Detachable tube seat gas shield

A technology of protective cover and seat gas, which is applied to devices for supplying/exhausting protective gas, welding accessories, etc., can solve problems such as welding deformation, achieve high gas sealing performance, ensure welding quality, and reduce manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the present invention more comprehensible, preferred embodiments are described below in detail with accompanying drawings.

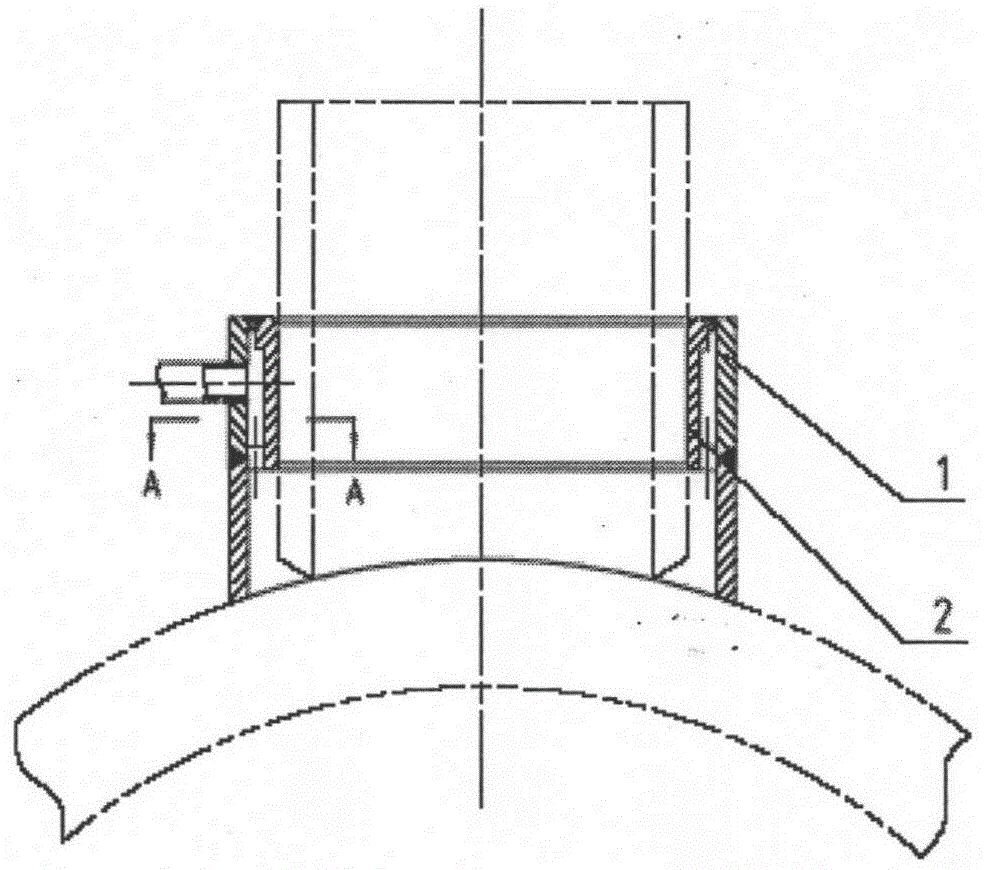

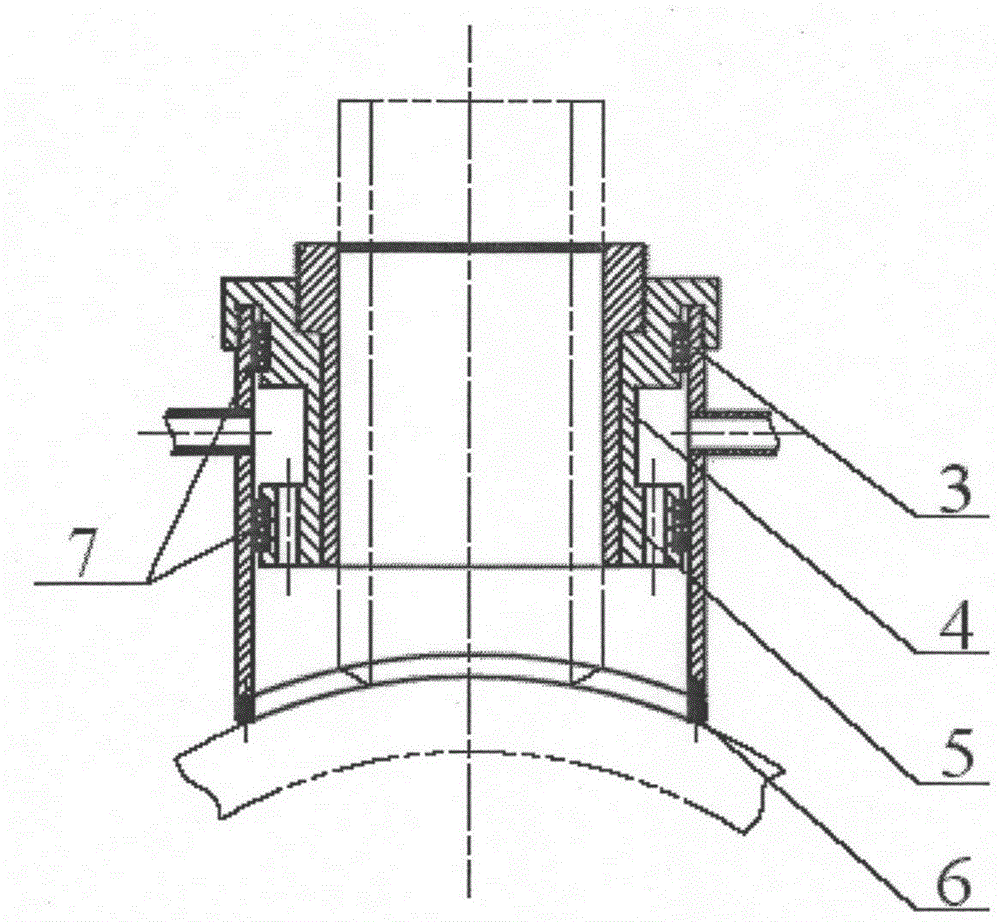

[0027] The present invention is a removable tube seat gas protective cover, such as Figure 3-Figure 4 As shown, it includes an outer cover 3, a sealing ring 4, a positioning ring 5, and a screw 6. The outer cover body 3, the sealing ring 4, and the positioning ring 5 are all designed with internal / external threads, and the parts are screwed to fix and matched.

[0028] Such as Figure 5-Figure 6 As shown, there are external threads on the top of the outer cover 3 for connection with the sealing ring 4. A plurality of air pipes 3-1 are welded in the middle of the outer cover 3 (4 air pipes are designed in this embodiment) to ensure the air tightness of the weld. The bottom of the outer cover 3 is in the shape of an arc (the arc radius is: R1), and the sponge cushion 3-2 is installed in cooperation with it, and the screw 6 is used for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com