Patents

Literature

171 results about "Mass exchange" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

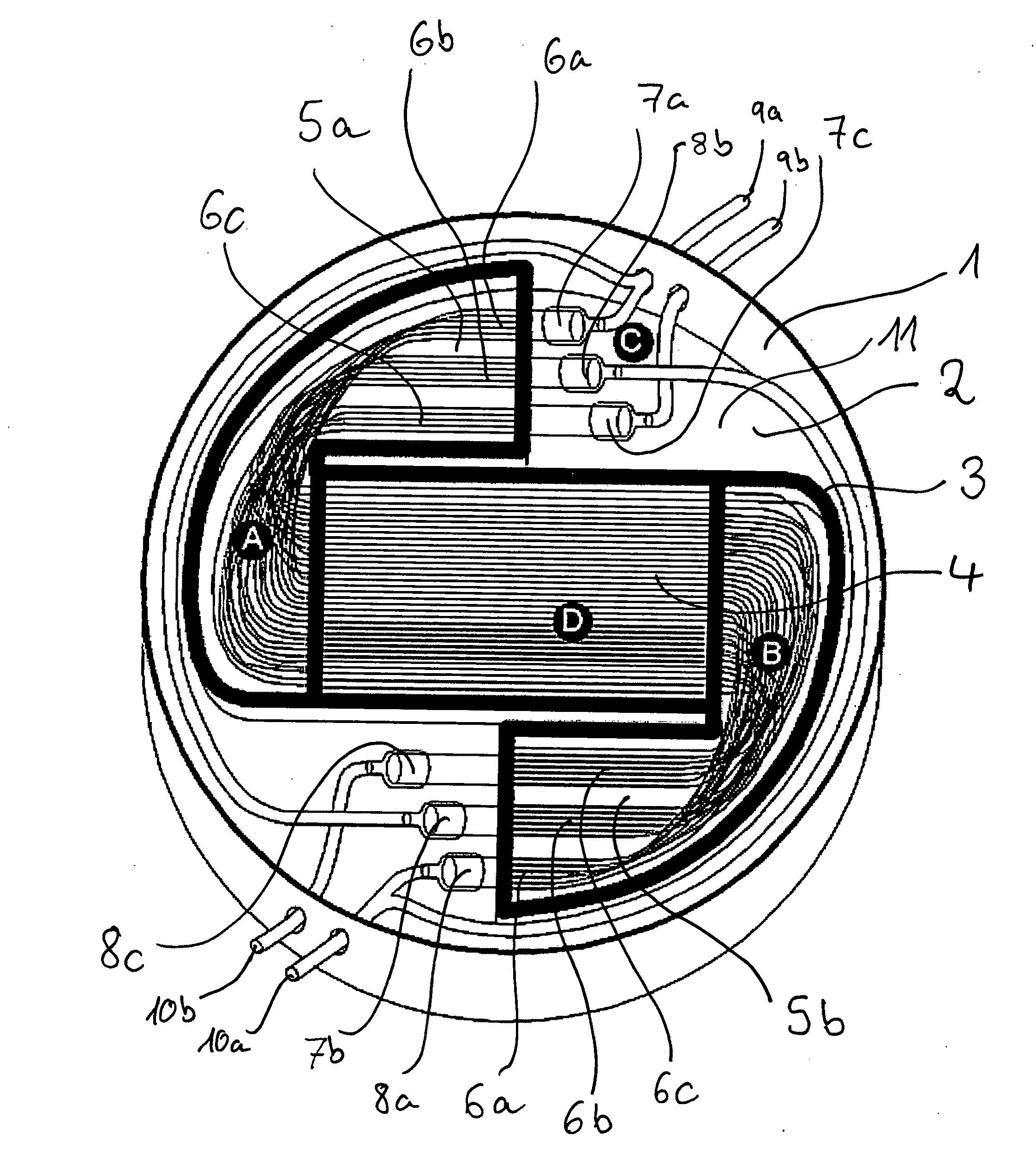

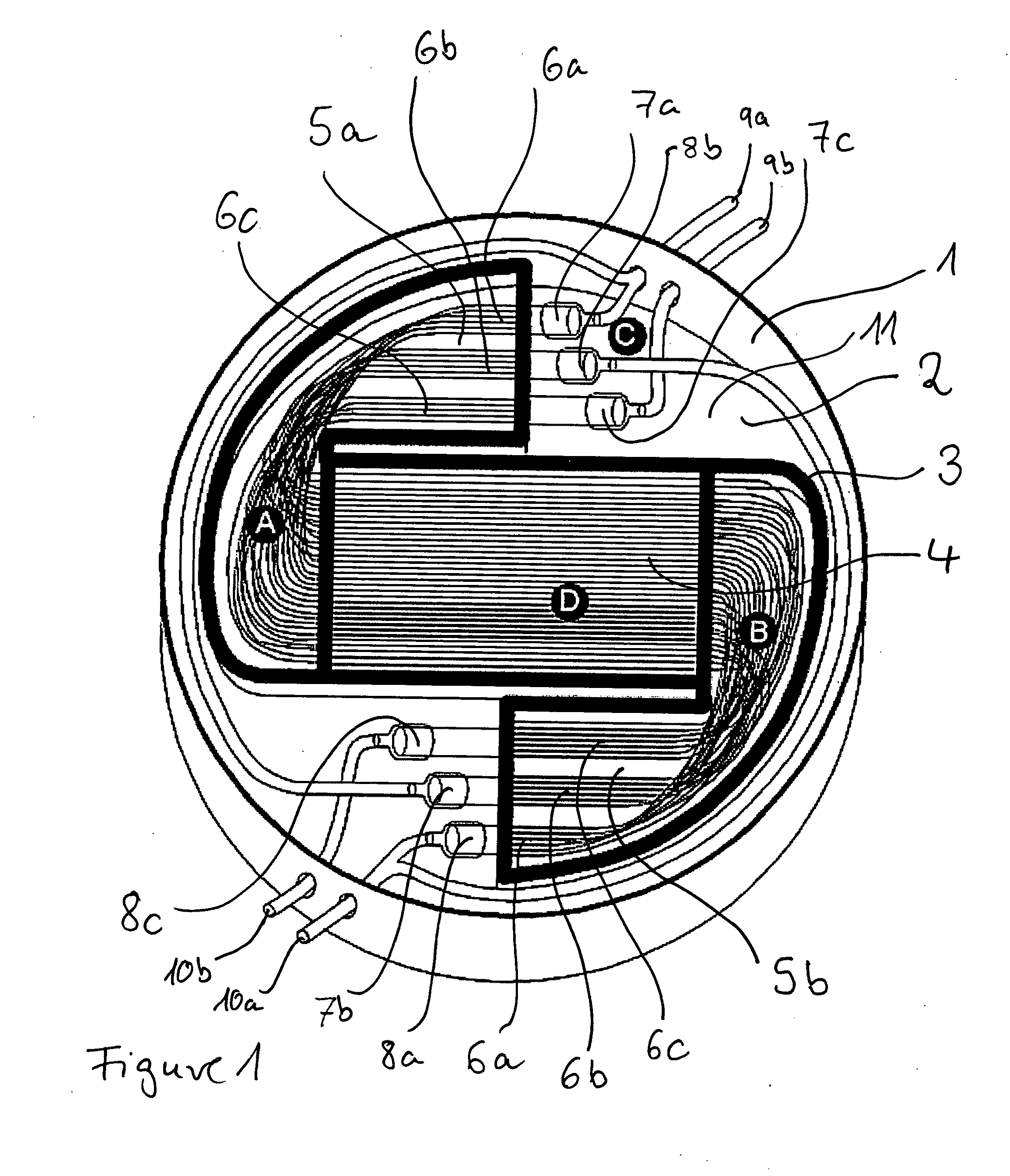

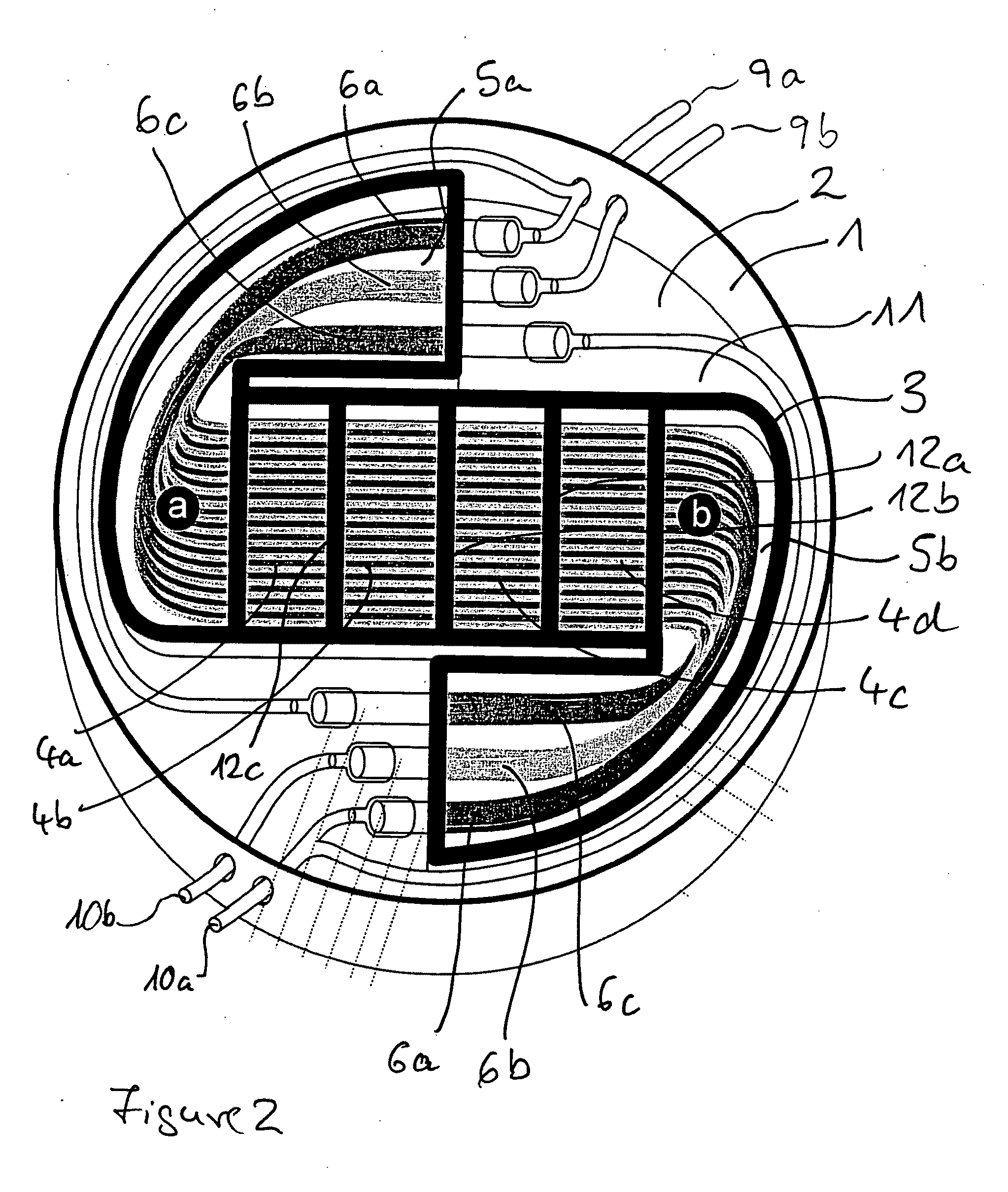

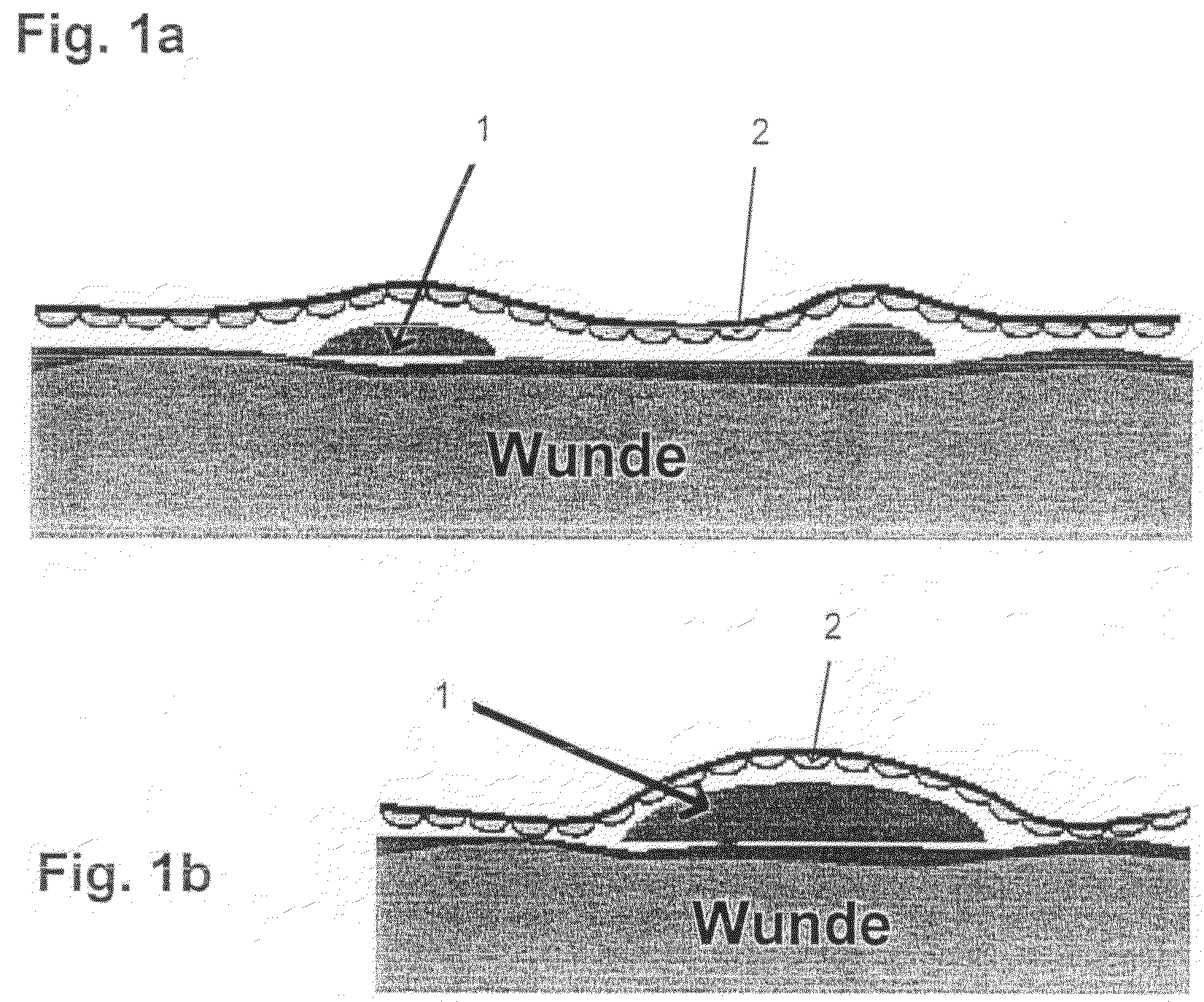

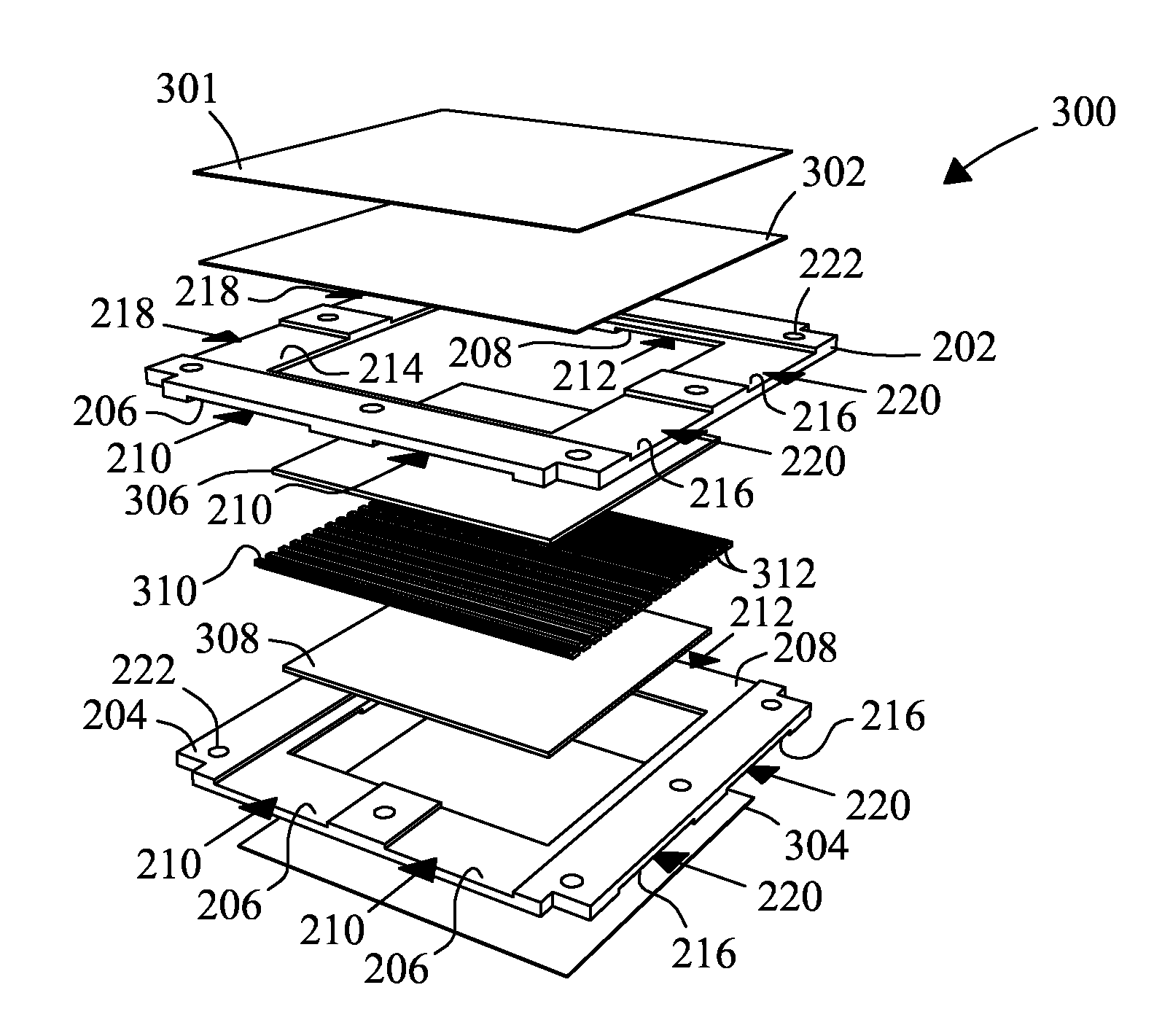

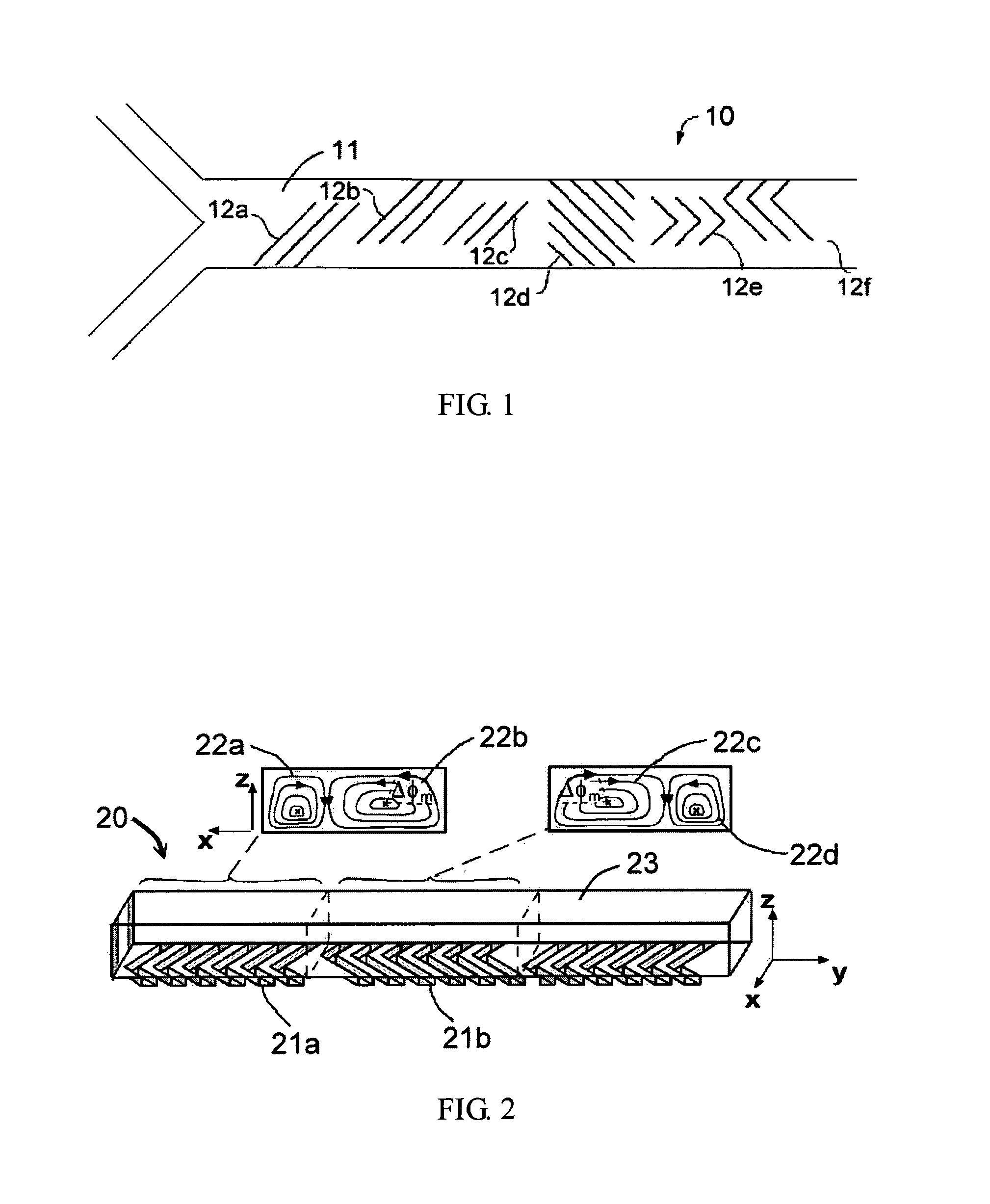

3-D petri-dish for the culture and studies of cells

InactiveUS20090191631A1High mass exchangePrevent gradientBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyPerfusion Culture

A three-dimensional (3-D) culture “Petri-dish” for research in regenerative medicine, biotechnology and clinical translation is described. This 3-D perfusion culture dish is to advance in vitro culture tools from static 2-D to dynamic 3-D perfusion culture. Interwoven hollow fiber capillary membranes divide the “Petri-dish” culture space into a controllable 3-D pattern of different compartments, serving the functions of the organ's larger vasculature. These physically active scaffolds, which can be suitable for cell adhesion or cell aggregate immobilization, offer a supply of cells with high-performance mass exchange including gas supply and under perfusion conditions. In contrast to static and discontinuous medium supply, a dynamic culture can be achieved with continuous or alternating medium supply and integral oxygenation. They provide a more physiologic supply in the cell macro environment, including homeostasis of oxygen, pH, nutrition, soluble factors, and gradients of metabolites for the cells. Also, medium perfusion can be achieved. Consequently the invention was made for cultures at tissue density, especially stem cells and support cells, which strive to create their own stem cell niche.

