Effective carbon dioxide conversion catalyst and preparing method thereof

A carbon dioxide and catalyst technology, applied in the field of synthesis gas generation, can solve problems such as catalyst stability and nickel catalyst deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

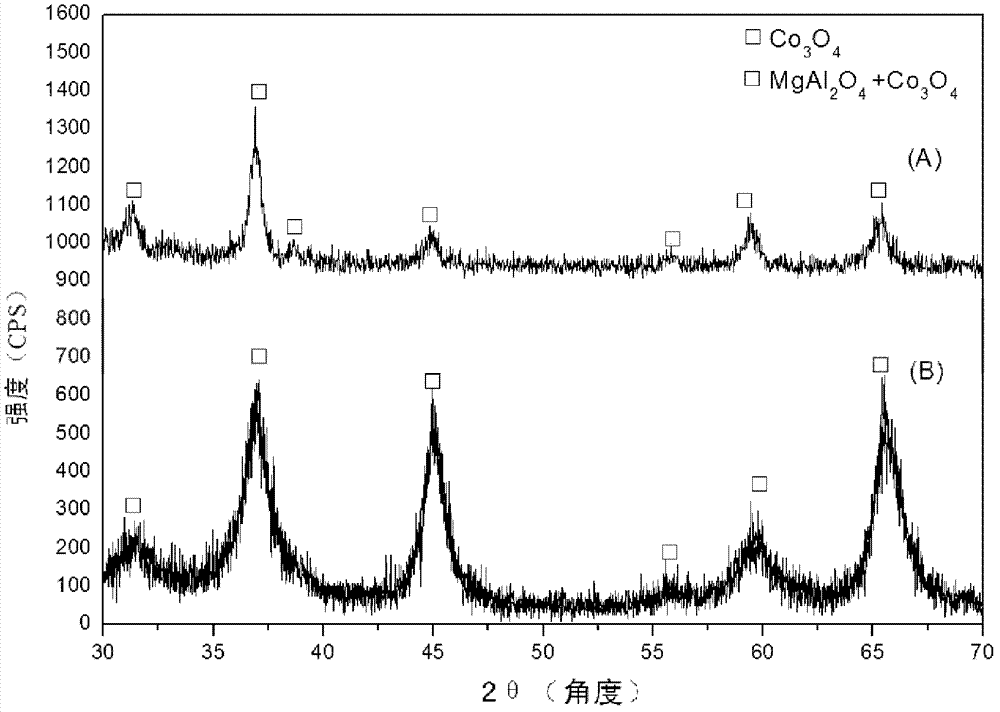

Image

Examples

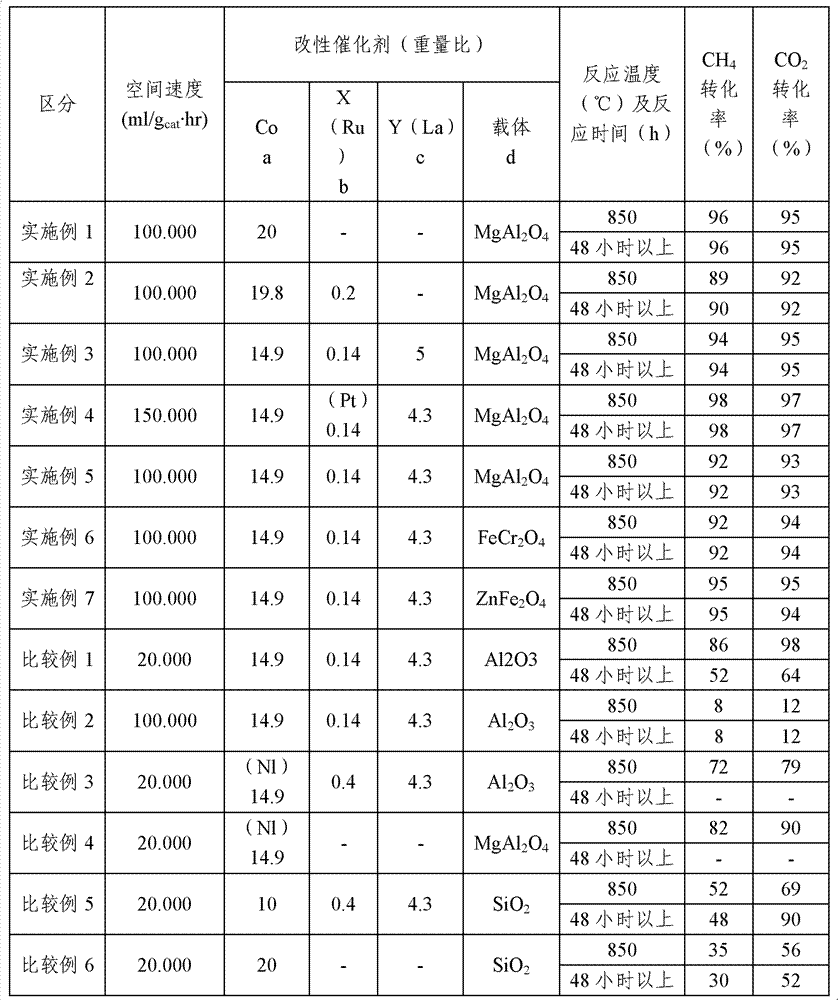

Embodiment 1

[0093] The precursor Mg(NO 3 ) 2 with Al(NO 3 ) 3 dissolved in distilled water to make the spinel structure MgO / Al 2 o 3 The ratio reaches 0.1, and then add the precipitant Na while stirring 2 CO 3 , titration precipitation was performed to bring the pH to 8.0. The precipitated material was filtered with distilled water to remove Na dissolved in the precipitated material. The filtered precipitate was fired at 500° C. to prepare a spinel-type support.

[0094] Relative to the amount of monolithic catalyst, prepare the support Mg / Al 2 o 4 to 80wt%, and mixed with 200ml distilled water, the Co(NO 3 ) 3 9H 2 O was dissolved and mixed in distilled water so that the proportion of Co became 20wt%. The mixed slurry is distilled by a vacuum distillation device to prepare a powder state. The prepared powder was dried at 80° C. for 3 hours, and then fired at 400° C. in an air atmosphere for 6 hours. The prepared catalyst is in a fixed bed reactor at 850°C and 0.1MPa, at 10...

Embodiment 2

[0096] The precursor Mg(NO 3 ) 2 with Al(NO 3 ) 3 dissolved in distilled water to make the spinel structure MgO / Al 2 o 3 The ratio reaches 0.1, and then add the precipitant Na while stirring 2 CO 3 , titration precipitation was performed to bring the pH to 8.0. The precipitated material was filtered with distilled water to remove Na dissolved in the precipitated material. The filtered precipitate was fired at 500° C. to prepare a spinel-type support.

