A vanadium-nitrogen microalloy high-strength phase transformation-induced plasticity steel seamless pipe and its preparation method

A phase-transformation-induced plasticity, seamless tube technology, applied in the steel field, can solve the problems of inability to guarantee the uniform rotation of the steel tube, restrictions on the specification and length of the steel tube, low work efficiency, etc., and achieves easy control of the heating process, low manufacturing costs, and surface quality. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The chemical composition of the steel selected in this embodiment is C: 0.18%, Si: 1.52%, Mn: 1.41%, V: 0.17%, N: 0.01%, P: 0.008%, S: 0.004%, and the balance For Fe.

[0047] The smelted ingot is forged into a bar, the bar is turned to remove the outer surface wrinkles and defects to form a tube blank, and then the tube blank is heated to 1200°C and kept for 2 hours before piercing, and then cooled to room temperature; the cooled tube blank The tube blank is cold-drawn for 4 passes to obtain a seamless cold-drawn steel tube with a wall thickness of 1.5mm and an outer diameter of 44mm.

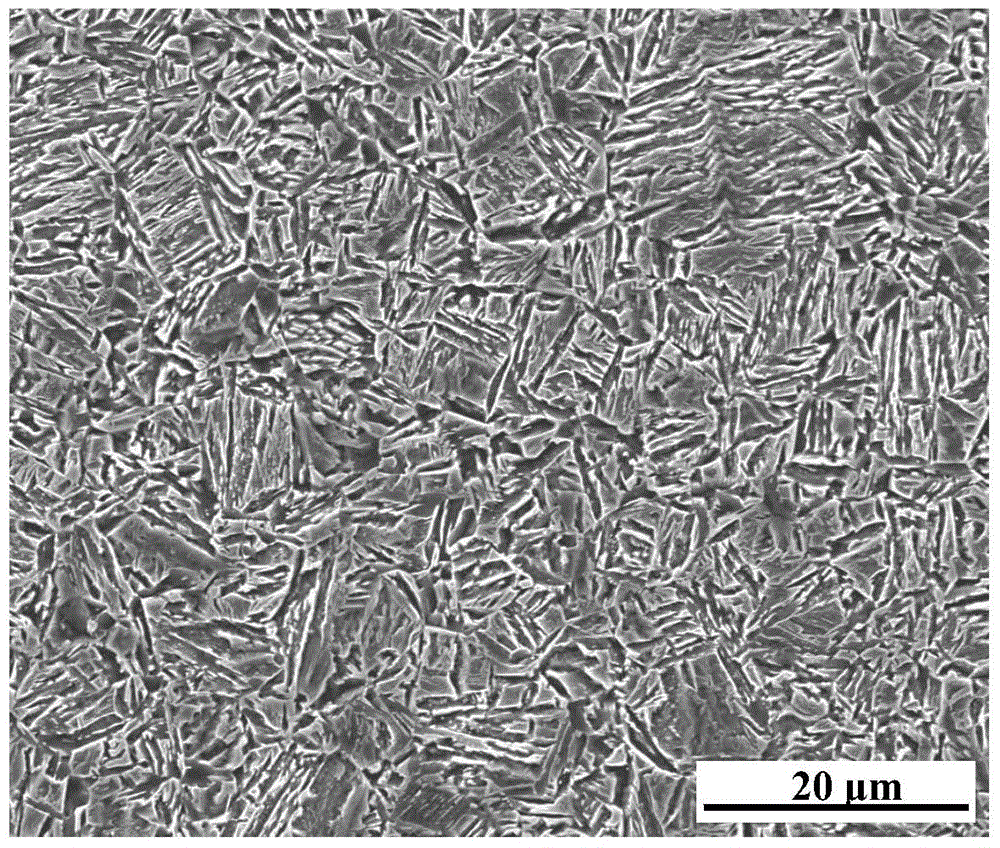

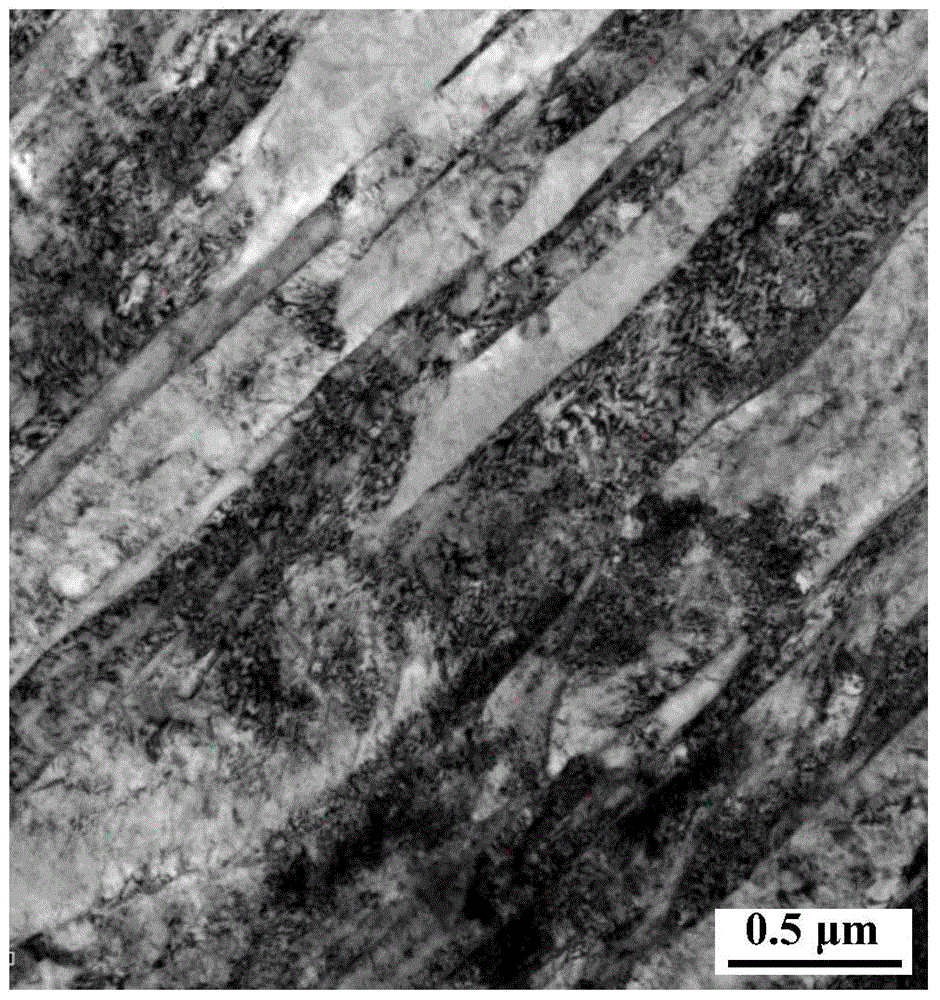

