Electronic cigarette heating assembly and portable small-smoke electronic cigarette atomizer thereof

A technology of heating components and electronic cigarettes, applied in tobacco and other fields, can solve problems such as complex manufacturing process, complex molding process, and limited application solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

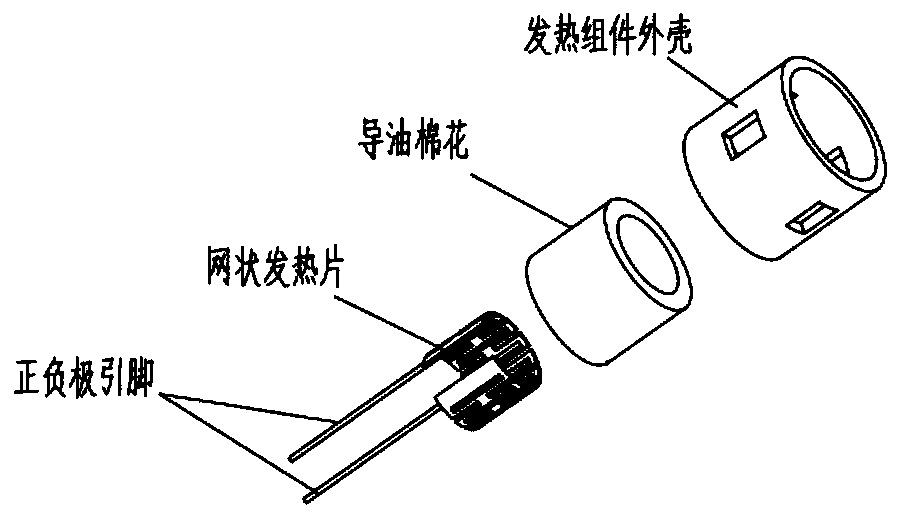

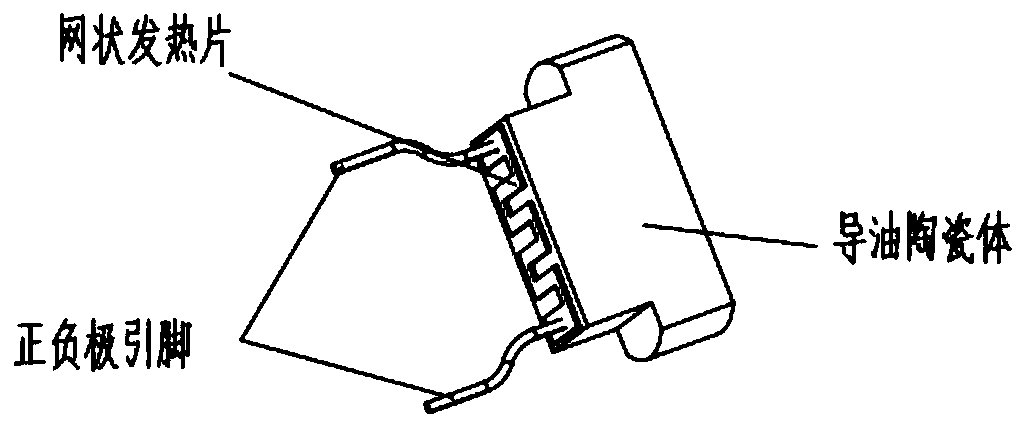

[0039] Example 1, such as Figure 3-5 As shown, an electronic cigarette heating assembly includes a bracket 100 and a seal 200 on the bracket 100. The bracket 100 includes an upper bracket 110 and a lower bracket 120 that are detachably connected or fixedly connected together. The upper bracket 110 The oil guide cotton sheet 300, the oil guide cotton cloth 400 and the mesh heating sheet 500 are sequentially sandwiched between the lower bracket 120; The bracket 120 is provided with a smoke outlet 127; the mesh heating sheet 500 is connected to the conductive electrode 600 to supply power to the mesh heating sheet 500;

[0040] Bracket 100 is the basic support structure of heating components. Since oil-conducting cotton sheet 300, oil-conducting cotton cloth 400 and mesh heating sheet 500 need to be fixed in bracket 100, bracket 100 is divided into upper bracket 110 and lower bracket 120. Upper bracket 110 The connection with the lower bracket 120 can be a fixed connection or a...

