Oil-free piston type air compressor for new energy vehicle

A technology of new energy vehicles and oil pistons, which is applied in the direction of liquid variable capacity machinery, mechanical equipment, variable capacity pump components, etc., can solve the problems of high maintenance cost, low efficiency, large energy consumption, etc., and improve the service life , Reduce noise, low exhaust temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

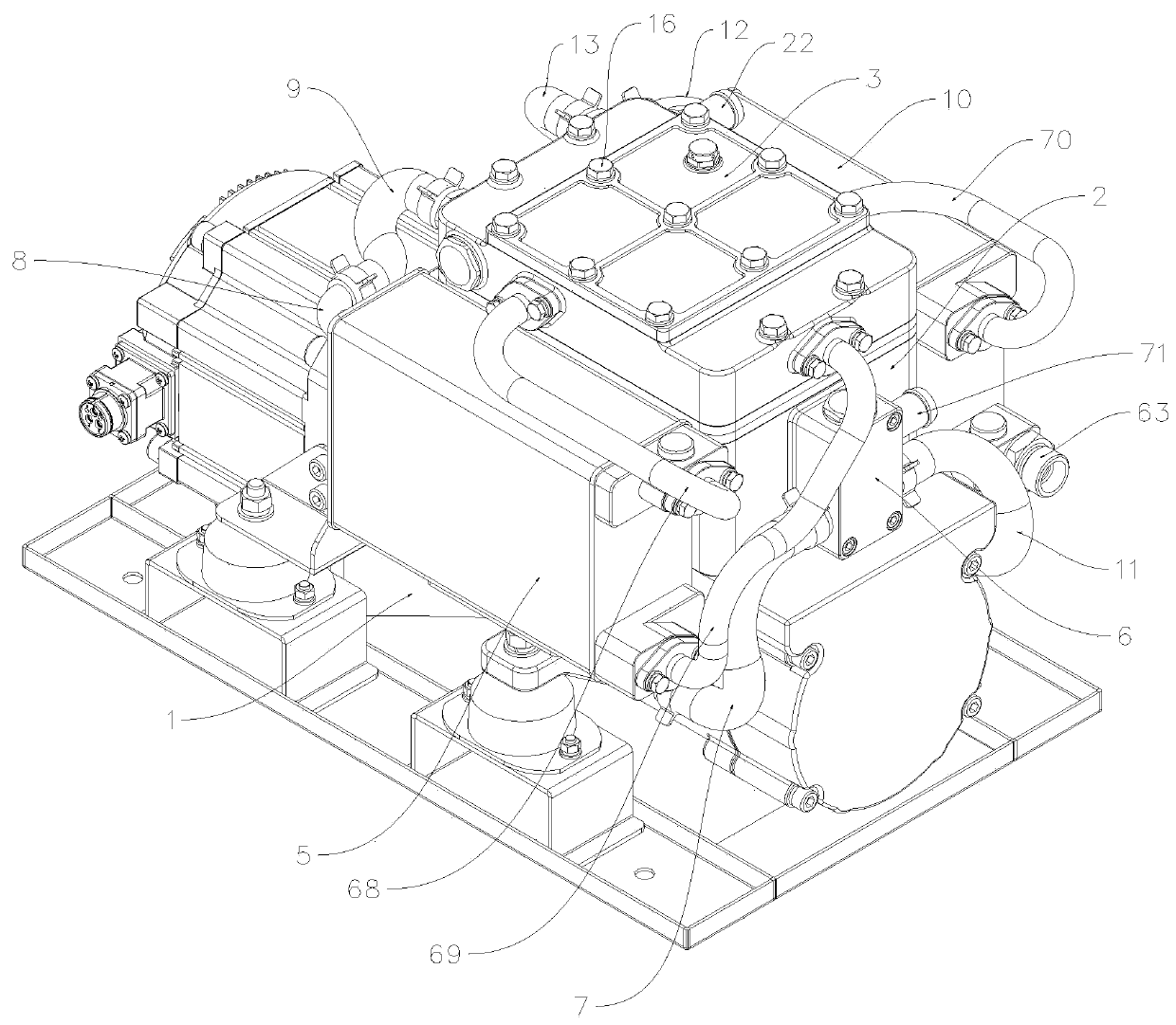

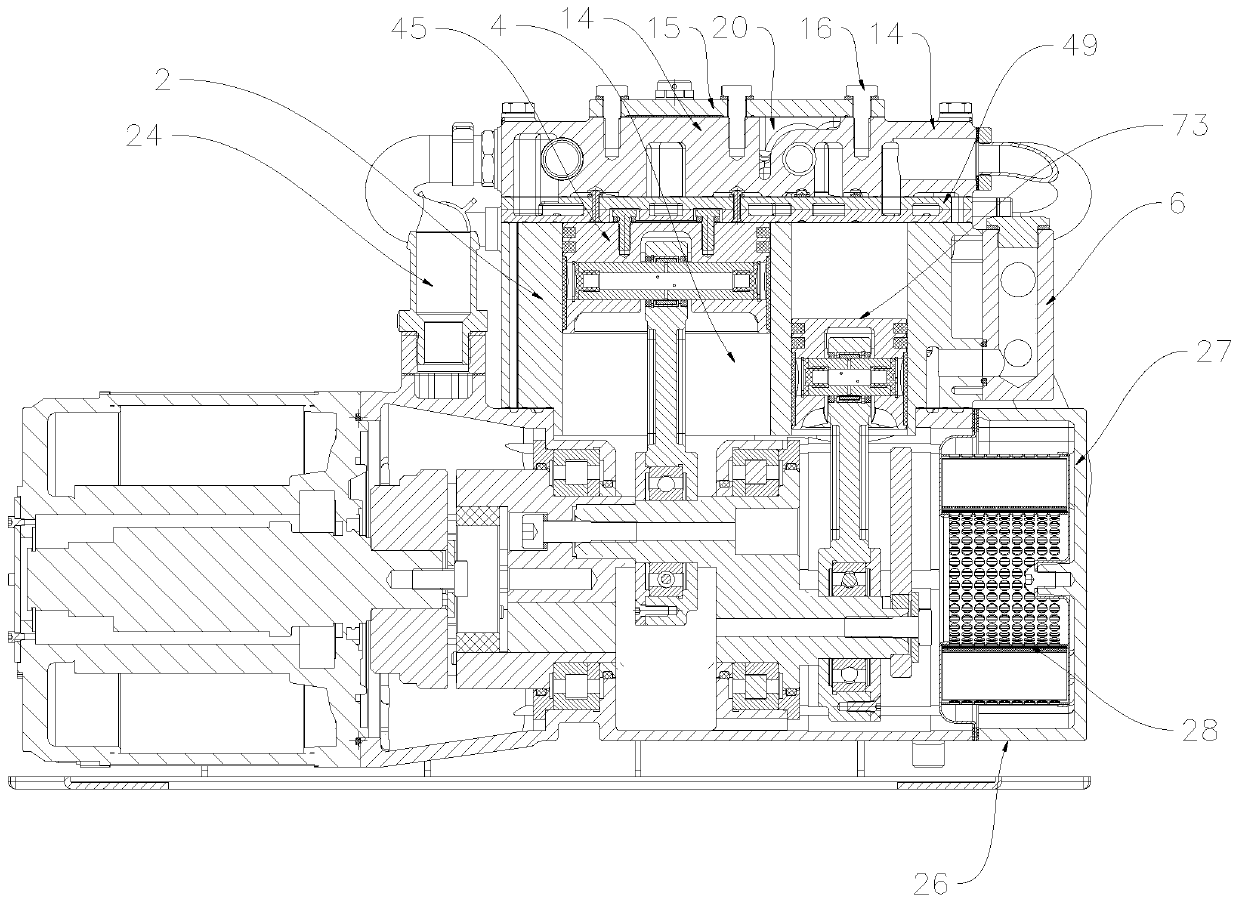

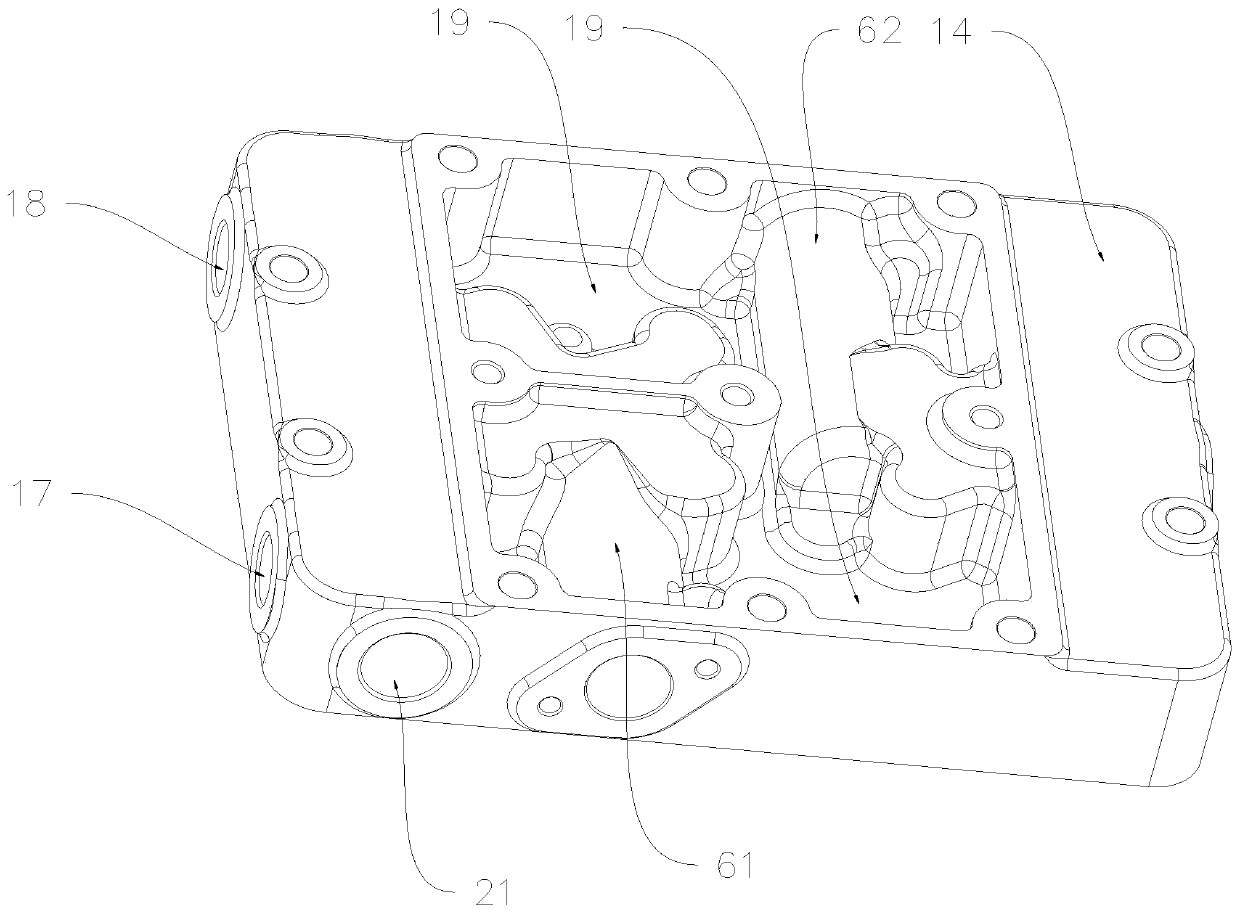

[0043] Oil-free piston air compressors for new energy vehicles, such as Figure 1 to Figure 23As shown, it includes a crankcase 1, a cylinder body 2, and a cylinder head assembly 3. The cylinder body 2 is provided with a piston cylinder 4. The cylinder body 2 is arranged above the crankcase 1 and connected with the crankcase 1. The cylinder head assembly 3 is located on Above the cylinder block 2 and connected with the cylinder block 2, the front side of the cylinder block 2 is provided with a low-pressure heat exchanger 5 connected with the crankcase 1, and the right end of the cylinder block 2 is provided with a manifold