Heat-insulation communication glass

A technology of glass and heat insulation, applied in the direction of parallel glass structure, sealing device, wing frame, etc., can solve the problem of reducing the stability of the steel parts, that is, the frame structure of the greenhouse glass house

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

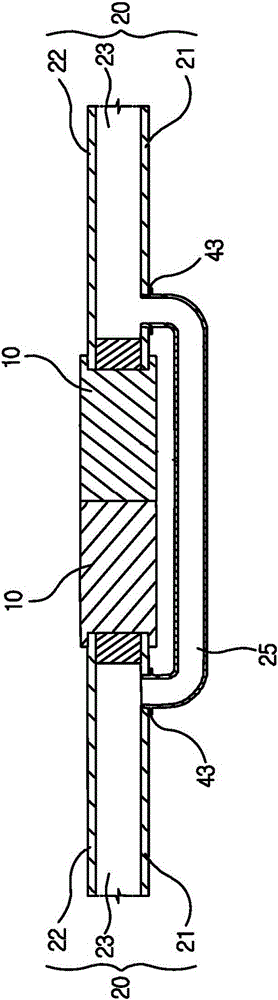

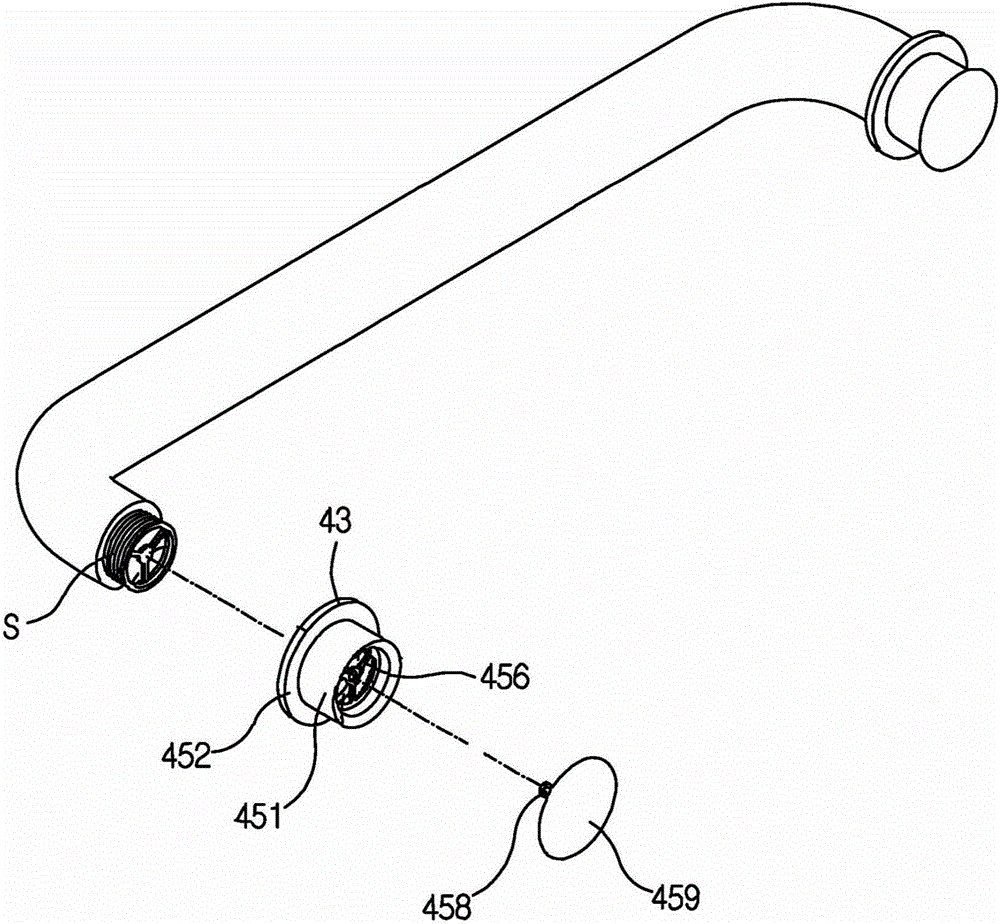

[0021] The reference signs in the drawings of the description include: casing side wall 451, wing plate 43, central column 458, docking column 456, cover plate 45, thread S, casing 452, connecting pipe 25, innermost glass 22, outermost Glass 21, inner cavity 23, steel part 10, heat insulating glass 20, air pump 30.

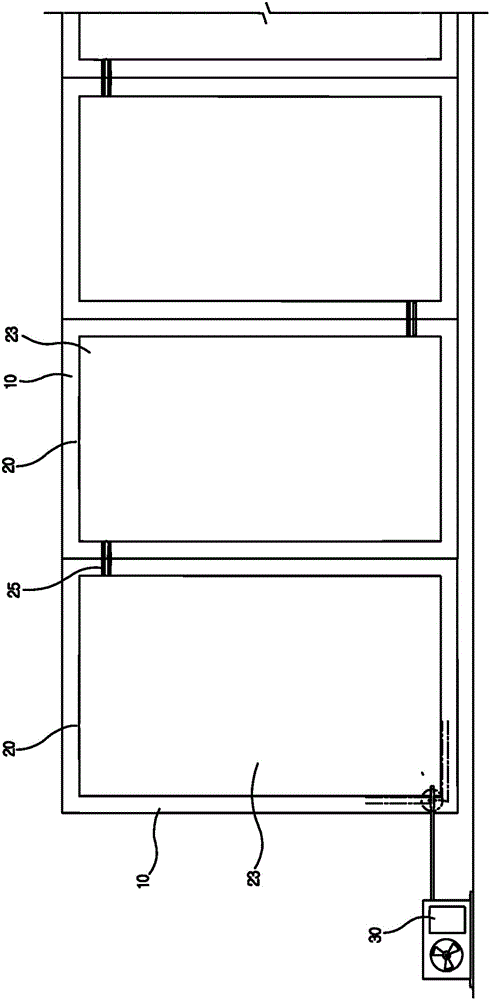

[0022] like figure 1 As shown, the temperature-insulating connecting glass in this embodiment includes a group of temperature-insulating glass 20 spliced with each other. Each piece of temperature-insulating glass is a double-layer glass structure. The glass 21 is made of ultra-clear float glass with good heat absorption, and the innermost glass 22 is made of low-emissivity glass, and the surfaces of the two glasses in contact with the inert gas are coated with a low-emissivity film.

[0023] The splicing place is provided with a steel piece 10 (ie window...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com