Molybdenite concentrate self-heating swirl roasting process and equipment

A self-heating and concentrate technology, which is applied in the field of molybdenite concentrate treatment, can solve the problems of difficult control of the residence time of materials roasting, low content of molybdenum oxysulfide, and difficulty in recycling, etc., so as to achieve easy control of residence time, complete desulfurization, The effect of easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

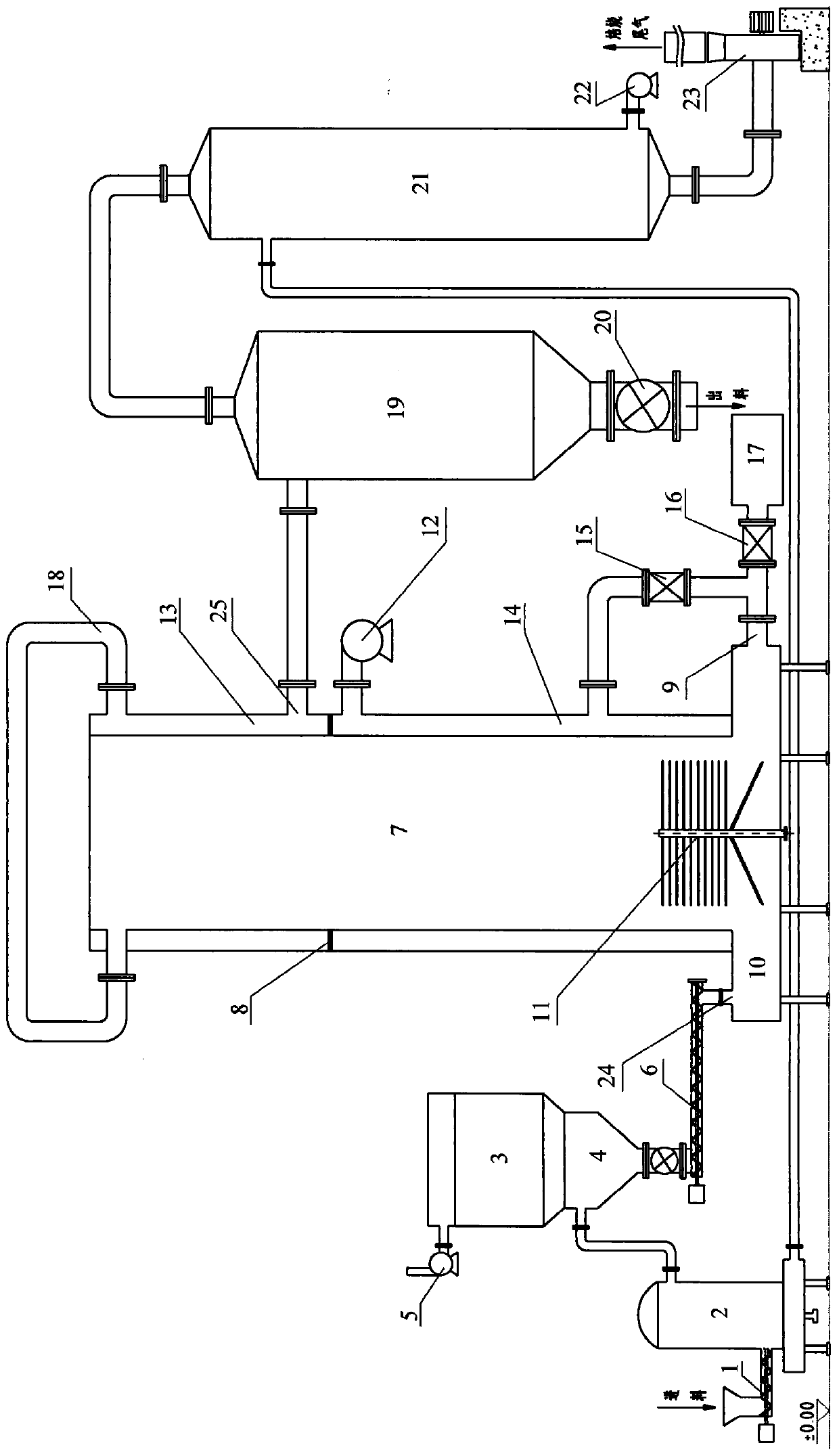

[0033] In the specific implementation process, the present invention utilizes a swirling flow roasting furnace with a furnace heat exchange device to roast molybdenite concentrate to produce industrial molybdenum oxide. The preheated air is fed into the swirling flow roasting furnace from the bottom of the furnace, and the swirling air distribution device makes the molybdenite concentrate undergo a roasting reaction in the state of swirling air flow, and the air from the swirling flow roasting furnace The materials coming out enter the interlayer heat exchange device on the upper part of the rotary roaster with the roasting airflow under the action of negative pressure, and complete the desulfurization reaction during the process of rotating and advancing in the interlayer heat exchange device, and the gas-solid mixture after the reaction enters the gas-solid separation and discharge device for further processing. Gas-solid separation to separate the roasted solid calcined sand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com