A foaming device for foamed asphalt

A foaming equipment and technology of foamed asphalt, which is applied in the processing of tar asphalt/petroleum asphalt/natural asphalt, petroleum industry, etc., can solve problems such as low thermal conductivity, affect the foaming index of asphalt, and reduce the amount of foam, and achieve the degree of dispersion The effect of homogenization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

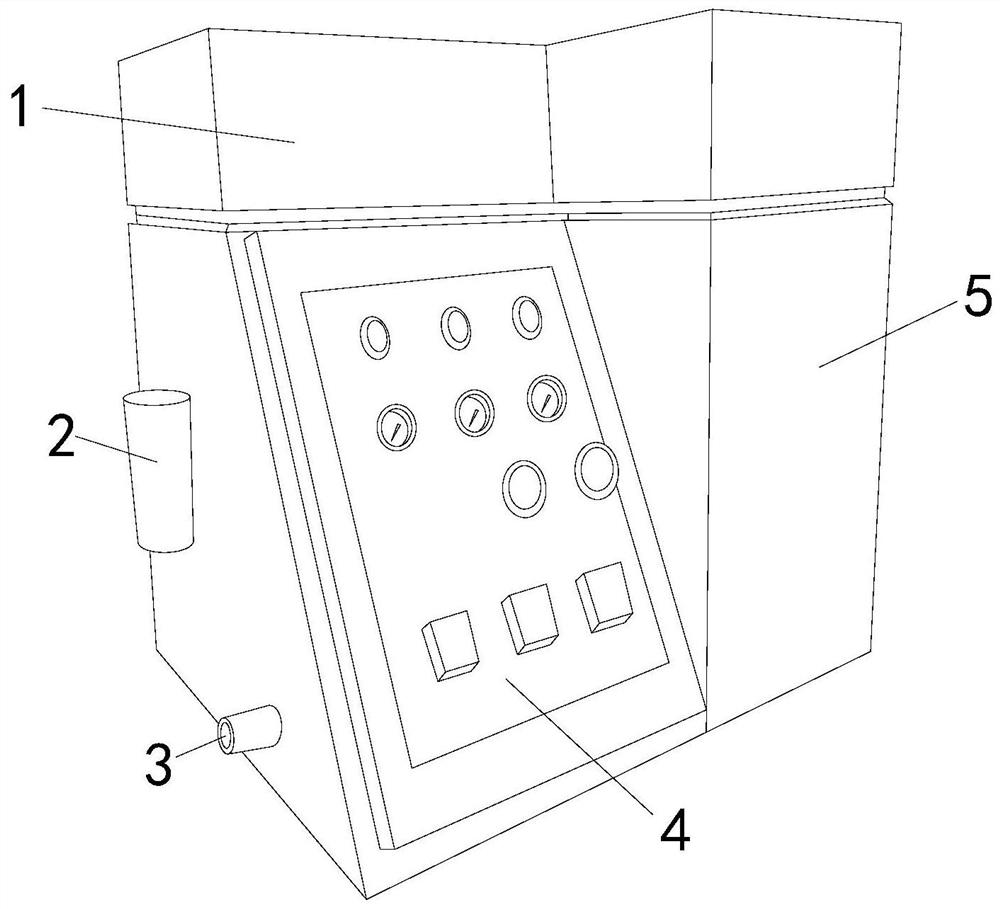

[0023] see figure 1 , the present invention provides a foaming equipment for foamed asphalt, the structure of which includes: a control box 1, an electric control box 2, an external connection pipe 3, an operation panel 4, and a foaming box 5, and the sides of the control box 1 are respectively equipped with electric The control box 2 and the external connection pipe 3 are connected to the operation panel 4 at the front position. The foam box 5 is located on the side of the control box 1 and the two are connected to each other. The control box 1 is the main structure of the equipment, mainly as the outer shell of the equipment to the inside Circuit components and mechanical components are protected, and the shell formed by trapezoidal geometry combined with a cuboid can divide the control area and the asphalt foaming area. The panel realizes the viewing of the command parameters and operation instructions of the equipment, and controls the operation of the equipment. The elec...

