Novel phenolic resin and application thereof in preparation of flexible graphite-based bipolar plate

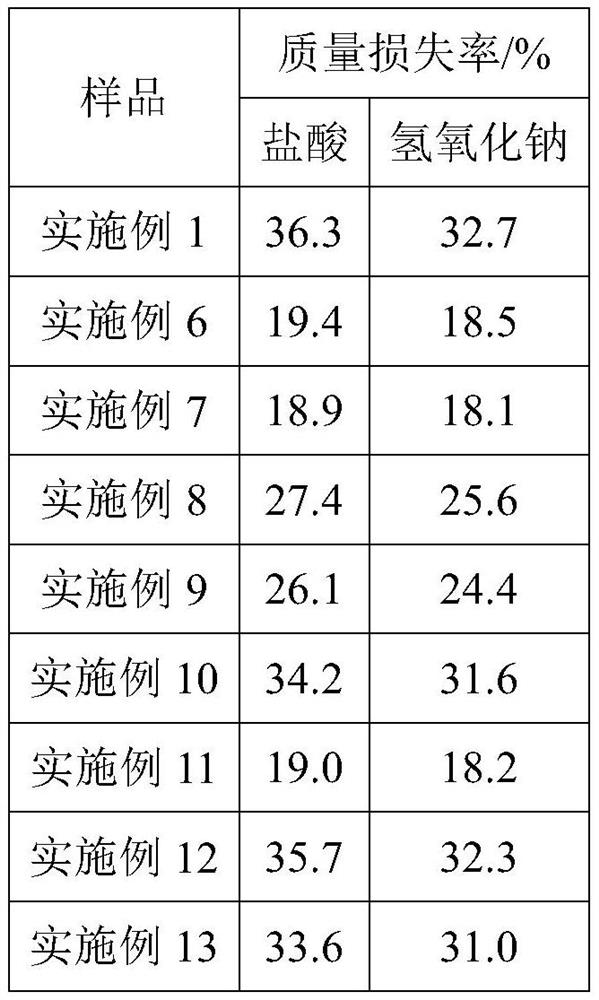

A phenolic resin and flexible graphite technology, applied in the field of bipolar plate processing, can solve the problems of unsatisfactory resin impregnation effect, affecting the gas permeability and mechanical properties of materials, etc., and achieve better air tightness and acid and alkali resistance. The effect of good mechanical properties, air tightness and acid and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Preparation of flexible graphite-based bipolar plates:

[0045] Preparation of flexible graphite paper:

[0046] Take 295 parts by weight of sulfuric acid with a concentration of 98%, add 5 parts by weight of a 60% concentration of hydrogen peroxide solution, cool down to 10 ° C, add scaly natural graphite with a particle size distribution of 30 to 80 meshes, react for 40min, then suction filter, remove Washing with ionized water, repeating the operation 3 times, drying at 110°C to obtain expandable graphite; treating at 1000°C for 8s to expand into worm-like graphite, and separating from gas and gas to obtain graphite worms with a length in the range of 0.6-1.2cm;

[0047] After that, the graphite worms are evenly paved and rolled to make a density of 0.1g / cm 3 Graphite sponge cake board; then carry out multi-pass rolling pressing to obtain flexible graphite paper, wherein the pressure applied in the rolling step is 100Mpa, the temperature is 230 ° C, and the rolling sp...

Embodiment 2

[0051] Preparation of flexible graphite-based bipolar plates:

[0052] The preparation of flexible graphite paper is different from Example 1: the density of the prepared flexible graphite paper is 1.6g / cm 3 ;

[0053] The preparation of the bipolar plate is different from that in Example 1: the pressure holding time of the vacuum tank is 8h.

[0054] The resin content in the flexible graphite-based bipolar plate is 23.6 wt %.

Embodiment 3

[0056] Preparation of flexible graphite-based bipolar plates:

[0057] The preparation of flexible graphite paper is different from Example 1: the density of the prepared flexible graphite paper is 1.5g / cm 3 ;

[0058] Preparation of bipolar plates:

[0059] Take the flexible graphite paper and put it into the vacuum tank, keep the negative pressure of 0.1MPa, and feed the phenolic resin diluent with a concentration of 25wt%. The phenolic resin diluent is ordinary tap water; the vacuum tank is kept under pressure for 6 hours and 6kg of compressed air is introduced; The flexible graphite paper filled with phenolic resin in the pores was taken out, and the residual resin on the surface was wiped; the solvent water in the graphite paper was dried under pressure at 80 °C, and then the resin in the graphite paper was cured under pressure at 130 °C to obtain flexible graphite. base bipolar plate.

[0060] The resin content in the flexible graphite-based bipolar plate is 22.1 wt %...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com