Iron ore slag sintered brick and a preparation technology of same

A technology of sintered bricks and iron ore, which is applied in the field of sintered bricks, can solve the problems of broken or burst sintered bricks, difficult sintering, complex components of iron ore slag, etc., and achieves the goal of saving land resources, protecting cultivated land, and wide sources of raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Iron ore slag sintered brick raw materials, by absolute dry weight, include the following components in parts by weight:

[0039] 32 parts by weight of iron ore slag;

[0040] Coal gangue 32.2 parts by weight;

[0041] Silt 21 parts by weight;

[0042] 8 parts by weight of clinker;

[0043] The above-mentioned iron ore slag, coal gangue and clinker are powders with a particle size of 0.1-0.3mm. The iron ore slag in this embodiment comes from the iron ore slag powder waste produced in Lujiang, Anhui.

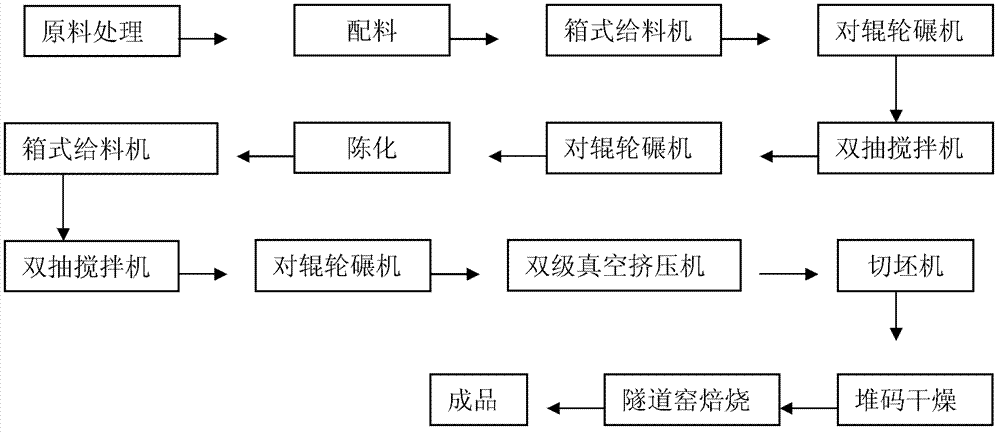

[0044] The preparation method of iron ore slag sintered brick (as figure 1 Shown process flow diagram, wherein the machine adopted is conventional equipment in the prior art) is:

[0045] Dry and dehydrate iron ore slag with a water content of 30% to a water content of 13-18%; grind coal gangue and clinker to a particle size of 0.1-0.3mm; The river silt is aged, dehydrated and dried until the water content is 13-18%; according to the ratio, coal gangue, river silt an...

Embodiment 2

[0050] Iron ore slag sintered brick raw materials, by absolute dry weight, include the following components in parts by weight:

[0051] 32 parts by weight of iron ore slag;

[0052]Coal cinder 31.5 parts by weight;

[0053] Silt 20 parts by weight;

[0054] 8 parts by weight of clinker;

[0055] The above-mentioned iron ore slag, coal cinder and clinker are powders with a particle size of 0.1-3mm. The iron ore slag in this embodiment comes from the iron ore slag waste produced in Lujiang, Anhui.

[0056] The preparation method of iron ore slag sintered brick is:

[0057] Dry and dehydrate the iron ore slag with a water content of 30% to a water content of 13-18%; grind the cinder and clinker to a particle size of 0.1-3mm; grind the river sludge with a water content of 25%-40% After aging, dehydration and drying to a moisture content of 13-18%; according to the proportion, coal cinder, river sludge and clinker are added to iron ore slag and mixed, and water is added to ad...

Embodiment 3

[0061] Iron ore slag sintered brick raw materials, by absolute dry weight, include the following components in parts by weight:

[0062] 28 parts by weight of iron ore slag;

[0063] 27.6 parts by weight of coal gangue;

[0064] Silt 18 parts by weight;

[0065] 5 parts by weight of clinker;

[0066] The above-mentioned iron ore slag, coal gangue and clinker are powders with a particle size of 0.1-0.3mm. The iron ore slag in this embodiment comes from the iron ore slag waste produced in Lujiang, Anhui.

[0067] The preparation method of iron ore slag sintered brick is:

[0068] Dry and dehydrate iron ore slag with a water content of 30% to a water content of 12-18%; grind coal gangue and clinker to a particle size of 0.1-0.3mm; The river silt is aged, dehydrated and dried until the water content is 12-18%; according to the ratio, coal gangue, river silt and clinker are added to the iron ore slag for mixing, and water is added to adjust the water content of the mixture to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com