Owner:BORNEMANN REIMHARD

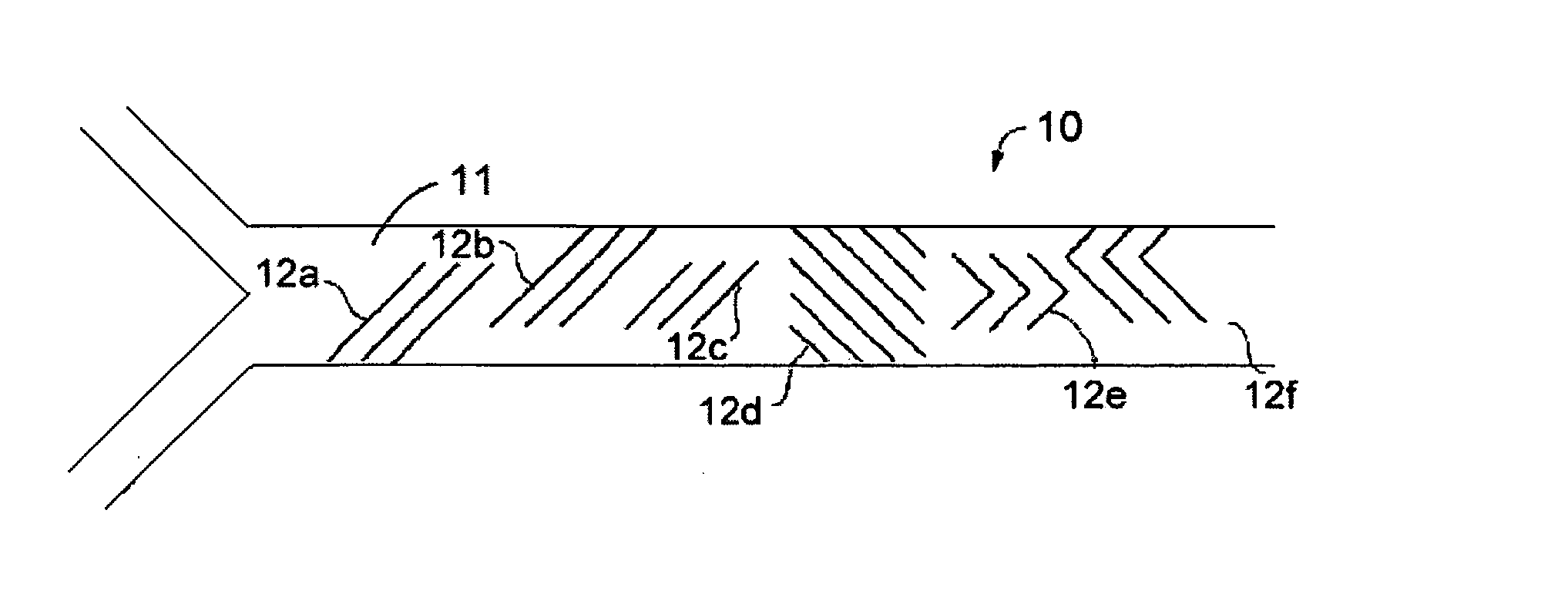

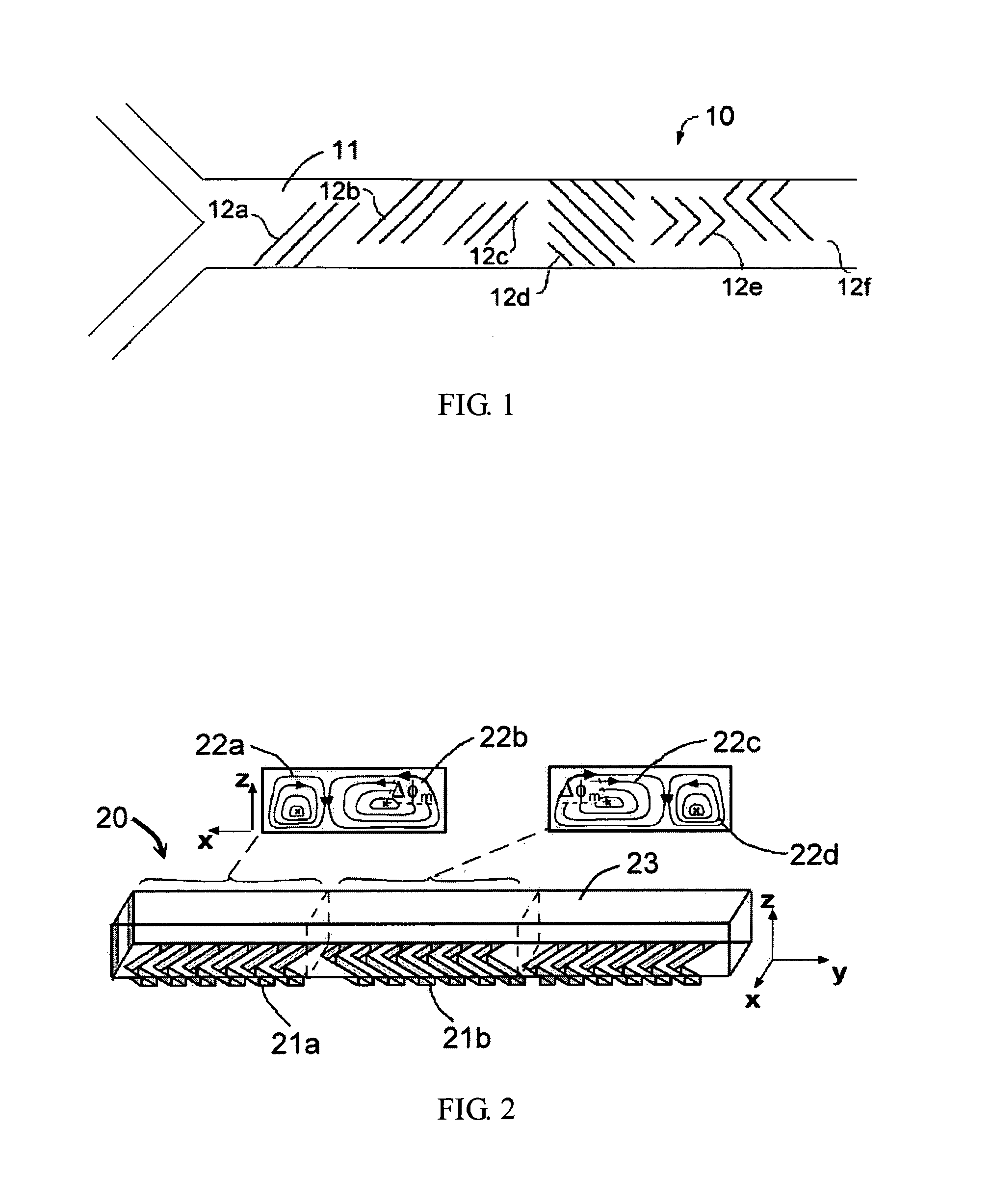

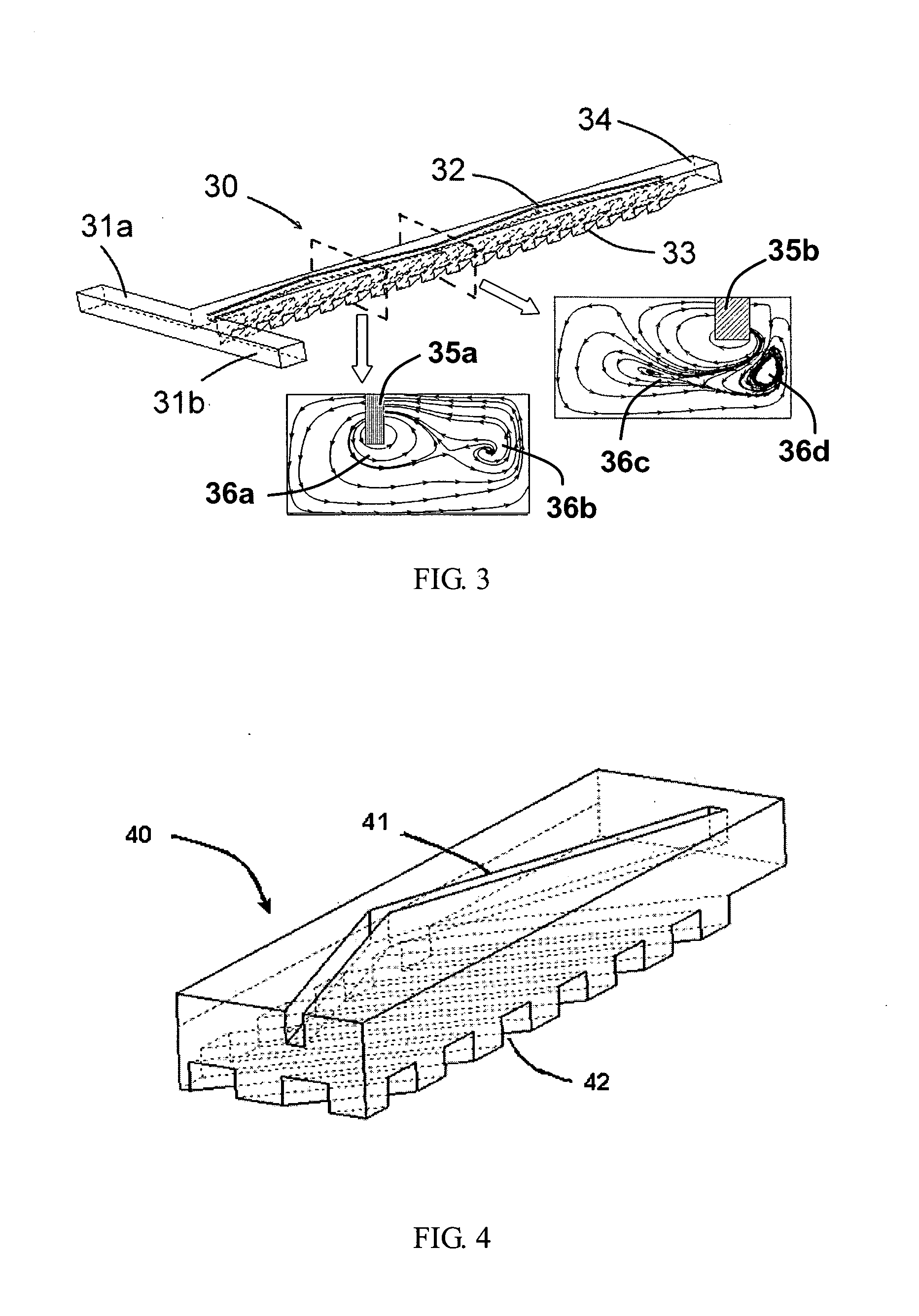

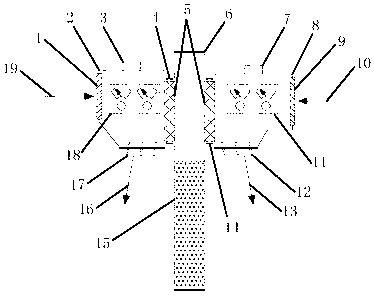

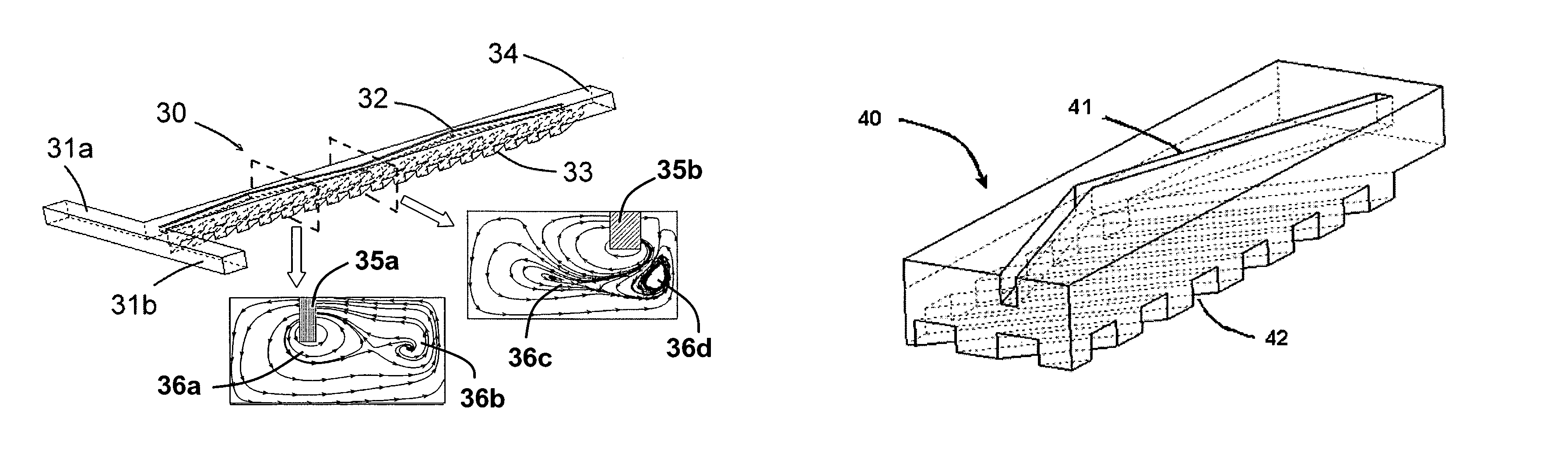

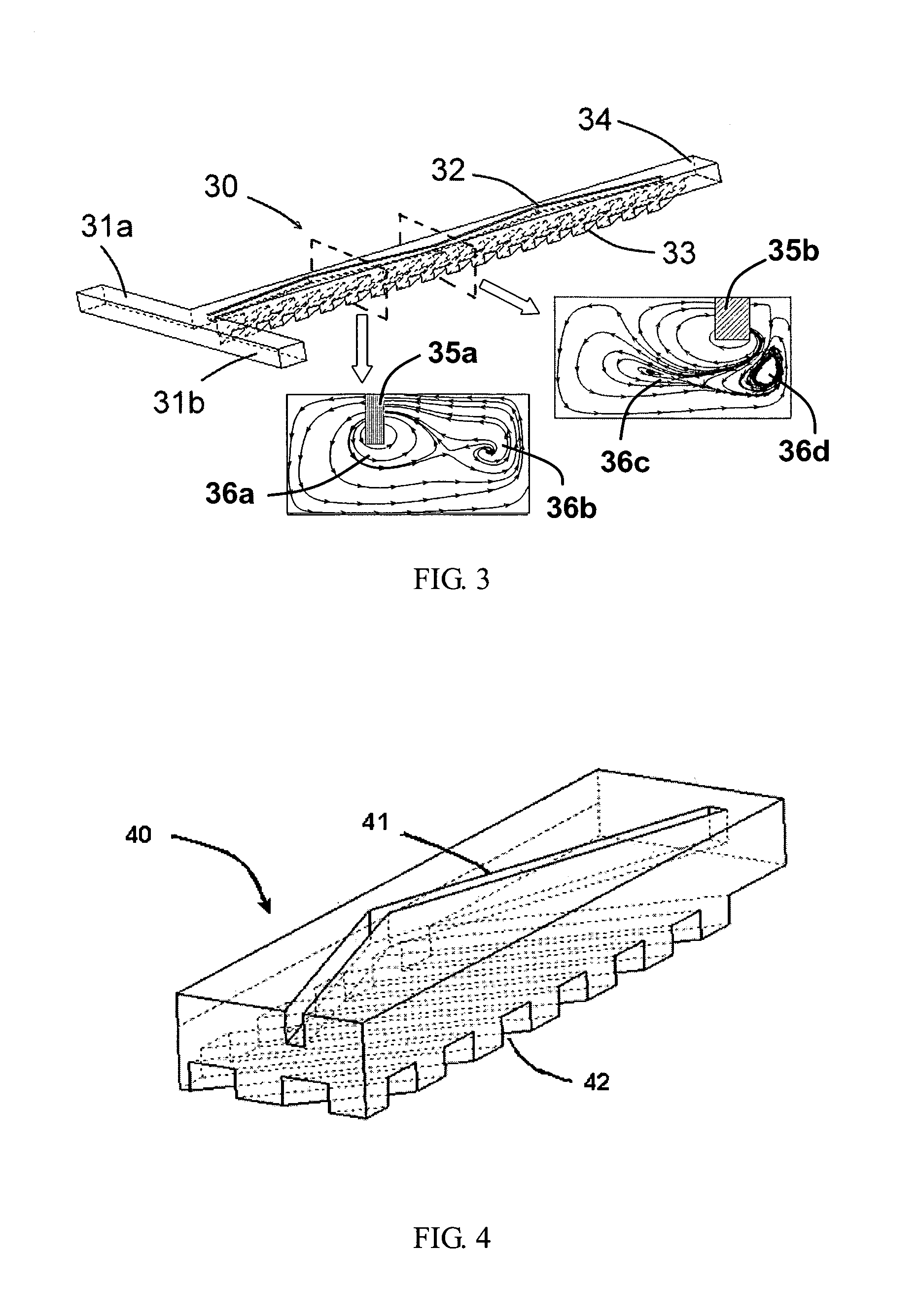

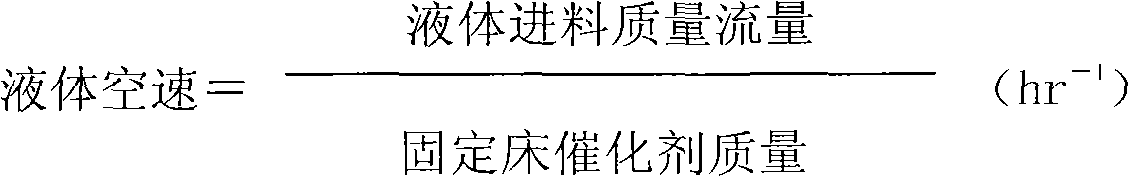

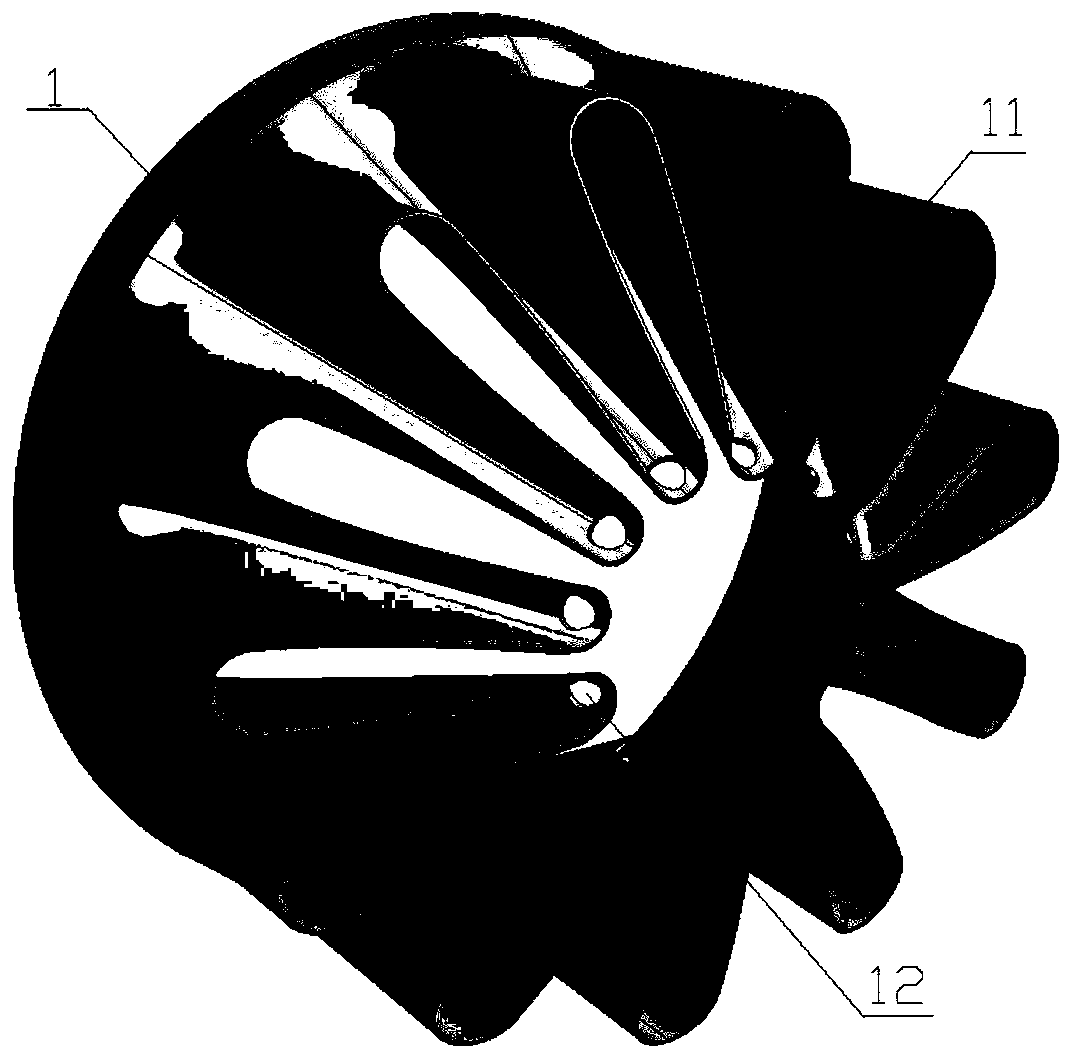

Twin-vortex micromixer for enforced mass exchange

InactiveUS20070263485A1Well mixedImprove mixing efficiencySemi-permeable membranesOther chemical processesShortest distanceLab-on-a-chip

