Pulse heating current control method and system of power battery and electric automobile

A technology of pulse heating and current control, which is applied in the direction of battery/fuel cell control devices, electric vehicles, vehicle parts, etc., can solve problems such as gear wear, affecting the precise control and stability of pulse heating current, and pulse heating current deviation, etc., to achieve Effects of reducing current control deviation, stabilizing heating rate, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

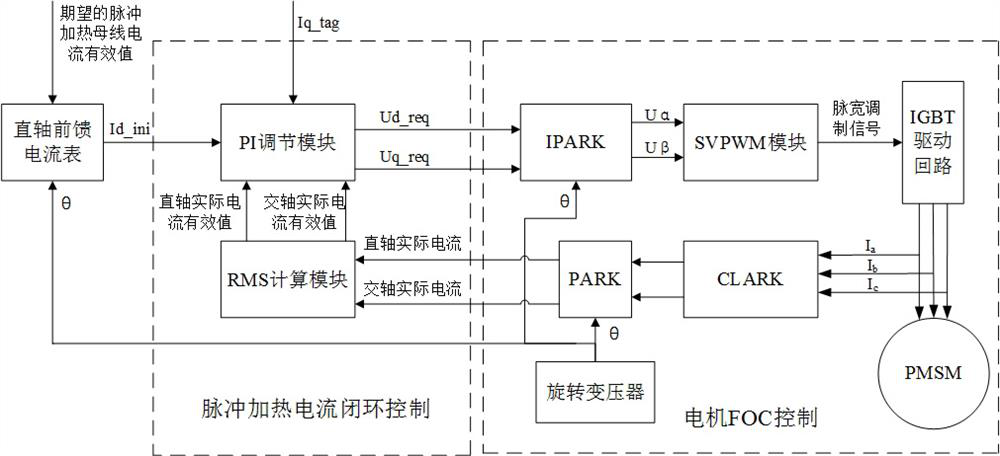

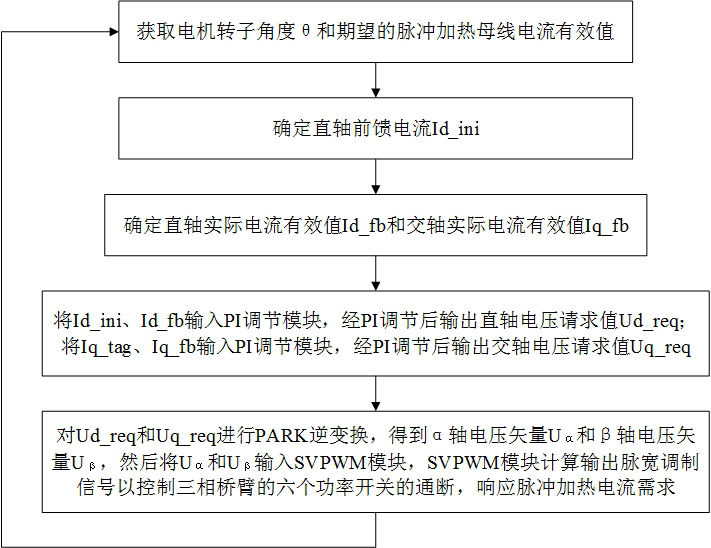

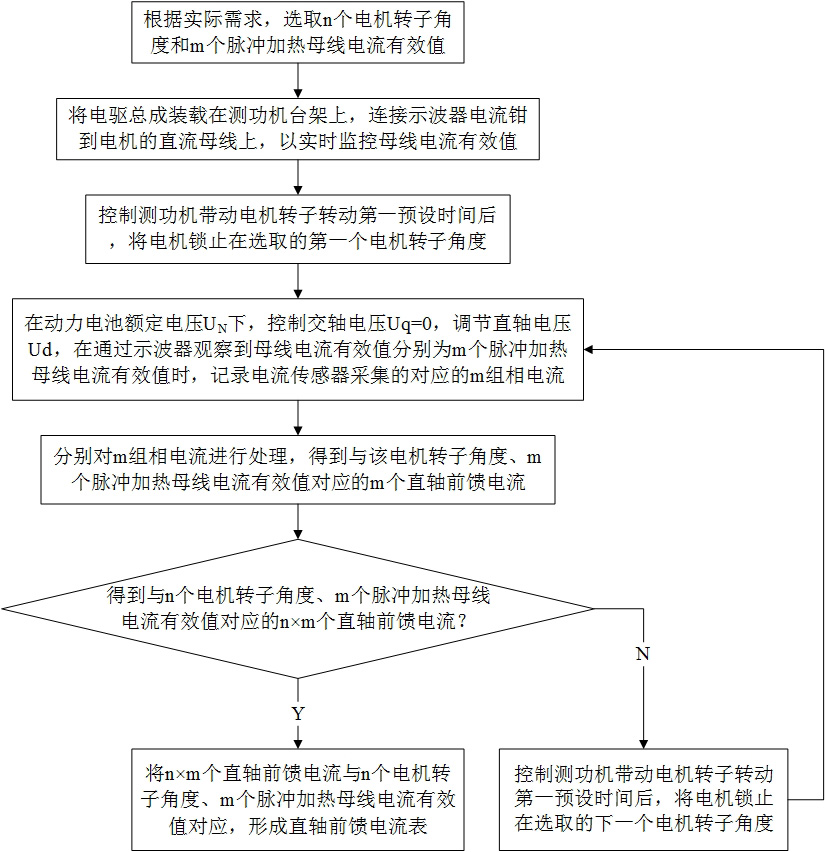

[0043] like figure 1 , figure 2 As shown, the pulse heating current control method of the power battery in this embodiment is executed by the motor controller, and the method includes:

[0044] Step 1: Obtain the rotor angle θ of the motor and the expected RMS current of the pulse heating busbar, and then perform Step 2.

[0045] The motor rotor angle θ is detected by the resolver, and the resolver sends the detected motor rotor angle θ to the motor controller. The expected effective value of the pulse heating bus current is obtained by the battery management system by querying the preset temperature-ammeter according to the temperature of the power battery; the preset temperature-ammeter is the temperature of the power battery obtained through the calibration method and the expected pulse heating bus current is valid. Correspondence table of values. The battery management system sends the desired pulse heating bus current rms value to the motor controller.

[0046] Step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com