High-thermal-conductivity organosilicone mud and preparation method thereof

A high thermal conductivity and silicone technology, applied in the field of heat conduction and heat transfer, can solve the problems of not obvious effect, poor heat transfer stability, and affecting the service life of electronic products, so as to avoid a significant decline in heat transfer performance and increase Filling amount, effect of good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

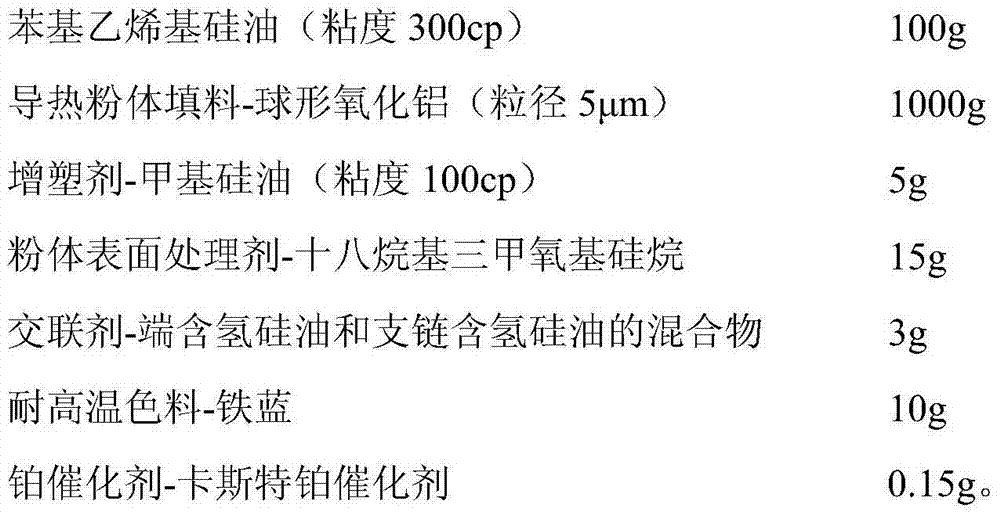

[0018] 1. A kind of organosilicon high thermal conductivity mud in this embodiment, its raw material is composed of:

[0019]

[0020] 2. The preparation method of the above-mentioned organosilicon high thermal conductivity mud in this embodiment, the steps are as follows:

[0021] First, add phenylvinyl silicone oil into the planetary machine, add thermal conductive powder filler in five batches, and stir and mix evenly under the vacuum protection condition of -0.095MPa; then add plasticizer, powder surface treatment agent, crosslinking agent in sequence Agent, high-temperature-resistant colorant, platinum catalyst, heated to 65°C for 0.5h under a vacuum protection condition of -0.095MPa, and reacted for 0.5h, then cooled to room temperature to obtain the finished silicone high thermal conductivity clay.

