Device and method for flue gas cyclone jet white removal coupling absorption heat pump waste heat recovery

An absorption heat pump and waste heat recovery technology, applied in combustion methods, separation methods, fluid heaters, etc., can solve the problems of low-temperature waste heat waste, whitening, clogging, etc., achieve good corrosion resistance, and increase heat and mass transfer coefficients Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

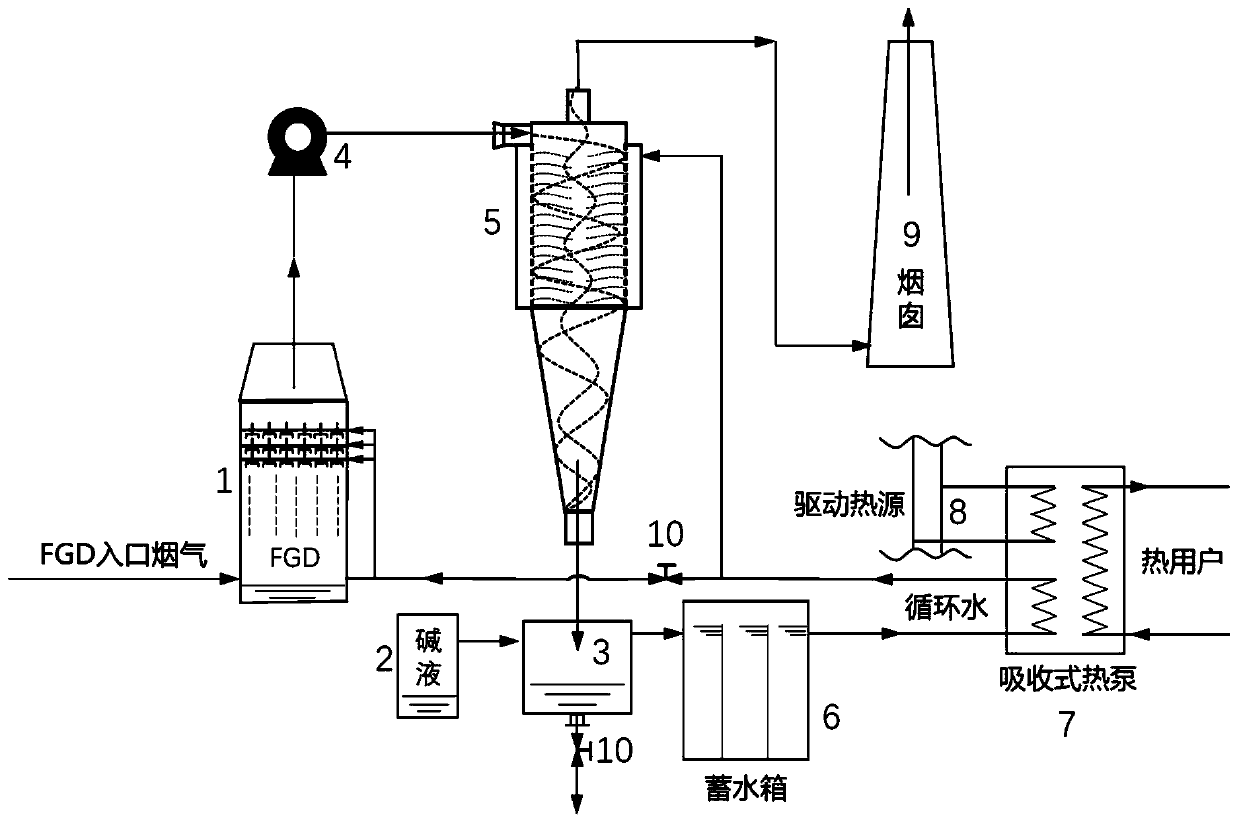

[0050] like figure 1 As shown, a flue gas swirl jet dewhitening coupling absorption heat pump waste heat recovery complete set, including: 1 is FGD wet desulfurization, 2 is lye tank, 3 is liquid collection tank, 4 is fan, 5 is swirl flow Ejector, 6 is a water storage tank, 7 is an absorption heat pump, 8 is a driving heat source, 9 is a chimney, and 10 is a valve.

