Link plate balling and annealing technology

An annealing process and chain plate technology, applied in the field of chain plate spheroidization annealing process, can solve the problems of large cold deformation capacity, large energy waste and high heat preservation temperature, and achieve the effects of large deformation capacity, short heat preservation time and low hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

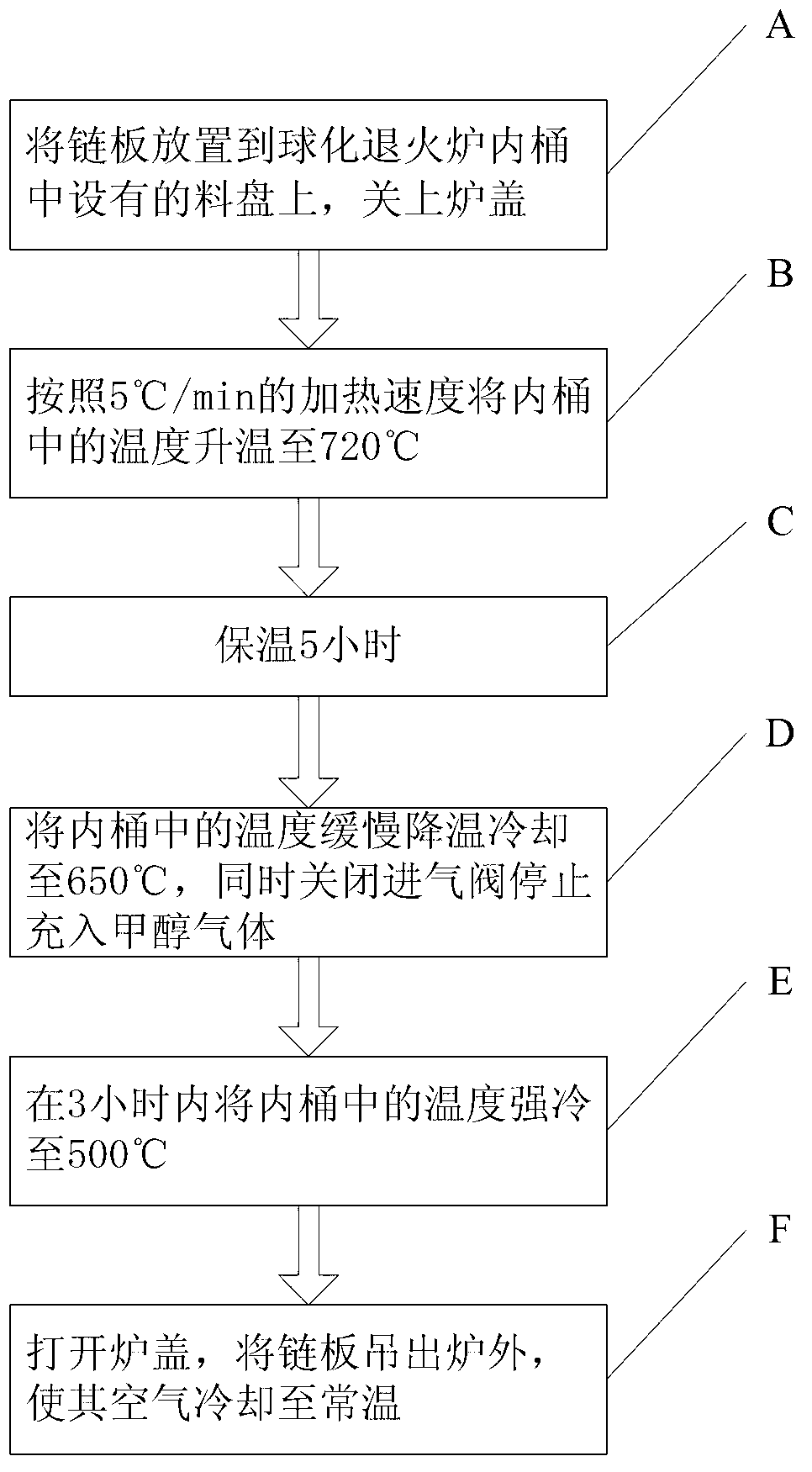

[0020] Such as figure 1 The shown spheroidizing annealing process for chain plates includes the following steps:

[0021] A: Place the chain plate on the material pan set in the barrel of the spheroidizing annealing furnace, and close the furnace cover;

[0022] B: Increase the temperature in the inner barrel to 720°C at a heating rate of 5°C / min;

[0023] B1: Open the exhaust valve at the exhaust port of the inner barrel of the spheroidizing annealing furnace;

[0024] B2: Set the spheroidizing annealing furnace to start to heat up. By monitoring the temperature sensor in the barrel of the spheroidizing annealing furnace, when the temperature in the barrel of the spheroidizing furnace rises to 300°C, open the air inlet valve at the inlet of the inner barrel at this time Fill the inner barrel with nitrogen; adjust the nitrogen flow rate to 15m by monitoring the gas flowmeter at the air inlet of the inner barrel 3 / hr;

[0025] B3: When the air in the inner barrel is exhausted through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com