The present invention discloses a vortex-modulation based micromixer for enforced mass exchange. The micromixer of the present invention comprises a mixing chamber with grooves on one wall thereof and a special-shape barrier on another wall. As different fluids are injected into the mixing chamber respectively from two inlets of the micromixer, the grooves and barriers of the micromixer of the present invention create the constructive interferences to form the active-like agitation of the fluid. For every groove, the flux passed by can be increased via its high pressure gradient. Understandably, the mixing efficiency of the fluids can be greatly improved within a very short distance. At last, the outlet of the micromixer is located in the downstream of the mixing chamber and further is able to connect with other elements. The present invention is entirely a passive micromixer and no additional energy is required. The present invention can apply to a continuous chemical analysis, particularly to a lab-on-a-chip or a micro total analysis system.

Owner:NATIONAL TSING HUA UNIVERSITY

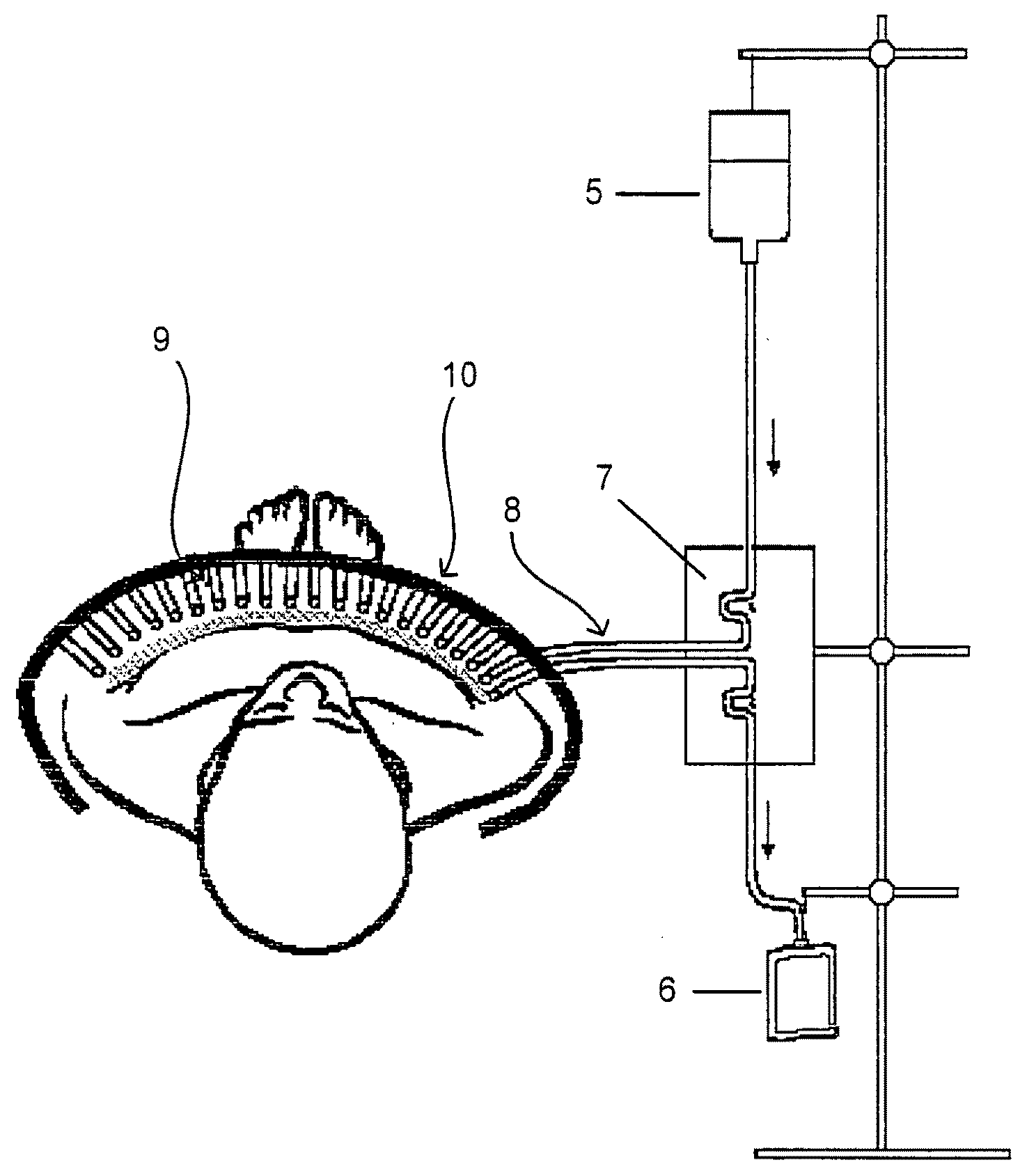

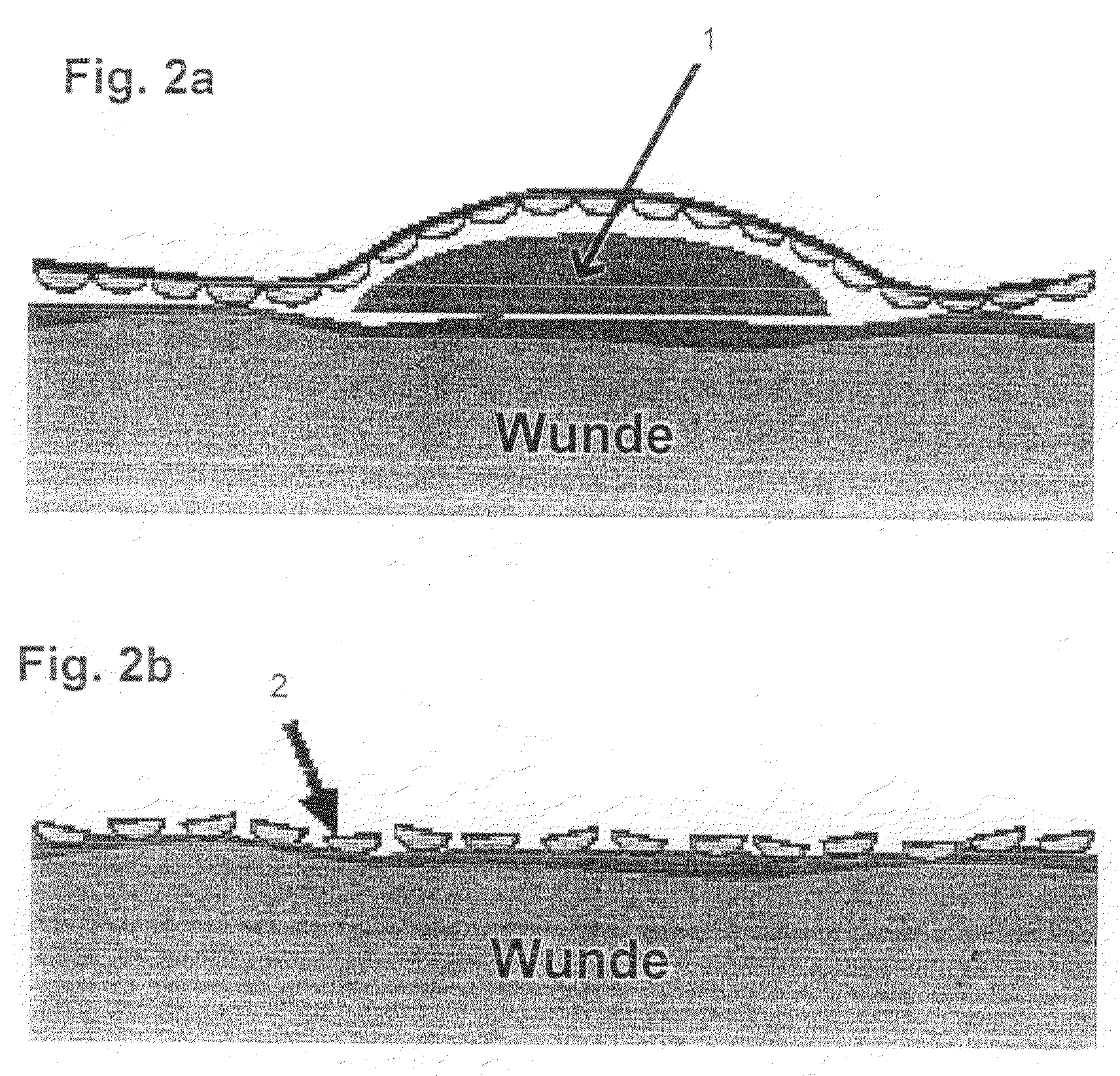

Artificial "arterio-venous" permeable hollow fiber capillary system

ActiveUS20090196855A1Improves mass exchangeModerate negative pressureBiocideSemi-permeable membranesFiberWound dressing

An artificial “arterio-venous” permeable hollow fiber capillary membrane system for wound treatment is described, that can be placed onto a wound, under the wound dressing, to enable fluid- / mass exchange, and thus enables pH- and electrolyte regulation, the supply of factors / mediators / medications, the removal of secretion- and / or waste material, and the support of therapeutically applied cells in the wound.

