Vacuum processing device

A vacuum processing device and plate technology, applied in the direction of plasma, coating, gaseous chemical plating, etc., to achieve the effect of improving gas tightness, eliminating problems, and preventing component deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

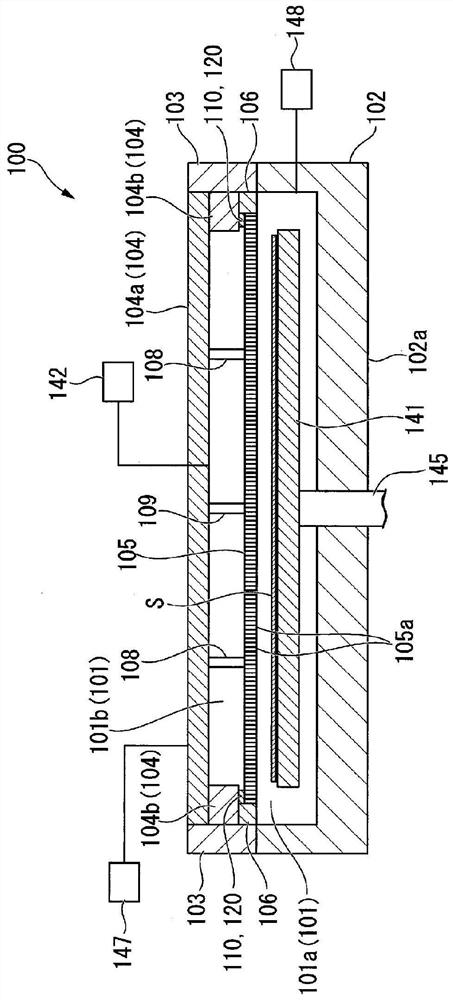

[0282] In the vacuum processing apparatus 100 of the above-mentioned embodiment, the formation of an oxide film has been studied, and in particular, the formation of an SiO film using TEOS (tetraethoxysilane) with a large molecular weight as a source gas has been studied. X film forming.

[0283] The following shows TEOS-SiO X Items in the film-forming process.

