Alkanolamine product distribution improvement method

A technology of alkanolamines and products, which is applied in the field of chemical synthesis and alkanolamine synthesis effects, which can solve the problems of unsatisfactory distribution and inconsistent content, and achieve the effect of improving the uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

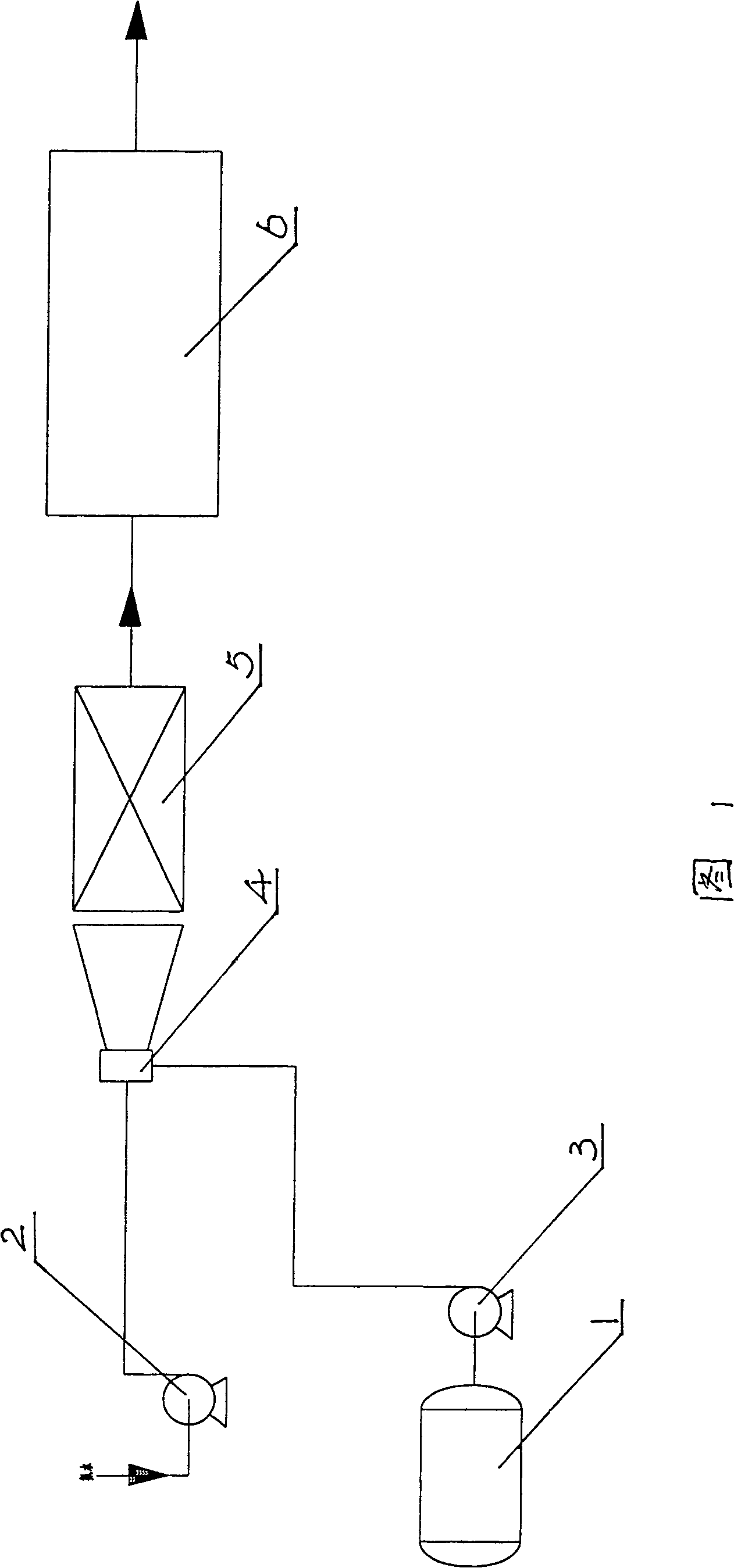

[0017] As shown in Figure 1, a method for improving the synthetic effect of ethanolamine of the present invention, taking ethanolamine as an example, its steps are as follows:

[0018] (1) The raw material liquid ammonia enters the mixer after being fully mixed with deionized water in a certain proportion, while ethylene oxide comes out of the raw material tank area and enters the intermediate tank first, and then is pumped to each section of the reactor to supplement the reaction process The required ethylene oxide in.

[0019] (2) Before ethylene oxide and ammonia water enter the reactor, the two streams of materials are delivered to a high-efficiency mixer to make them fully contact. The high-efficiency mixer used is a combination of Venturi and static mixers. The combination method is better, and the equipment is convenient for processing and industrialization.

[0020] (3) The fully mixed ethylene oxide and ammonia water enter the reactor immediately. The reactor is div...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com