Owner:BORNEMANN REINHARD

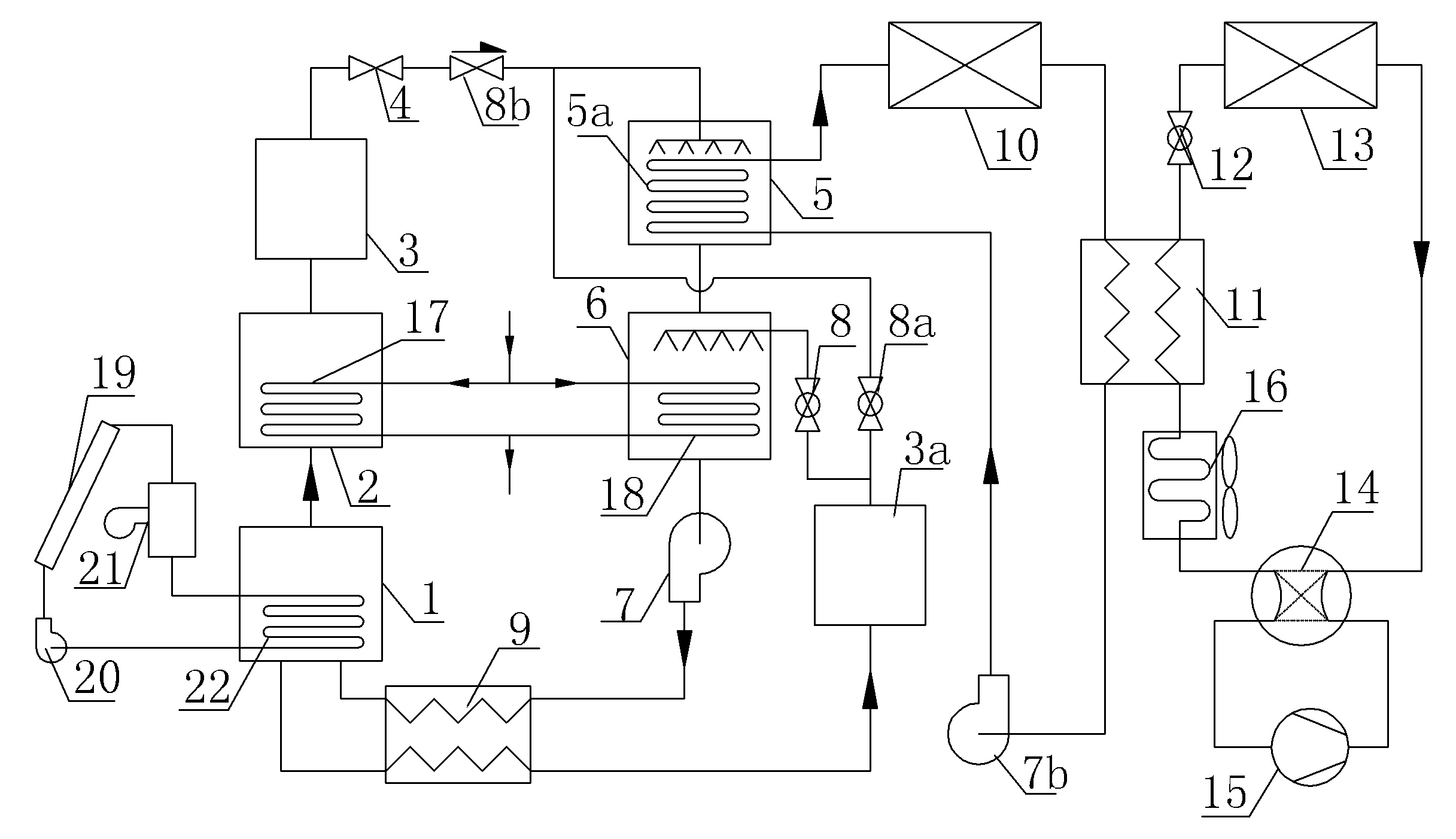

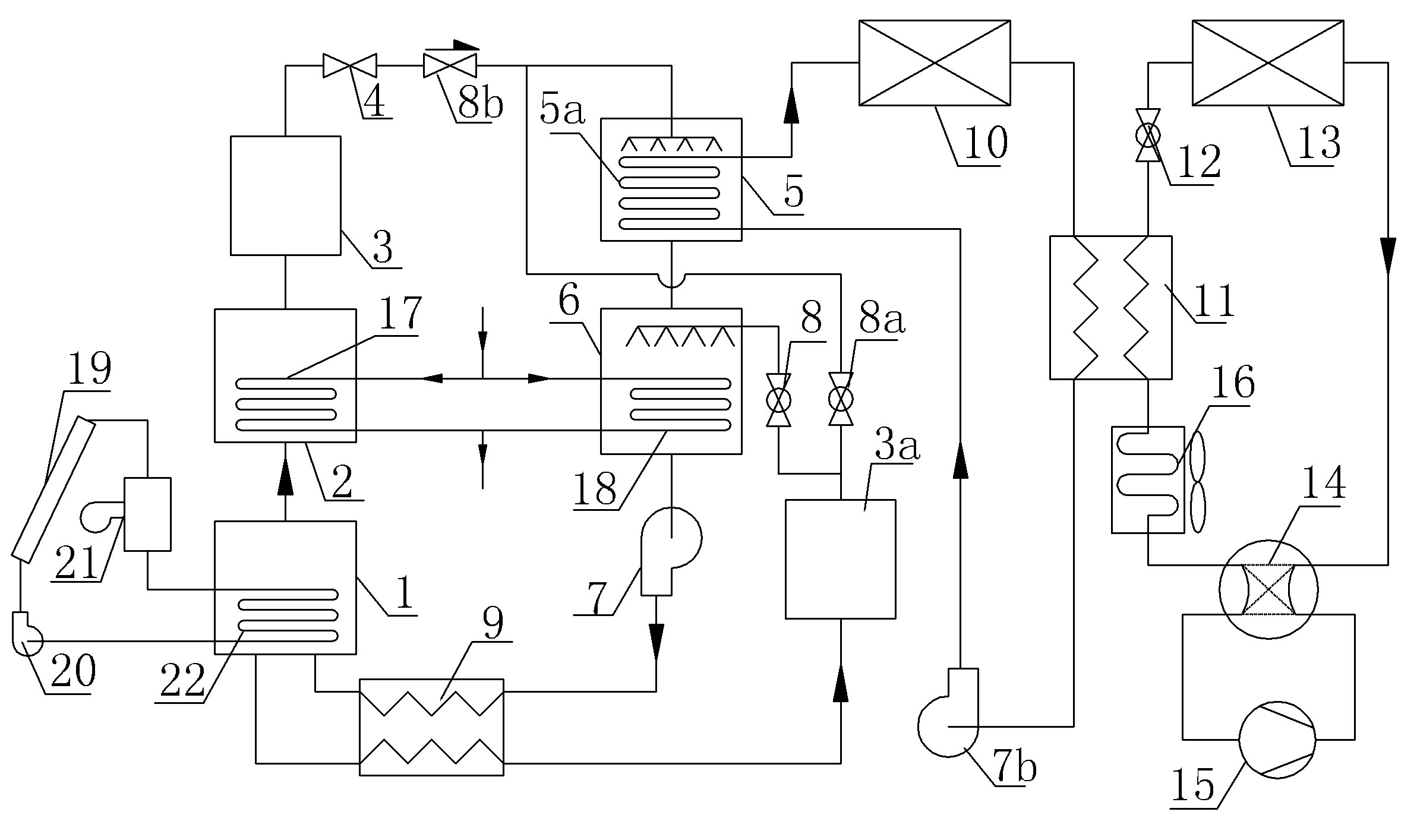

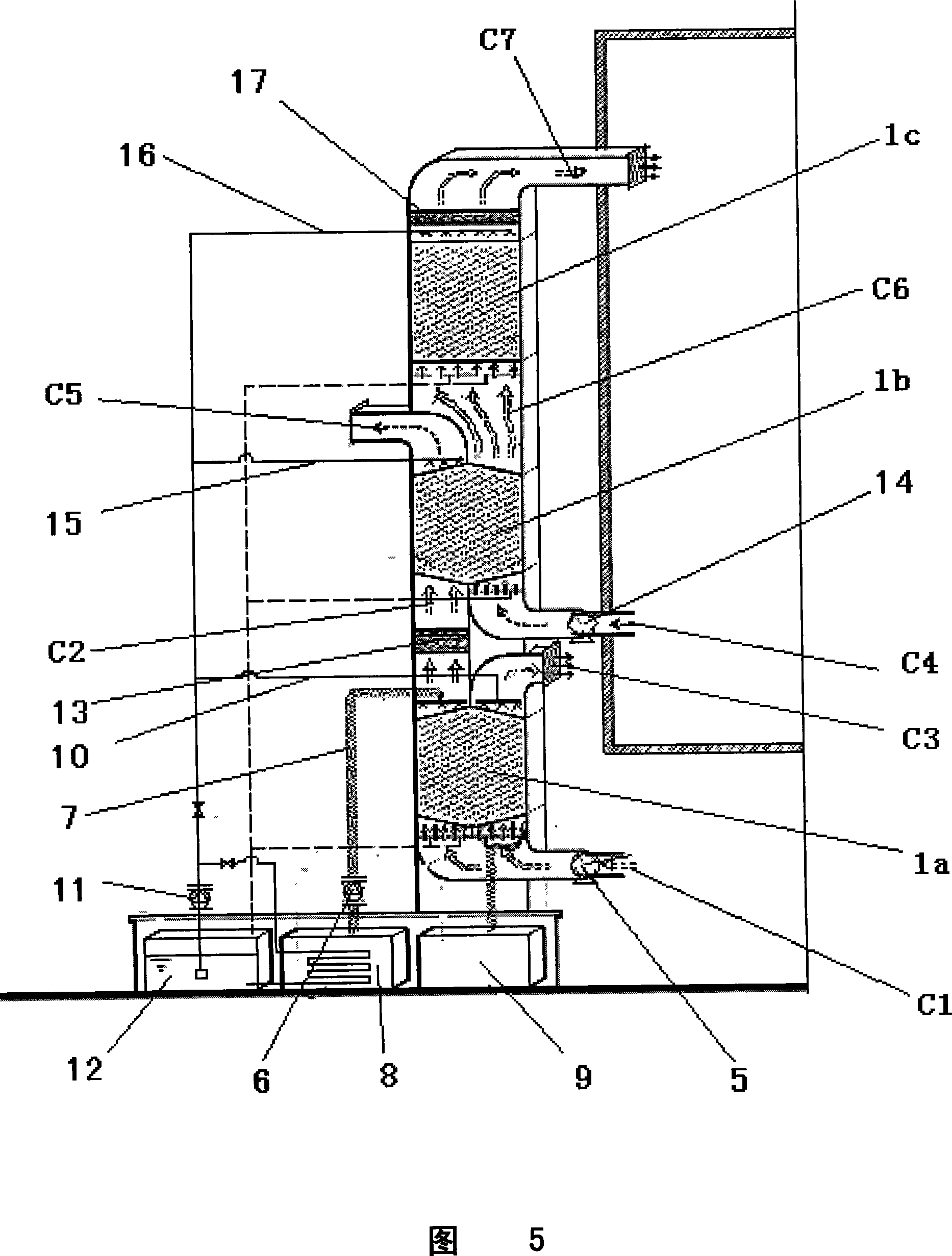

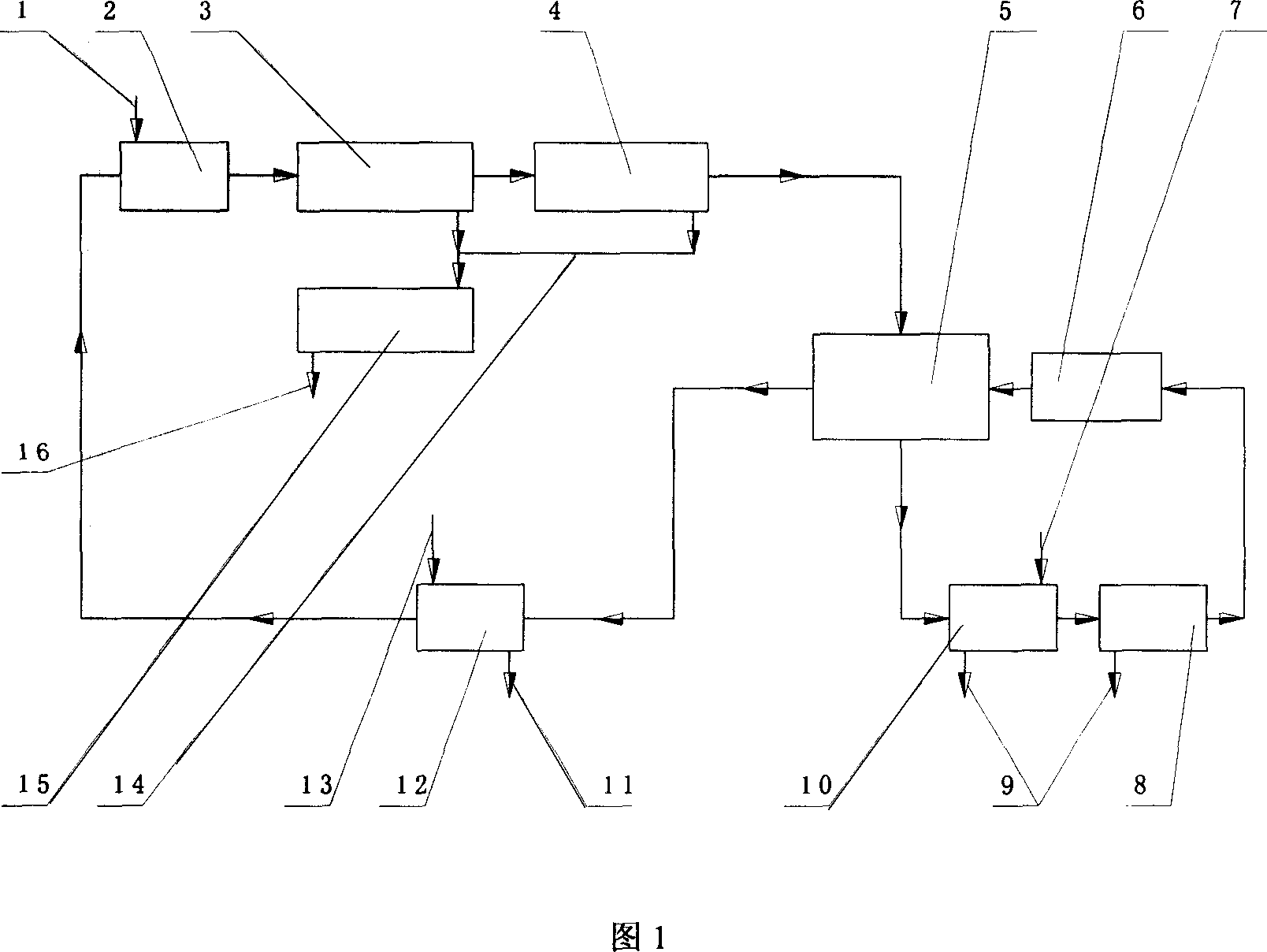

Solar energy and electric energy combined heat pump system and cooling and heating method

InactiveCN101963412ATo achieve hierarchical utilizationContinuously workingHeating and refrigeration combinationsThermal energyIntermediate heat exchanger

The invention discloses a solar energy and electric energy combined heat pump system and a cooling and heating method. The heat pump system comprises a solar energy absorption heat pump unit, an intermediate work medium circulating device and a compression heat pump unit, wherein a solar drive absorption heat pump drives the absorption heat pump unit to prepare a lower-temperature intermediate work medium or higher-temperature intermediate work medium; the intermediate work medium bears partial / all cold energy / heat energy required by a user through first heat mass exchange equipment, and enters an intermediate heat exchanger of the compression heat pump unit for heat exchange; and the cold energy / heat energy contained in the intermediate work medium is recycled once again through the heat pump unit so as to save the electric consumption of the compressor of the compression heat pump unit. The system realizes high-efficiency utilization of a low-level renewable energy source solar energy, and has the advantages of stable and reliable operation, efficient energy utilization, good energy-saving effect and wild application prospect.

