CO2 adsorption/desorption circulating treatment device and preparation method and treatment method thereof

A cycle treatment and desorption technology, applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of insufficient contact area between carbon dioxide and adsorption materials, poor continuous working ability, secondary pollution, etc., and achieve good removal Application potential, high heat and mass transfer coefficient, effect of low flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below in conjunction with the examples and drawings, but the implementation of the present invention is not limited thereto.

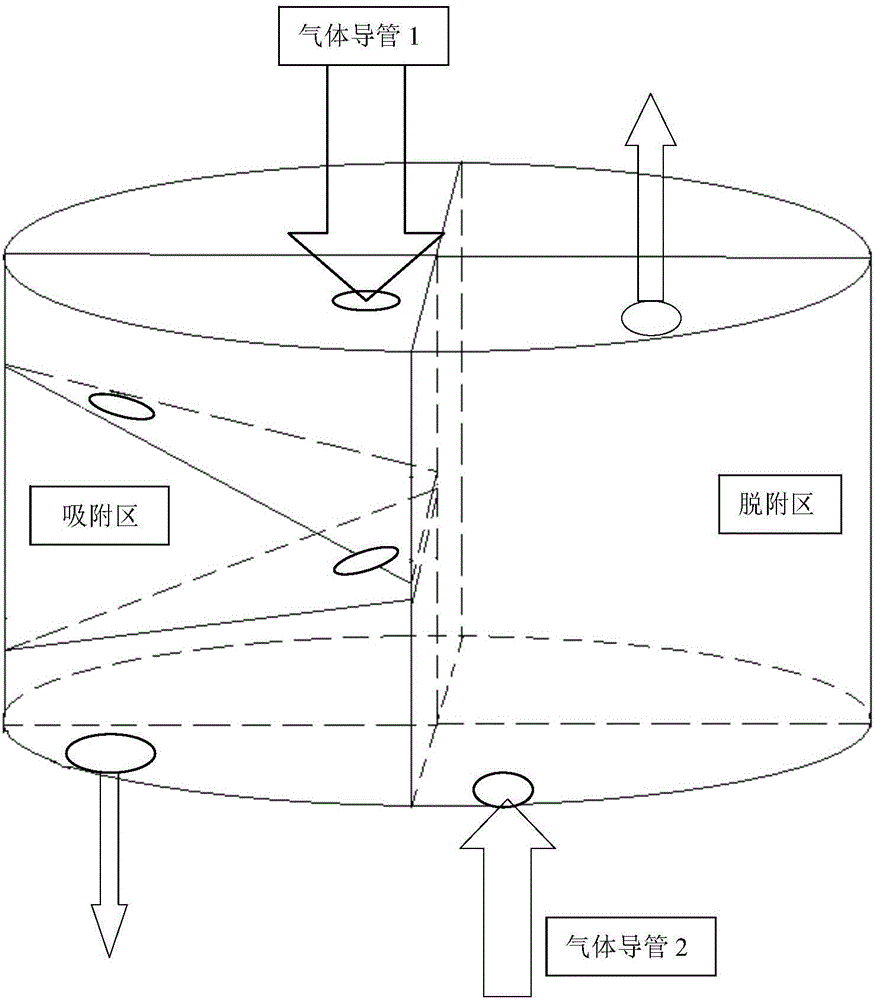

[0043] See Figure 4 , The CO in this example 2 The adsorption / desorption cycle processing device includes a power drive device, a runner 1 and a gas duct. The power drive device includes a runner motor 2 and a conveyor belt 3. The rotation of the runner motor drives the conveyor belt to rotate, and then drives the runner to rotate. A plurality of gas inlet and outlet holes are arranged on the upper part, and each gas inlet and outlet hole is respectively connected with a gas pipe.

