Motor pulse current control method and device and electric vehicle

A pulse current and current technology, which is applied in battery/fuel cell control devices, electric vehicles, control devices, etc., can solve problems such as overcurrent of components, changes in the magnitude of pulse current, and burnt hardware, so as to ensure reliability and safety , the effect of stable heating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

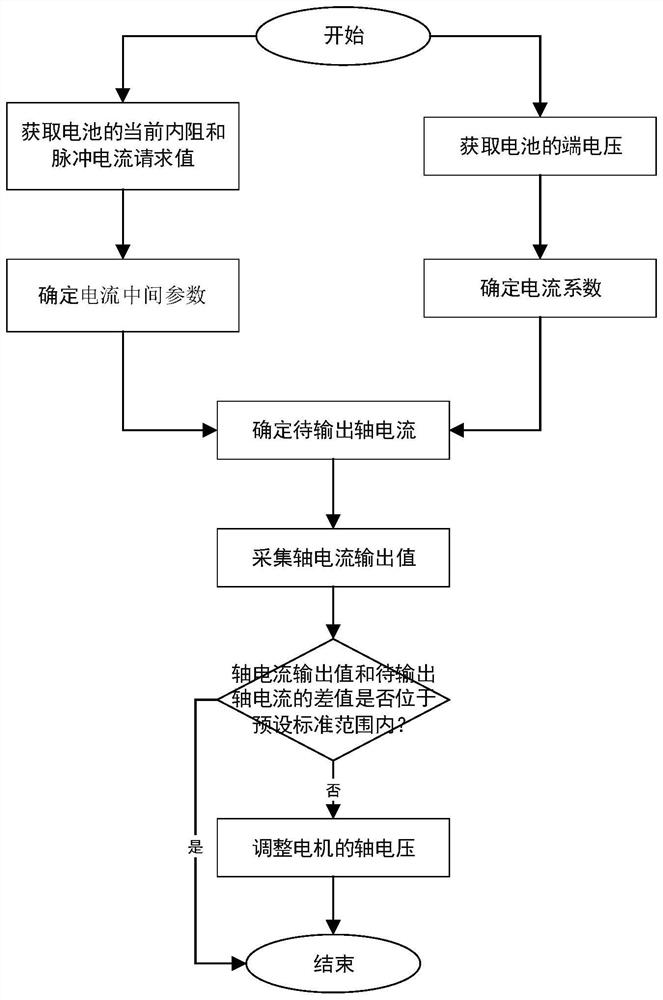

[0025] Such as figure 1 , an embodiment of the present invention provides a motor pulse heating current control method, wherein the method includes:

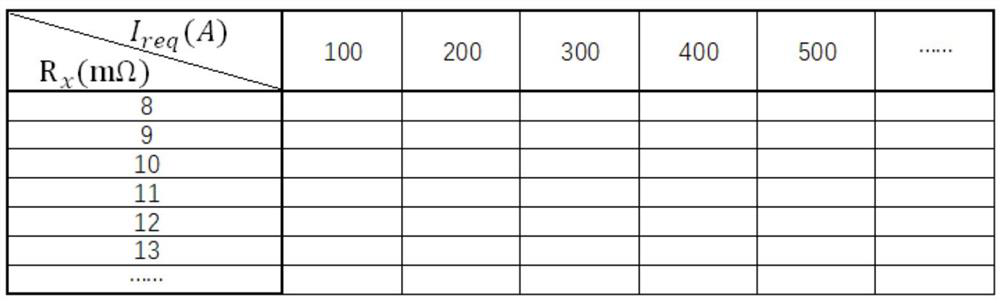

[0026] When it is determined that the power battery has a pulse heating demand, obtain the pulse heating current request value of the power battery and the current internal resistance R of the power battery, and then input the pulse current request value and the current internal resistance R of the power battery into the first preset calibration table Check the current intermediate parameters (such as Table 1).

[0027]

[0028] Table 1

[0029] Find the current terminal voltage U of the battery through the second preset calibration calibration table (such as Table 2) x The corresponding current coefficient α below.

[0030] u x (V)

α x

100 200 300 400 ……

[0031] Table 2

[0032] Then, the product of the current intermediate parameter and the current coefficient α is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com