Owner:HENAN UNIV OF SCI & TECH

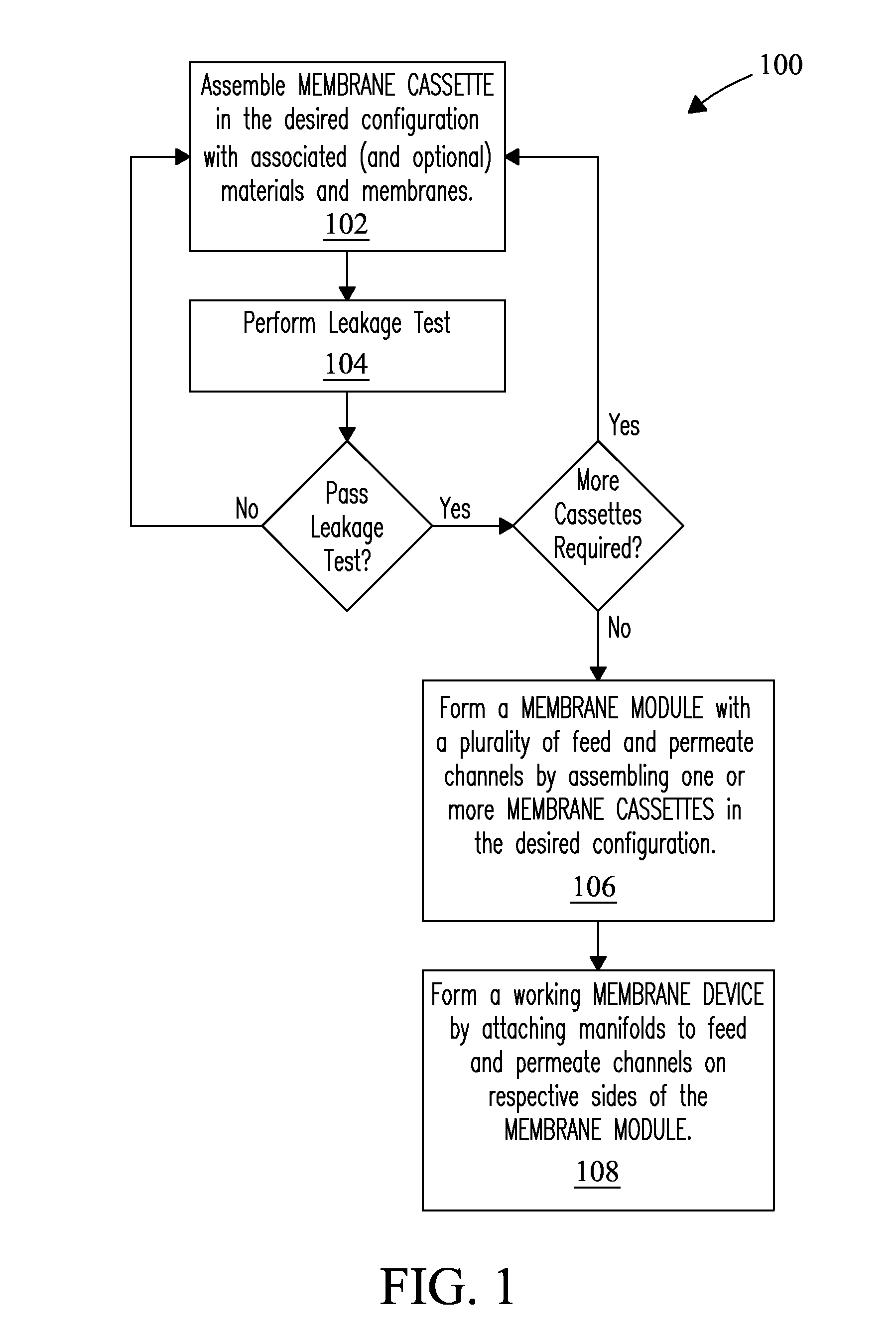

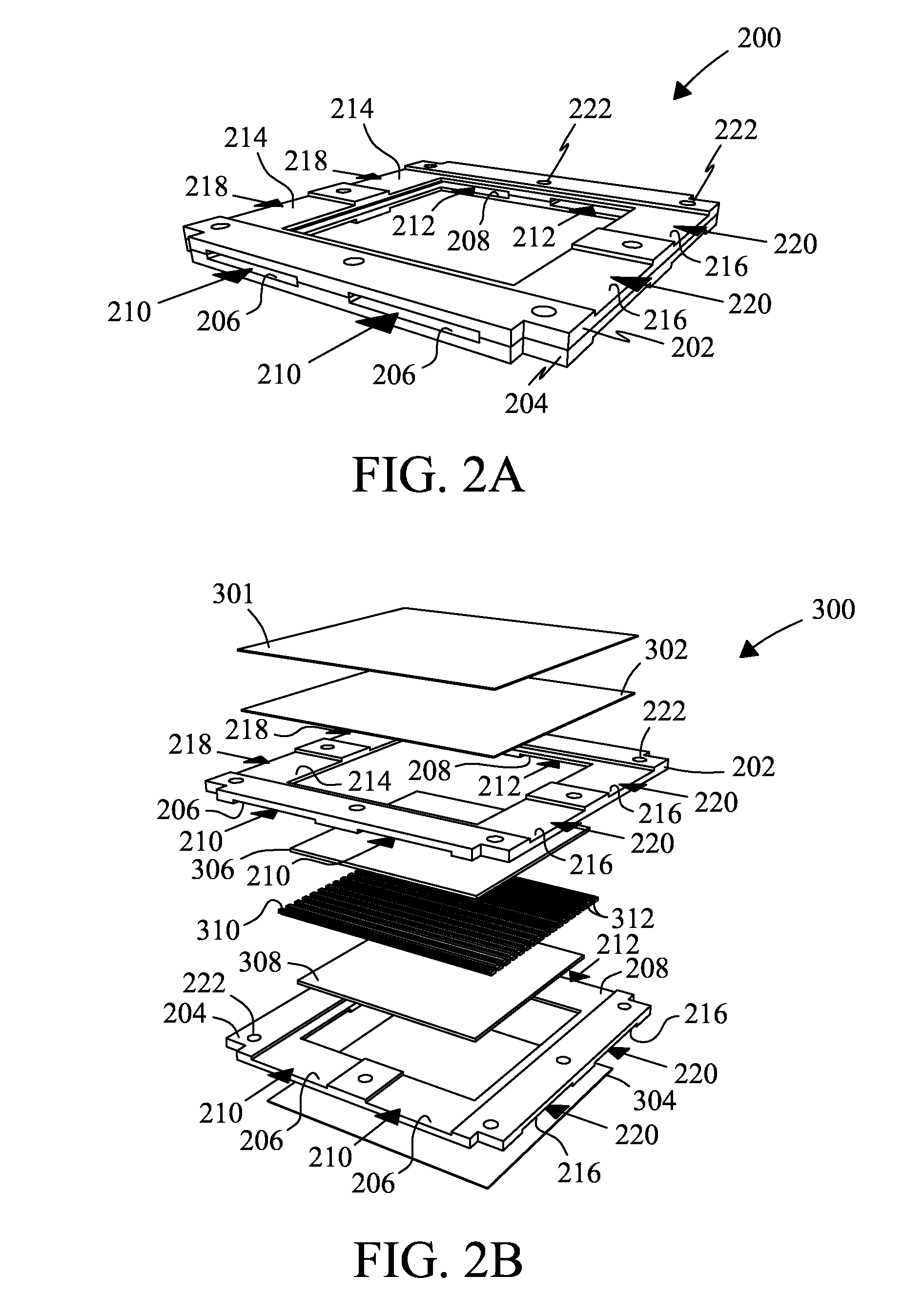

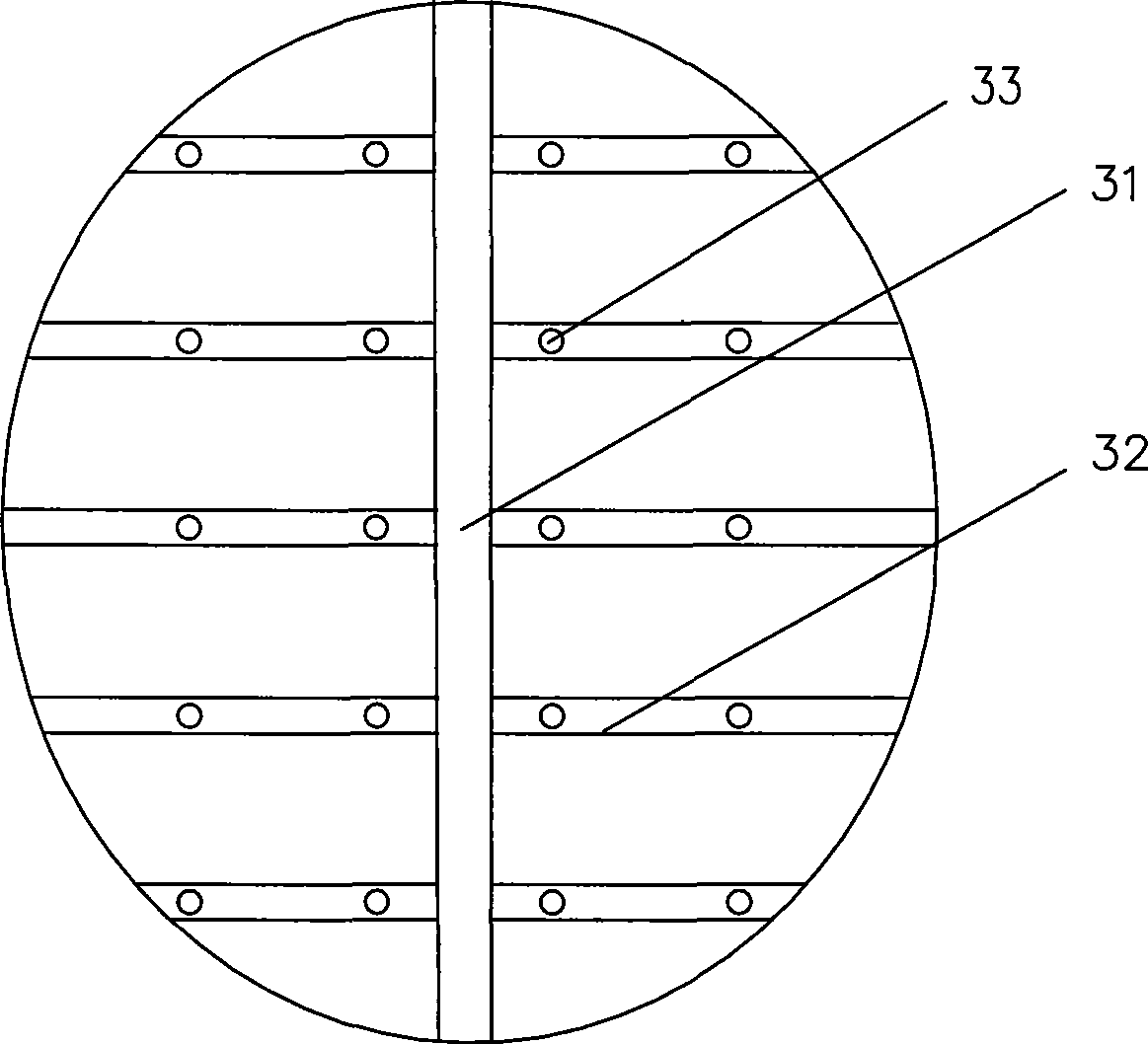

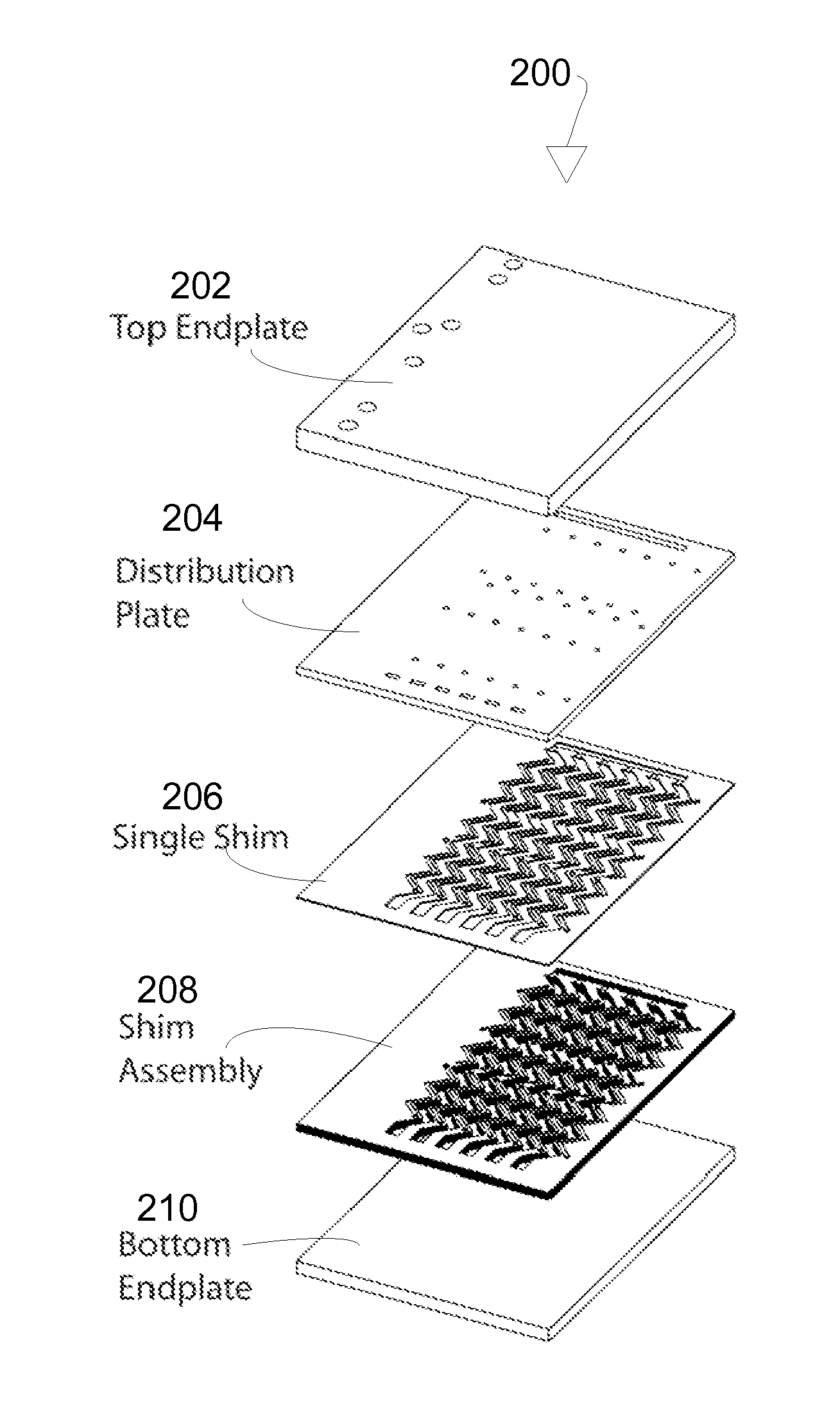

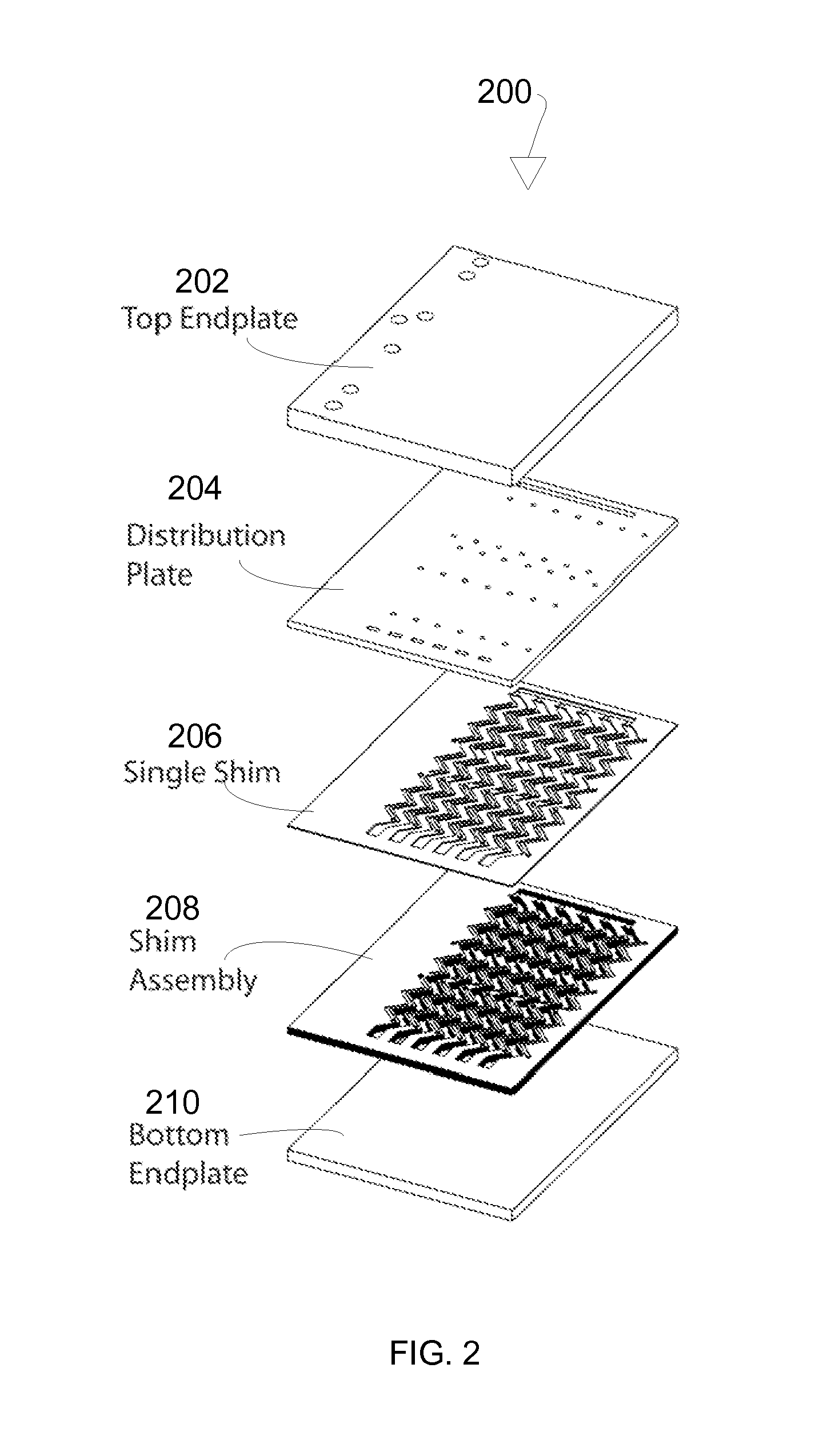

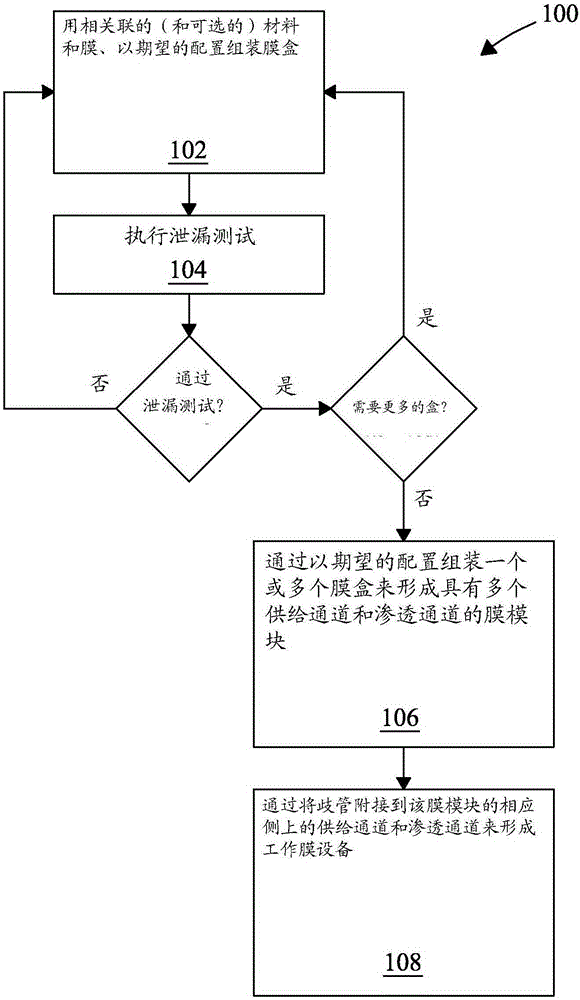

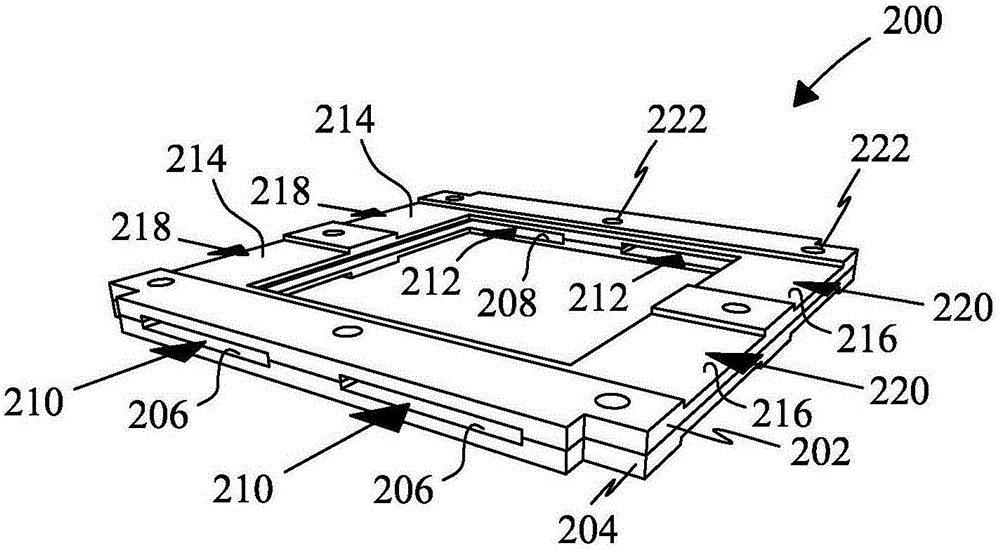

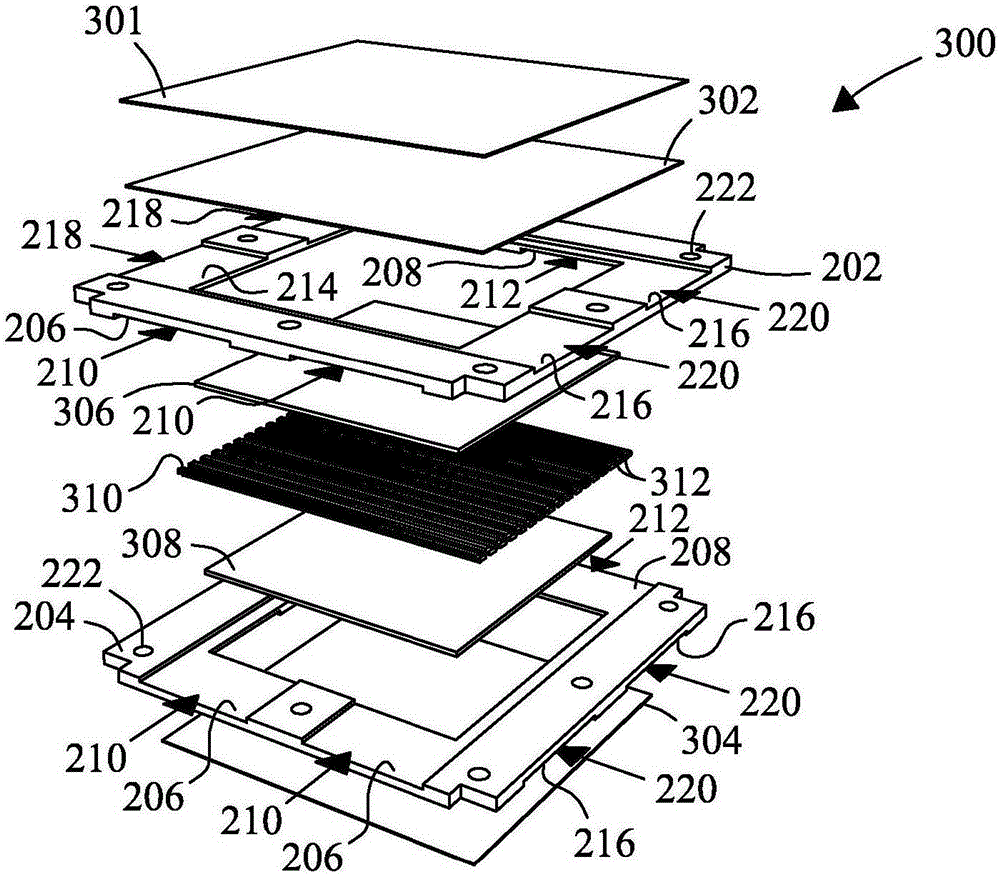

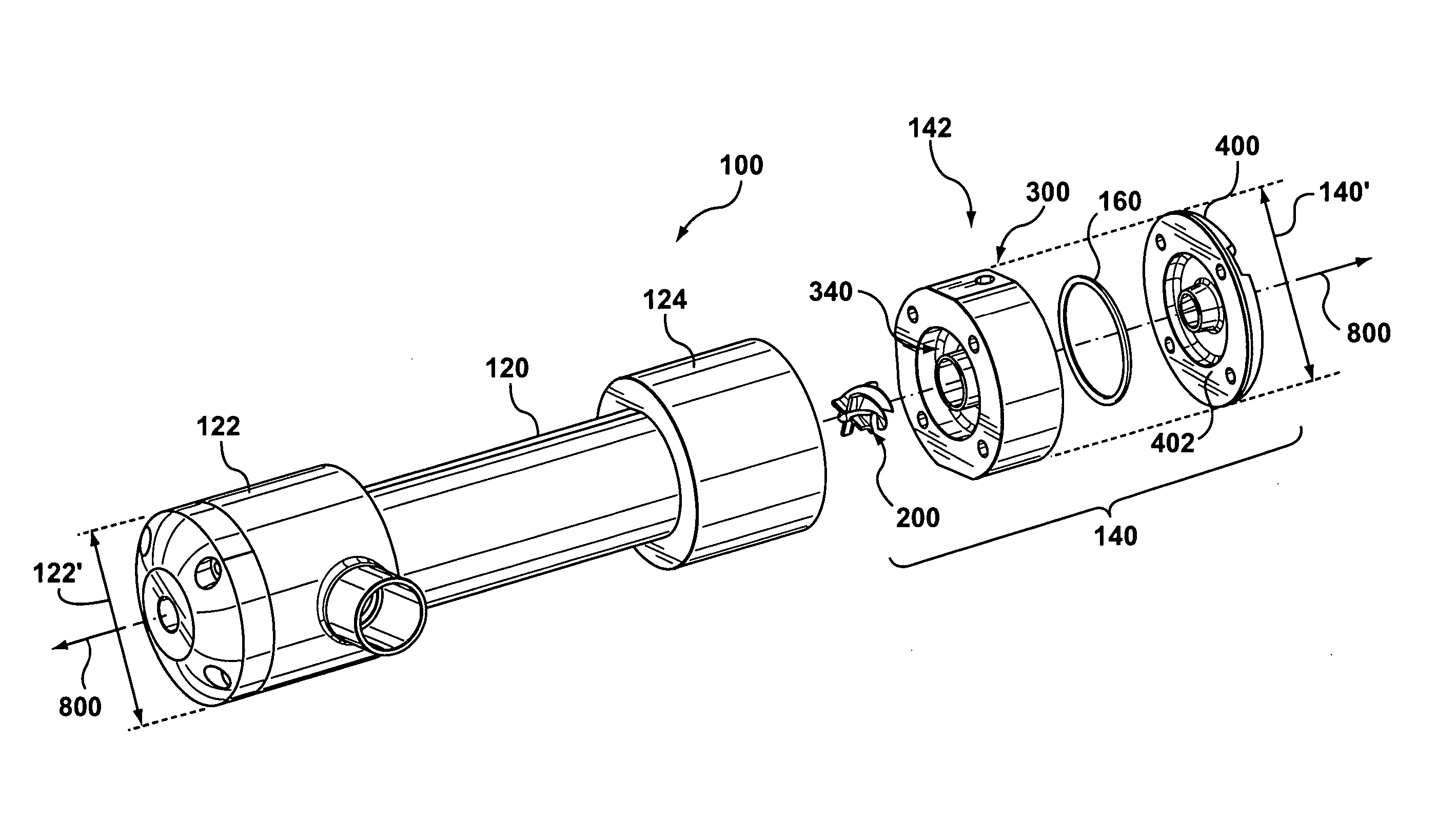

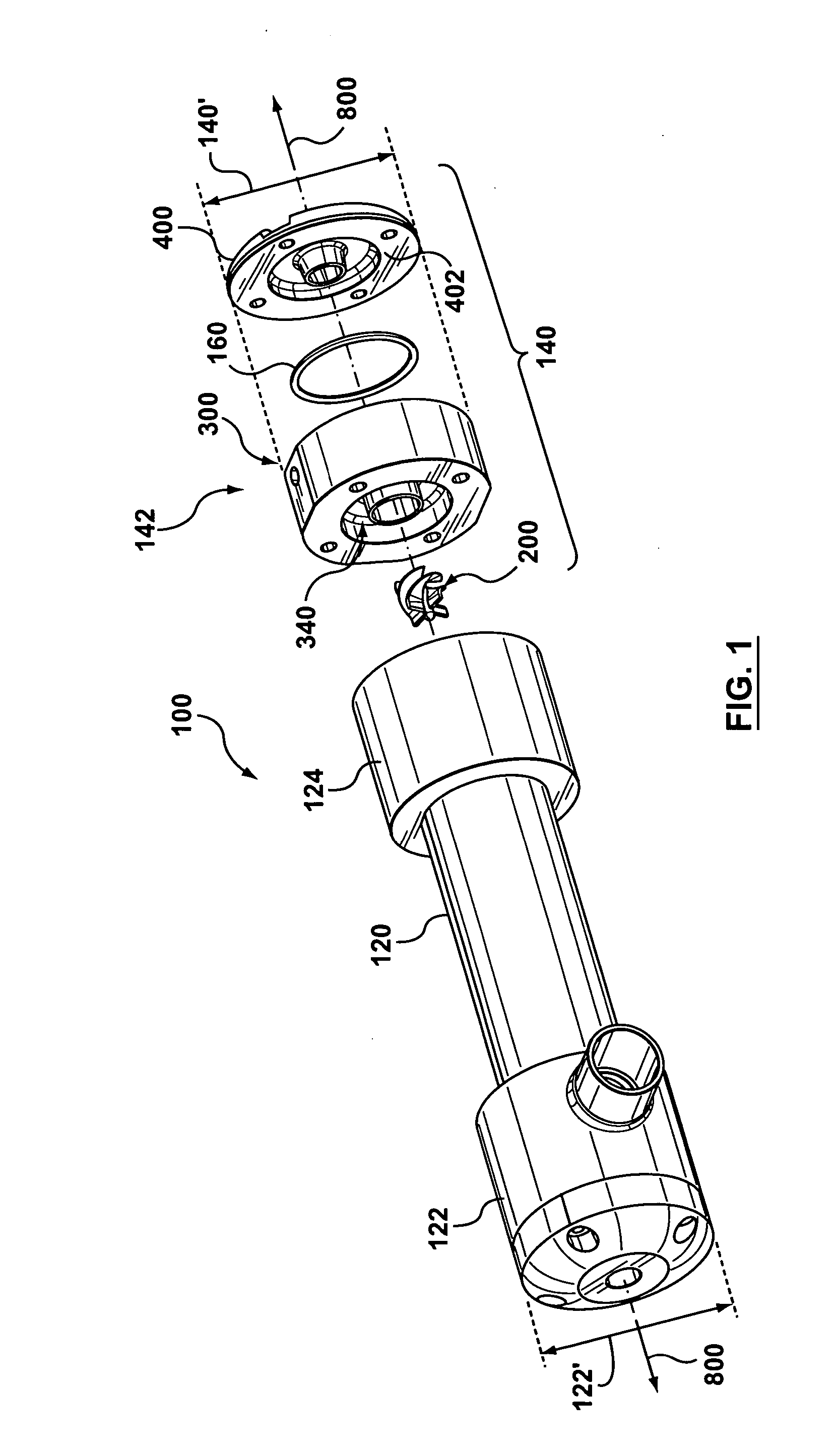

Membrane device and process for mass exchange, separation, and filtration

ActiveUS20140238235A1Reduce and minimize transportMinimize flow resistanceLighting and heating apparatusUltrafiltrationChemical physicsFiltration

A membrane device and processes for fabrication and for using are disclosed. The membrane device may include a number of porous metal membranes that provide a high membrane surface area per unit volume. The membrane device provides various operation modes that enhance throughput and selectivity for mass exchange, mass transfer, separation, and / or filtration applications between feed flow streams and permeate flow streams.

Owner:BATTELLE MEMORIAL INST

Flue gas waste heat recovery method and system for oil and gas boiler

InactiveCN101398181AReduce the burden onTo achieve the purpose of pre-coolingLighting and heating apparatusCombustion technology mitigationRecovery methodFlue gas

The invention discloses a recycling method and a system for the afterheat of the smoke gas of oil and natural gas boilers. The method comprises the steps as follows: the smoke gas with high temperature is pre-sprayed and cooled in the inlet pipe seat of the smoke gas with high temperature through a nozzle before entering the main cylinder of an afterheat recycling device; the smoke gas with high temperature after being pre-sprayed and cooled is led to enter into the main cylinder along the tangent direction of the main cylinder, rotate and float upwards in the main cylinder; the smoke gas with high temperature which rises in a rotating way is mainly sprayed and cooled in the middle upper part of the main cylinder through the nozzle; the smoke gas with high temperature flows out of the main cylinder from the upper part of the main cylinder after conversely contacting and changing heat with spraying water fog. In the invention, pre-spraying and cooling are adopted to lead the smoke gas with high temperature to be directly contacted and mixed and change heat with the spraying and cooling water fog when the smoke gas with high temperature passes through a smoke gas inlet; on one hand, the burden of a mist trap can be reduced; on the other hand, the burden of heat and mass exchange of the main cylinder can be reduced, thus leading the volume of the main cylinder to be smaller and the structure of the main cylinder to be more compact.

