Method for providing heated hydraulic fluid for hydraulic component test

A technology of hydraulic components and hydraulic oil, applied in the hydraulic field, can solve the problems of difficult control of temperature accuracy, unstable heating rate, easy deterioration of oil, etc., and achieve the effect of stable heating rate, no deterioration of oil, and no carbonization of oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

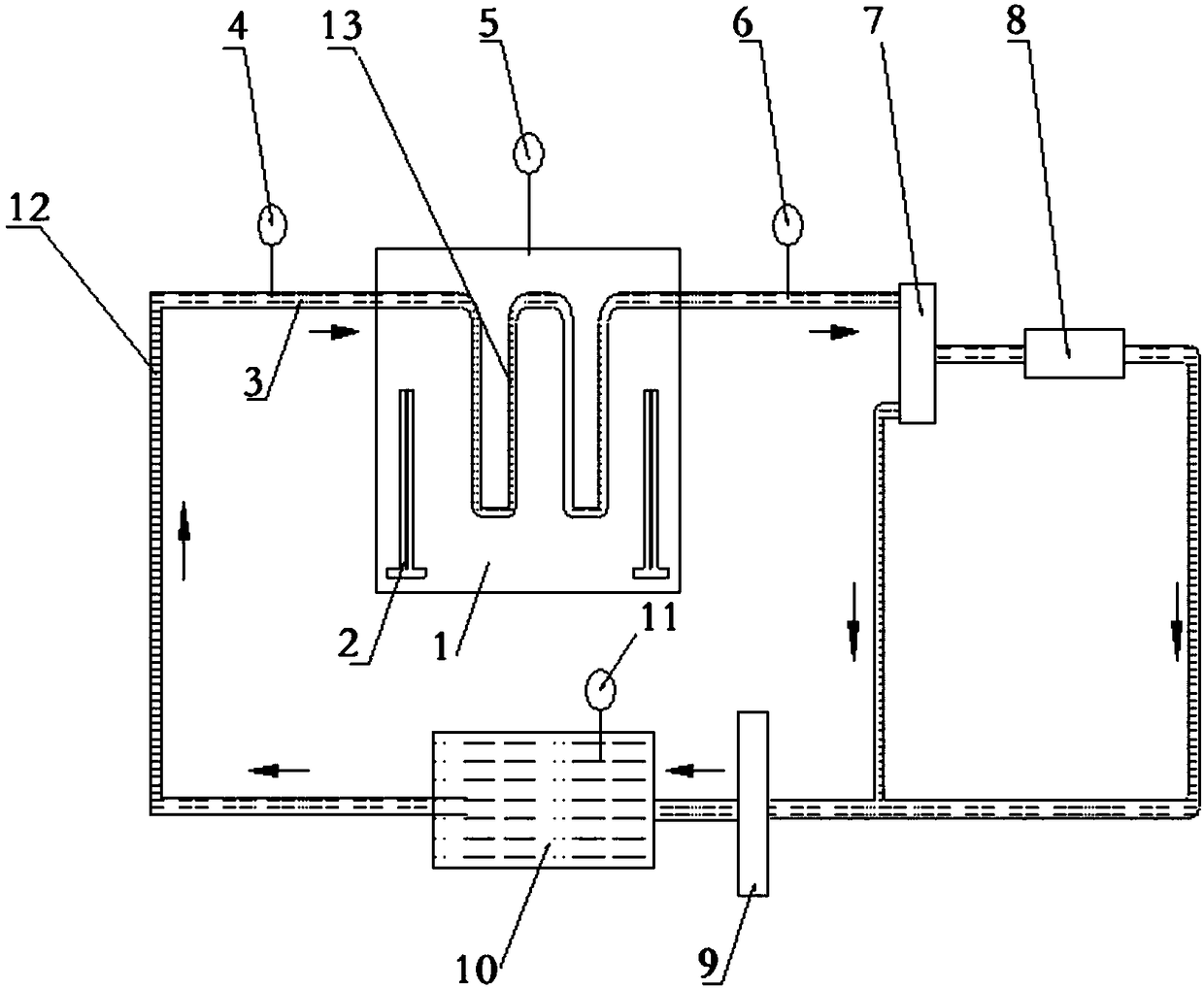

[0011] Referring to the accompanying drawings, a method for providing heated hydraulic fluid for hydraulic component testing, including a hydraulic pipeline 12 and a hydraulic oil tank 10 connecting hydraulic components 8, a liquid heating device 1, the body of the liquid heating device is an aluminum ingot, An electric heating tube 2 is provided in the aluminum ingot, a tortuous liquid passage 13 is also provided in the aluminum ingot, and a first temperature sensor 5 is provided on the surface of the body aluminum ingot of the liquid heating device 1; 2) the liquid heating device 1 is passed through The hydraulic pipeline 12 is in circular communication with the hydraulic element 8 and the hydraulic oil tank 10, and the hydraulic pipeline 12 is divided into a first branch and a second branch through a reversing valve 7 between the liquid heating device 1 and the hydraulic element 8. The branch path enters the hydraulic oil tank 10 after passing through the hydraulic element 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com