block 6 connected with the cylinder block 2, The manifold block 6 and the low-pressure heat exchanger 5 are connected through the first water inlet pipe 7, and the right end of the low-pressure heat exchanger 5 is provided with a first water outlet 8, and the first water outlet 8 is connected with the cylinder head assembly 3 through the first drain pipe 9 T...

Embodiment 2

[0050] Oil-free piston air compressors for new energy vehicles, such as Figure 1 to Figure 23 As shown, on the basis of Embodiment 1, the water channel outer wall 34 and the cylinder outer wall 32 are connected by reinforcing ribs 39, and the reinforcing ribs 39, the water channel outer wall 34, and the cylinder outer wall 32 are enclosed to form a sound-insulating cavity 40, and the sound-insulating cavity 40 is provided with There is a fixed mount 41 connected to the cylinder body 2, the lower end of the fixed mount 41 is flush with the lower end of the soundproof cavity 40, and the upper end of the fixed mount 41 is located in the soundproof cavity 40. The fixed mount 41 includes a cylinder 42 and a cylindrical body The connecting rib 43 connected to the periphery of the body 42, the cylindrical body 42 is connected with the cylinder body 2 through the connecting rib 43, and the middle part of the cylindrical body 42 is provided with an installation through hole 44. A soun...

Embodiment 3

[0052] Oil-free piston air compressors for new energy vehicles, such as Figure 1 to Figure 23 As shown, on the basis of Embodiment 2, the upper end of the crankcase 1 is provided with a bar-shaped air inlet 23 arranged from front to back, and the top of the bar-shaped air inlet 23 is provided with an air inlet joint 24 connected with the crankcase 1, Both sides of the upper end of the crankcase 1 are provided with two air intake passages 25 arranged in parallel, the air intake passages 25 are arranged horizontally from left to right, the left end of the air intake passage 25 communicates with the strip air inlet 23, and the right side of the crankcase 1 An air filter assembly 26 connected to the crankcase 1 is arranged on the side, and the air filter assembly 26 includes an air filter housing 27 and an air filter element 28 arranged in the inner cavity of the air filter housing 27. The air filter air inlet 29 communicated with the right end of the air intake passage 25, the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com