Synthesis Process of Catalyst Activated Carbon Composites for Dioxin Decomposition

A composite material, synthesis process technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, separation methods, etc. Equalize the problem to avoid the formation of agglomerates, reduce the probability of cracking, and increase the specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

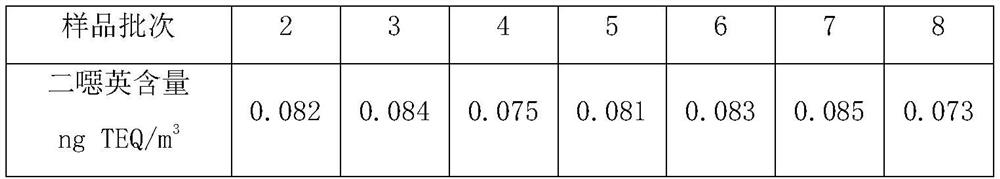

Examples

Embodiment 1

[0025] The synthesis process of the catalytic activated carbon composite material for decomposing dioxins, comprising the following steps,

[0026] A, activated carbon (the activated carbon is washed and dried with deionized water) is pulverized, and crosses 200 mesh sieves to obtain product A;

[0027] B, A product is dropped into the container that concentrated sulfuric acid is housed, and nitrogen gas is passed into the bottom of the container, and the flow rate of said nitrogen gas is 30mL / min, soaked for 3h, washed until pH is 6.5, and dried to obtain B product;

[0028] C. Take 6 parts of product B and 1 part of AgNO 3 , 1 part of Mn(NO 3 ) 2 and 2 parts of Fe(NO 3 ) 3 , add a mixed solution of 10 parts of alcohol and 30 parts of deionized water, stir for 0.5h, the stirring temperature is 70°C, and the stirring speed is 400rpm, to obtain product C;

[0029] D. Add a complexing agent to product C, the complexing agent is citric acid and ethylene glycol, 3.95 parts of...

Embodiment 2

[0035] The synthesis process of the catalytic activated carbon composite material for decomposing dioxins, comprising the following steps,

[0036] A, activated carbon (the activated carbon is washed and dried with deionized water) is pulverized, and crosses 300 mesh sieves to obtain product A;

[0037] B, A product is dropped into the container that concentrated sulfuric acid is housed, and nitrogen gas is passed into the bottom of the container, and the flow rate of said nitrogen gas is 60mL / min, soaked for 3h, washed until pH is 7, and dried to obtain B product;

[0038] C. Take 3 parts of product B and 1 part of AgNO 3 , 1 part of Mn(NO 3 ) 2 and 1 part of Fe(NO 3 ) 3 , adding a mixed solution of 15 parts of alcohol and 30 parts of deionized water, stirring for 1.5h, the stirring temperature is 90°C, and the stirring speed is 450rpm, to obtain product C;

[0039] D. Add complexing agent to product C, the complexing agent is citric acid and ethylene glycol, 3.95 parts of...

Embodiment 3

[0045] The synthesis process of the catalytic activated carbon composite material for decomposing dioxins, comprising the following steps,

[0046] A, activated carbon (the activated carbon is washed and dried with deionized water) is pulverized, and crosses a 250 mesh sieve to obtain the A product;

[0047] B, A product is dropped into the container that concentrated sulfuric acid is housed, and nitrogen gas is passed into the bottom of the container, and the flow rate of said nitrogen gas is 80mL / min, soaked for 3h, washed until pH is 7, and dried to obtain B product;

[0048] C. Take 7 parts of product B and 2 parts of AgNO 3 , 2 parts of Mn(NO 3 ) 2 and 2 parts of Fe(NO 3 ) 3 , adding a mixed solution of 20 parts of alcohol and 45 parts of deionized water, stirring for 1 h, the stirring temperature is 90°C, and the stirring speed is 450rpm, to obtain product C;

[0049] D. Add a complexing agent to product C, the complexing agent is citric acid and ethylene glycol, ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com