Rubber material, cooling rubber pipe prepared from rubber material and automobile engine comprising cooling rubber pipe

A kind of rubber compound, rubber technology, applied in the field of automobile fuel system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0111] According to one aspect of the present invention, a method for preparing the above-mentioned rubber compound includes the following steps:

[0112] Mix the ingredients of the formula to obtain the rubber compound;

[0113] The preparation method of the above-mentioned rubber compound provided in the present application, the preparation method mixes each raw material of the formula amount to obtain the rubber compound. The above preparation method has the advantage of easy operation.

[0114] In a preferred embodiment of the present invention, the preparation method includes the following steps:

[0115] (a) Mix the mineral powder, coupling agent and plasticizer to obtain mixture A;

[0116] (b) Mix the binary ethylene propylene rubber with the anti-aging agent to obtain mixture B;

[0117] (c) Mix the other raw materials except mineral powder, coupling agent, plasticizer, binary ethylene propylene rubber and anti-aging agent to obtain mixture C;

[0118] (d) Mix the mixture B and ...

Embodiment 1~5

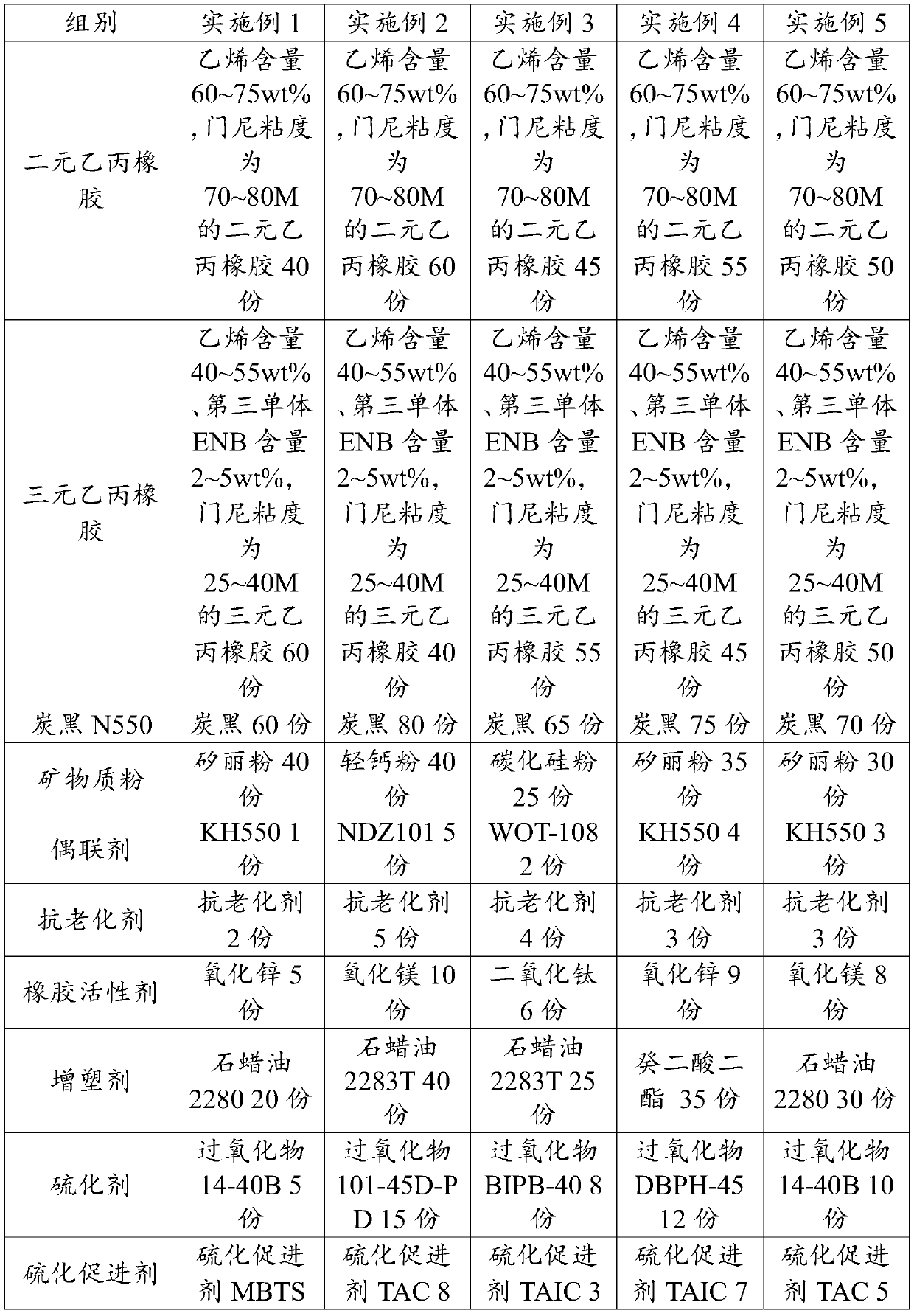

[0136] Weigh each raw material according to the weight ratio of raw materials in the following table:

[0137]

[0138]

