A heat and mass exchange enhanced structure and design method thereof

A technology for strengthening structure and heat and mass exchange, applied in the field of heat and mass transfer, can solve the problems affecting the economy, safety and reliability of the system, affecting the comprehensive heat and mass transfer efficiency of the system, etc. Heat and mass transfer effect, the effect of strengthening the heat and mass transfer process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

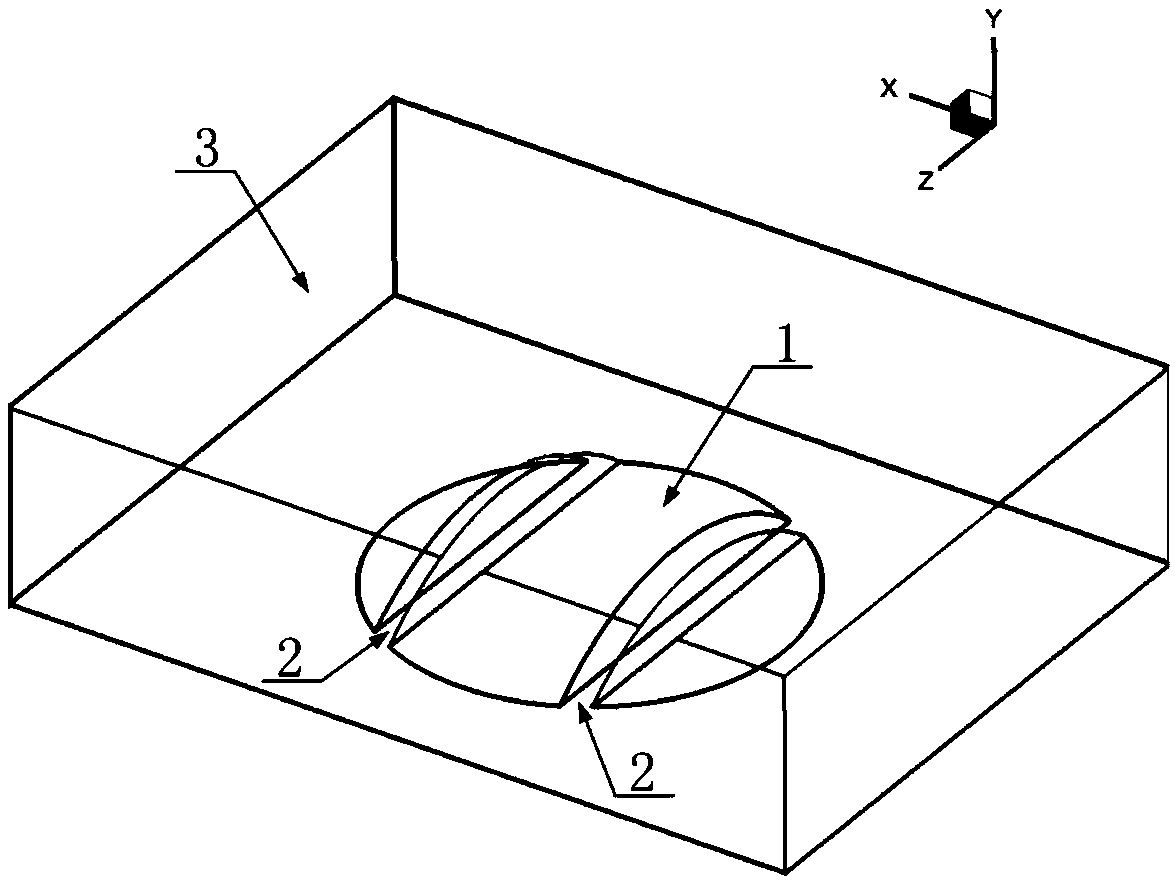

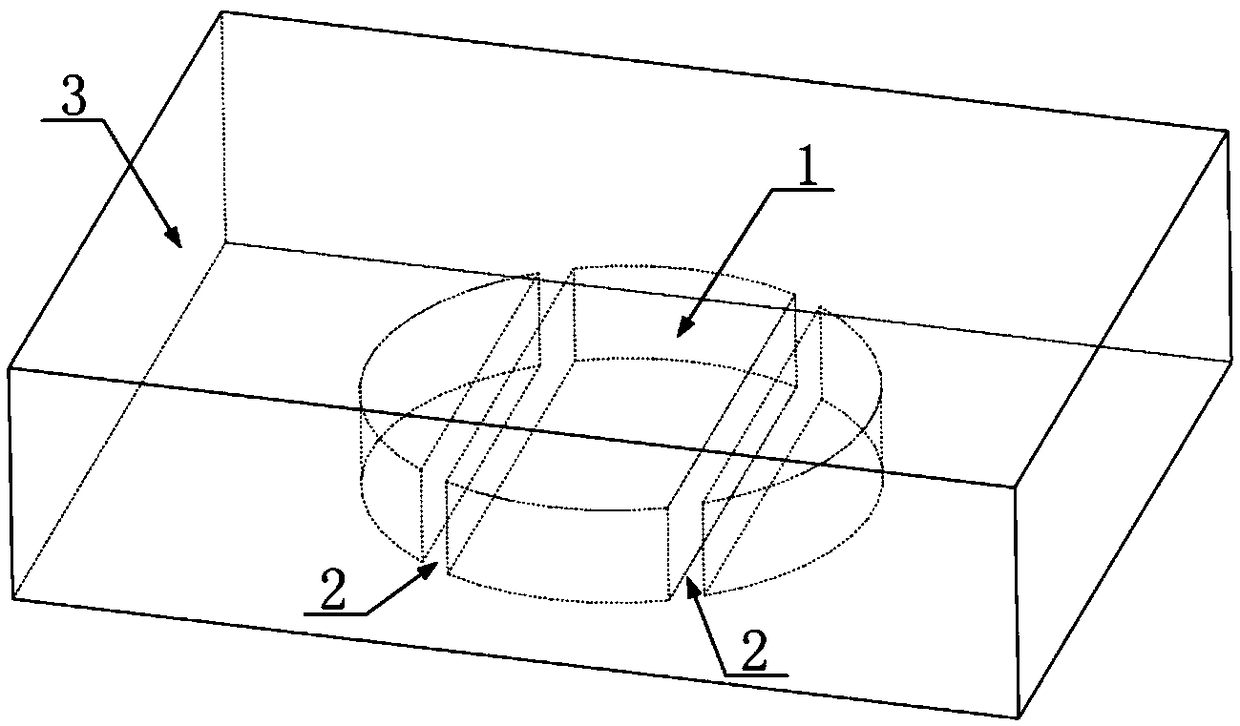

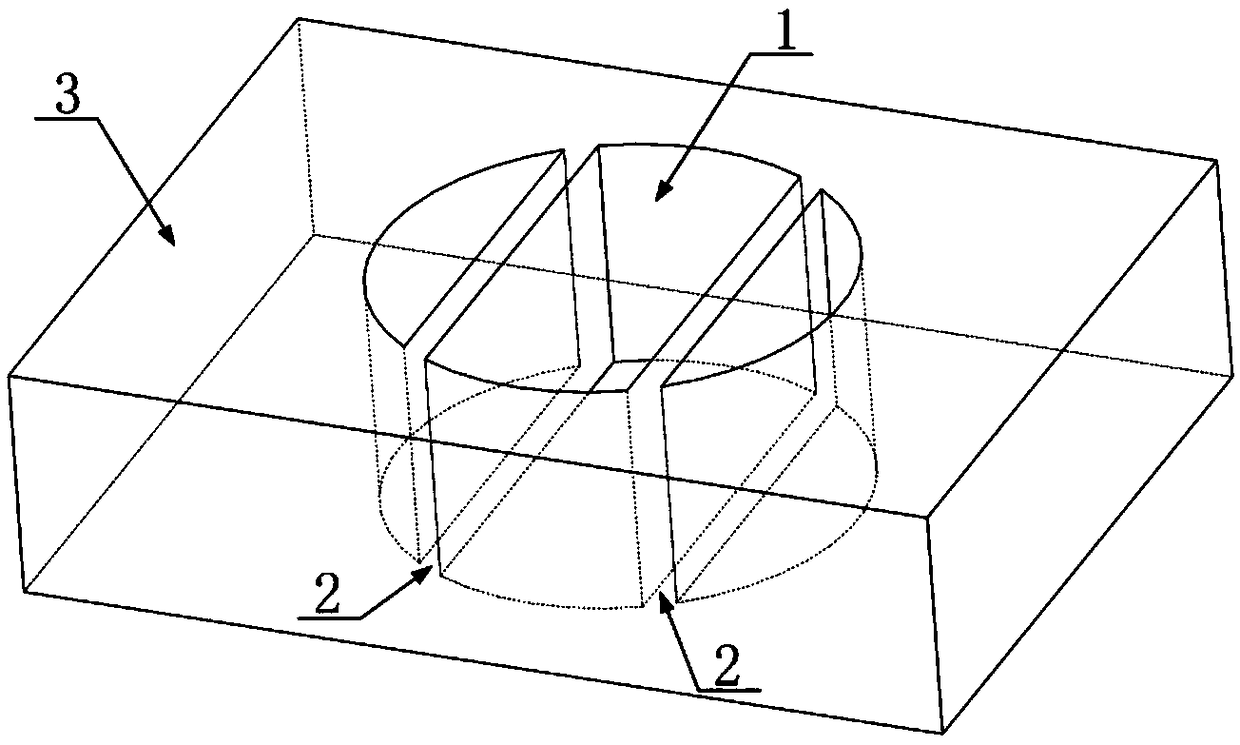

[0036] see Figure 1 to Figure 5 As shown, a heat and mass exchange strengthening structure of the present invention, that is, a flow control structure with a self-jet, is composed of a convex flow control structure matrix 1 and a self-jet channel 2 penetrating through it, and the self-jet channel 2 is connected to the Areas such as the main stream of flow and the wake of flow control structures. It can be applied to the heat and mass transfer process of various working fluids in the tube or outside the tube of channels of various sizes.

[0037] In the conventional case of arranging the convex flow control structure matrix 1 for heat and mass transfer, the fluid flow structure is affected by the flow control structure and working conditions (such as flow state, working fluid, channel shape and arrangement position, etc.), which in turn affect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com