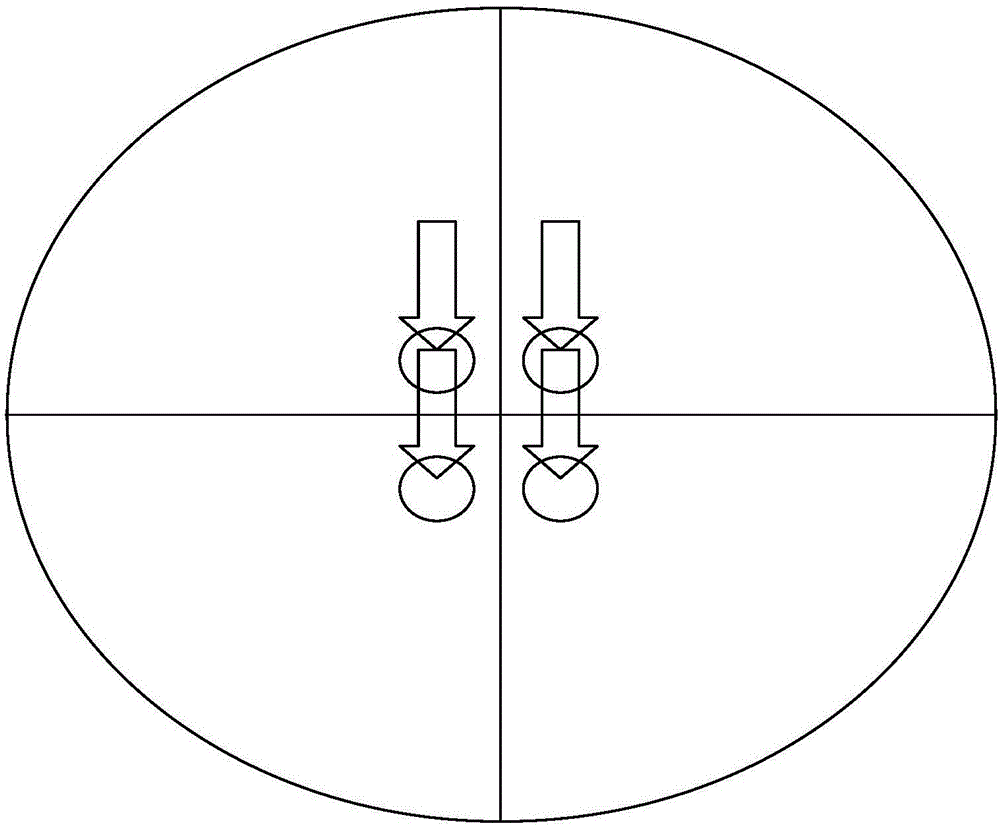

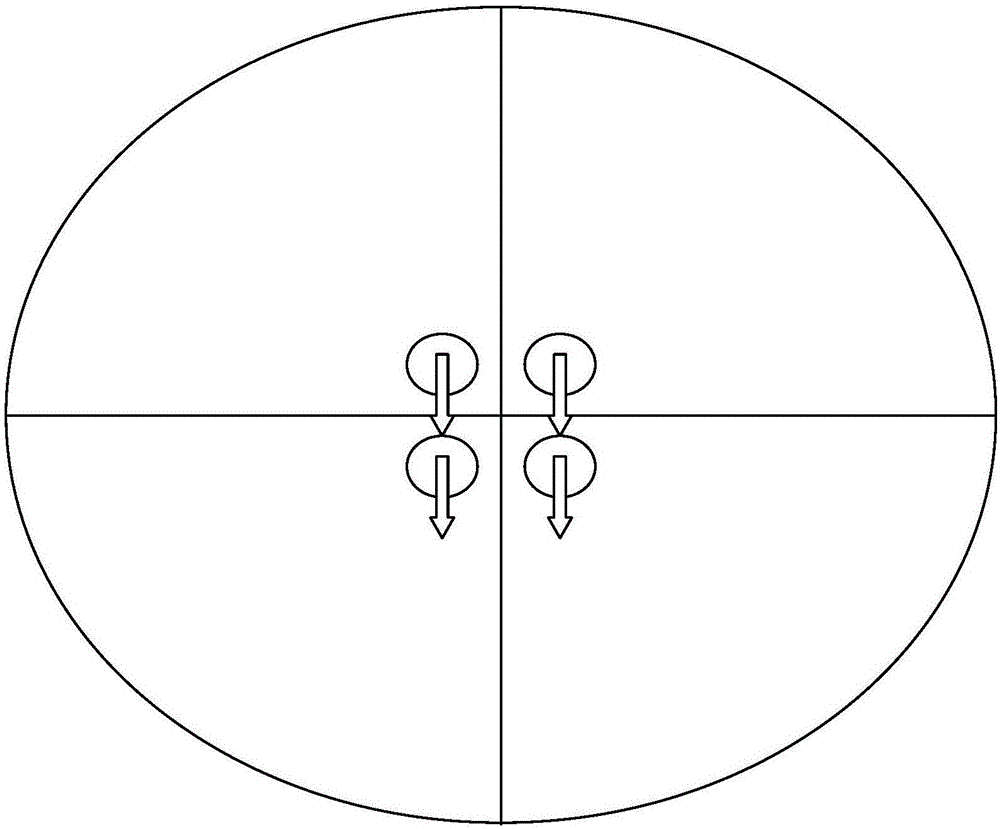

[0044] See figure 1 In this embodiment, the runner is a hollow cylinder, and the internal cavity is divided into four zones, and gas inlet and outlet holes are opened above and below each zone for the gas to be adsorbed or purified gas to pass through. The size of the gas inlet and outlet holes depends on the size...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com