Fuel reforming process for internal combustion engines

a technology for internal combustion engines and fuel reforming, which is applied in the direction of combustible gas chemical modification, combustion air/fuel air treatment, combustion-air/fuel-air treatment, etc. it can solve the problems of not reducing greenhouse pollutants, water application, and device drawbacks, so as to increase the efficiency of the world's remaining fossil fuels. , the effect of increasing the combustive power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

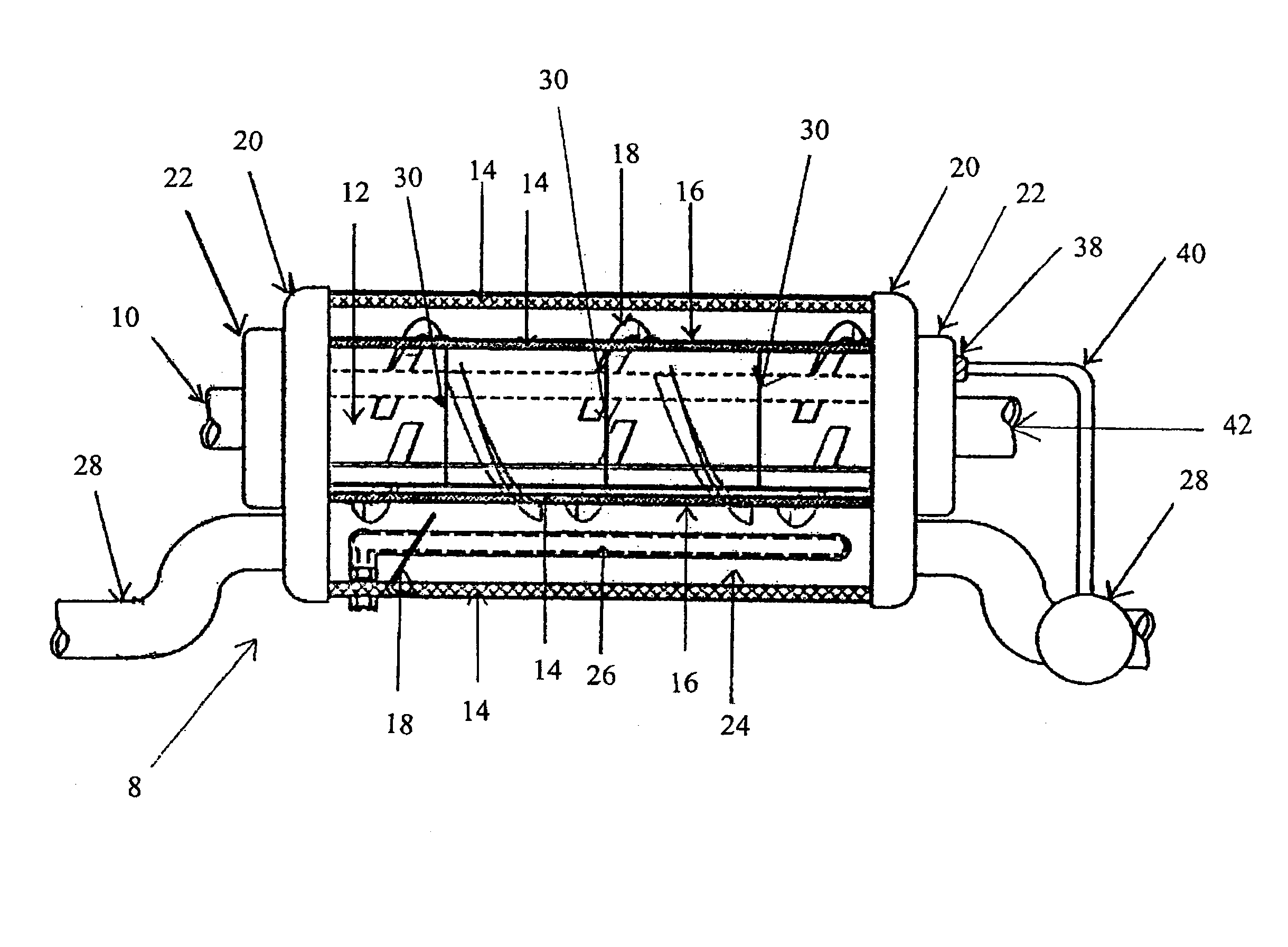