[0284] · Substrate heating temperature: 430°C

[0285] ·The size of the processed substrate S: 1500×1800mm

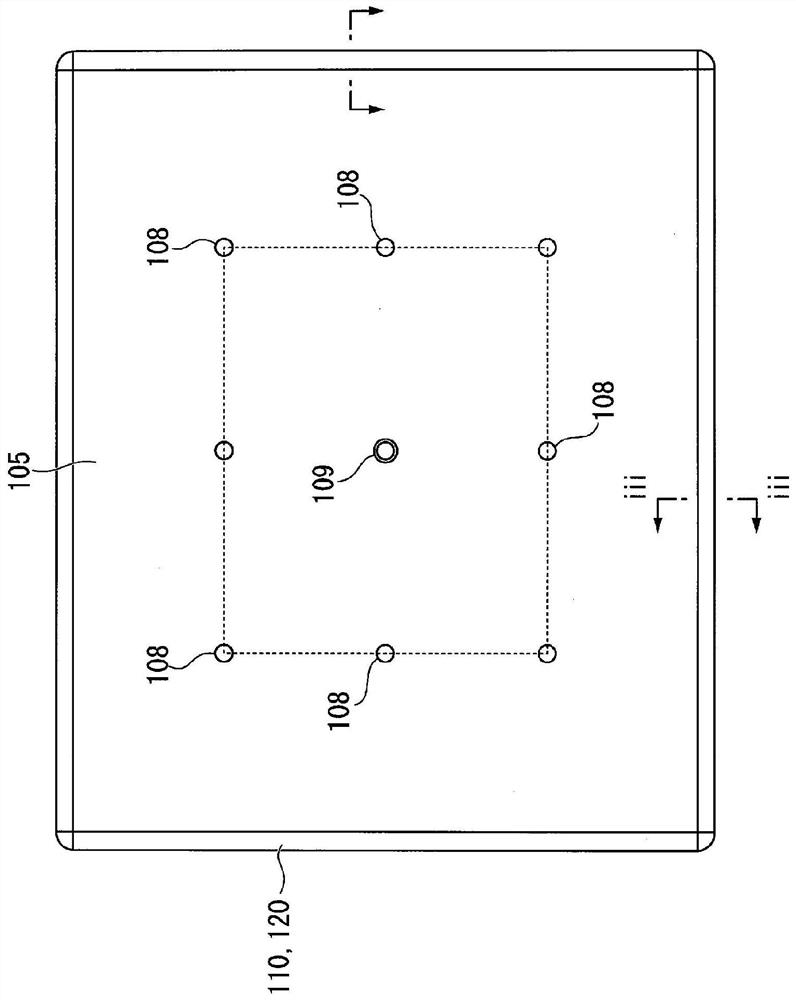

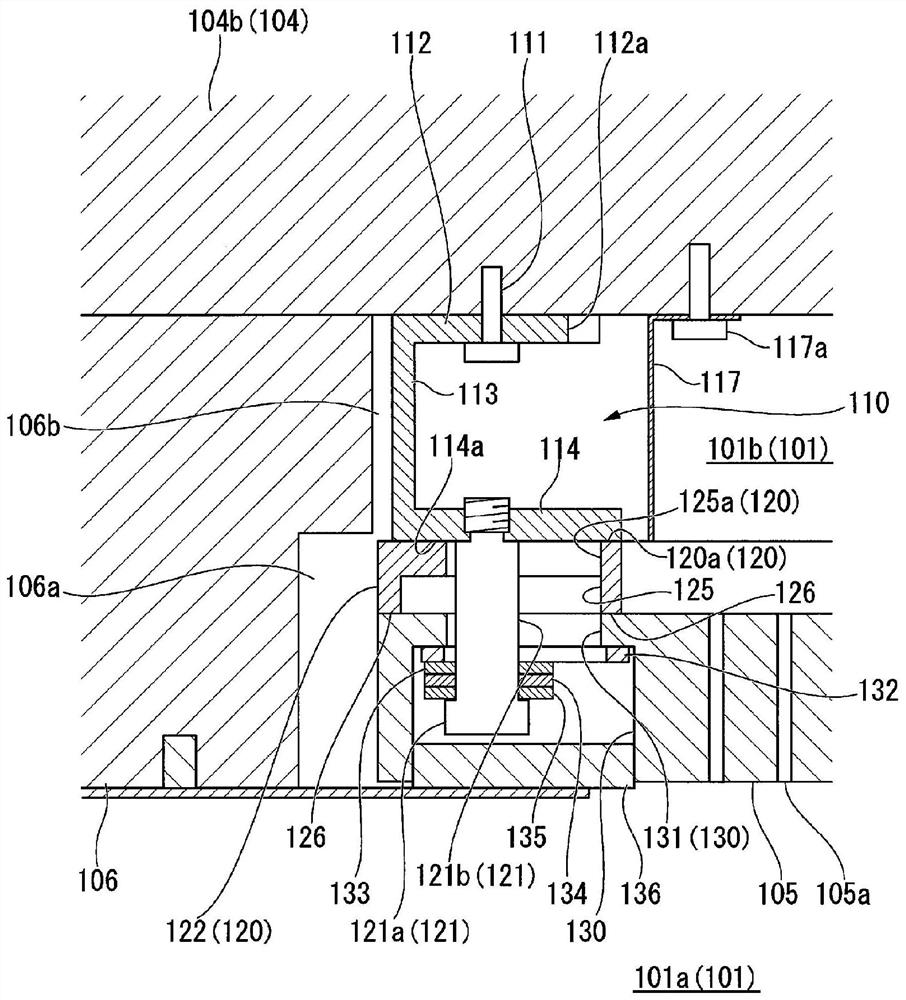

[0286] · Width dimension of slide plate 120: 35mm

[0287] · Thickness dimension of slide plate 120: 10mm

[0288] · Depth dimension of groove 125: 5mm

[0289] · Width dimension of leg portion 126: 3 mm

[0290] ·Height dimension of electrode frame 110: 32.5mm

[0291] ·Thickness dimension of the longitudinal plate surface 113: 3mm

[0292] Figure 9 The simulation results of the temperature distribution in the shower plate are shown.

[0293] exist Figure 9 , one quarter of the shower plate is sho...

experiment example 2

[0296] As in Experimental Example 1, SiO was investigated using TEOS (tetraethoxysilane). X film forming.

[0297] Here, the width dimension is the same, but the device has an electrode frame with a dense block structure in which the sliding plate and the electrode frame in the above embodiment are integrally formed without grooves and spaces.

[0298] Figure 10 The simulation results of the temperature distribution in the shower plate are shown.

[0299] exist Figure 10 , one quarter of the shower plate is shown. That is, the lower left is the central position of the shower plate.

[0300] From this result, in the vacuum processing apparatus in Experimental Example 2, the highest temperature in the shower plate was 423.15°C, the lowest temperature was 338.16°C, and the in-plane temperature distribution Δ=84.99°C.

[0301] Furthermore, it can be seen that by improving the in-plane temperature distribution of the shower plate 105, the stress distribution in SiN can be im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com