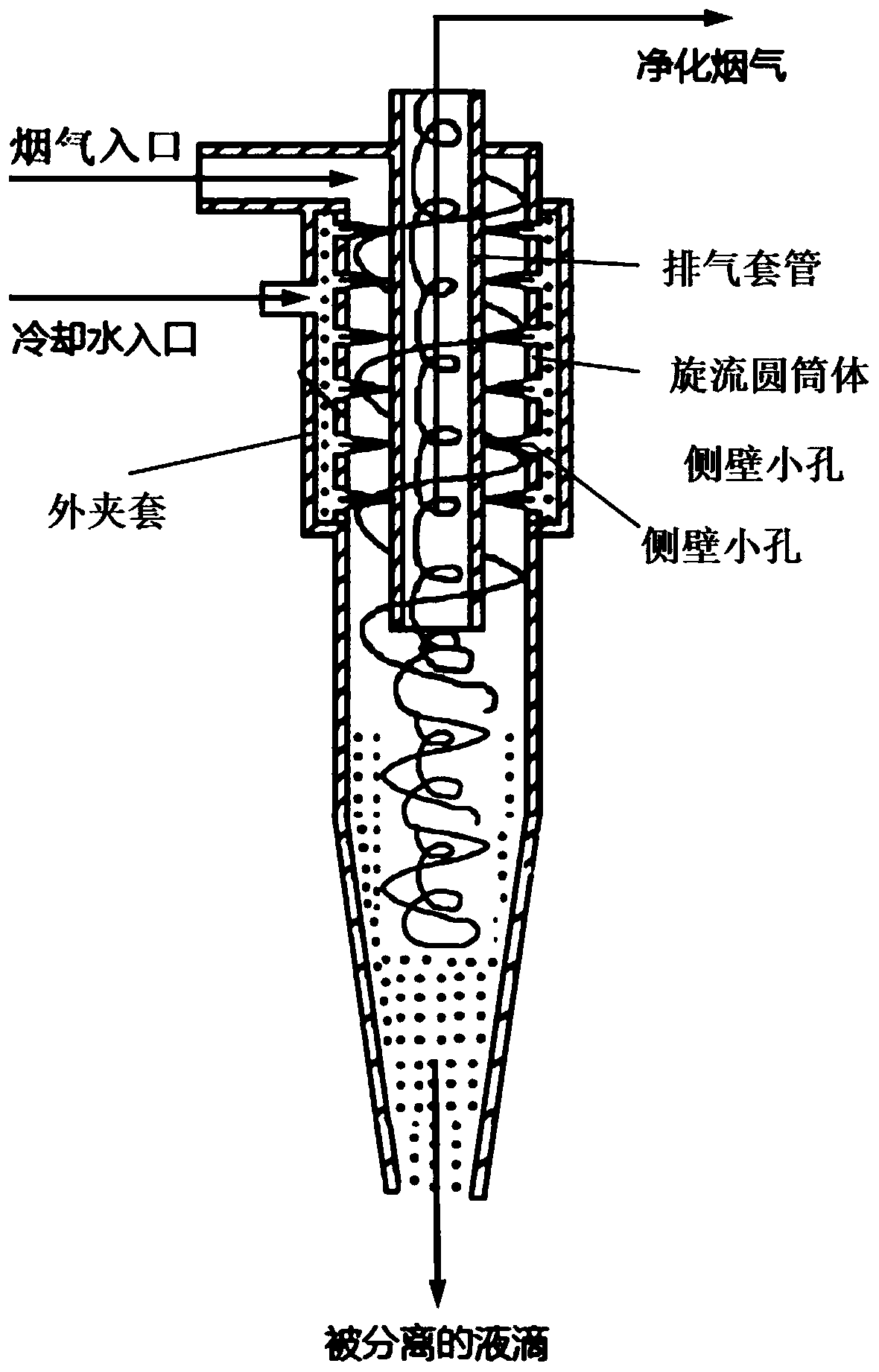

[0051] The technical idea of the present invention is as follows: the FGD wet desulfurization device connected with the inlet flue gas is used for flue gas wet desulfurization; the fan connected with the FGD outlet flue gas provides power for the flue gas to enter the swirling jet; The connected swirl ejector uses the high-speed rotation of the flue gas to atomize the cooling water to promote the heat and mass transfer between the flue gas and the liquid droplets, as well as the separation and collection of the liquid droplets; the liquid collection connected to the bottom flow port of the swirl ejector The tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com