Double Flame Retardant Gasifier

A technology of gasification furnace and flame retardant, which is applied in the manufacture of combustible gas and petroleum industry. It can solve the problems of difficult matching of fan size, uneven fuel combustion, and difficult uniform air volume. It has a promising market prospect, is conducive to environmental sanitation, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

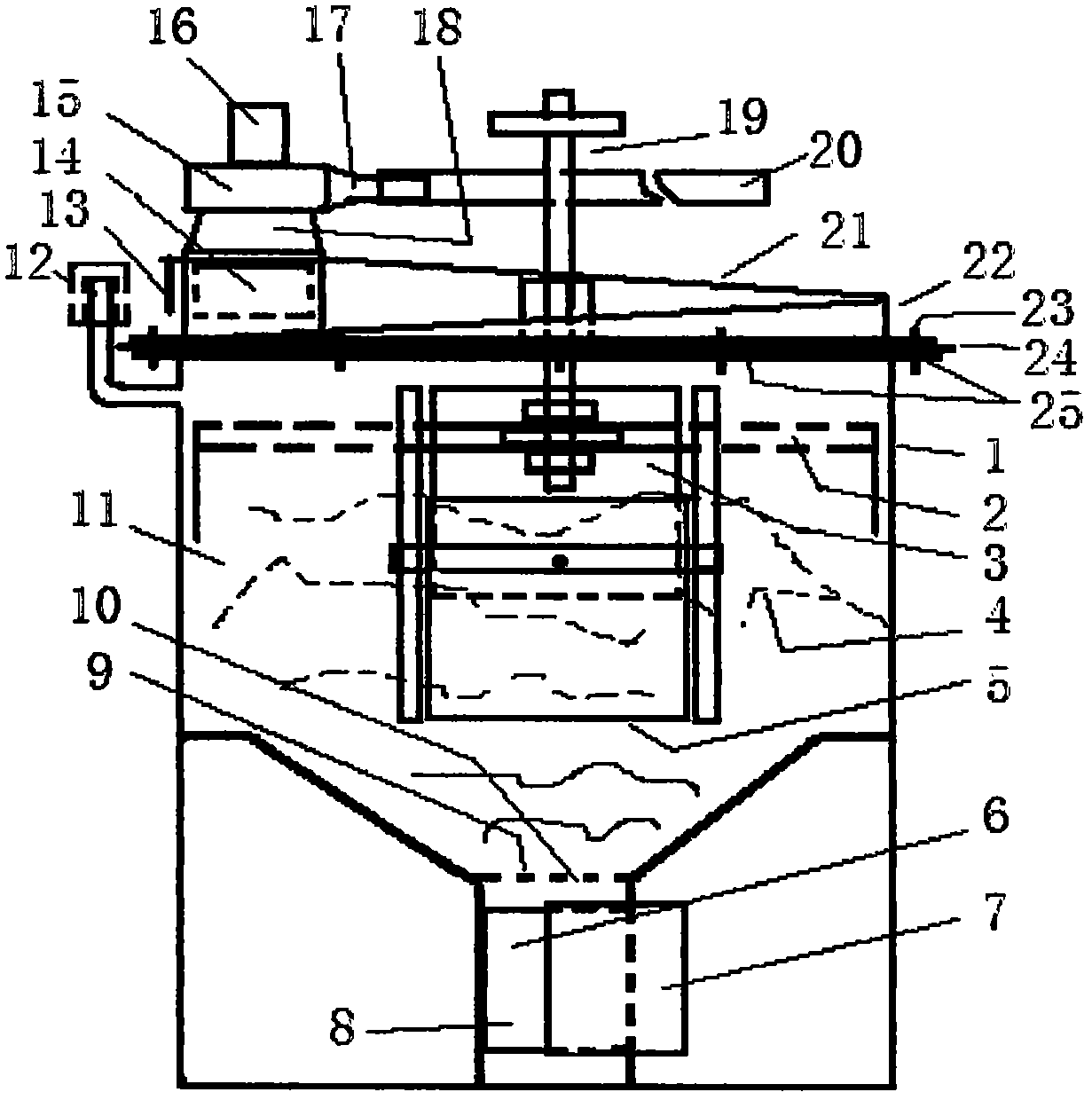

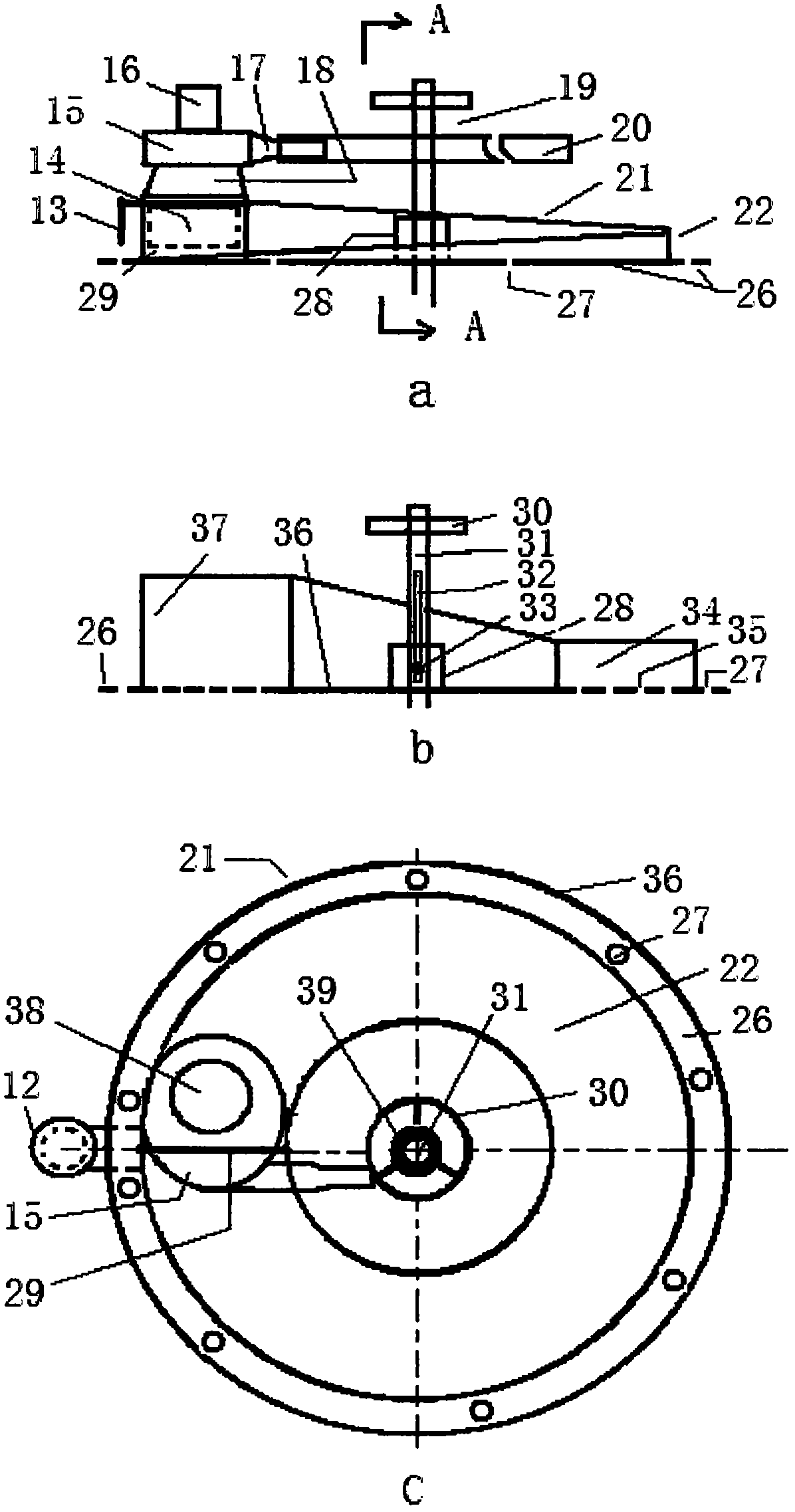

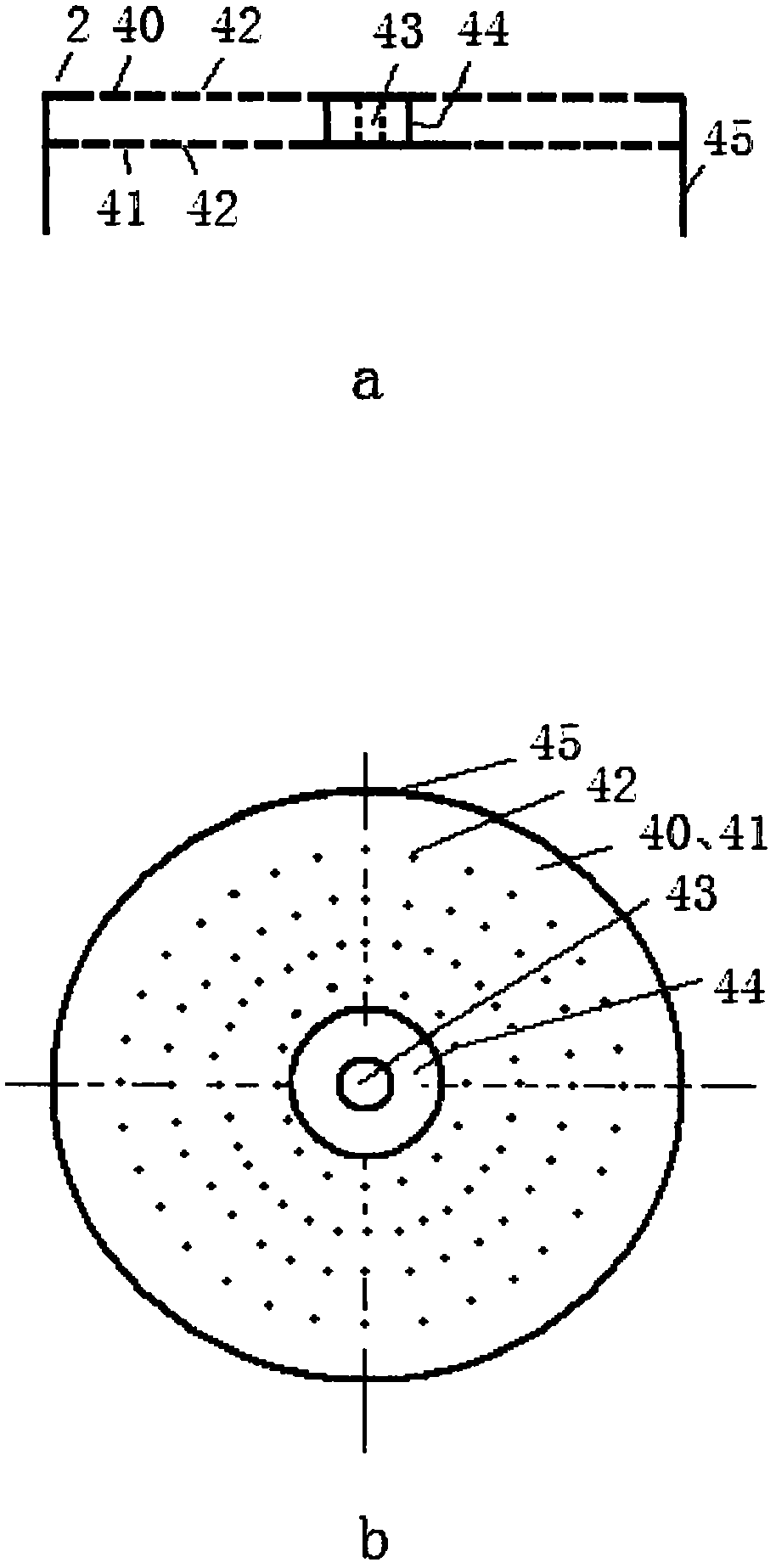

[0025] In the following, the present invention will be further described with reference to the contents of the present invention in conjunction with the drawings, descriptions of the drawings, and implementation.

[0026] A double flame retardant gasification furnace, its shape is a cylinder, mainly composed of a furnace body 1, a furnace cover 21, a double flame retardant 2, a lifter 19, a suction fan 15, a spiral pipe 22, a gasification chamber 11, and a feed port 3 , an air inlet 7, and a safety valve 12, characterized in that: a spiral pipe 22 is arranged above the furnace cover 21, the air outlet above the pipe is connected to a suction fan 15, and above the gasification chamber 11 in the furnace body 1, double flame retardants 2 are arranged , and the center of the furnace cover is provided with a lifter 19 connected to the double flame retardant 2; the double flame retardant 2 realizes that when the gasification chamber 11 is filled with fuel 4, the double flame retardan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com