[0139] Note: The anti-aging agent in the example 1 is obtained by compounding the anti-aging agent 445 and the anti-aging agent ZMMBI in a mass ratio of 1.3: 2.2; the anti-aging agent in the embodiment 2 is made up of the anti-aging agent 445 and the anti-aging agent ZMMBI in a mass ratio of 1.6: The anti-aging agent in Example 3 was compounded with a mass ratio of anti-aging agent 445 and anti-aging agent ZMMBI at a mass ratio of 1.4: 1.7; the anti-aging agent in Example 4 was compounded with anti-aging agent 445 and Anti-aging agent ZMMBI is compounded with a mass ratio of 1.5:1.9; the anti-aging agent in Example 5 is compounded with anti-aging agent 445 and anti-aging agent ZMMBI with a mass ratio of 1.5:2;

[0140] According to the above raw material ratio, each raw material is respectively weighed, and then each raw material of the formula amount is mixed t...

Embodiment 6~8

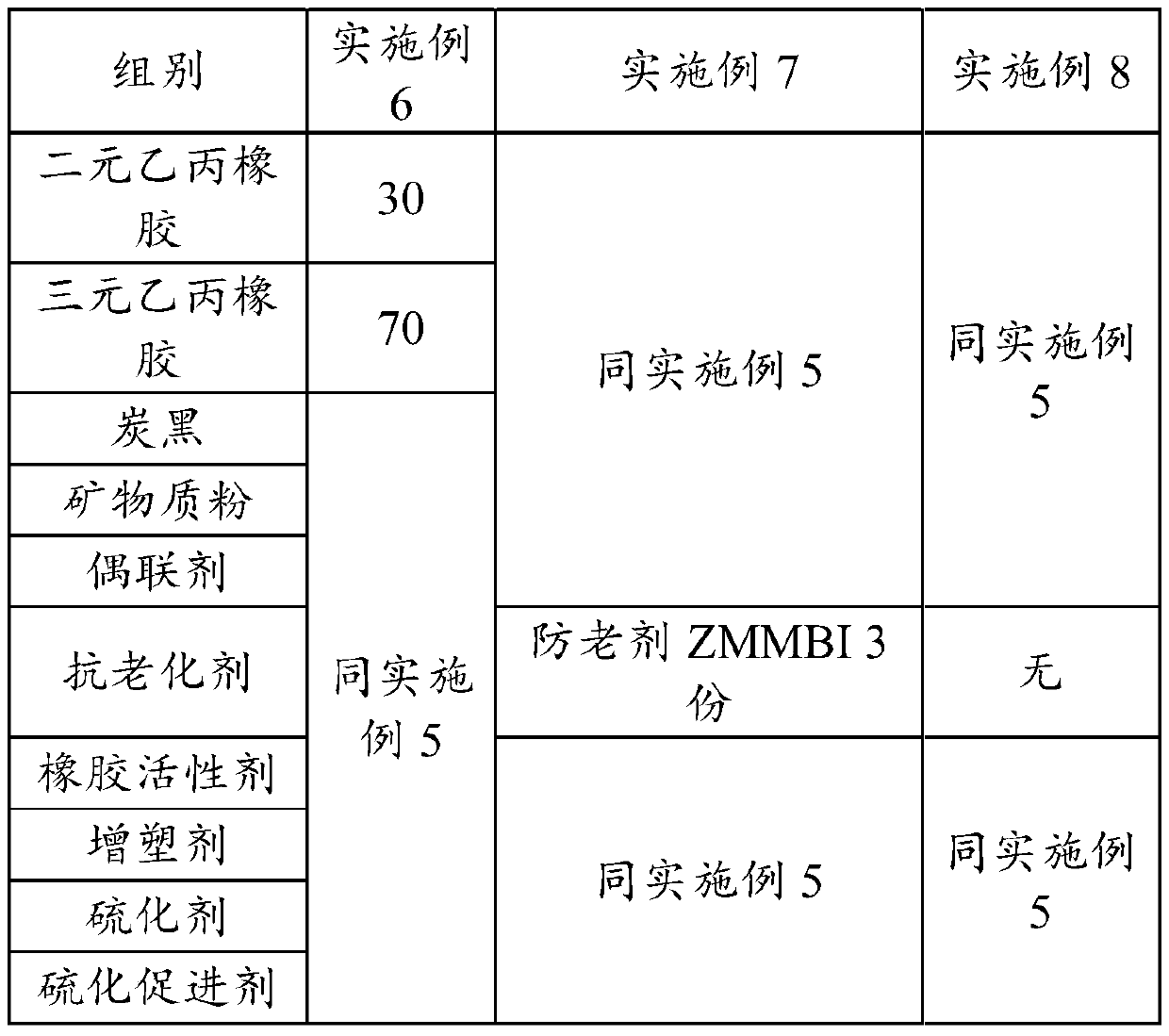

[0150] Weigh each raw material according to the weight ratio of raw materials in the following table:

[0151]

[0152] Then, referring to the methods of Examples 1 to 5, the cooling hoses of Examples 6 to 8 were prepared respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com