Ship tail gas high-efficiency desulfurization device and using method thereof

A technology for ship exhaust and desulfurization equipment, which is applied in the field of ship desulfurization and can solve the problems of air pollution and incomplete desulfurization of ship exhaust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

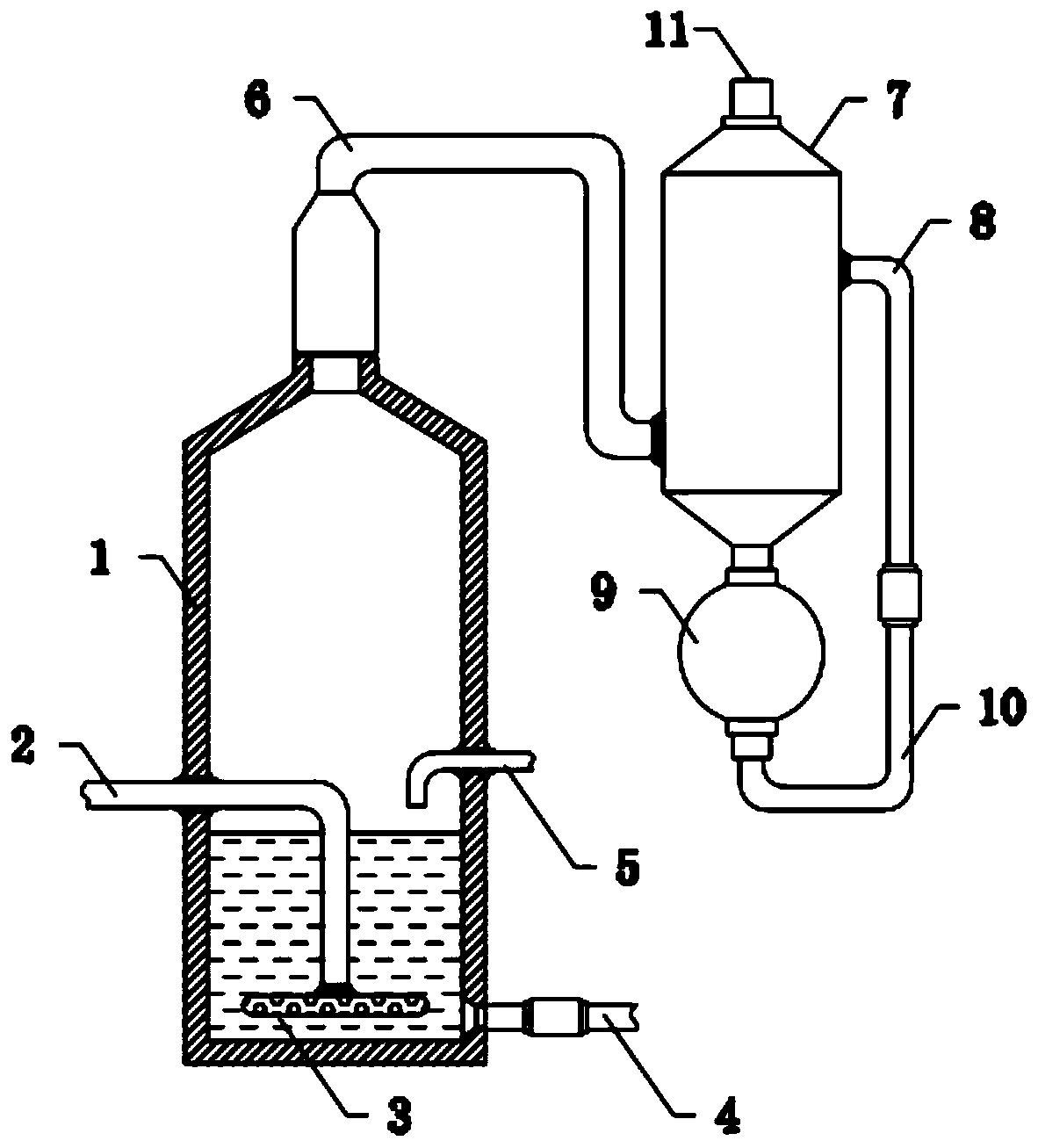

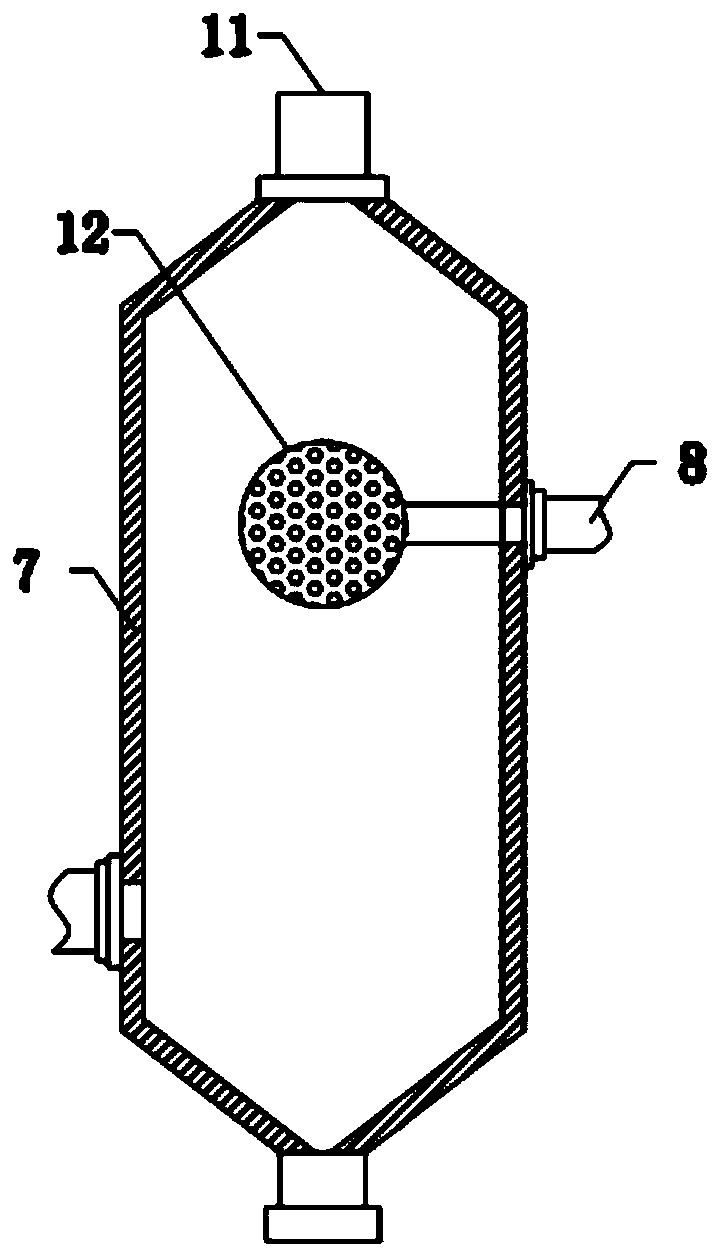

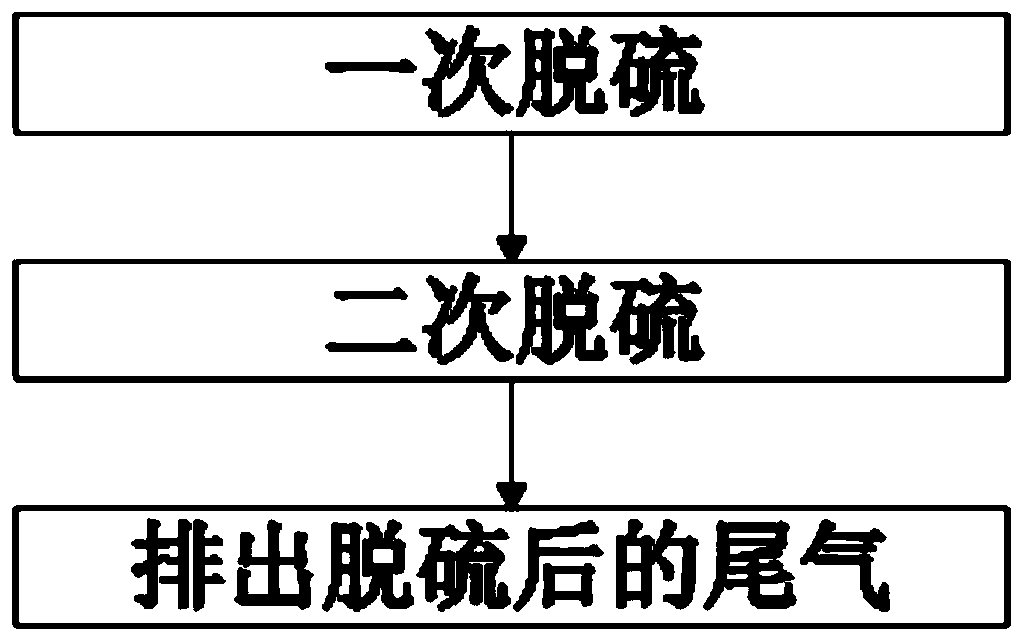

[0028] see Figure 1-3 , the present invention provides a technical solution: a high-efficiency desulfurization equipment for ship exhaust gas, including a primary desulfurization cylinder body 1, a ship exhaust gas inlet pipe 2, and an extraction pipe 4, and the ship exhaust gas inlet pipe 2 is arranged on one side of the primary desulfurization cylinder body 1 In the middle of the wall, the exhaust gas of the ship is pre-filtered to filter the impurities and dust. The high-temperature exhaust gas enters the inner cavity of the primary desulfurization cylinder 1, and the primary desulfurization cylinder 1 discharges the exhaust gas into the primary desulfurization cylinder 1 through the outlet pipe 3. In the stored desulfurization liquid, seawater is used as the desulfurization liquid. The seawater desulfurization process is a desulfurization method that uses the alkalinity of seawater to remove sulfur dioxide in flue gas. In the desulfurization absorption tower, a large amou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com