Rapid annealing method for ohmic contact of metal and silicon carbide

A rapid annealing, ohmic contact technology, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., to achieve the effect of improving flexibility, improving quality, and increasing heating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Referring to the accompanying drawings,

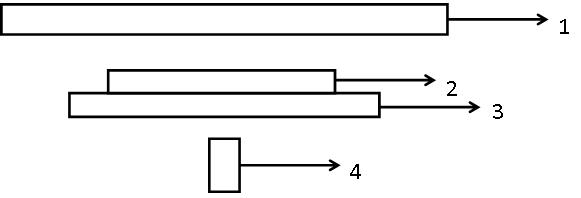

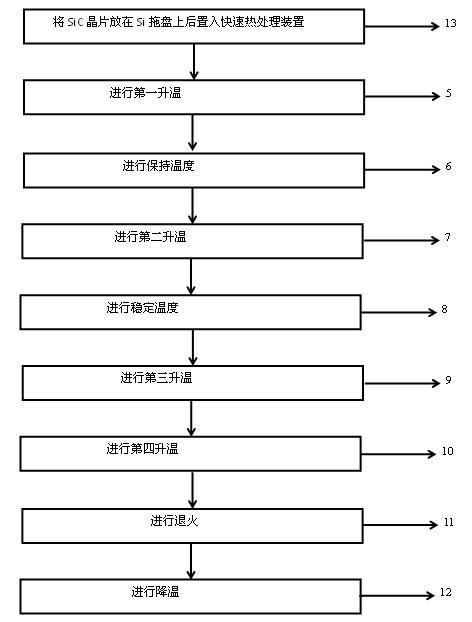

[0024] 1) Put the SiC wafer 2 on the Si wafer tray 3 and put it into the rapid heat treatment device 13, place the 3-inch 4H silicon carbide wafer (SiC wafer) 2 to be rapidly annealed on the 4-inch Si wafer tray 3, and then put it into the In the rapid heat treatment device 13, the heating surface 1 of the rapid annealing device is above the SiC wafer 2, the temperature measuring device 4 is below the Si wafer tray 3, and the protective gas Ar is filled at the same time;

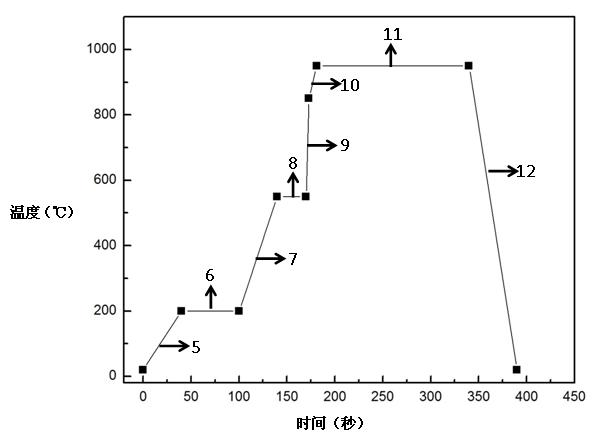

[0025] 2) The first heating stage 5, the temperature maintaining stage 6, the SiC wafer 2 is heated for the first time, heated to 200°C, which is the first temperature, maintained at the temperature for 60 seconds, and the heating rate is 5°C / s;

[0026] 3) In the second heating stage 7 and the temperature stabilization stage 8, the temperature of the SiC wafer 2 is raised for the second time, from 200°C to 550°C, which is the second temperature, the temperatu...

Embodiment 2

[0031] Referring to the accompanying drawings,

[0032] 1) Place the 2-inch 6H silicon carbide wafer (SiC wafer) 2 to be rapidly annealed on the 4-inch Si wafer 4, and then put it into the rapid heat treatment device 13. The heating surface 1 of the rapid annealing device is above the silicon carbide wafer. The temperature device 4 is below the Si chip tray 3, filled with protective gas N2;

[0033] 2) The first heating stage 5, the temperature maintaining stage 6, the SiC wafer 2 is heated for the first time, heated to 300°C, which is the first temperature, kept for 180 seconds, and the heating rate is 10°C / s;

[0034] 3) In the second heating stage 7 and the temperature stabilization stage 8, the temperature of the SiC wafer 2 is raised for the second time, from 200°C to 600°C, which is the second temperature, the temperature is stabilized for 60 seconds, and the heating rate is 20°C / s;

[0035] 4) In the third heating stage 9, the SiC wafer 2 is heated for the third time, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com