Owner:GUANGZHOU DESHANG ENERGY TECH

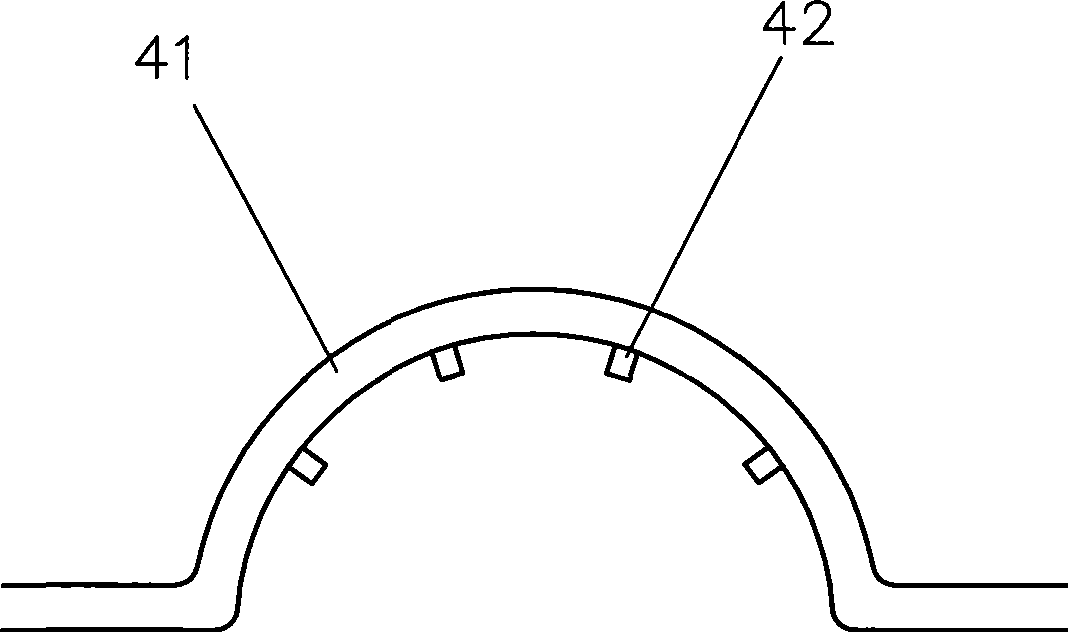

Double-layer air curtain system for refrigeration storage

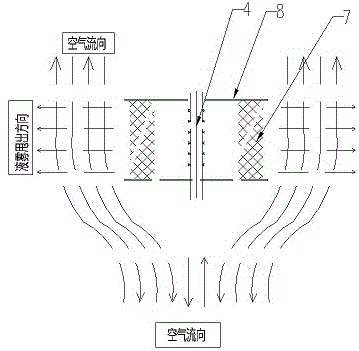

InactiveCN102798191ASimple structureEasy to operateLighting and heating apparatusAir currents for screeningCold airEngineering

The invention relates to a double-layer air curtain system for a refrigeration storage, and the double-layer air curtain system is provided with two different air curtain devices. The system is composed of a cross-flow air curtain machine, a centrifugal air curtain machine, a grating, a flow guide plate, manual-type adjusting switches, a hanging plate, a fastening screw, and a wiring terminal. In the system, the cross-flow air curtain machine is installed on the outside wall body of the refrigeration storage, a cross-flow fan is used for injecting a normal-temperature airflow so as to form an air curtain, and the air curtain is used for preventing hot air outside the storage from intruding into the storage; simultaneously, the centrifugal air curtain machine is installed on the inside wall body of the refrigeration storage, a centrifugal fan is used for injecting a low-temperature airflow, and the low-temperature airflow is used for preventing cold air in the storage from flowing outwards, and maintaining a low-temperature environment in the storage. The manual-type adjusting switches at the both sides of each of the air curtain machines are used for adjusting the air supply speed and the air supply angle of the air curtain, so that the heat-insulating effect of the air curtain can be improved. By virtue of the system, the sealing performance of the air curtain of the refrigeration storage is improved, air heat and mass exchange in the areas of the both sides of the air curtain is effectively suppressed, and an energy-saving effect is achieved; simultaneously, the system has dustproof, anti-pollution, anti-mosquito effects and the like, and is especially suitable for refrigeration storages for storing foods.

Owner:SHANGHAI OCEAN UNIV

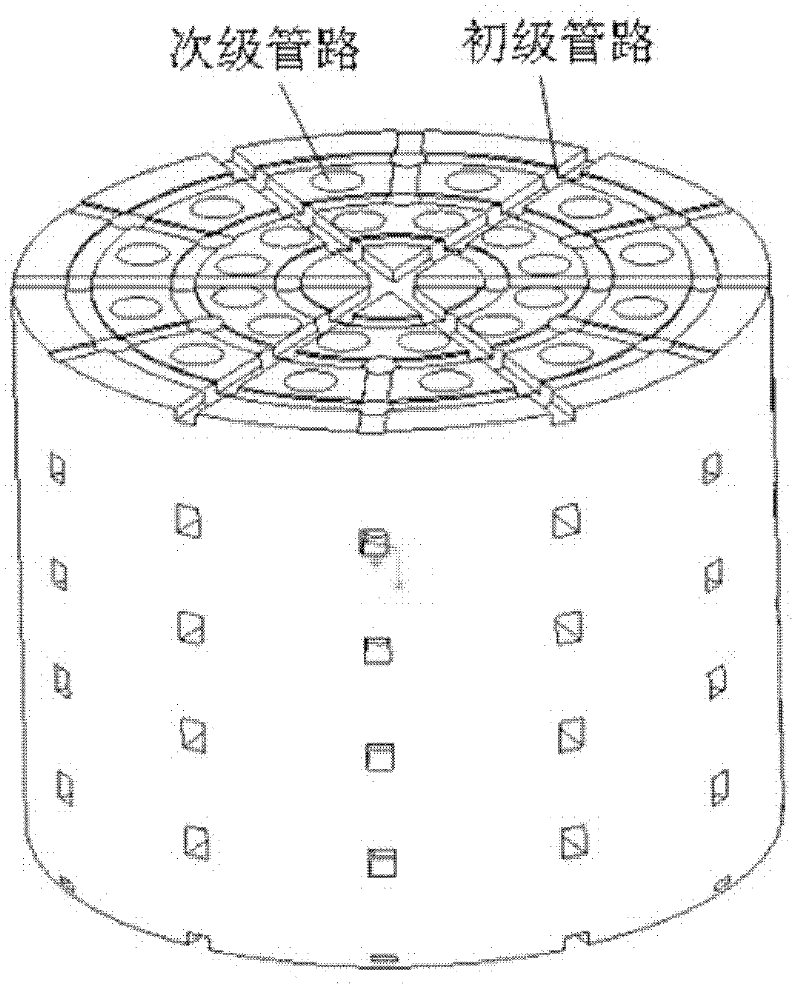

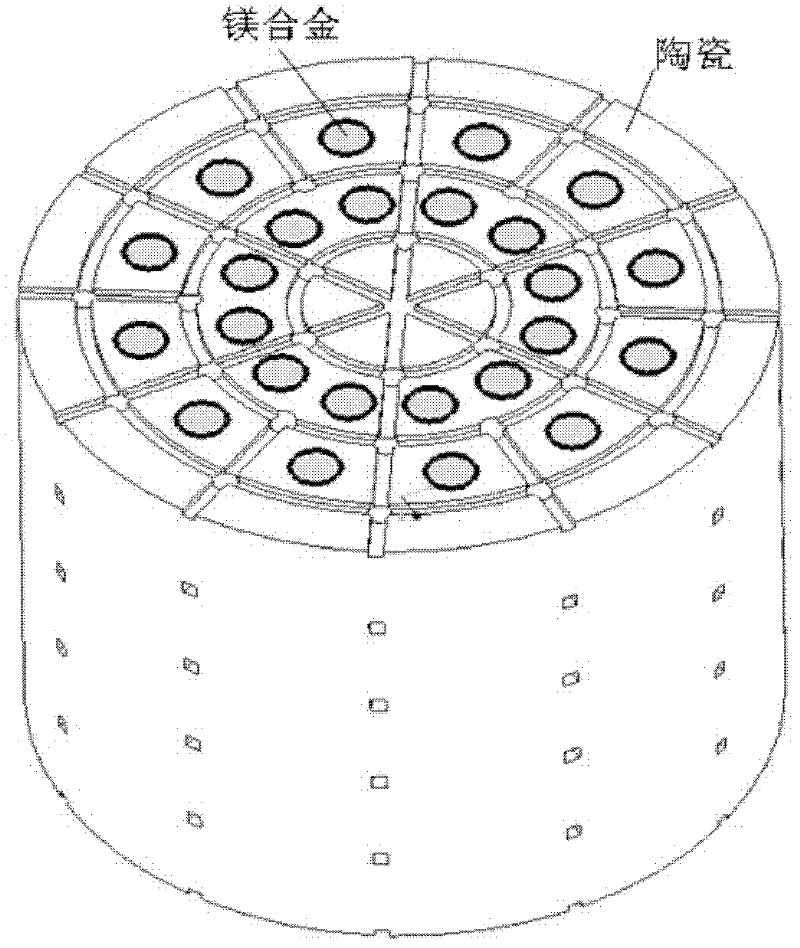

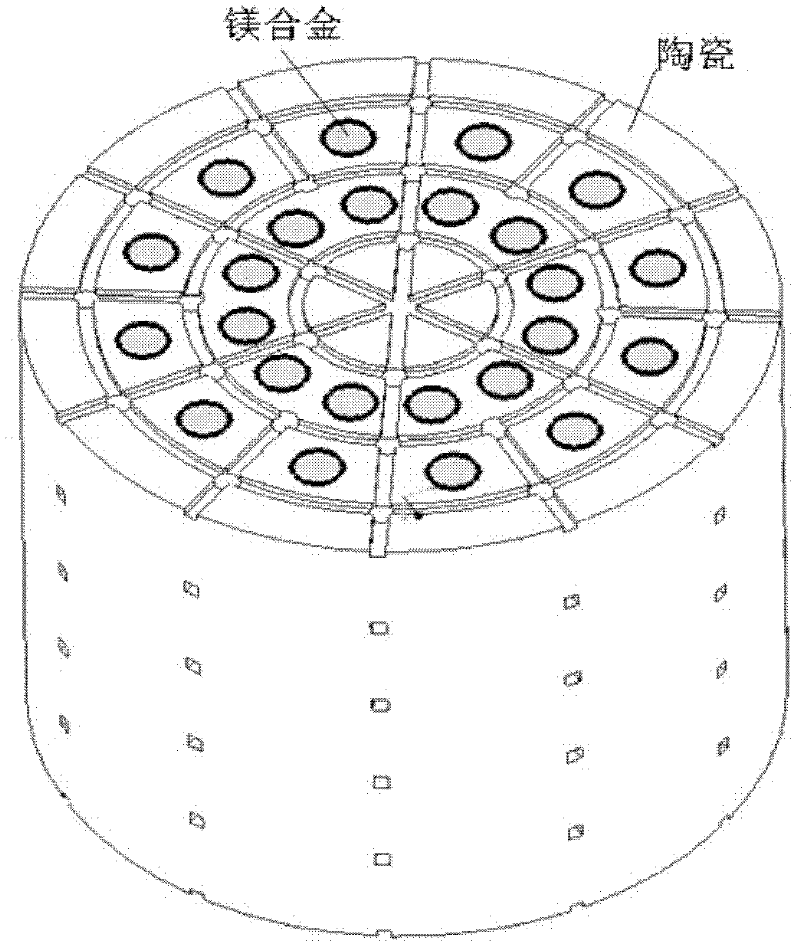

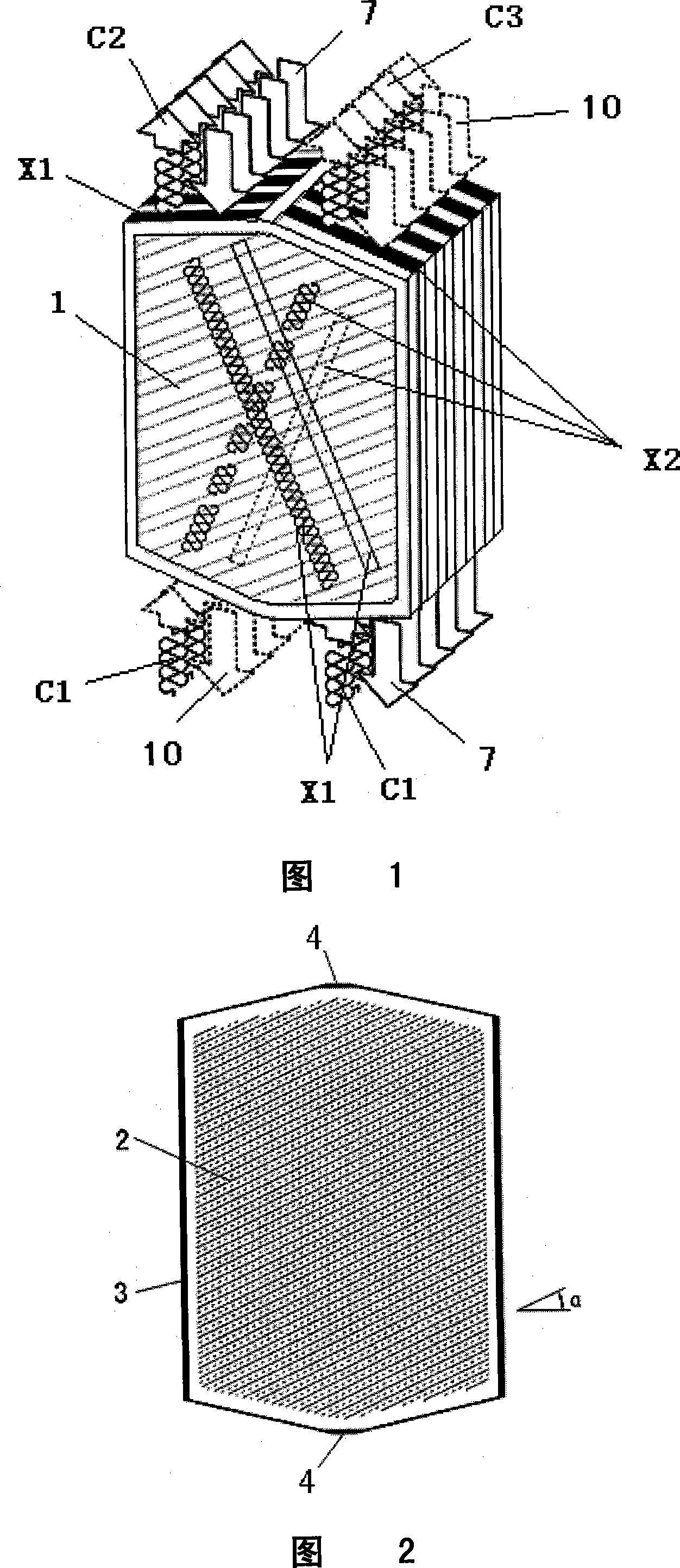

Porous magnesium alloy/biological ceramic bionic composite support and quick forming method thereof

ActiveCN102327648AImprove mechanical propertiesContinuous mechanical strengthBone implantBiomechanicsRapid prototyping

The invention relates to a porous magnesium alloy / biological ceramic bionic composite support and a quick forming method thereof. The quick forming method comprises the following steps of: performing appearance relativity, microstructural bionic design and structural optimization by means of reverse engineering and a computer-aided design (CAD) technology on the basis of analytical results of structures and biomechanics of different bone coloboma parts to establish a CAD model of the support; manufacturing a porous bioactive ceramic frame with two stages of pipelines which are not communicated mutually by a method for forming ceramics directly by photocuring; and casting molten magnesium alloy into a secondary pipeline of the biological ceramic frame by a vacuum suction casting method, cooling and solidifying to obtain the porous magnesium alloy / biological ceramic bionic composite support, wherein a primary pipeline is used for meeting the requirements of tissue growth and nutritionalmetabolism, and the magnesium alloy is filled into the secondary pipeline to enhance the mechanical property of the composite support and reduce a contact area of the magnesium alloy and body fluid, so that mass exchange of the magnesium alloy and a human body environment is avoided within a period of time of degrading ceramics to ensure the filled magnesium alloy provides continuous mechanical strength in the process of bone healing.

Owner:XI AN JIAOTONG UNIV

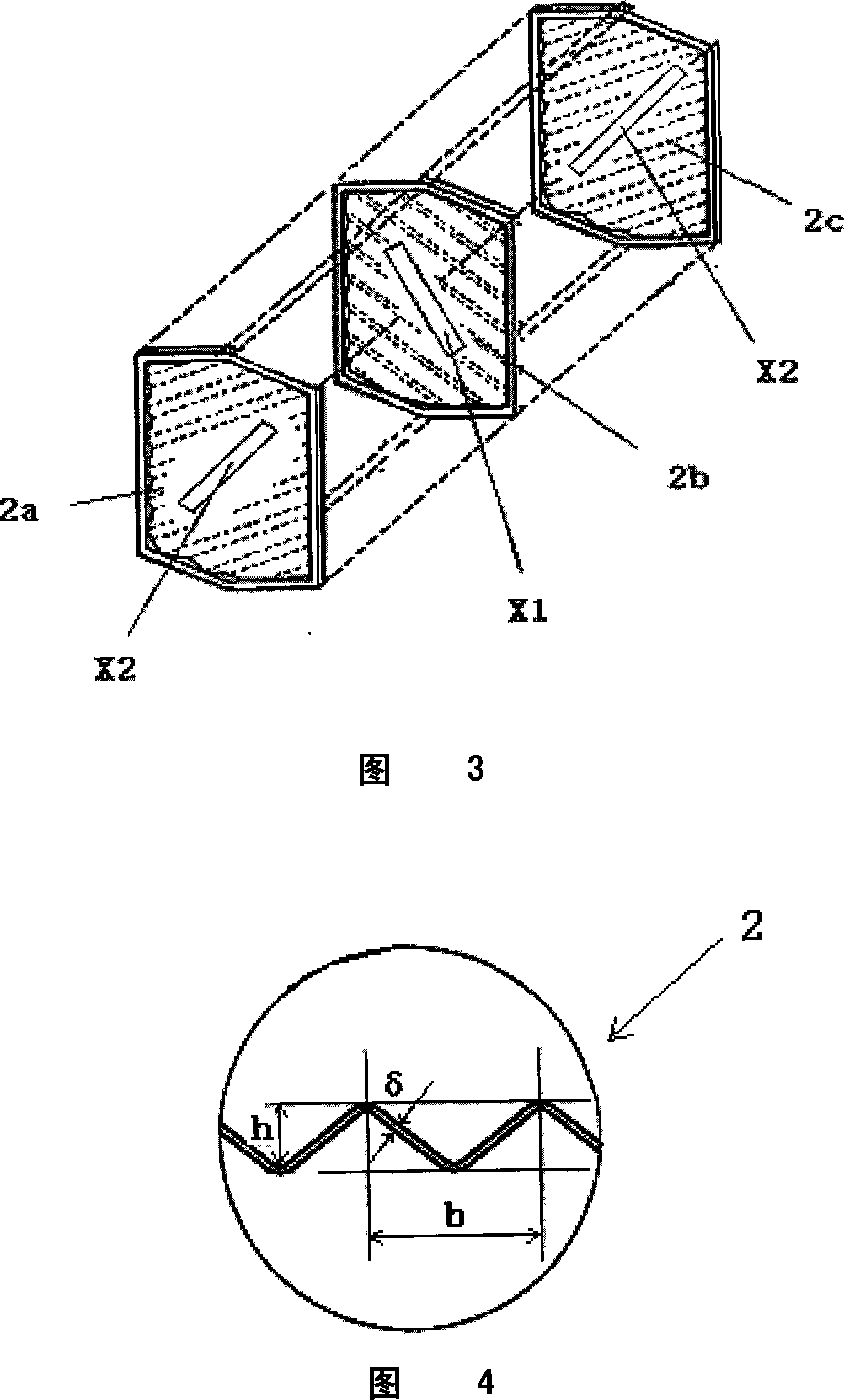

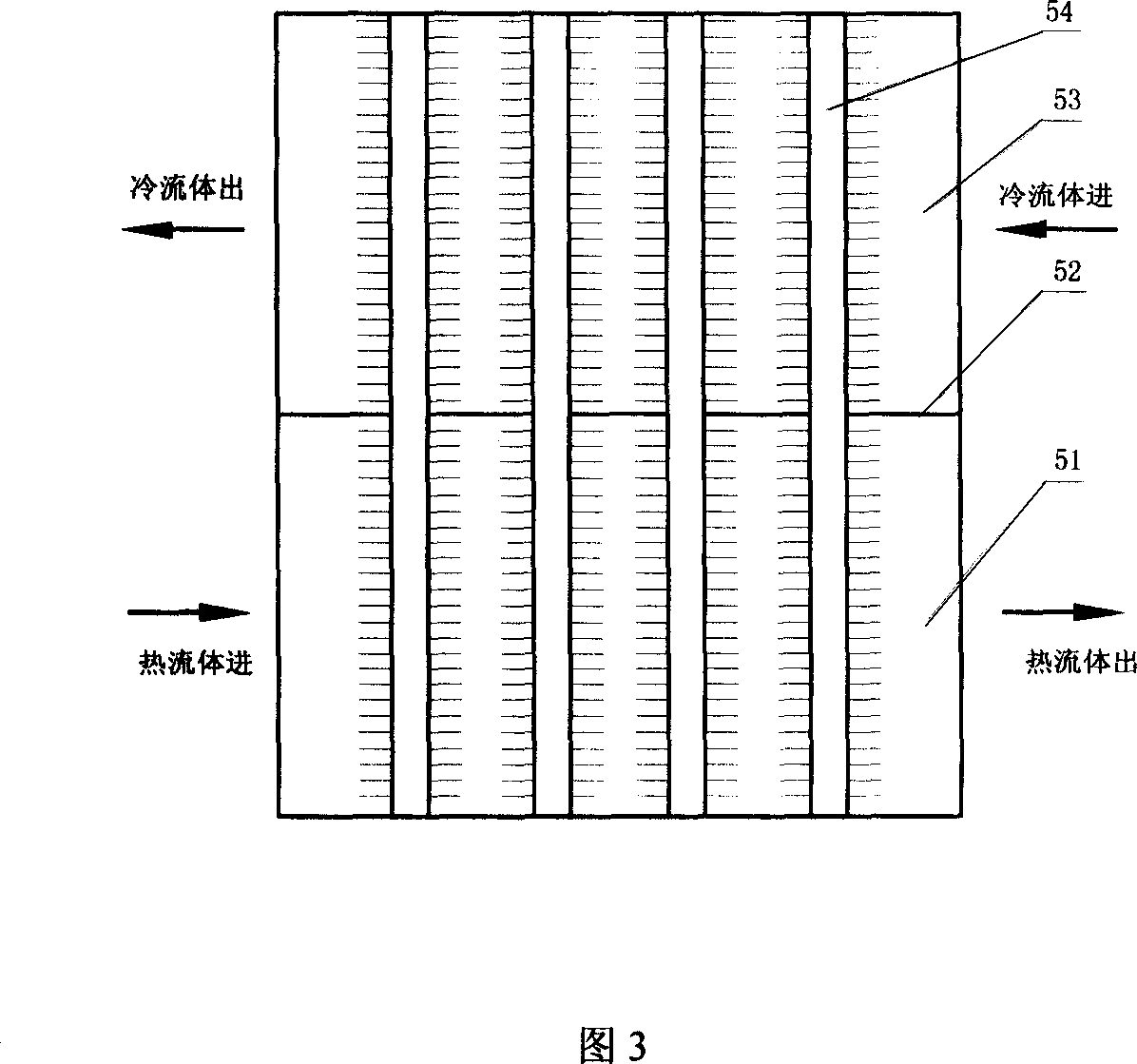

Corrugated plate type water evaporation and cooling type heat exchanging tampering device

InactiveCN101187486ASmall pressure dropHydrophilicLighting and heating apparatusAir conditioning systemsVoid ratioEvaporation

The invention relates to a corrugated plate water evaporative cooling heat and mass exchanger, which is characterized in that the invention comprises a plurality of plastic sheets which are provided with twill weaves, the adjacent plastic sheets are mutually alternatively arranged according to the direction of the corrugation. The two sides of the plastic sheet are respectively bounded with supporting frames which are arranged on the two sides of the plastic sheet into a whole, and the top portion and the bottom portion of the plastic sheet are respectively bounded with a supporting flattop which is horizontally arranged on the top portion and the bottom portion of the plastic sheet into a whole. The invention can be widely applied to a cooling dehumidifying system of an air-conditioner. The positive and negative of each layer of corrugated plastic medium are alternatively bounded in the direction of the corrugation, which can not only exchange two different quality of humid heat in two channels simultaneously, but also utilize the heat exchange between the adjacent channels to cooling down the temperature when in dehumidifying. The invention has a good fluid distribution, the surface area S of the rate of heat and mass exchange can achieve 350-700m2 / m3, void ratio beta can achieve 90-95%. The invention can be widely applied in a new generation of dehumidifying evaporating cooling, or evaporating and indirect evaporating cooling air-conditioning systems.

