Pneumatic-electric-control volume-variable type amount of liquid control device

A technology for volume control and control device, which is applied in the direction of using electric device flow control, infusion set, enema/irrigator, etc., can solve the problem of inaccurate measurement and control, inability to separate liquid and gas, and affect the accuracy of measurement and control. and other problems, to achieve the effect of improving gas tightness, ensuring smooth operation and reliability, and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

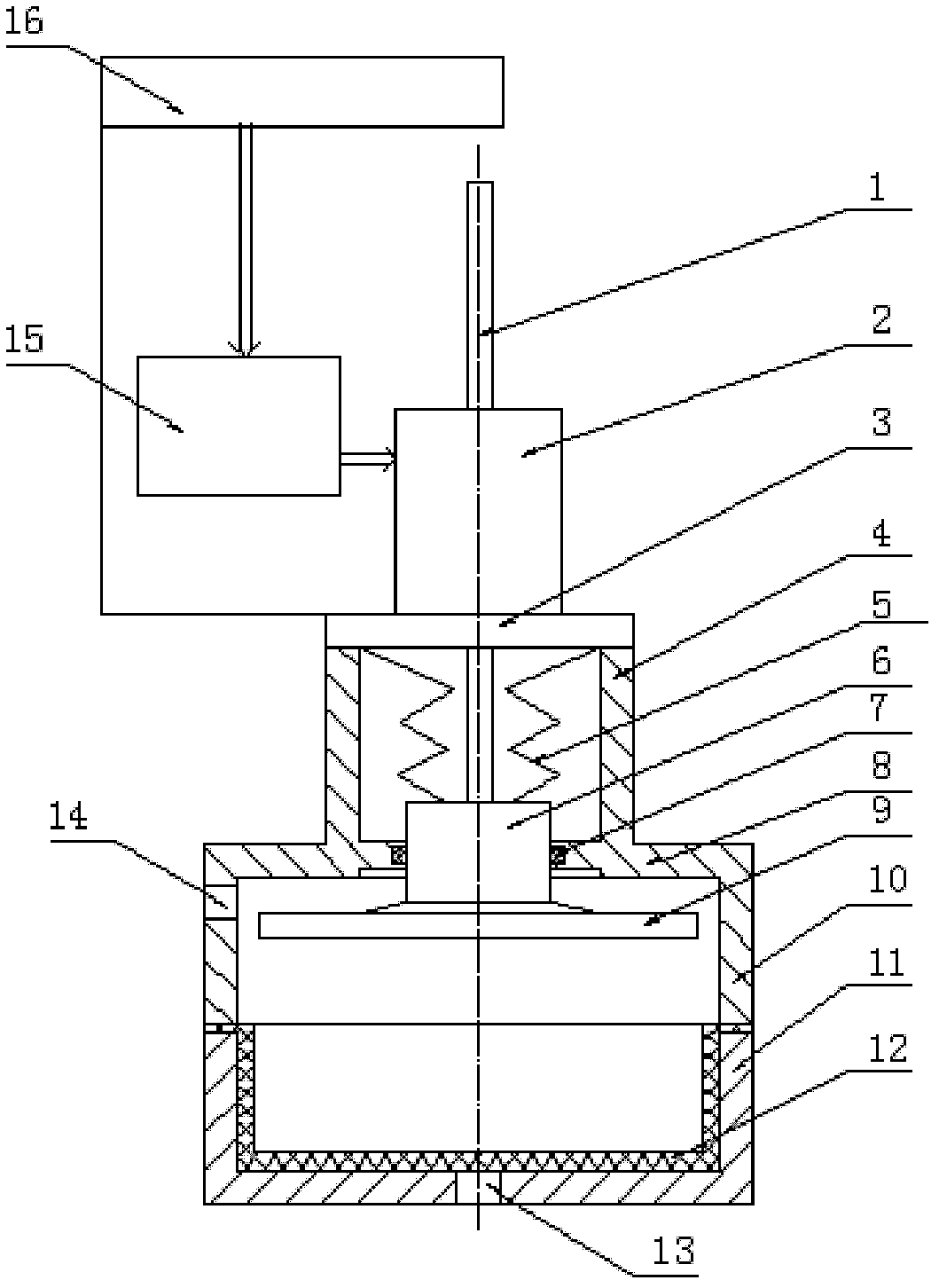

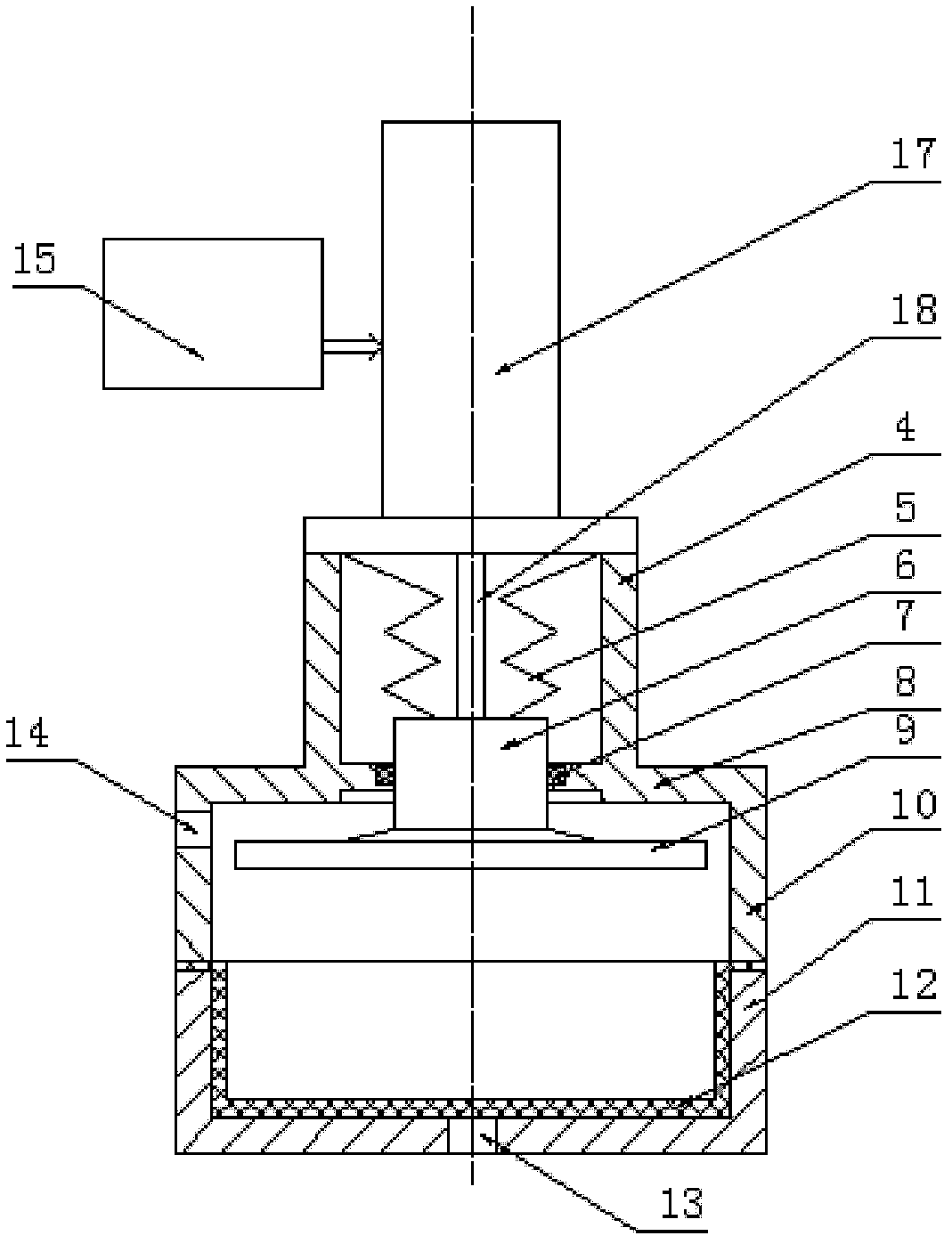

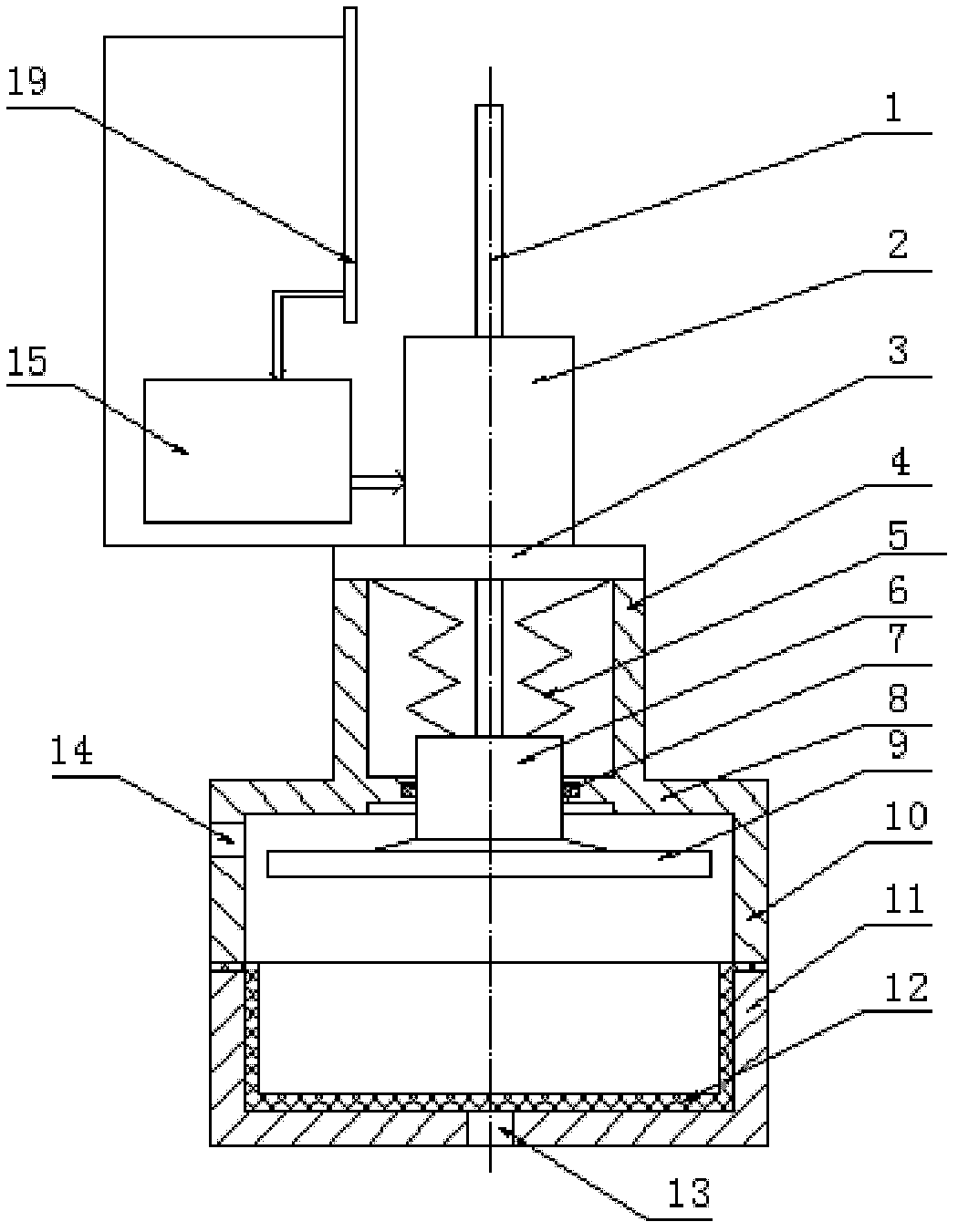

[0025] A gas-electric control volume variable liquid volume control device, which is mainly composed of a tank body, an isolation membrane 12, an adjustment plate 9, a lifting drive mechanism, a control unit and a sealing unit, and the tank body is composed of a lower tank body 11 and an upper tank body 10 and an upper support box 4, an isolation film is installed between the lower tank body and the upper tank body, a support box is formed on the upper part of the lower tank body, a liquid inlet and outlet 13 is formed on the bottom surface of the lower tank body, and an air control valve is formed on the side wall of the upper tank body Interface 14; the adjustment disc is installed horizontally in the upper tank body, the disc seat 6 made o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com