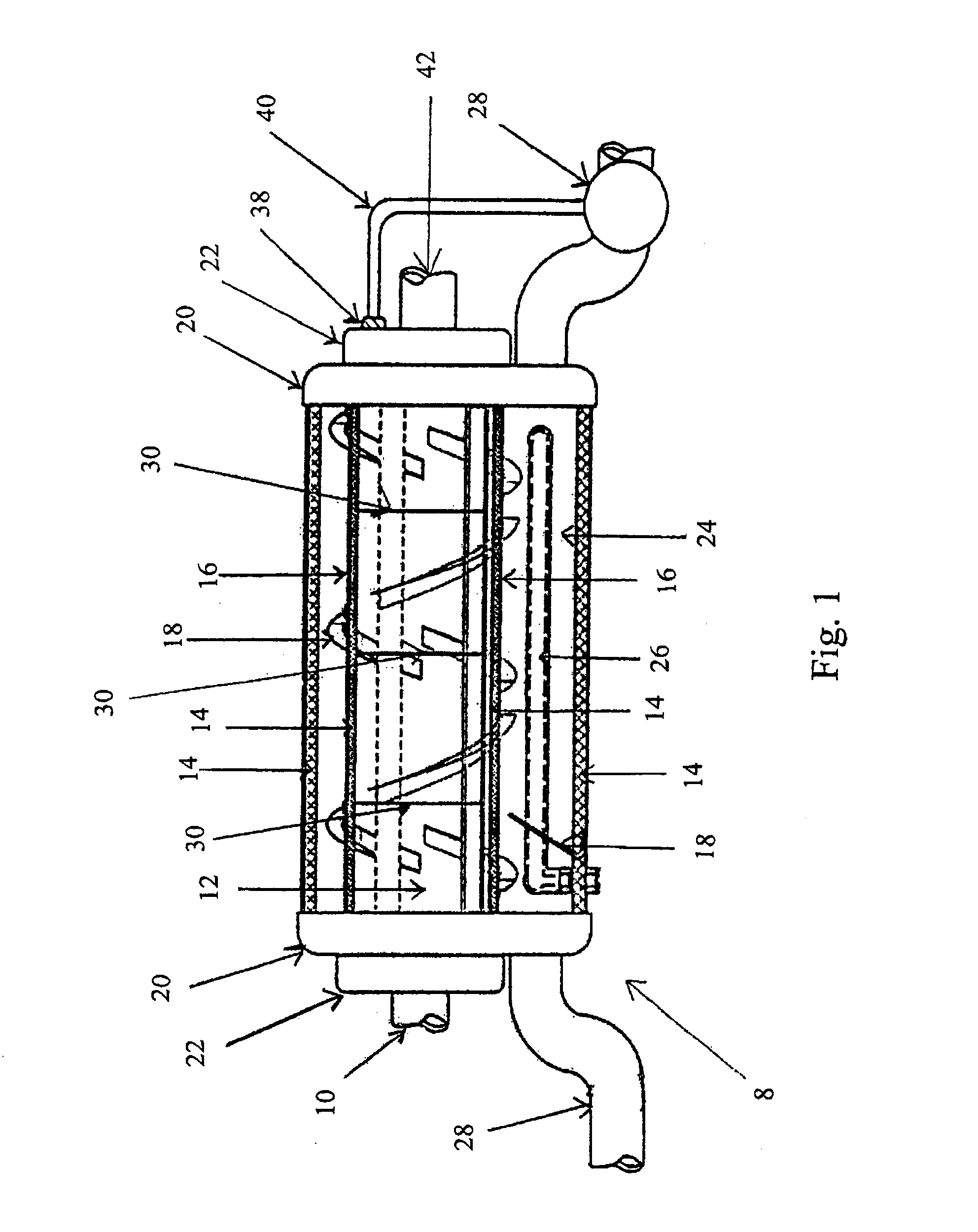

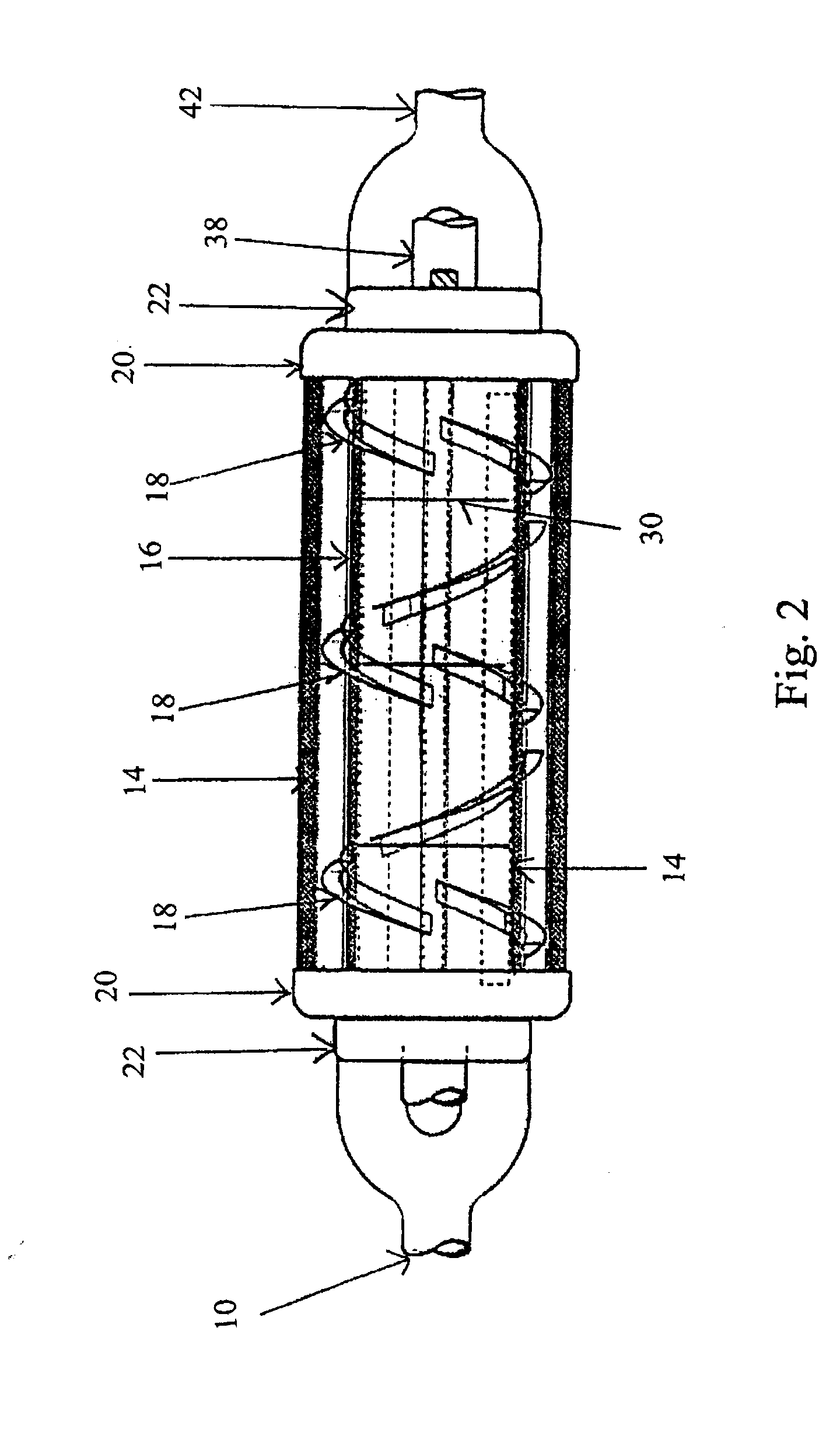

[0025]The present invention is directed towards a fuel reforming device for internal combustion engines, which are discussed in terms of internal combustion engines, and more particularly, to a fuel reforming process that increases fuel efficiency and reduces green house gas pollutants. The following discussion includes a description of the fuel reforming process, system, and device for internal combustion engines. Reference will now be made in detail to exemplary embodiments of the disclosure, which are illustrated in the accompanying figures.

[0026]Referring to FIG. 1, a fuel reforming device 8 is designed to convert a liquid fuel that is passed from a fuel filter into a gaseous fuel prior to entering an engine's fuel injectors. The present disclosure is significantly smaller in size and is contained in comparison to prior art. The fuel reforming device 8 is installed onto injectors (not shown in the figures) to perform this process.

[0027]Referring to FIGS. 1-2, the liquid fuel exi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| catalytic temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com