lens drive

A technology of lens driving device and lens barrel, which is applied in the direction of installation, machine/engine, generator/motor, etc., can solve the problems of being easily interfered by magnetic fields, poor reliability, etc., and achieves simple structure, easy assembly, and high stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

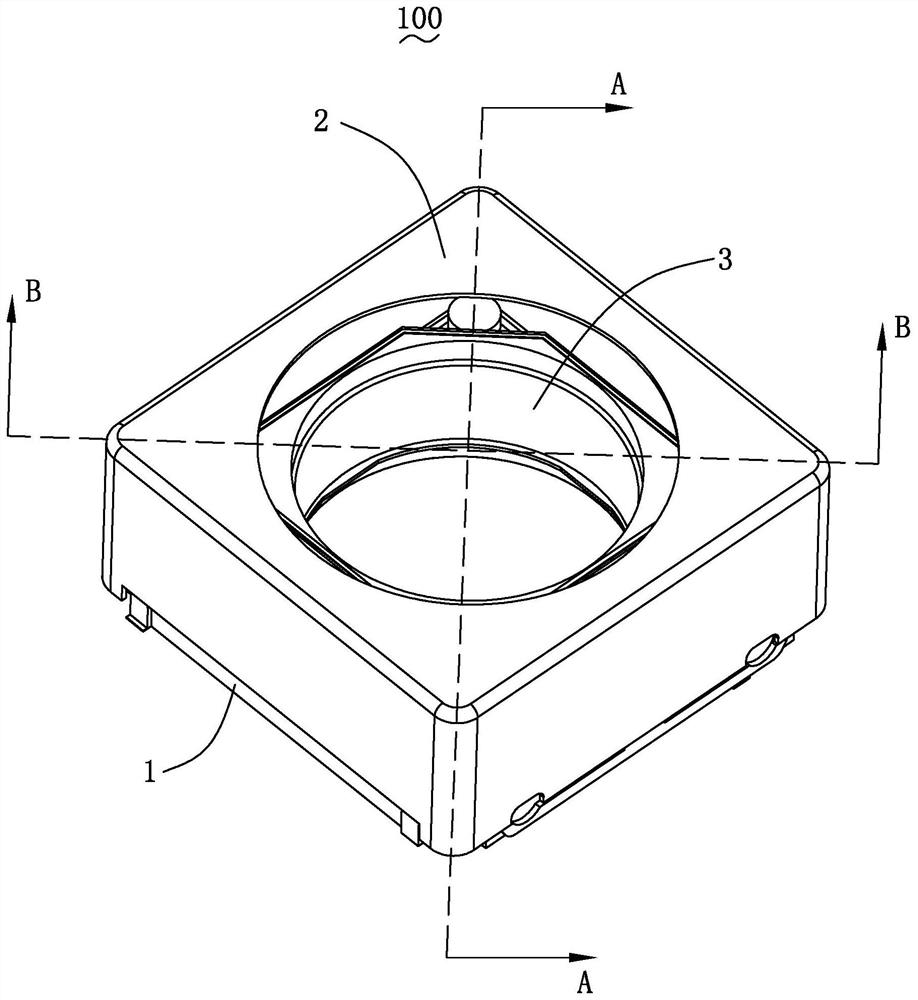

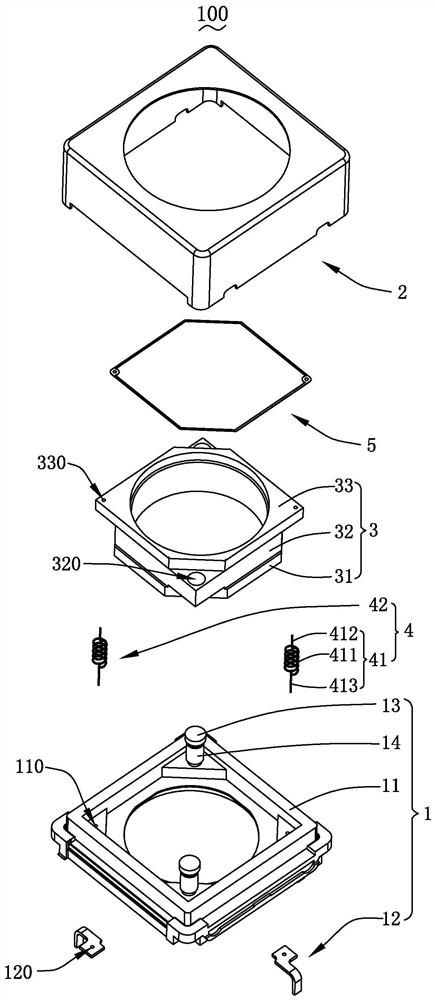

[0030] see Figure 1 to Figure 3 , the present invention provides a lens driving device 100, which includes a base 1, an upper cover 2 that is closed with the base 1 to form a storage space, a lens barrel 3 accommodated in the storage space, and sandwiched between the base 1 and the two elastic pieces 4 between the lens barrel 3 and the conductive wire 5 connecting the two elastic pieces 4 .

