Warp tension collection device

A collection device and tension technology, applied in textiles, textiles, papermaking, looms, etc., can solve the problems of warp yarn tension without warp let-off motor, poor product quality, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below with reference to the accompanying drawings and embodiments.

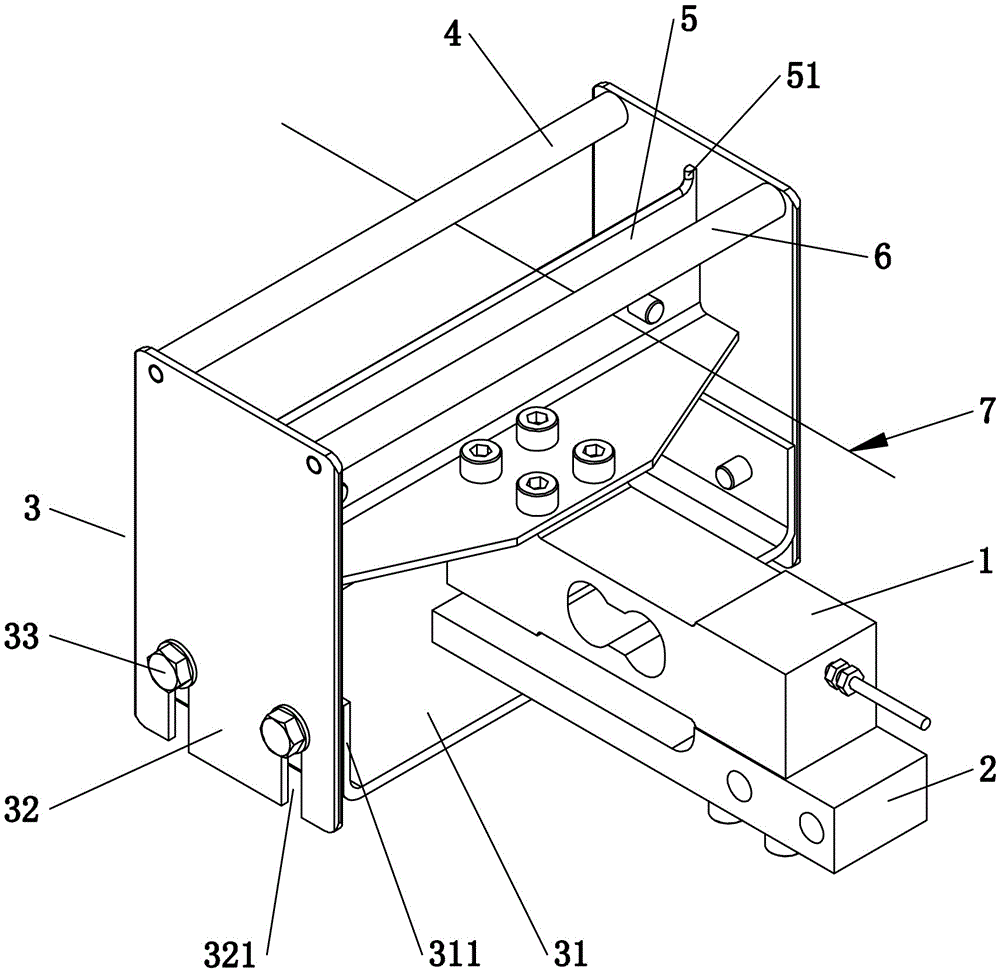

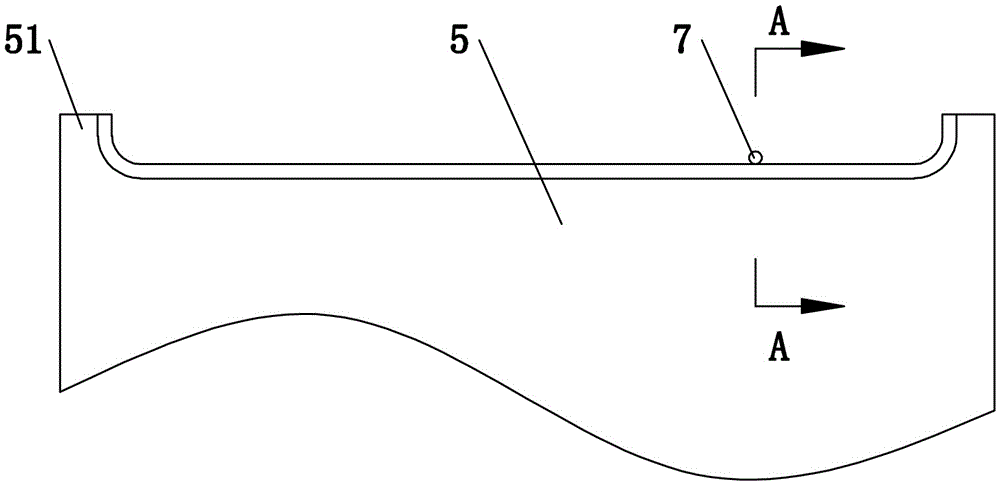

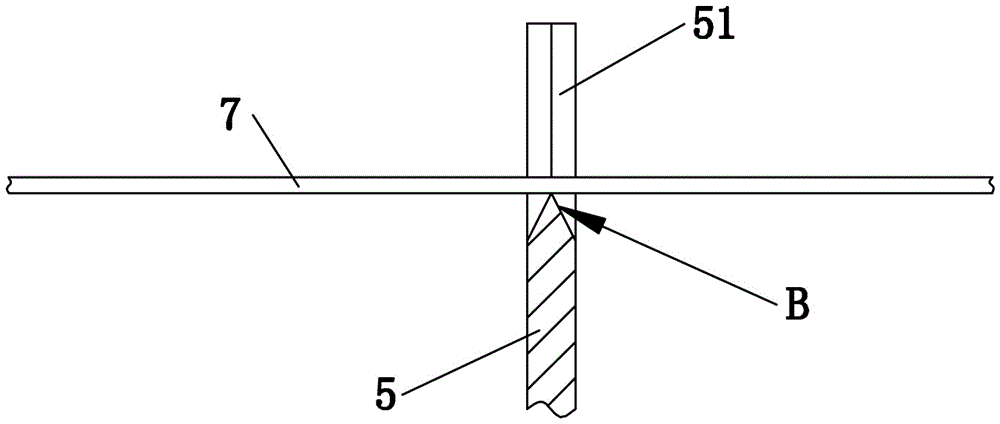

[0020] see Figure 1 to Figure 4 As shown, a warp tension acquisition device includes a bracket assembly 3, a tension sensor 1, a sensor bracket 2, a sheet yarn supporting assembly 5, and a yarn pressing rod. The tension sensor 1 is connected to the bracket assembly 3 through the sensor bracket 2, and the sheet The yarn supporting assembly 5 is arranged on the tension sensor 1, and the yarn pressing bar is located on the upper part of the yarn supporting assembly 5 and is connected with the support assembly 3. The tension sensor 1 is electrically connected with the control circuit of the electric control box of the loom, and the electric control box The control circuit controls the let-off servo 8 of the loom according to the signal collected by the tension sensor 1, and then the let-off servo 8 controls the speed of the let-off servo motor 9 of the loom....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com