Detonating fuse heat insulating protection device and detonating method

A heat insulation protection and detonating cord technology, applied in blasting, blasting barrels, weapon accessories, etc., can solve the problems of limited blasting output, high temperature resistance, and inflexibility, so as to ensure blasting safety, integrity, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

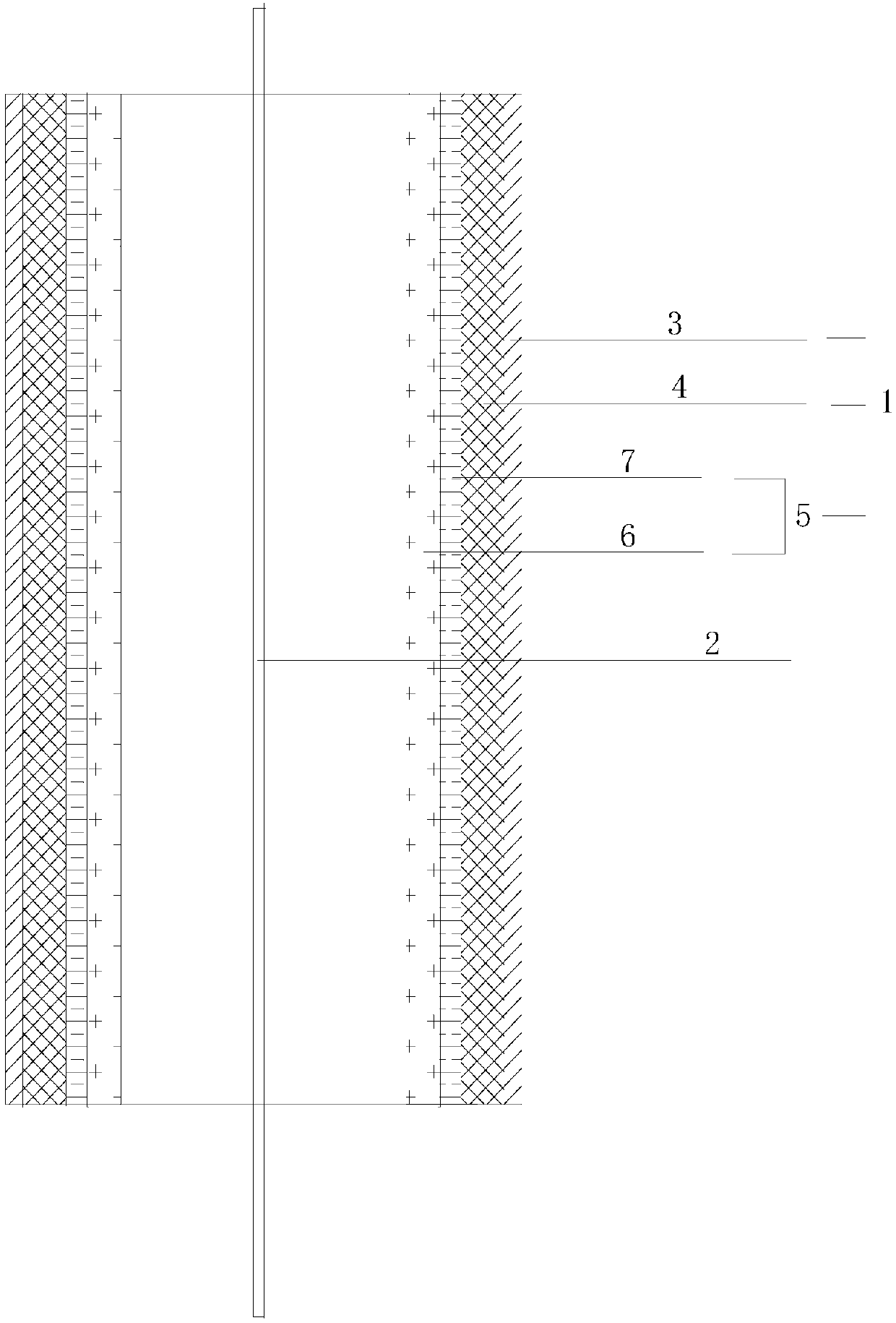

[0037] Such as figure 1 As shown, this embodiment provides a detonating cord heat insulation protection device, which includes a heat insulation protection cylinder 1 and a pre-embedded wire 2 .

[0038] Such as figure 1 As shown, the side wall of the heat insulation protection cylinder 1 includes a water-permeable layer 3, a water-absorbing layer 4, and a waterproof layer 5 arranged in sequence from outside to inside, and further, the waterproof layer 5 includes insulation layers arranged in sequence from inside to outside Water layer 6 and glue coating layer 7.

[0039] The heat insulation protection cylinder 1 is a hollow cylinder with openings at both ends, its inner diameter is 4mm-8mm larger than the diameter of the detonating cord, and its thickness is 2mm-12mm. On the one hand, the detonating cord 8 is easy to penetrate into the heat insulation protection cylinder 1 On the other hand, there is space for the water-absorbing layer 4 on the side wall of the heat-insulat...