[0097] Relative to the amount of monolithic catalyst, prepare support MgO / Al 2 o 3 to 80wt%, and mixed with 200ml distilled water, the Co(NO 3 ) 3 9H 2 O, Ru(NO) (NO 3 ) 3 They were respectively dissolved and mixed in distilled water to achieve a ratio of 19.8wt% Co-0.2wt% Ru. The mixed slurry is distilled by a vacuum distillation device to prepare a powder state. The prepared powder was dried at 80° C. for 3 hours, and then sintered at 400° C. in an air atmosphere for 6 hours. The prepared catalyst is in a fixe...

Embodiment 3

[0099] The precursor Mg(NO 3 ) 2 with Al(NO 3 ) 3 dissolved in distilled water to make the spinel structure MgO / Al 2 o 3 The ratio reaches 0.1, and then add the precipitant Na while stirring 2 CO 3 , titration precipitation was performed to bring the pH to 8.0. The precipitated material was filtered with distilled water to remove Na dissolved in the precipitated material. The filtered precipitate was fired at 500° C. to prepare a spinel-type support.

[0100] Relative to the amount of monolithic catalyst, prepare the support Mg / Al 2 o 4 to 80wt%, and mixed with 200ml distilled water, the Co(NO 3 ) 3 9H 2 O, ZrOCl 2 、Ru(NO)·(NO 3 ) 3 Dissolved and mixed in distilled water respectively to achieve a ratio of 14.86wt%Co-0.14wt%Ru-5wt%Zr. The mixed slurry is distilled by a vacuum distillation device to prepare a powder state. The prepared powder was dried at 80° C. for 3 hours, and then sintered at 400° C. in an air atmosphere for 6 hours. The prepared catalyst is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com