Owner:黄之栋 +2

Twin-vortex micromixer for enforced mass exchange

InactiveUS7794136B2Well mixedImprove mixing efficiencyOther chemical processesFlow mixersShortest distanceLab-on-a-chip

The present invention discloses a vortex-modulation based micromixer for enforced mass exchange. The micromixer of the present invention comprises a mixing chamber with grooves on one wall thereof and a special-shape barrier on another wall. As different fluids are injected into the mixing chamber respectively from two inlets of the micromixer, the grooves and barriers of the micromixer of the present invention create the constructive interferences to form the active-like agitation of the fluid. For every groove, the flux passed by can be increased via its high pressure gradient. Understandably, the mixing efficiency of the fluids can be greatly improved within a very short distance. At last, the outlet of the micromixer is located in the downstream of the mixing chamber and further is able to connect with other elements. The present invention is entirely a passive micromixer and no additional energy is required. The present invention can apply to a continuous chemical analysis, particularly to a lab-on-a-chip or a micro total analysis system.

Owner:NATIONAL TSING HUA UNIVERSITY

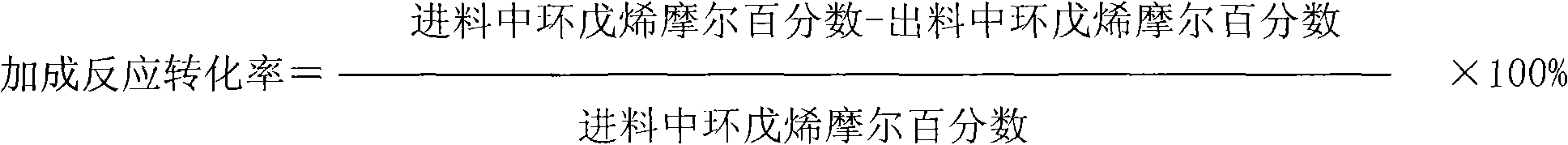

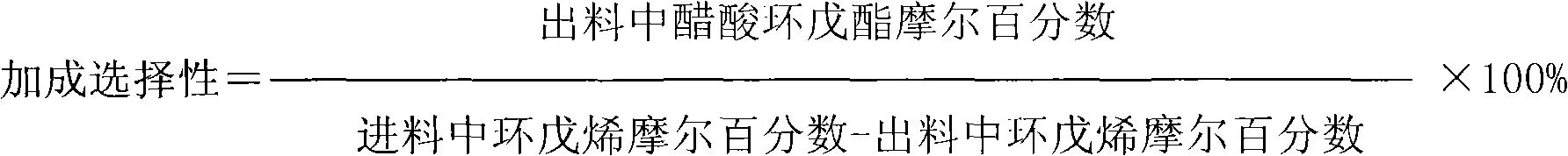

Method for preparing cyclopentanol from cyclopentene through indirect hydration method

ActiveCN102399133AEasy to recycleNo pollution in the processPreparation by alcoholysisProcess systemsCyclopentene

The invention relates to a method for preparing cyclopentanol from cyclopentene through an indirect hydration method. The method comprises steps that: liquid phase cyclopentene and acetic acid are subject to an addition reaction with a fixed-bed catalyst, such that cyclopentyl acetate is obtained, wherein the catalyst is sulfonic cation exchange resin with a mass exchange capacity of 3-5.5mmol / g;the product of the addition reaction is processed through rectification separation, such that refined cyclopentyl acetate is obtained; the refined cyclopentyl acetate is subject to an ester exchange reaction with methanol under the existence of a catalyst CaO, such that cyclopentanol and methyl acetate are produced; the produced methyl acetate is removed during the reaction process; the product of the ester exchange reaction is filtered, such that the catalyst is removed; and the obtained product is processed through rectification separation, such that the product cyclopentanol is obtained. The method provided by the invention provides substantial positive effects. The addition reaction and the ester exchange reaction have relatively high conversion rate and selectivity, and an average overall yield reaches approximately 80%. More importantly, no substance with high acidity and corrosivity is appeared in the reaction system during the whole reaction process. The raw materials which are not reacted can easily be recovered and reused, and almost no environment pollution is caused.

Owner:CHINA PETROLEUM & CHEM CORP +1

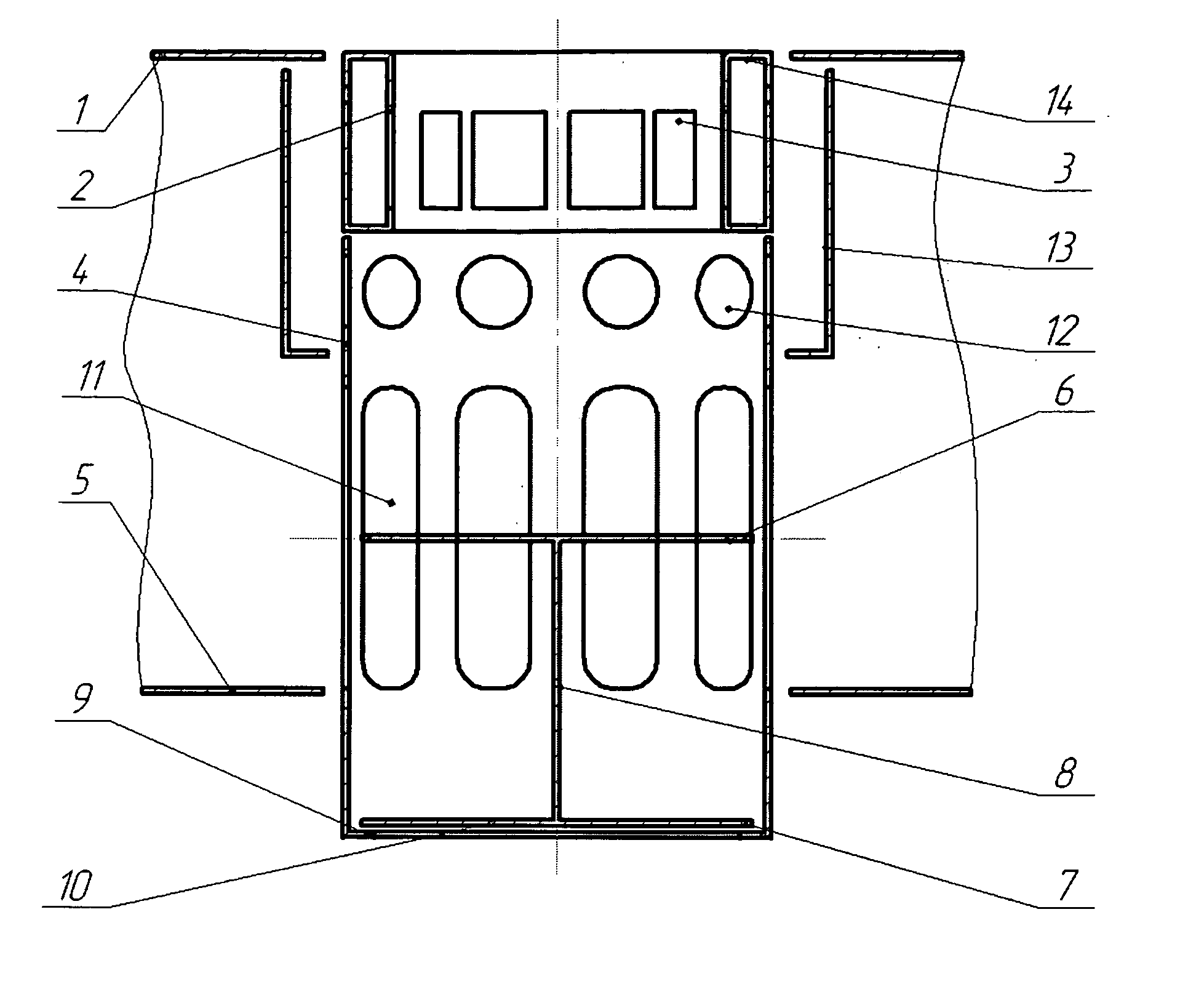

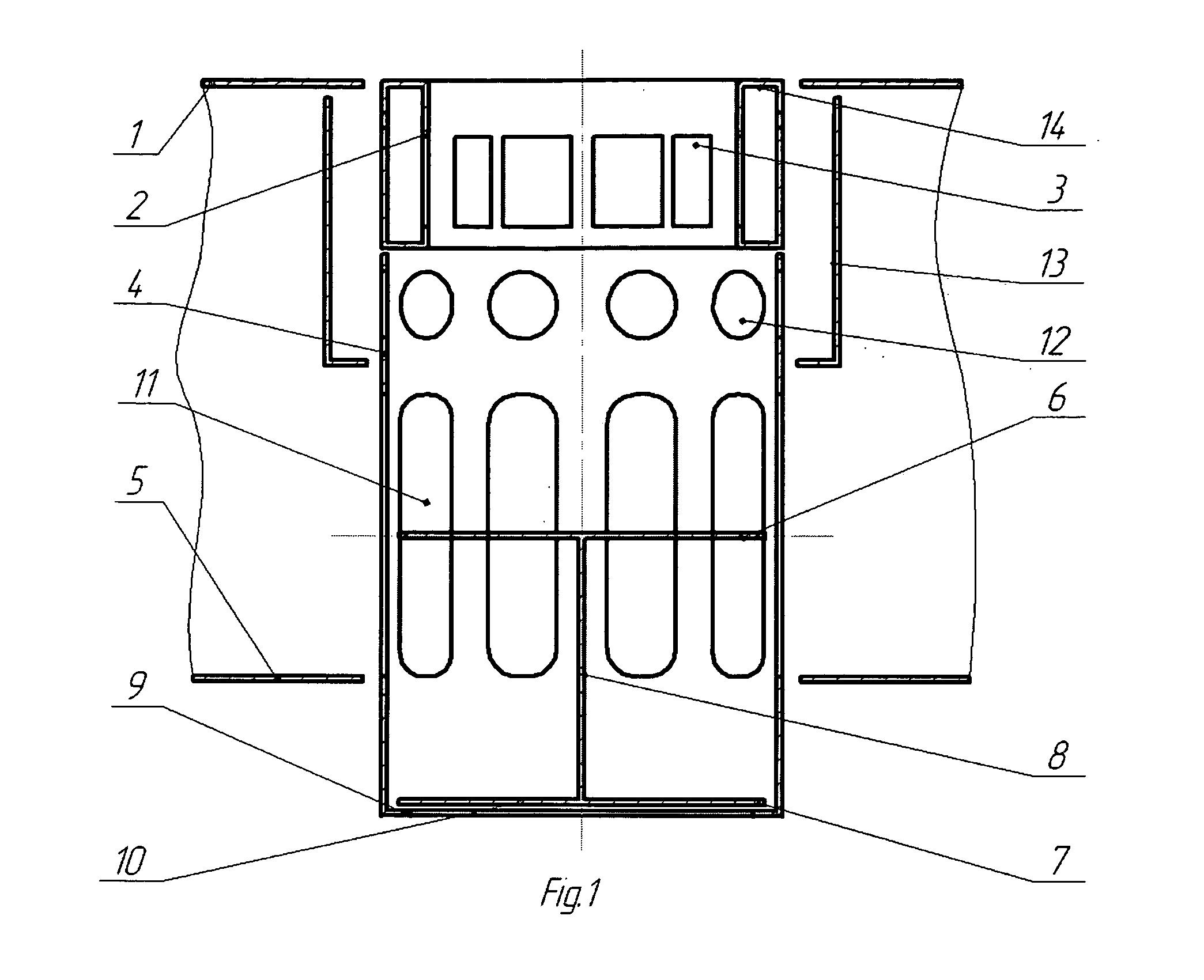

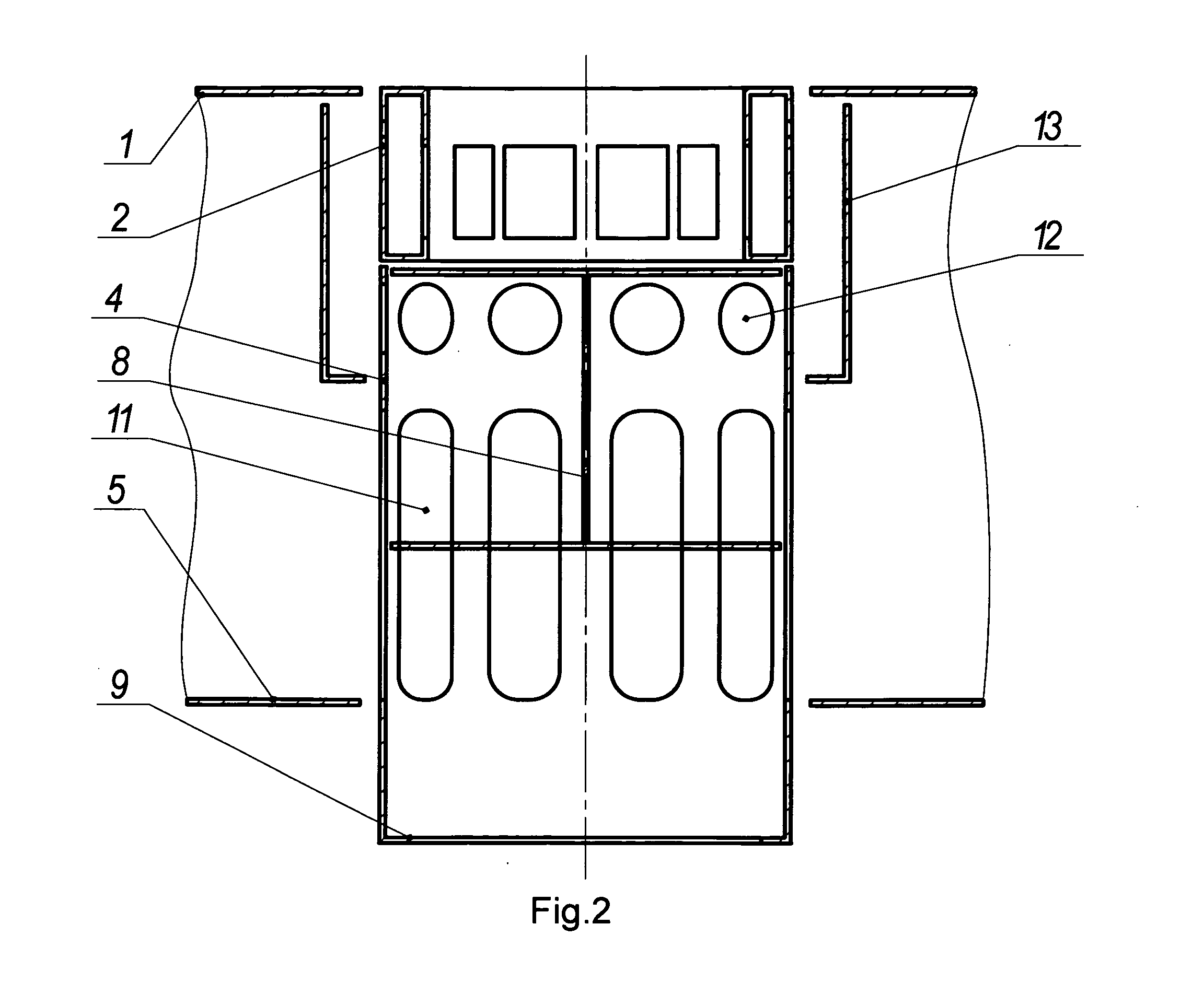

Mass exchange contact device

ActiveUS20100221156A1Increasing reliability and durabilityReduce metal contentUsing liquid separation agentMachines/enginesGratingCatalytic distillation

A mass-exchange contact device is proposed, comprising an upper tray, contact element including a barbotage unit configured as an inner cap with strips tangently bent out, a lower tray, a casing including a ring-shaped descending limiter, windows circumferentially disposed on the casing's walls (lower row), orifices circumferentially disposed on the casing's walls (upper row) above the windows, a double-acting valve composed of an upper and lower plates fixedly attached to a distance rod, and a cover bushing disposed coaxially to and around the upper region of casing embracing the contact element. Embodiments comprise a number of rows of the proposed devices situated one above the other, and separated by multi-layer packing fittings. In catalytic distillation columns, the fittings can be filled with catalytic material. Alternatively, the fitting is substituted with a grating that supports a catalytic granular layer. The device allows improving operation, reliability, durability, reducing its weight and costs.

