Wet-process two-stage phosphoric acid concentration method

A wet-process phosphoric acid and phosphoric acid concentration technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of reduced concentration and quality of phosphoric acid in finished products, larger heating area for heaters, and low solubility of impurities, etc. Achieve the effects of improving concentration and quality, easy localization of equipment, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

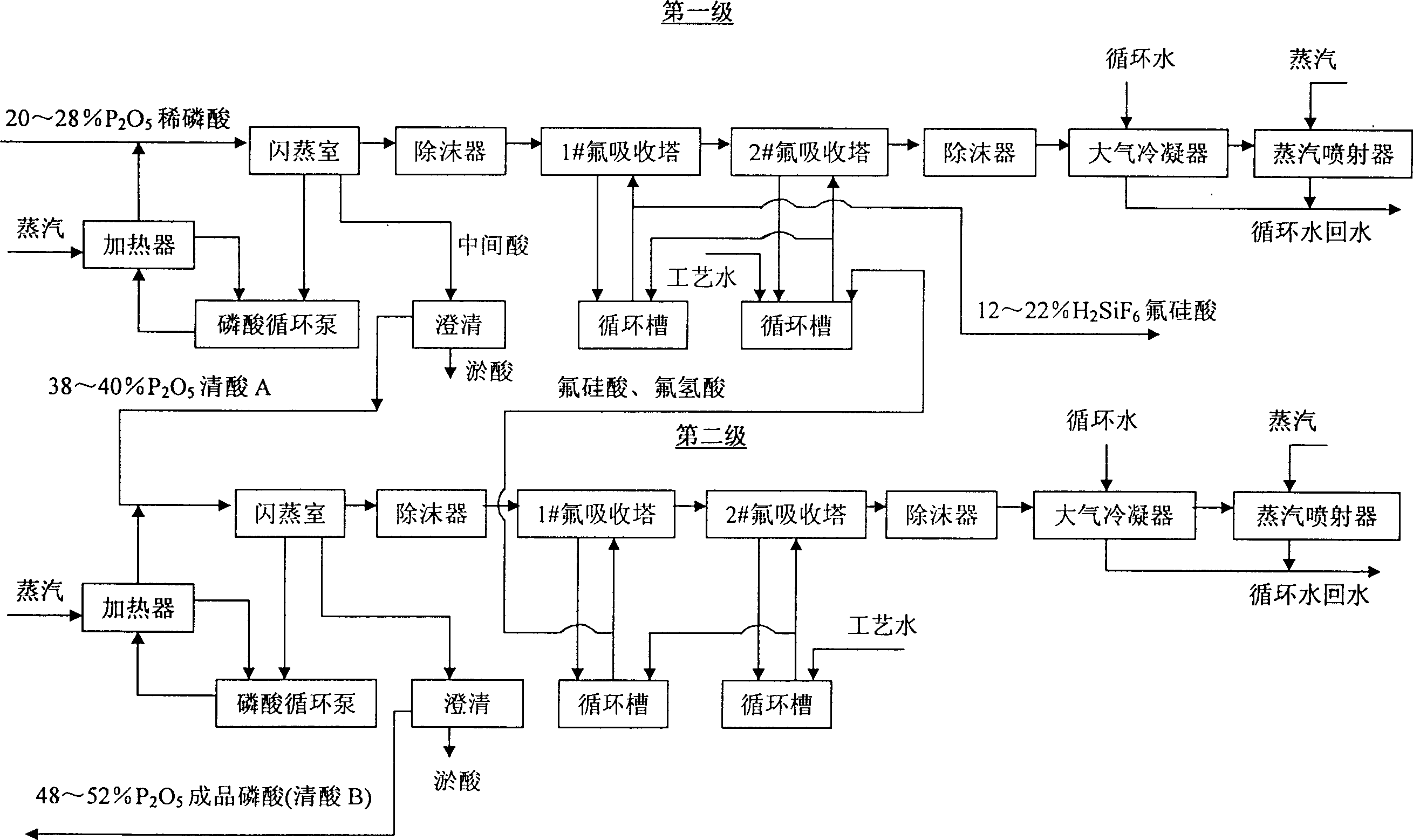

[0023] Combined with the accompanying drawings and Table 1, 200,000 tons / year P 2 o 5 The concentration system adopts a two-stage series concentration process, the first stage concentration: the concentration is 28%P 2 o 5 , Filtration-grade dilute phosphoric acid with a solid content of ≤2.5% is added to the forced circulation loop (composed of a flash chamber, a phosphoric acid circulation pump, and a heater), and the phosphoric acid is heated by steam through the heater. The temperature difference between the front and rear of the heater is 5-6 ℃, heater heat transfer coefficient 5000kJ / (m 2 h°C), the temperature of the circulating acid is controlled at 80-85°C, and the water is flash-evaporated in the flash chamber (pressure 20-25kPa) under vacuum to concentrate the phosphoric acid to a concentration of 40%P 2 o 5 The intermediate acid is clarified in the intermediate acid storage tank to remove part of the suspended solids to obtain clear acid A, and the solid content...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com