Embodiment 2

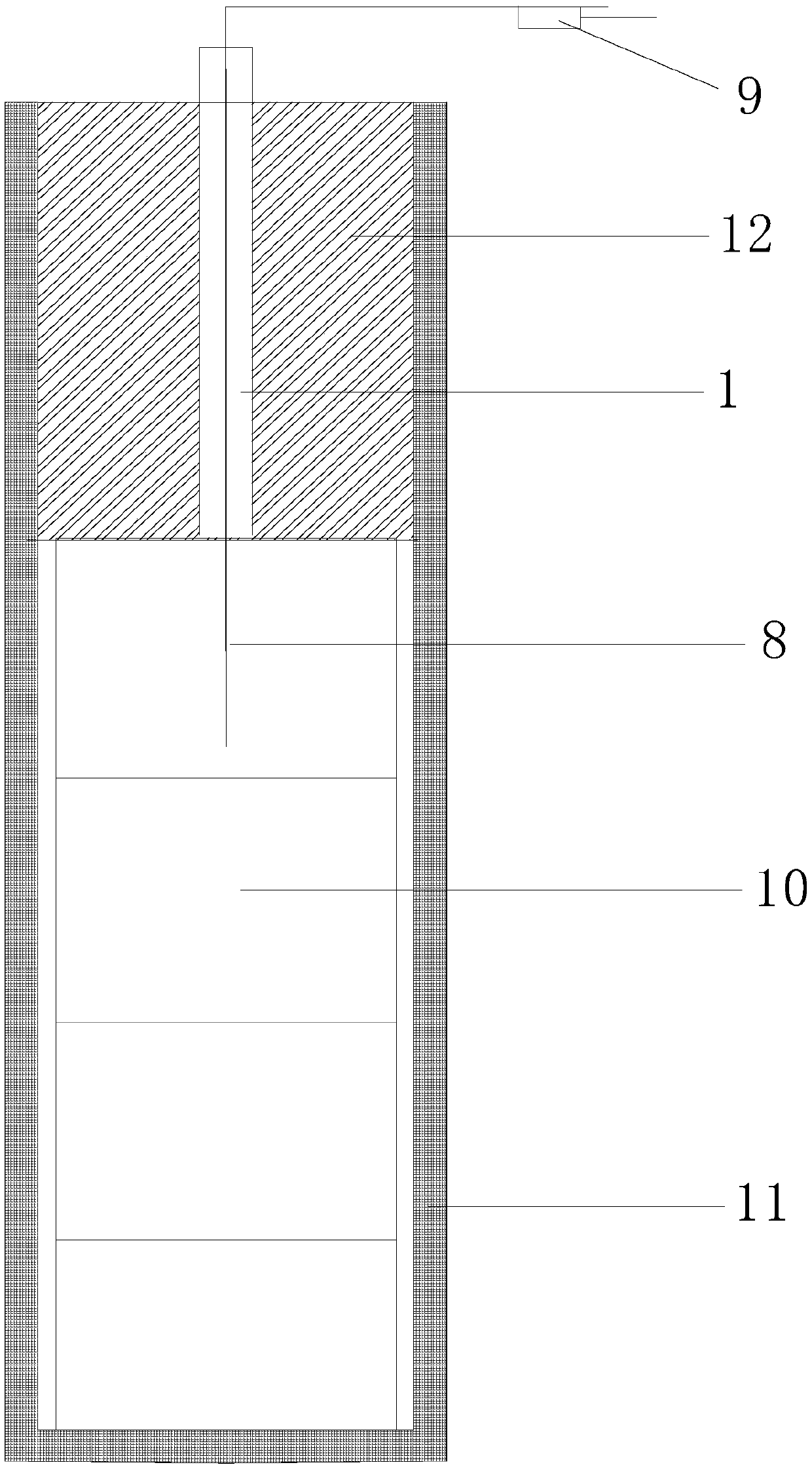

[0048] Such as figure 1 and figure 2 As shown, this embodiment provides a blasting method, which is realized based on the detonating cord heat insulation protection device of the above-mentioned embodiment 1, and includes the following steps:

[0049] Step 1: Measure the depth of the high-temperature blast hole 11, and calculate the charge amount, charge depth, and plugging length.

[0050] Step 2. Calculate the length of the detonating cord 8 and the length of the heat-insulating protection cylinder 1. The length of the detonating cord 8 should be greater than the length of the blockage by 1.5m to 2.5m, and the length of the heat-insulating protection cylinder 1 is about 80cm less than the length of the detonating cord 8. Wherein the end of binding detonator is about 30cm shorter, and the end of connecting explosive is about 50cm shorter.

[0051] Step 3: Pierce a hole at one end of the detonating cord 8, put one end of the pre-embedded wire 2 through the hole and tie a kn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com