Low stove pressure convection continuous roller bottom type annealing furnace and annealing technique

An annealing process and annealing furnace technology, which is applied in the field of low furnace pressure convection continuous roller hearth type bright annealing furnaces, can solve the problems such as the inability to meet the annealing requirements of ultra-long condenser tubes, the inability to completely eliminate the internal stress of the workpiece, and the short automation degree of the process. Achieve the effect of ensuring heat treatment quality, uniform and efficient heat transfer, and reducing airflow interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

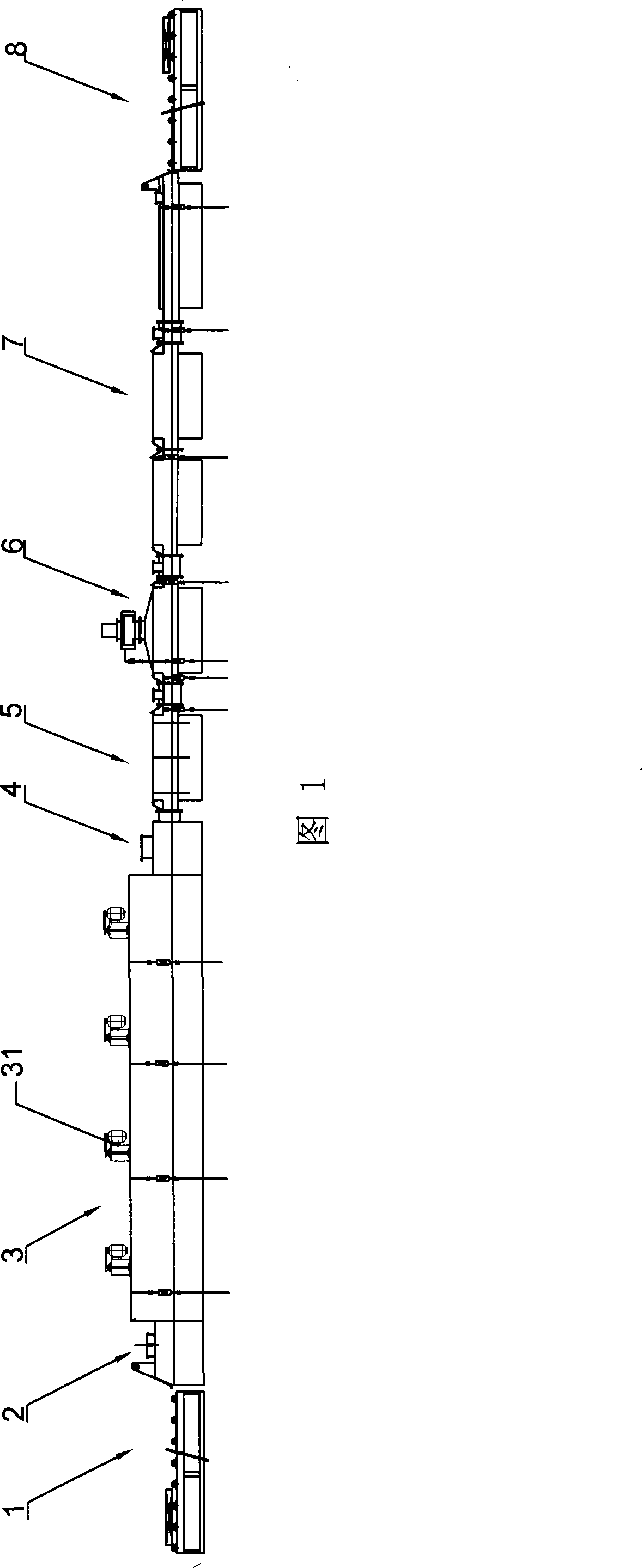

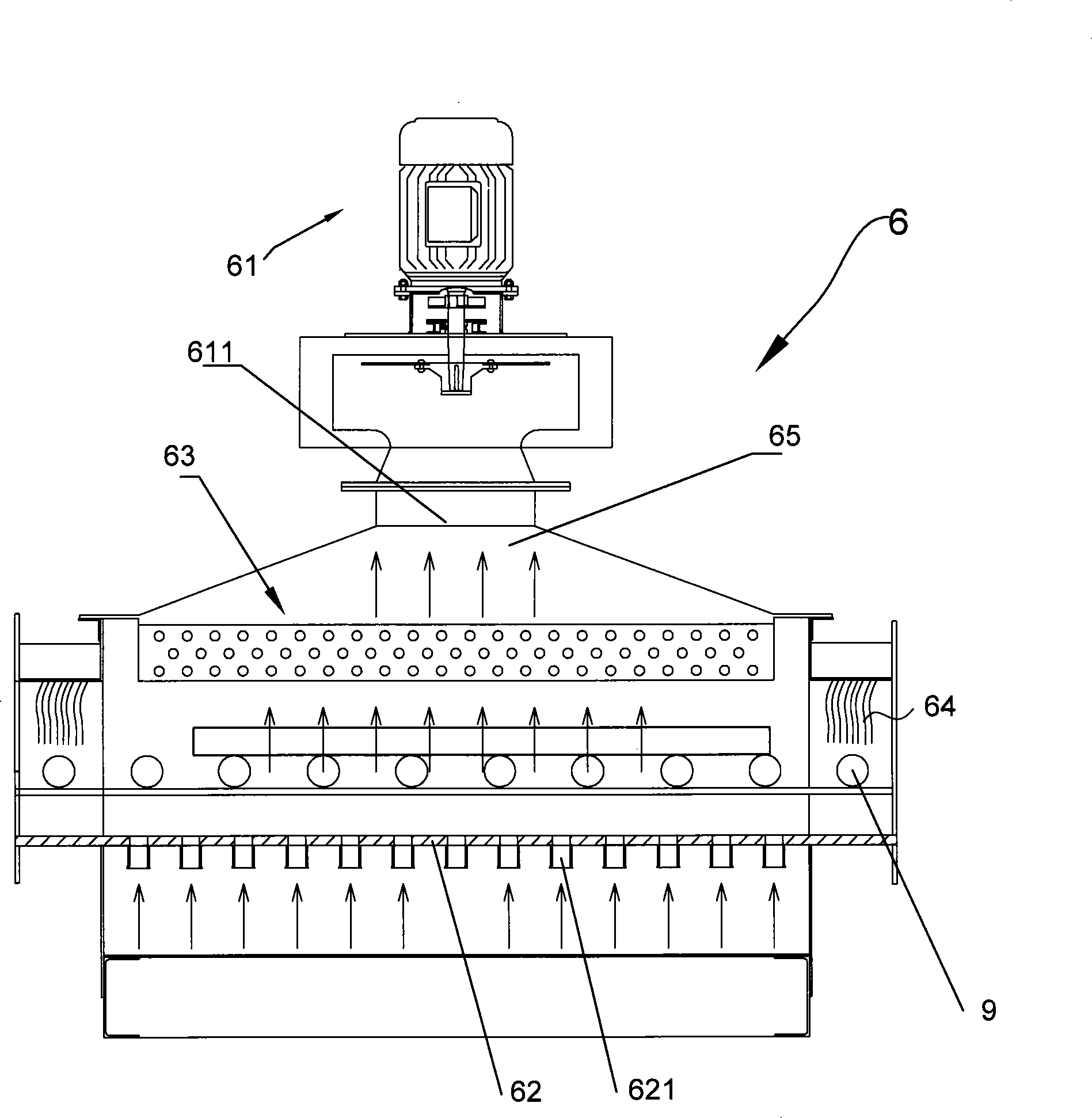

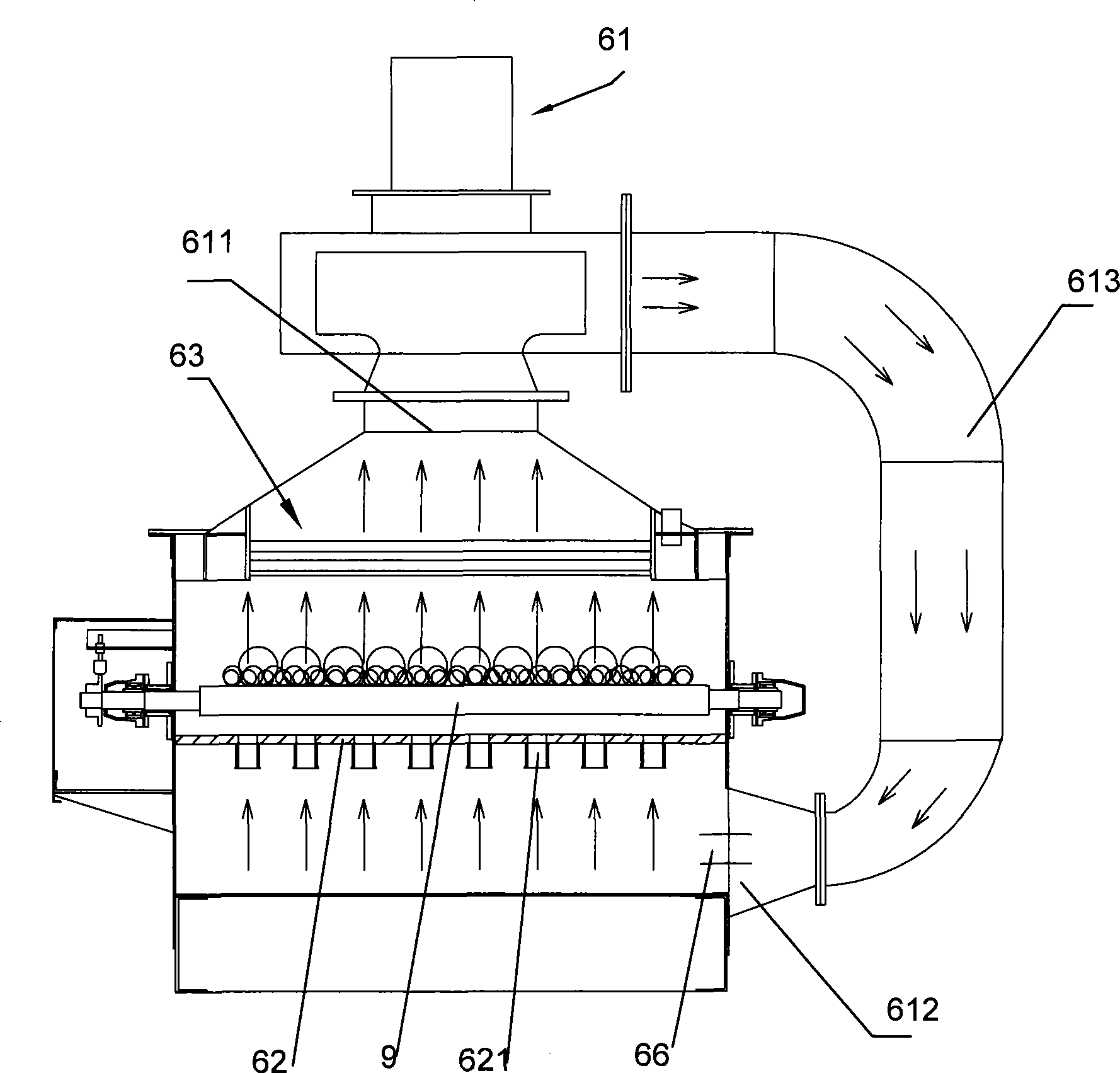

[0028] See attached drawings 1 to attached Figure 8 , a low furnace pressure convection continuous roller hearth annealing furnace, comprising a charging table 1, a front chamber 2, a heating chamber 3, a rear chamber 4, a water cooling chamber 5, a strong cooling chamber 6, a rear chamber 7, a discharge Platform 8 and the roller table transmission system running through the annealing furnace, the specific structure of each part is:

[0029] 1. Roller table transmission system: it is composed of a plurality of idler rollers 9 and gear sets, chains and motors connected with the plurality of idler rollers 9, and the plurality of idler rollers 9 move along the Continuous movement in the length direction of the roller, and a plurality of rollers 9 form a roller table that can continuously transport workpieces;

[0030] 2. Loading platform 1: It is mainly constructed by the skeleton of the material platform. The loading platform 1 is divided into two sections, which are automatic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com