Low-melting-point metal-water-based conductive composite slurry and preparation method thereof

A low melting point metal, composite slurry technology, applied in conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, circuits, etc., can solve the volatilization damage of organic carriers, poor conductivity of composite slurry, rheological properties It can improve the comprehensive performance, reduce the sintering temperature, and make the preparation process simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

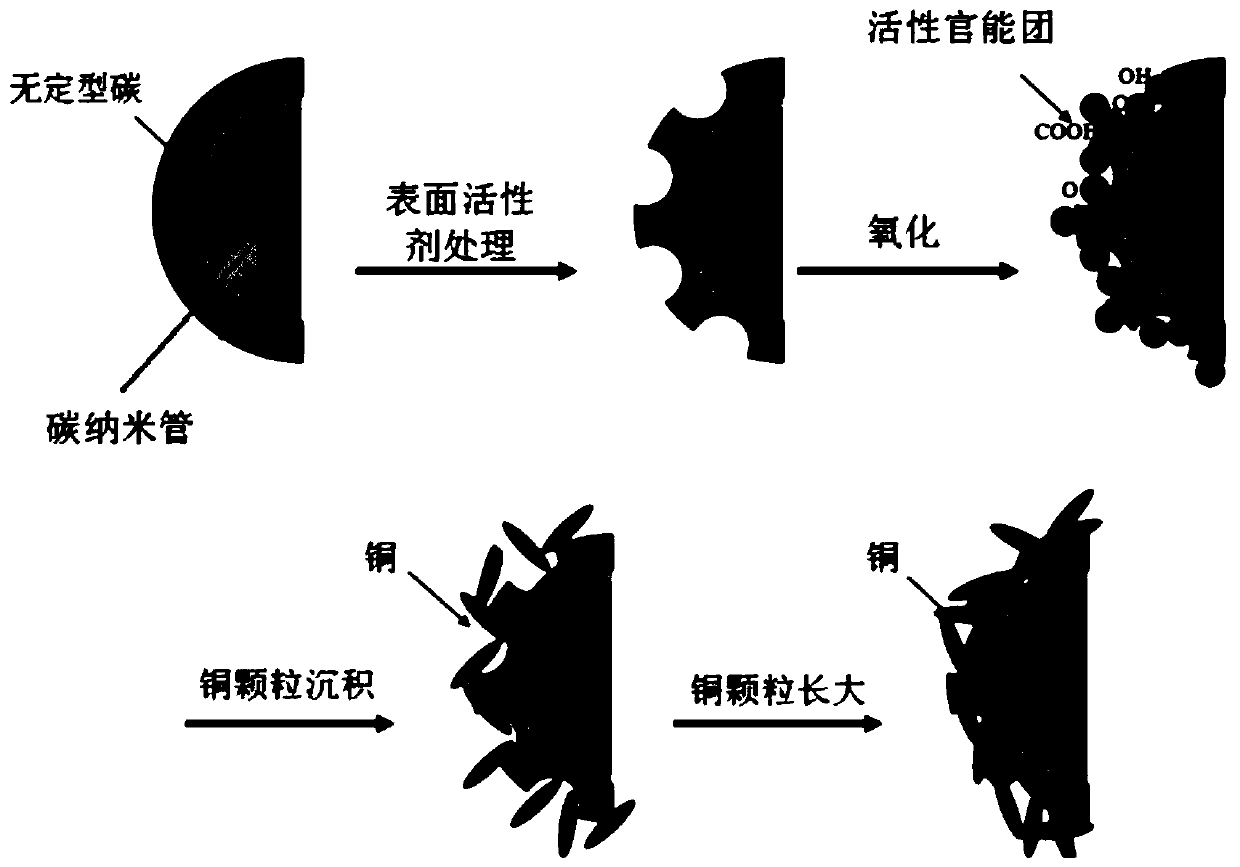

[0049] Step 1, first add the ionic surfactant sodium dodecylbenzene sulfonate into the deionized water at 5g / L, ultrasonically oscillate to dissolve it, then add carbon nanotubes to the solution at 2g / L, and ultrasonically oscillate for 4h , to obtain the treated carbon nanotube solution, and centrifuge at 6000r / min for 7 minutes in a centrifuge, and finally pour off the supernatant to obtain carbon nanotubes.

[0050] Step 2, prepare the copper sulfate solution that mass volume ratio is 10g / L at room temperature, add sodium citrate, potassium sodium tartrate and EDTA total 10g / L (by 1:1:1 adding) in this copper sulfate solution, stir Mix to obtain a gel-like mixture A; then add NaOH solution in the gel-like mixture A to adjust the pH to 10, and stir to obtain a main salt mixed solution; then add catalyst nickel sulfate 0.8g / L to the main salt mixed solution, and the reducing agent Formaldehyde 30g / L, stabilizer 2,2-bipyridine 0.02g / L, dispersant polyvinylpyrrolidone (PVP) 1g / ...

Embodiment 2

[0055] Step 1, first add the ionic surfactant sodium dodecylbenzene sulfonate into the deionized water at 8g / L, ultrasonically oscillate to dissolve it, then add carbon nanotubes to the solution at 4g / L, and ultrasonically oscillate for 4.5 h, the treated carbon nanotube solution was obtained, and then centrifuged by a centrifuge at a speed of 7000 r / min for 5 minutes, and finally the supernatant was poured off to obtain carbon nanotubes.

[0056] Step 2, prepare the copper sulfate solution that mass volume ratio is 12g / L at room temperature, add sodium citrate, potassium sodium tartrate and EDTA total 12g / L (by 1:1:1 adding) in this copper sulfate solution, stir Mix to obtain a gel-like mixture A; then add NaOH solution in the gel-like mixture A to adjust the pH to 11, and stir to obtain a main salt mixed solution; then add catalyst nickel sulfate 0.9g / L to the main salt mixed solution, and the reducing agent Formaldehyde 32g / L, stabilizer 2,2-bipyridine 0.03g / L, dispersant p...

Embodiment 3

[0061] Step 1, first add the ionic surfactant sodium dodecylbenzene sulfonate into the deionized water at 11g / L, ultrasonically oscillate to dissolve it, then add carbon nanotubes at 6g / L to the solution, and ultrasonically oscillate for 5h , to obtain the treated carbon nanotube solution, and centrifuge at 6500r / min for 6 minutes in a centrifuge, and finally pour off the supernatant to obtain carbon nanotubes.

[0062] Step 2, prepare the copper sulfate solution that mass volume ratio is 13g / L at room temperature, add sodium citrate, potassium sodium tartrate and EDTA total 13g / L (by 1:1:1 adding) in this copper sulfate solution, stir Mix to obtain a gel-like mixture A; then add NaOH solution to the gel-like mixture A to adjust the pH to 12, and stir to obtain a main salt mixed solution; then add catalyst nickel sulfate 1g / L to the main salt mixed solution, and reducer formaldehyde 33g / L, stabilizer 2,2-bipyridine 0.04g / L, dispersant polyvinylpyrrolidone (PVP) 1.3g / L;, use Na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com