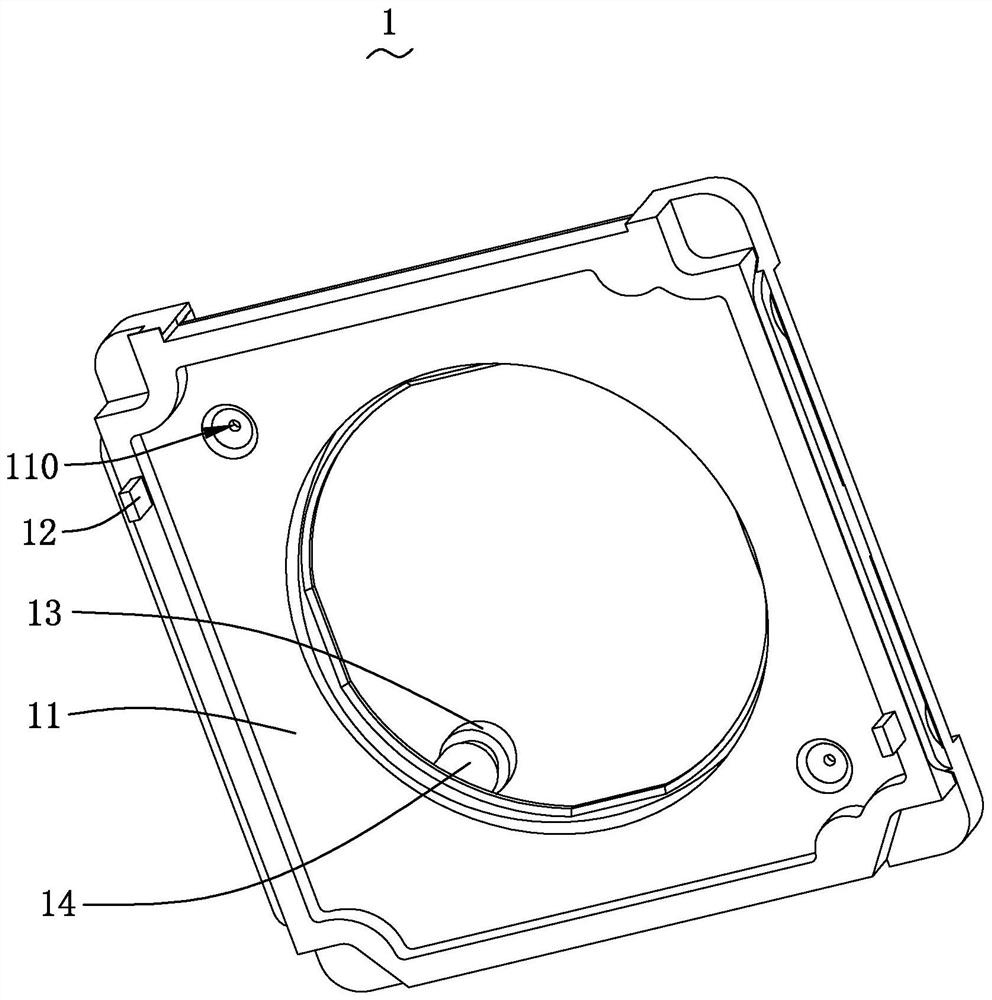

[0031] The base 1 includes a base 11, a conductive terminal 12 with one end embedded in the base 11 and the other end electrically connected to the outside world, fixed on the end of the base 11 close to the lens barrel 3 and along the optical axis The guide column 13 arranged in the direction and the metal sleeve 14 sleeved on the outer surface of the guide column 13 .

[0032] The conductive terminal 12 includes a first through hole 120 penetrating along the optical axis direction, and the base 11 includes a second through hole 110 penetrating through the base 11 and corresponding to ...

Embodiment 2

[0043] Compared with Embodiment 1, the different technical features of this embodiment are:

[0044] Both the first elastic part and the second elastic part are made of two-way memory alloy. When the first elastic member and the second elastic member are supplied with electric current, the temperature of the first elastic member and the second elastic member increases due to the thermal effect, and they begin to shrink under the action of the shape memory effect, driving the The lens barrel 3 moves toward the direction close to the base 1; when the current is reduced or the energization is stopped, the temperature of the first elastic member and the second elastic member decreases, and the first elastic member and the second elastic member The elastic member returns to the initial state, driving the lens barrel 3 to move away from the base 1 to the initial position. It can be understood that, the first elastic member and the second elastic member are connected in series, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com