Embodiment 2

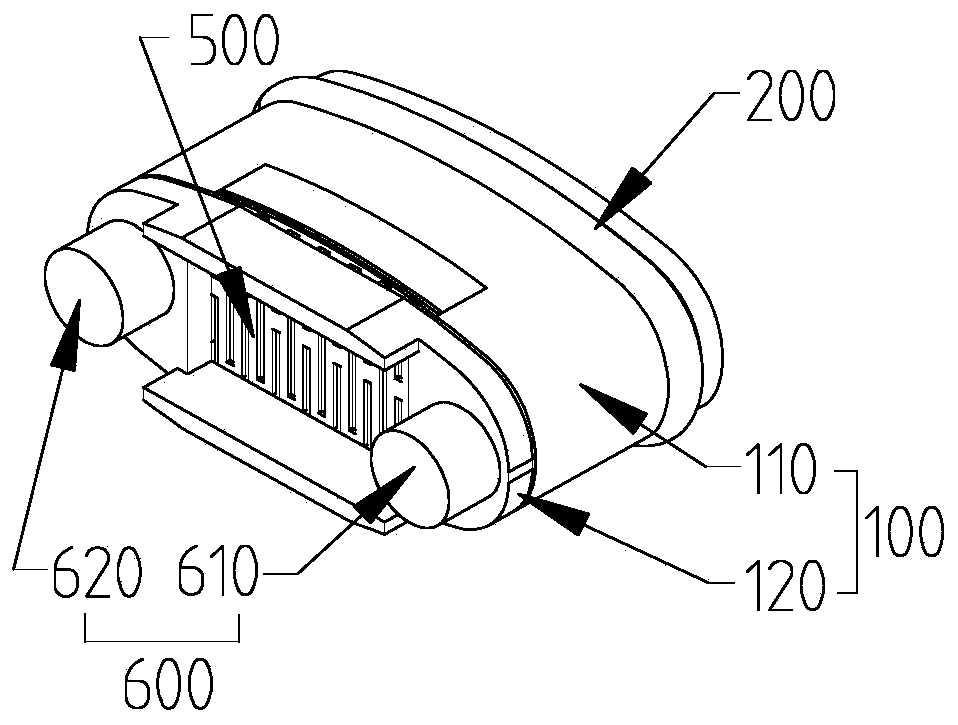

[0051] Example 2, such as Figure 6-8 As shown, this embodiment is an improvement on the basis of Embodiment 1.

[0052] Wherein, compared with Embodiment 1, the sealing member 200 of this embodiment is a sealing cylinder whose height matches the height of the upper bracket 110 , and the sealing cylinder fits outside the upper bracket 110 . In order to prevent the sealing cylinder from slipping, ribs 210 extending inward are provided on the top and bottom surfaces of the sealing cylinder, and a circle of grooves 114 is provided at the lower part of the upper bracket 110, and the ribs 210 are respectively buckled on the top surface of the upper bracket 110 and the groove 114 Inside, the sealing cylinder is fixed outside the upper bracket 110.

[0053] Another structure different from that of Embodiment 1 is: the conductive positive electrode 610 and the conductive negative electrode 620 are independently provided, and a through hole is provided on the lower bracket 120, and on...

Embodiment 3

[0056] Example 3, such as Figure 9-10 As shown, a portable small vape electronic vaporizer includes a casing 1, and an oil cup 3 is arranged inside the casing 1, and the oil cup 3 is fixed in the casing 1 through a base 6, and the bottom of the oil cup 3 is provided with an embodiment 1, a smoke channel 2 is provided between the oil cup 3 and the casing 1. The base 6 is provided with a conductive terminal 5, the conductive terminal 5 is in electrical contact with the conductive electrode 600 to conduct electricity, and the conductive terminal 5 is electrically connected to the battery of the electronic cigarette. Two conductive terminals 5 are also provided, which are respectively in piezoelectric contact with the conductive positive electrode 610 and the conductive negative electrode 620 .

[0057] According to smoke channel 2 quantity, present embodiment is as follows Figure 9 The channels on both sides of the oil cup 3 and as Figure 10 Side channel shown.

[0058] Su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com