Multifunctional device used for plating layer research

A multifunctional and dual-purpose technology, applied in coating, hot-dip plating process, energy efficiency improvement, etc., can solve the problems of difficult resistance heating of carbon rods, poor uniformity of heating area, high equipment investment, etc., to achieve convenient experimental operation and The effect of daily maintenance, compact structure and simple overall layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

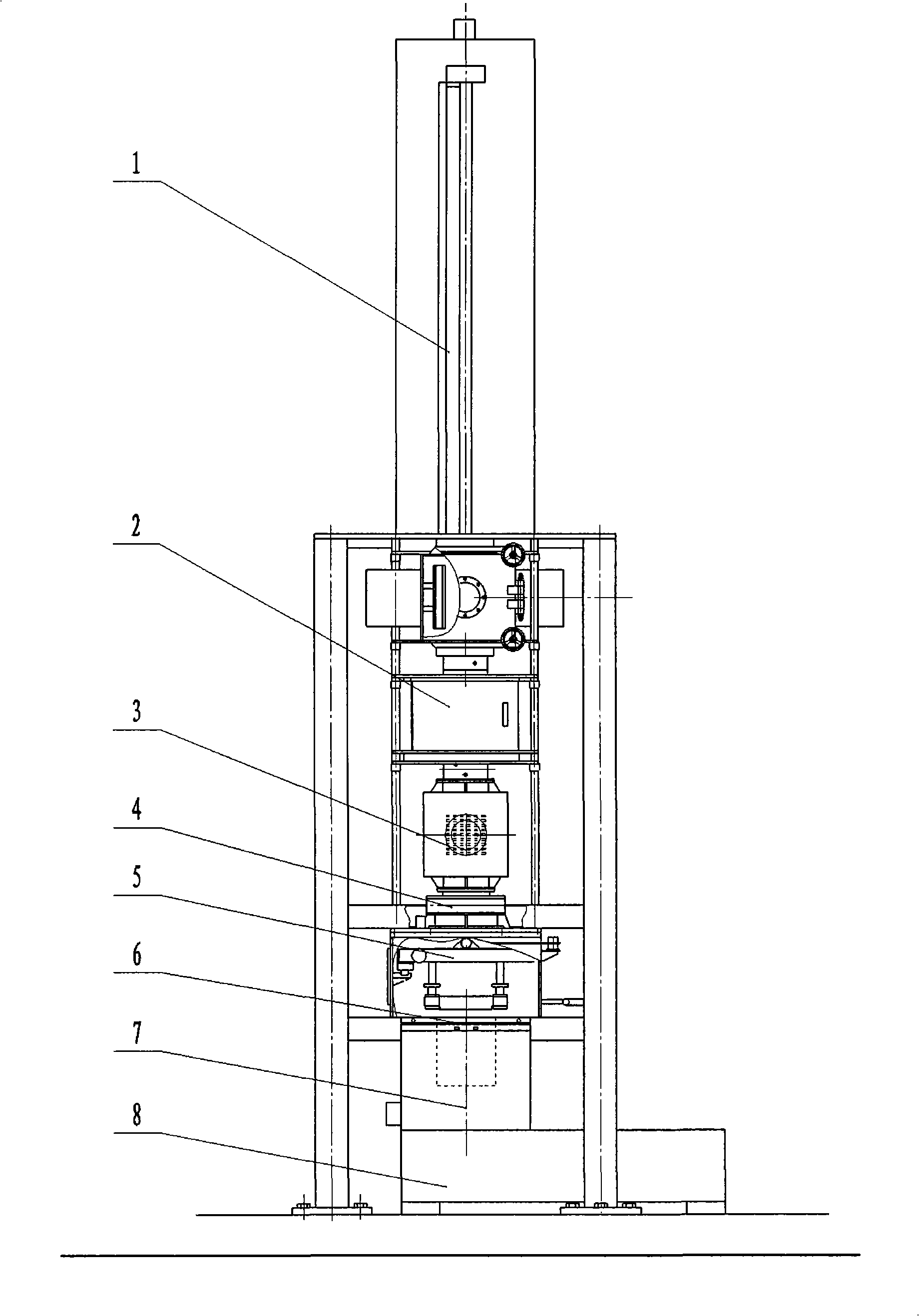