Embodiment 2

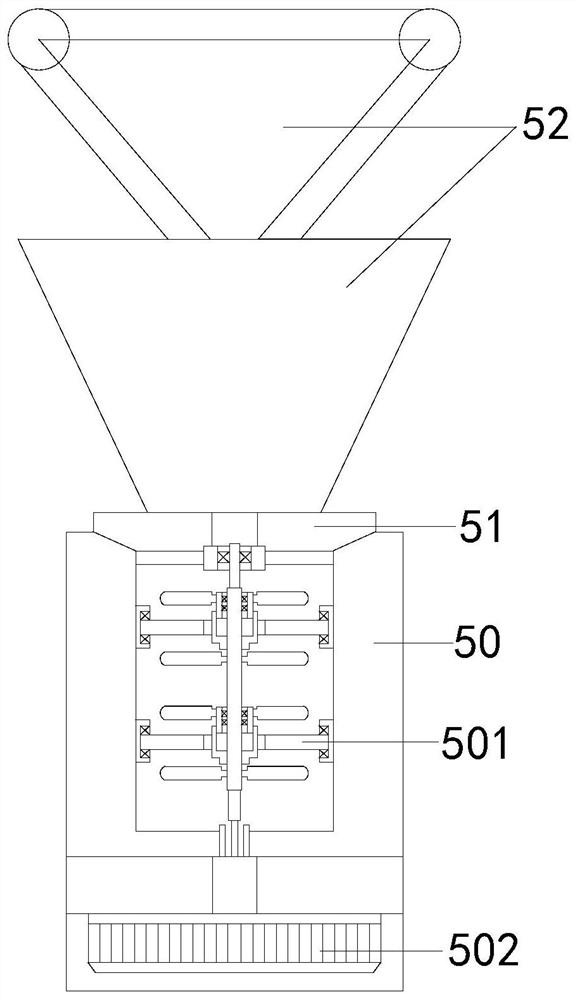

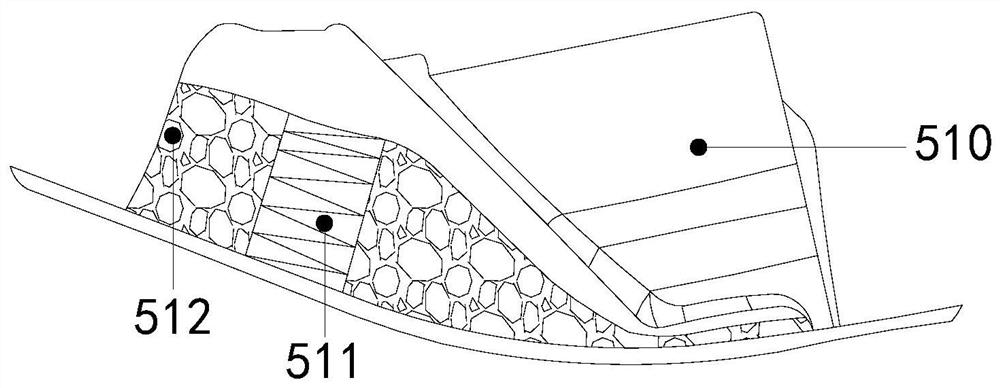

[0029] The description of the second embodiment drawn in conjunction with the first embodiment, combined with image 3 , Figure 4 and Figure 5 The upper and lower ends of the base point suspension 510 are connected to the anti-spring tube 511, and the side of the anti-spring tube 511 is provided with an air bag 512 connected thereto. Connected with it, the air intake triangular bucket 520 is located at the top of the structure of the bubble increasing bucket 52, and its bottom end runs through the uniform distribution box 540 connected to the swing frame 51 and the drive frame 50 at the same time. The ring plate 5300 is provided with a shaft 5301 and its There are honeycomb grooves 5302 and slide rails 5303 distributed on the side, the moving wheel 5304 fits and connects to the slide rail 5303 and its side is connected to the honeycomb wheel 5305, when in use, the asphalt raw material is put into the air intake triangular bucket 520, and one end of the gas injection pipe 52...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com