Embodiment 2

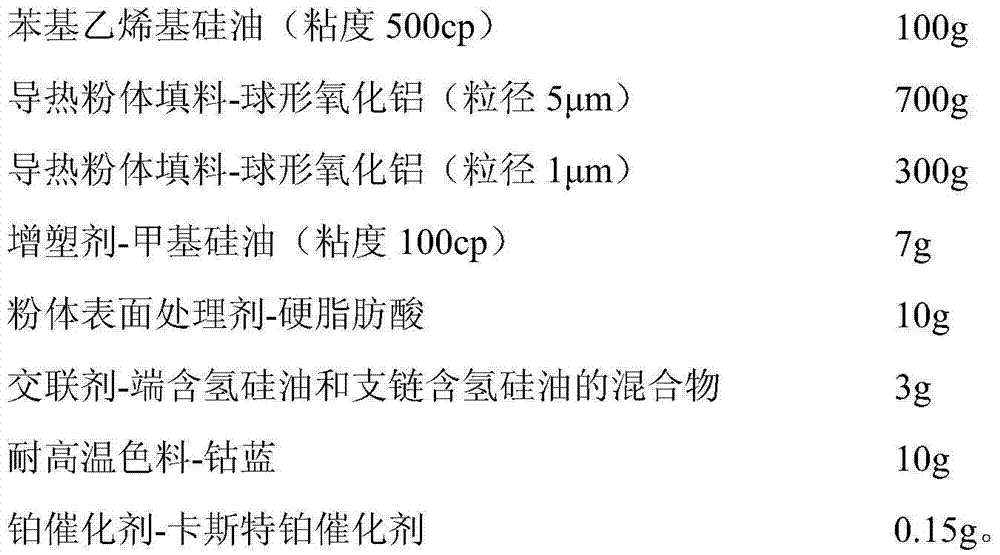

[0023] 1. A kind of organosilicon high thermal conductivity mud in this embodiment, its raw material is composed of:

[0024]

[0025] 2. The preparation method of the above-mentioned organosilicon high thermal conductivity mud in this embodiment, the steps are as follows:

[0026] First, add phenylvinyl silicone oil into the planetary machine, add thermal conductive powder filler in five batches, and stir and mix evenly under the vacuum protection condition of -0.095MPa; then add plasticizer, powder surface treatment agent, crosslinking agent in sequence Agent, high-temperature-resistant colorant, platinum catalyst, heated to 60°C for 1 hour under a vacuum protection condition of -0.095MPa, and cooled to room temperature to obtain the finished silicone high thermal conductivity clay.

Embodiment 3

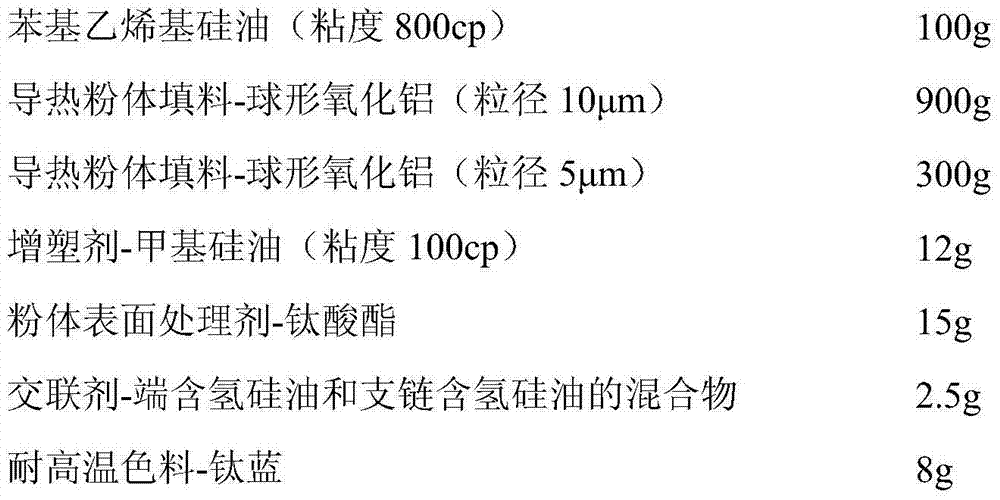

[0028] 1. A kind of organosilicon high thermal conductivity mud in this embodiment, its raw material is composed of:

[0029]

[0030]

[0031] 2. The preparation method of the above-mentioned organosilicon high thermal conductivity mud in this embodiment, the steps are as follows:

[0032] First, add phenyl vinyl silicone oil into the planetary machine, add thermal conductive powder filler in six batches, and stir and mix evenly under the vacuum protection condition of -0.095MPa; then add plasticizer, powder surface treatment agent, crosslinking agent in sequence Agent, high-temperature-resistant colorant, platinum catalyst, heated to 55°C for 2 hours under a vacuum protection condition of -0.095MPa, and cooled to room temperature to obtain the finished silicone high thermal conductivity clay.

[0033] The physical and chemical properties of the finished organosilicon high thermal conductivity paste prepared in various embodiments of the present invention are shown in T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com