and then the reducing gas H 2 until the pressure is 500 Pa, the ball mill product is heated to 200 oC , treated at a constant temperature for 20 min, to remove oxides on the surface of the ball-milled product to obtain a substrate material;

[0047] (2) Raise the ...

Embodiment 3

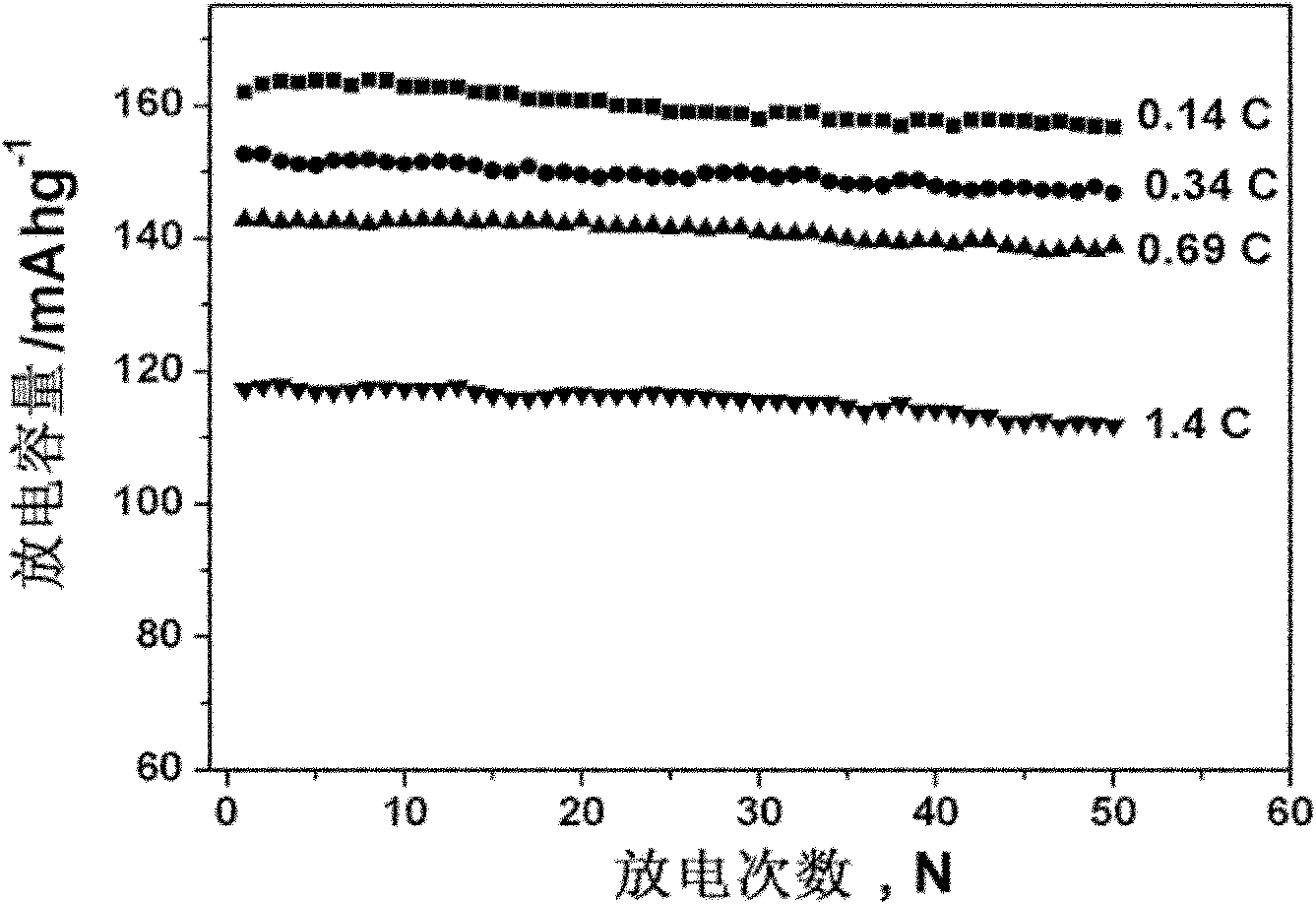

[0050] The invention discloses a method for preparing a lithium-ion battery positive electrode composite material, which utilizes plasma-enhanced chemical vapor deposition to synthesize in-situ grown graphene-coated lithium-ion battery positive electrode material LiFePO 4 , including the following steps:

[0051] (1) Mix 2.86 grams (0.05 moles) of metal iron powder, 15.1 grams (0.1 moles) of iron phosphate, and 6.37 grams (0.05 moles) of lithium phosphate in proportion, and put the above mixture into a ball mill container filled with an argon atmosphere. Ball milled for 48 h, the ball milled product was placed in the plasma reaction device as a substrate, the reaction chamber was evacuated by a mechanical pump to remove impurities and water vapor, and the pressure was lowered to below 5 Pa, and then the reducing gas H 2 until the pressure is 1000 Pa, the ball mill product is heated to 100 oC , treated at a constant temperature for 30 min, to remove oxides on the surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com