Firewood and carbon co-firing kiln

A mixed firing and kiln technology, which is applied in the field of ceramic kilns, can solve problems such as difficult control and unstable heating speed of the kiln chamber, and achieve the effect of reducing the burning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

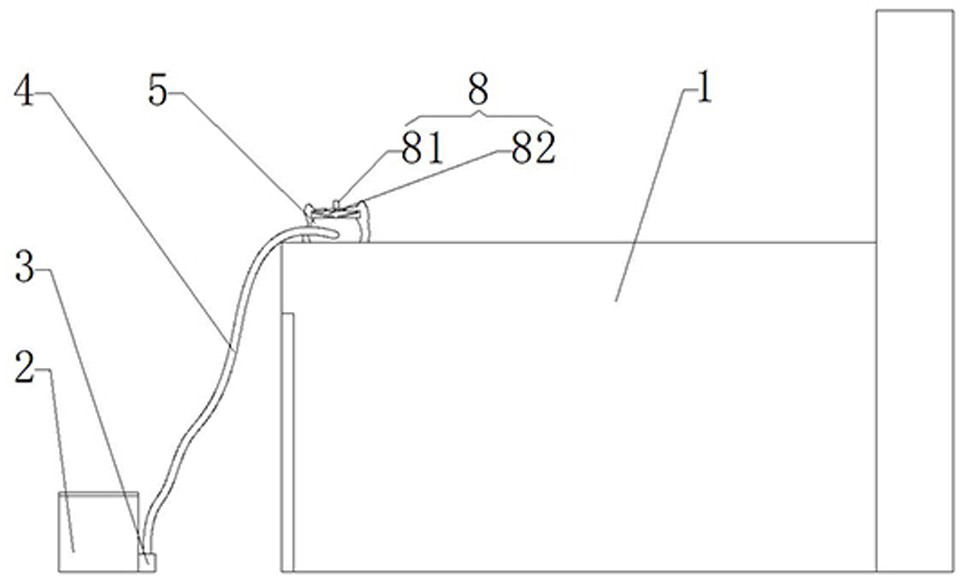

[0036] Such as Figure 1 to Figure 11 As shown, a firewood-carbon mixed firing kiln includes a firewood kiln body 1, a disperser 2 and a mud pump 3, the entrance of the firewood kiln body 1 is located at the left end of the firewood kiln body 1, and the disperser 2 is connected to the mud pump 3 , the hose 4 of the mud pump 3 is connected to the firewood kiln body 1 through a dispersion device;

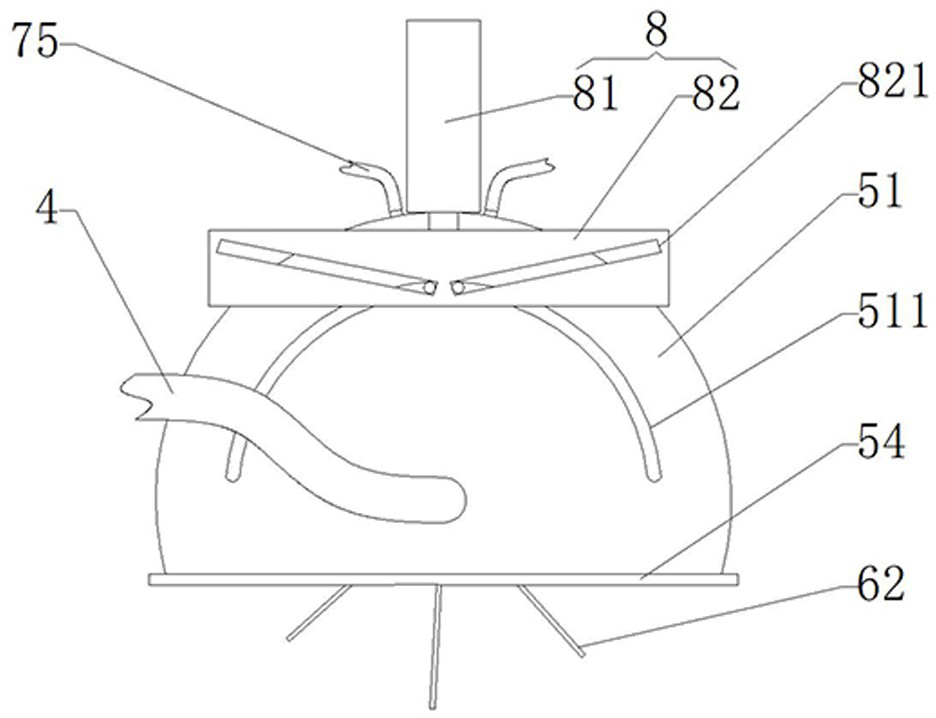

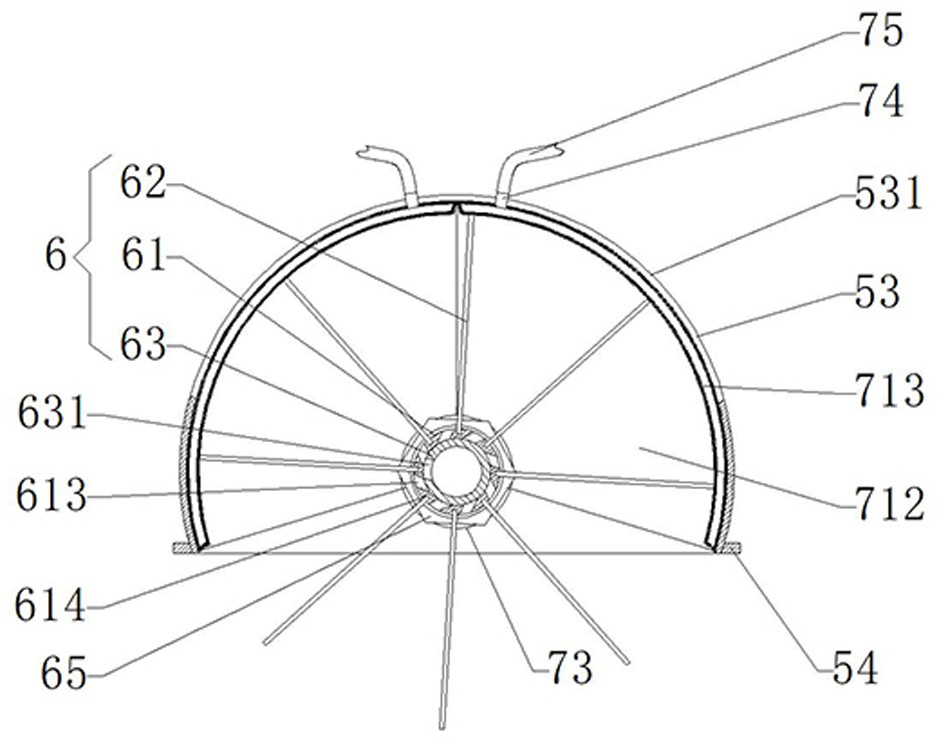

[0037] Described dispersing device comprises casing 5, dispersing assembly 6, protection assembly 7 and adjusting assembly 8, and described casing 5 is made up of front plate 51, back plate 52 and arc plate 53, and described front plate 51 is that bottom surface is horizontal plane, The top surface is an arcuate bow-shaped plate with an arc-shaped protrusion upward. The upper part of the front plate 51 is provided with an arc-shaped through hole 511 coaxial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com