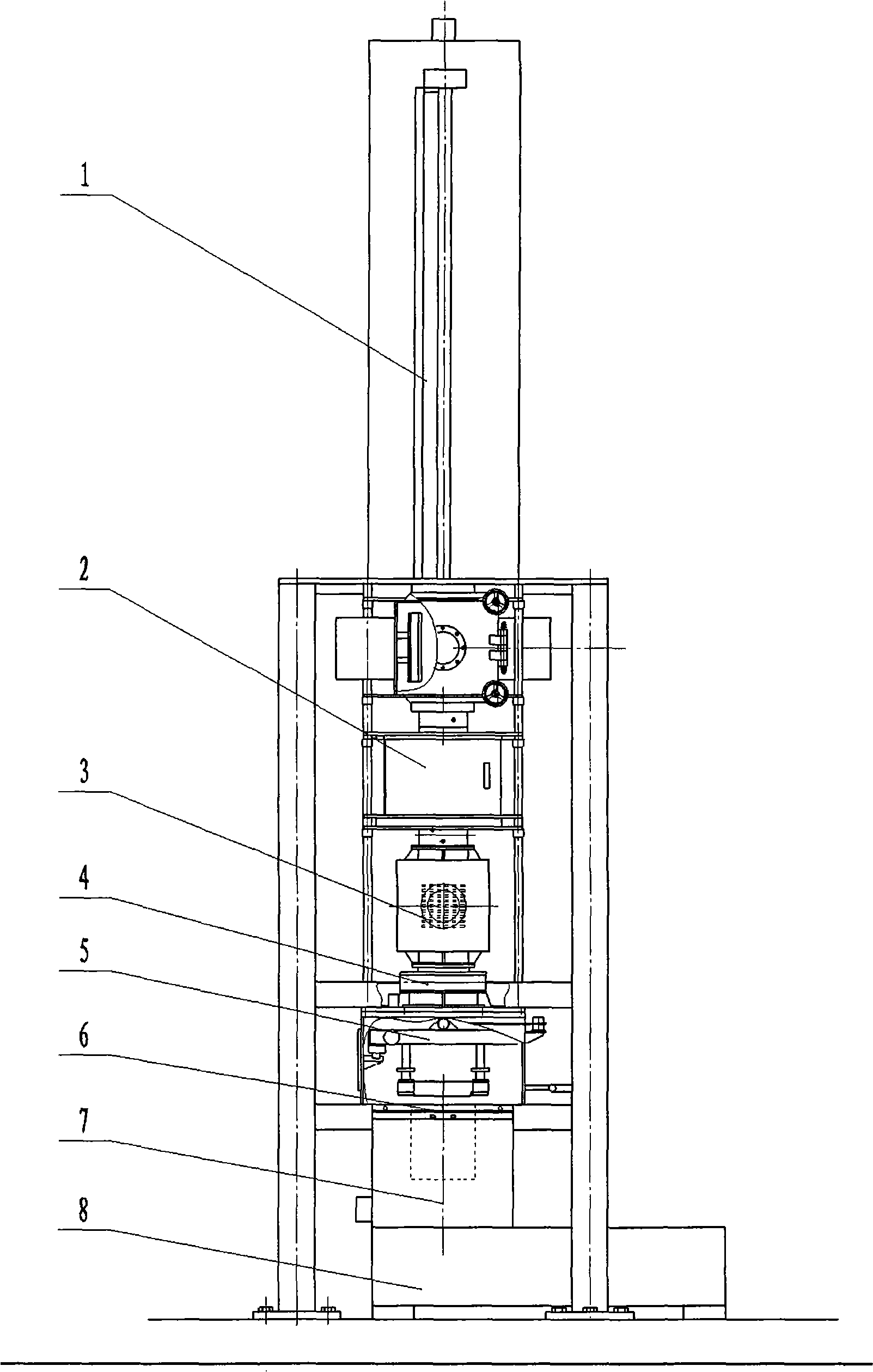

[0022] 1 to 3 are specific embodiments of the present invention.

[0023] Fig. 1 is a structural representation of the present invention, wherein, drive system 1, normal pressure and vacuum dual-purpose infrared radiation furnace 2, infrared radiation furnace 2, electromagnetic induction heating furnace 3, high-temperature-resistant high-vacuum isolation room 4, air knife 5, Sample clamping mechanism 6, hot-dip metal melting furnace 7, hydraulic transmission and sealing system 8.

