A roasting furnace roasting control method

A control method and roasting furnace technology, which are applied to furnace control devices, furnaces, furnace types, etc., can solve the problems of high investment cost of refractory materials, idle furnace refractory materials, and environmental pollution in workshops, so as to ensure roasting quality and temperature stability. , reduce the effect of manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the examples, but the protection scope of the present invention is not limited by the examples.

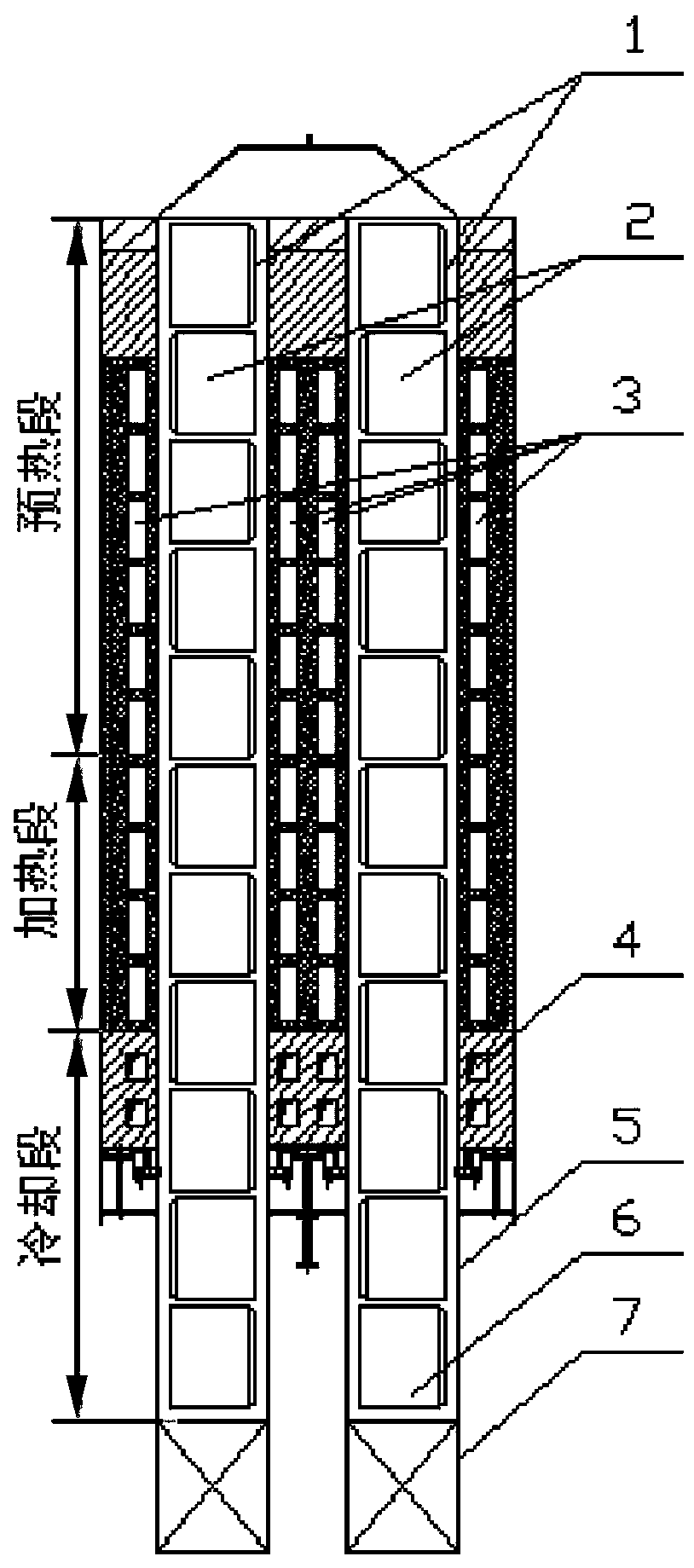

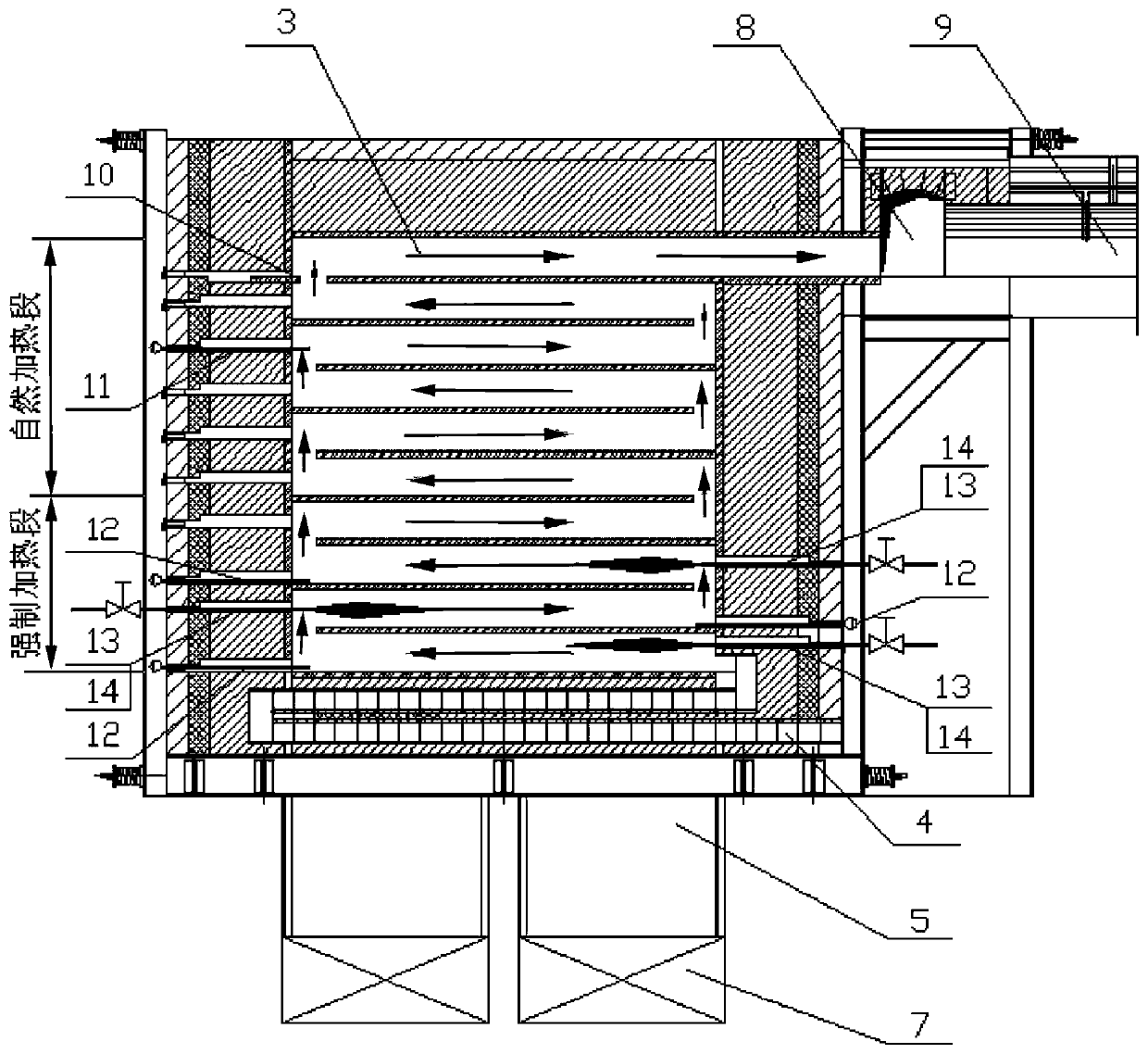

[0027] Such as figure 1 As shown, a roasting furnace roasting control method, the roasted product green body 2 and filling material are added from the top entrance of the material box 1, and run from top to bottom by its own gravity, and the high-temperature flue gas in the fire channel 3 on both sides is from bottom to bottom. Upward flow forms an indirect countercurrent heating method; the temperature inside the fire path 3 is divided into a forced heating section and a natural heating section according to the temperature level of each layer. The forced heating section mainly controls the temperature of the fire path to the target temperature range through the fuel added by the burner. The natural heating section mainly maintains the temperature level of each layer of fire path by burning ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com