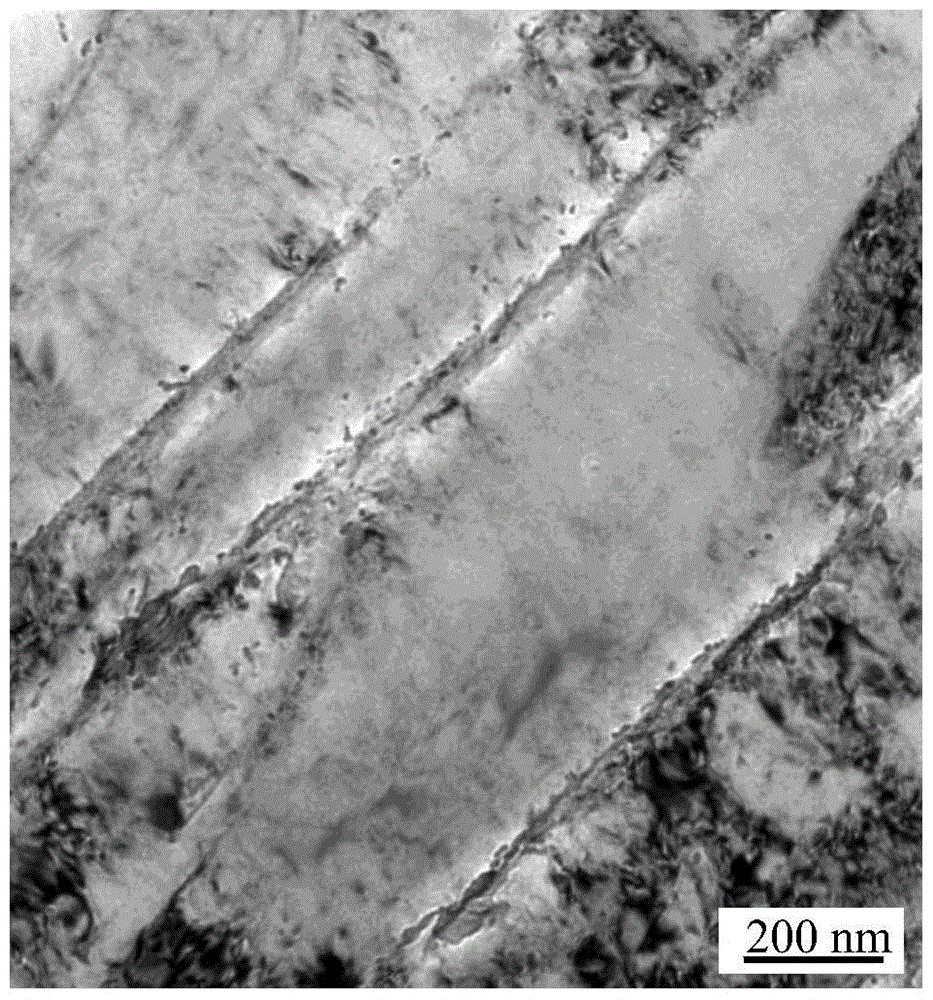

[0048] The seamless cold-drawn steel pipe is heated to the austenitization temperature range of 910-950°C with a medium-frequency heating induction coil at a heating rate of 35°C / s, and cooled with compressed air at a rate of about 60°C / s after annealing for 30-90s to 470-500°C in the bainite region, isothermally treated for 30-90s, and then naturally cooled to room temperature to obta...

Embodiment 2

[0055] The chemical composition of the steel used in this embodiment is C: 0.20%, Si: 1.0%, Mn: 1.20%, V: 0.19%, N: 0.018%, P: 0.019%, S: 0.005%, and the balance For Fe.

[0056] The smelted ingot is forged into a bar, the bar is turned to remove the outer surface wrinkles and defects to form a tube blank, and then the tube blank is heated to 1250°C and kept for 2 hours before piercing, and then cooled to room temperature; the cooled tube blank The tube blank is cold-drawn for 5 passes to obtain a seamless cold-drawn steel tube with a wall thickness of 2.3 mm and an outer diameter of 56 mm.

[0057] The seamless cold-drawn steel pipe is heated to the austenitization temperature range of 920-950°C with a medium-frequency heating induction coil at a heating rate of 30°C / s, and cooled with compressed air at a rate of about 50°C / s after annealing for 60-90s to 480-500°C in the bainite region, isothermally treated for 30-100s, and then naturally cooled to room temperature to obtai...

Embodiment 3

[0062] The chemical composition of steel selected in this embodiment is C: 0.21%, Si: 1.14%, Mn: 1.49%, V: 0.20%, N: 0.023%, P: 0.06%, S: 0.004%, and the balance For Fe.

[0063] The smelted ingot is forged into a bar, the bar is turned to remove the outer surface wrinkles and defects to form a tube blank, and then the tube blank is heated to 1250°C and kept for 3 hours before piercing, and then cooled to room temperature; the cooled tube blank The tube blank is cold-drawn 7 times to obtain a seamless cold-drawn steel tube with a wall thickness of 0.9 mm and an outer diameter of 1000 mm.

[0064] The seamless cold-drawn steel pipe is heated to the austenitization temperature range of 910-950°C with a medium-frequency heating induction coil at a heating rate of 35°C / s, and cooled with compressed air at a rate of about 60°C / s after annealing for 60-90s to 470-500°C in the bainite zone, isothermally treated for 30-100s, and then air-cooled to room temperature to obtain the phase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com