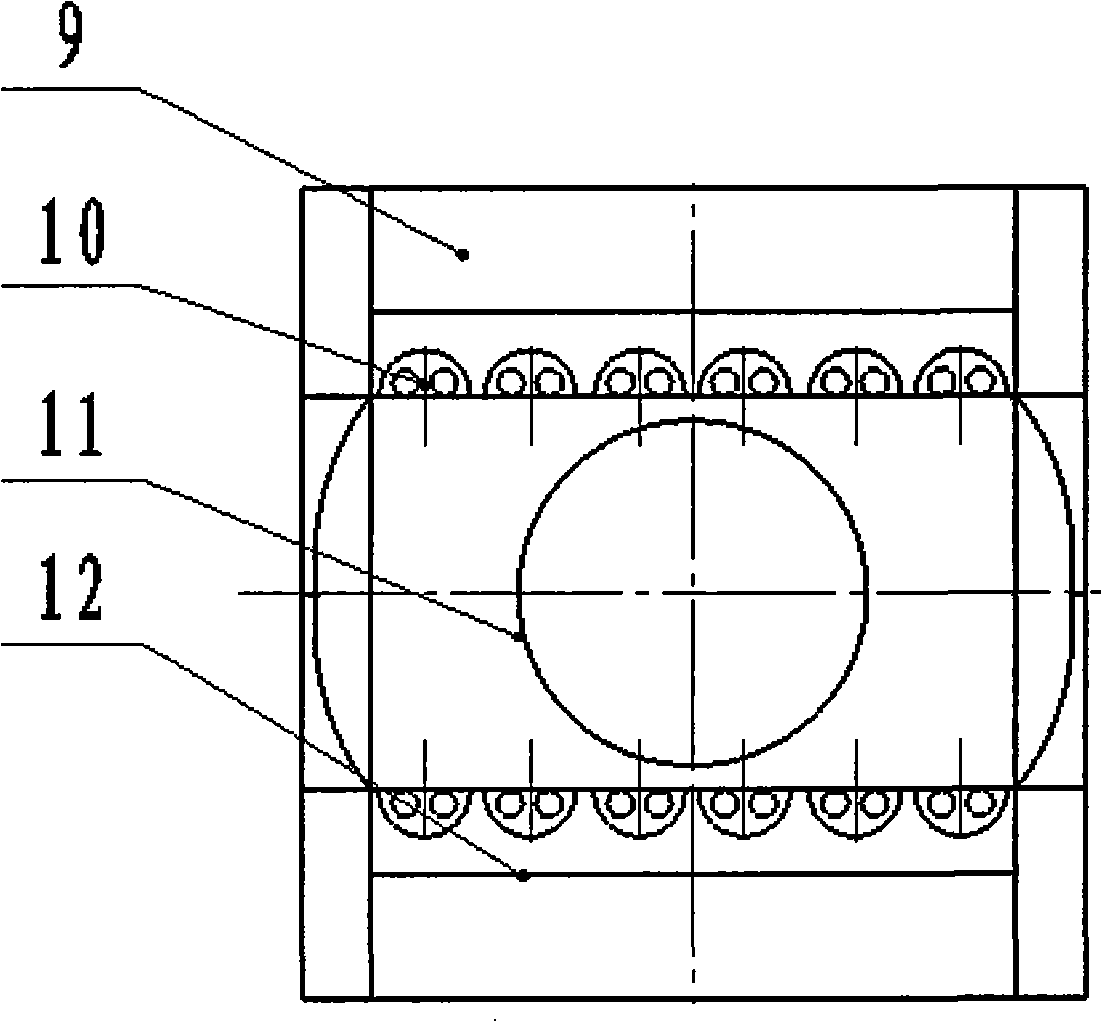

[0024] FIG. 2 is a schematic diagram of an infrared radiation furnace, wherein, the outer water cooling jacket 9 of the infrared radiation furnace, the infrared heater 10 of a luan tube, the quartz flange 11 , and the reflective panel 12 . An infrared heater with side-by-side luan tubes with high efficiency and low energy consumption is designed. The short-wave infrared rays emitted by the heater pass through the quartz flange and gather on the sample in the quartz flange. The back of each group of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com