Owner:MALETA BOGDAN +1

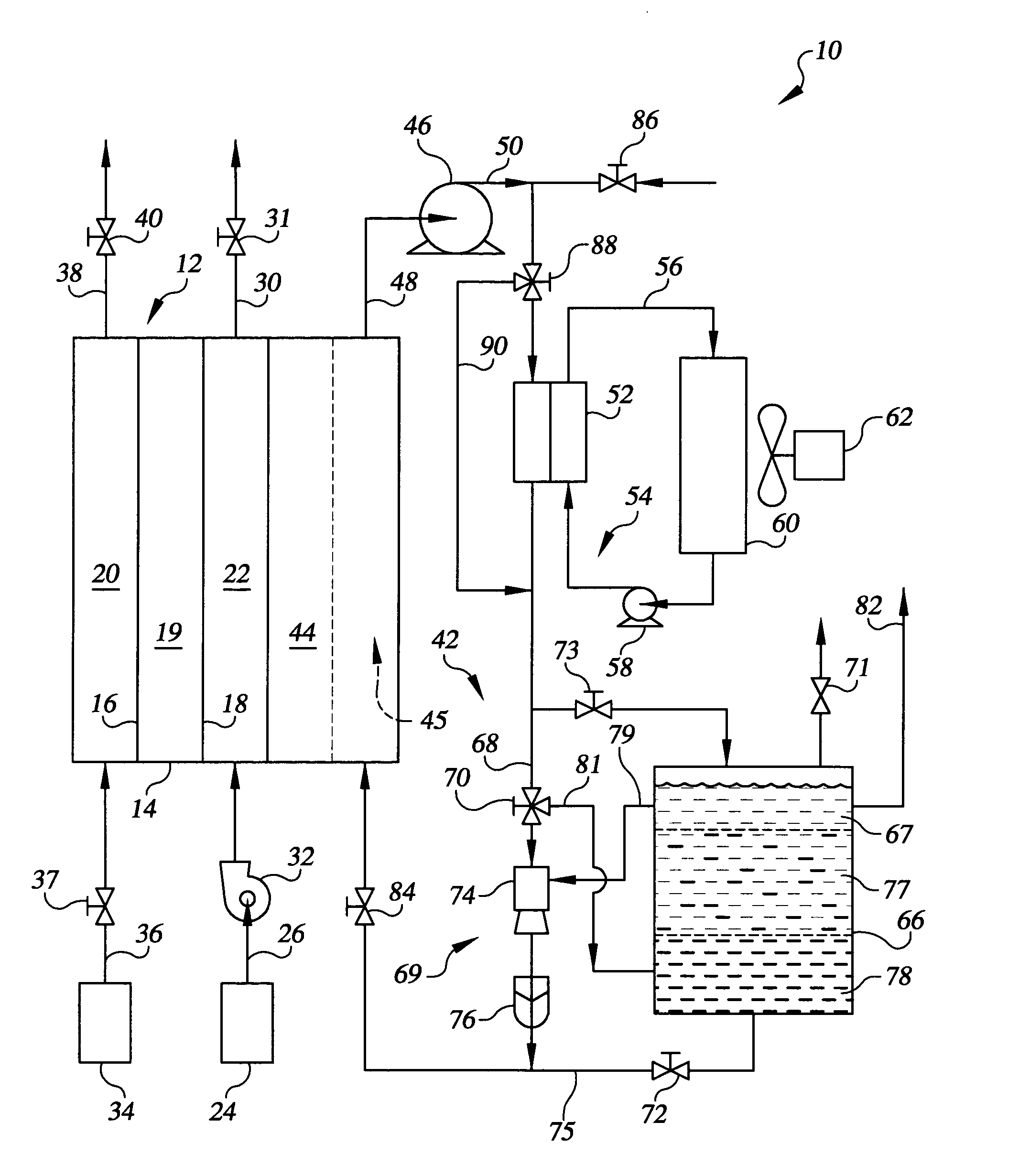

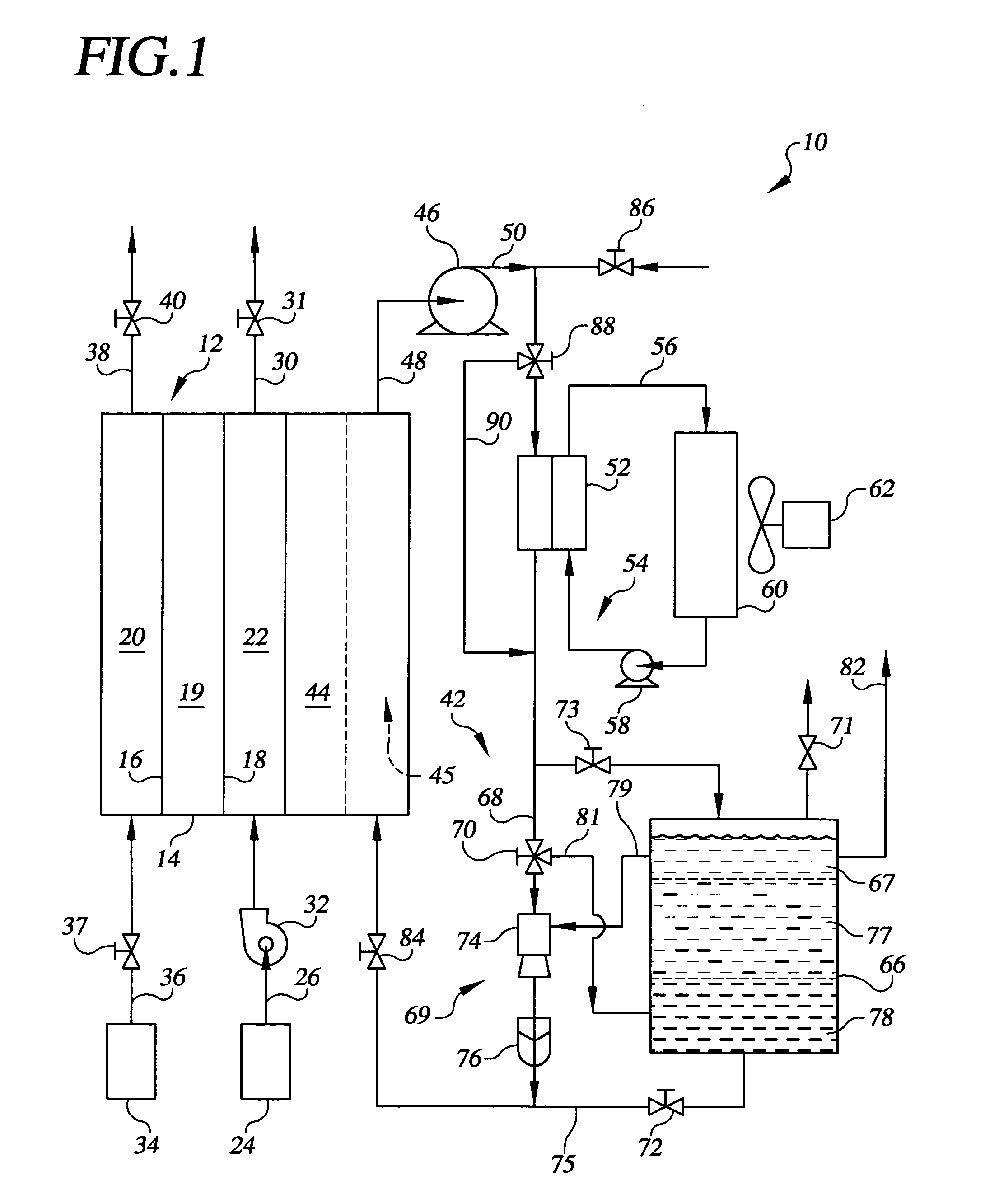

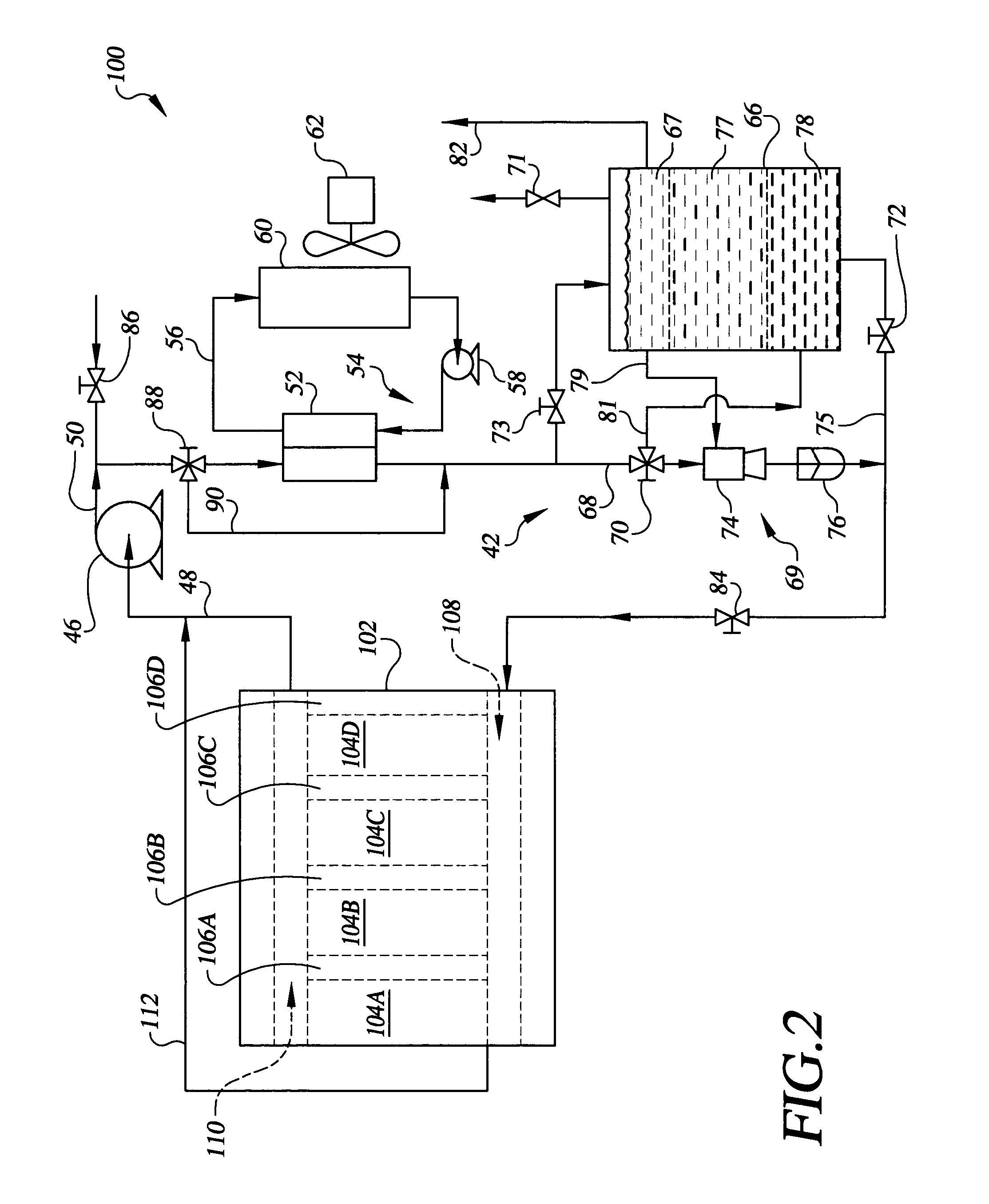

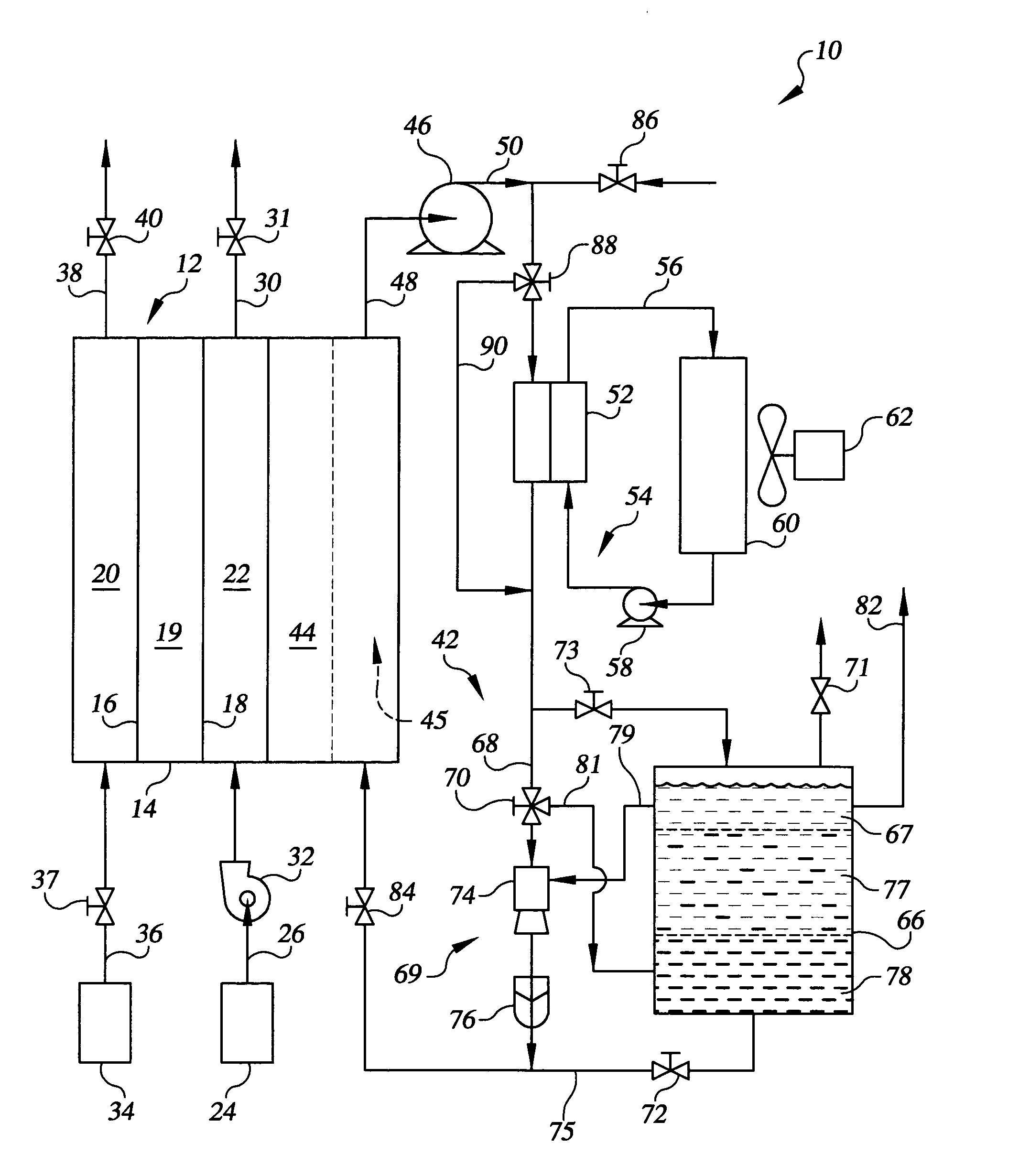

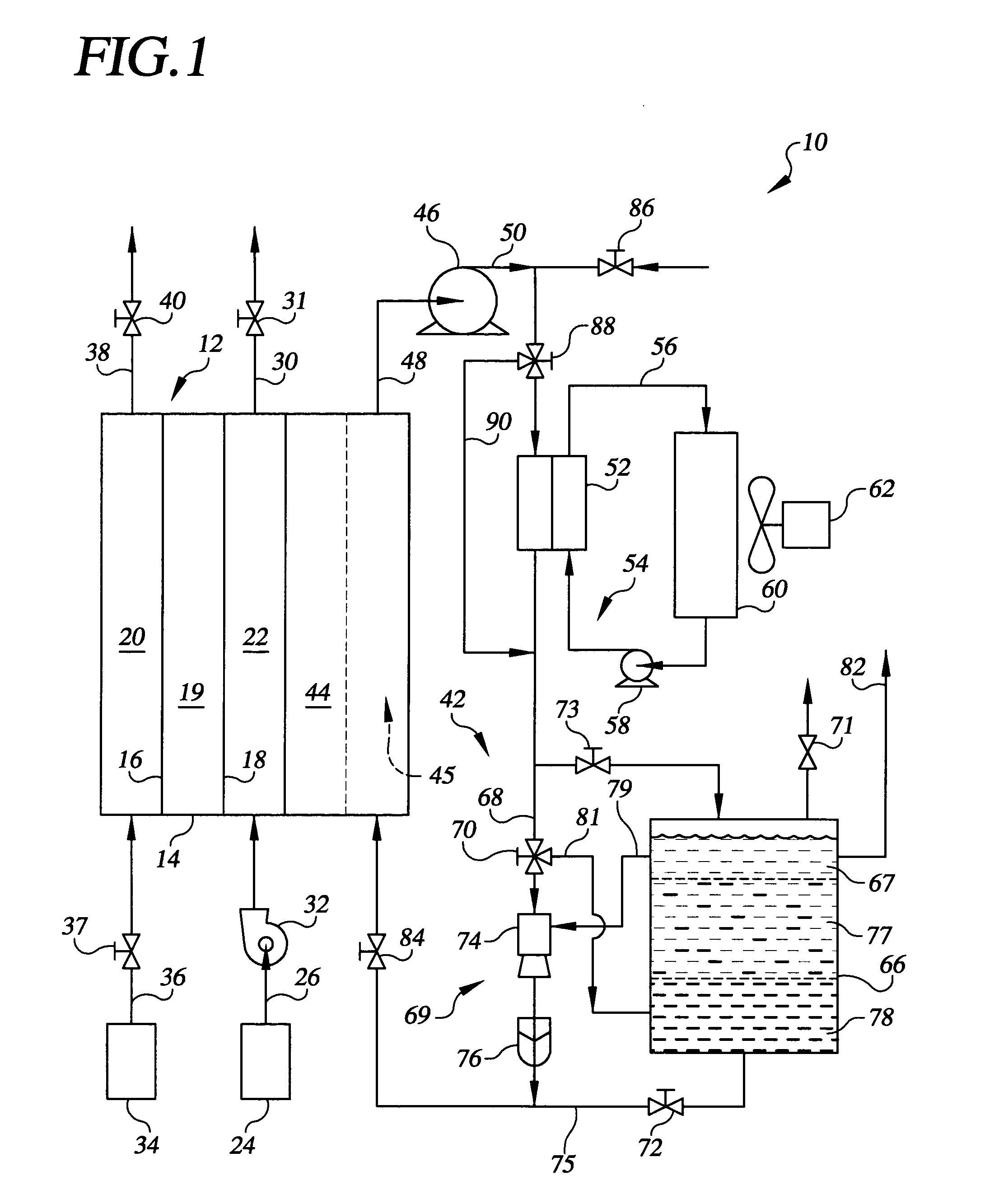

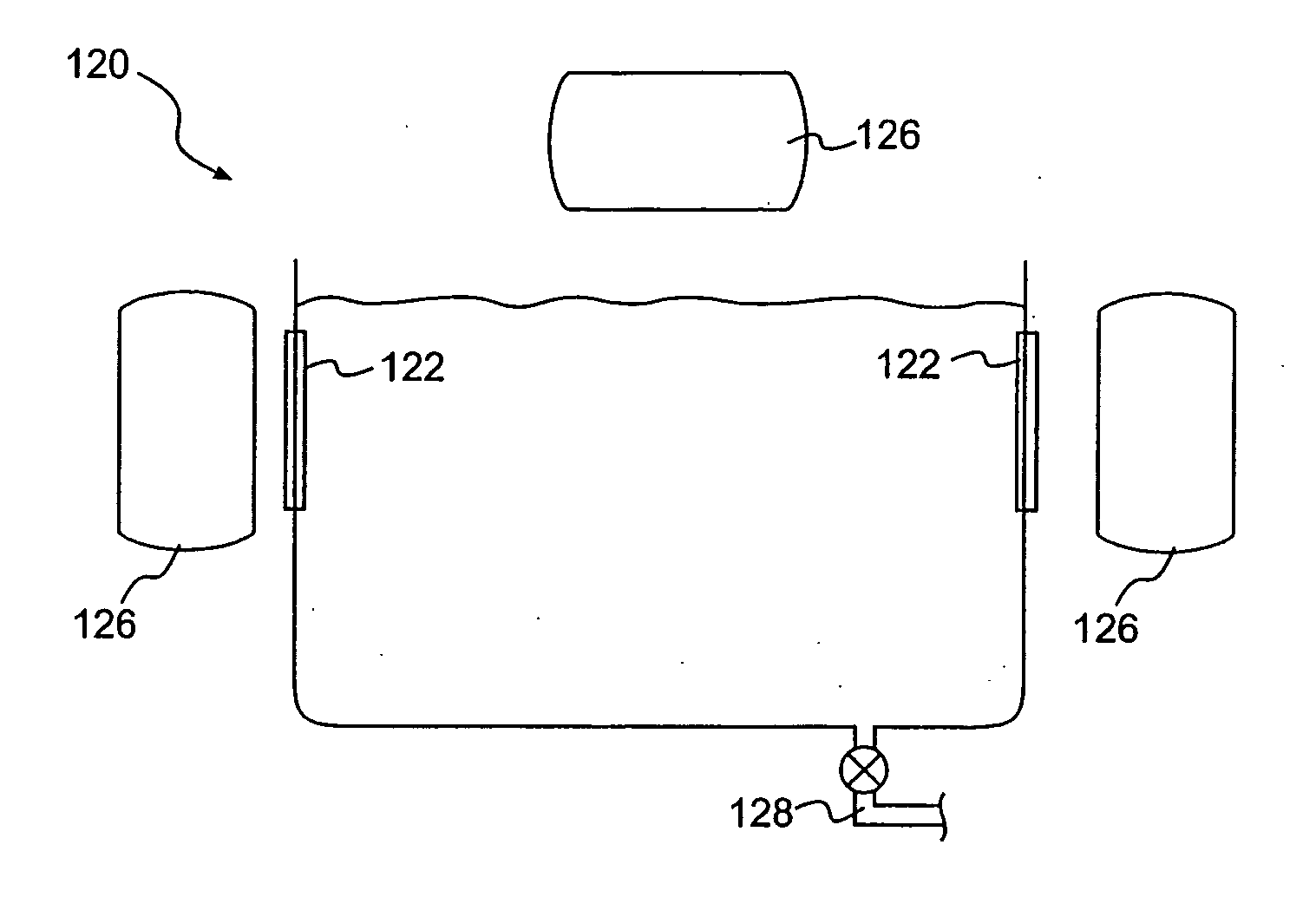

Freeze tolerant fuel cell power plant with a two-component mixed coolant

A freeze tolerant fuel cell power plant (10) includes at least one fuel cell (12), a coolant loop (42) having a porous water transport plate (44) secured in a heat and mass exchange relationship with the fuel cell (12) and a coolant pump (46) for circulating a coolant through the plate (44) and for transferring water into or out of the plate (44) with the coolant. A coolant heat exchanger (52) removes heat from the coolant, and an accumulator (66) stores the coolant and fuel cell product water and directs the product water out of the accumulator (66). The coolant is a two-component mixed coolant liquid circulating through the coolant loop (42) consisting of between 80 and 95 volume percent of a low freezing temperature water immiscible fluid component and between 5 and 20 volume percent of a water component.

Owner:INT FUEL CELLS

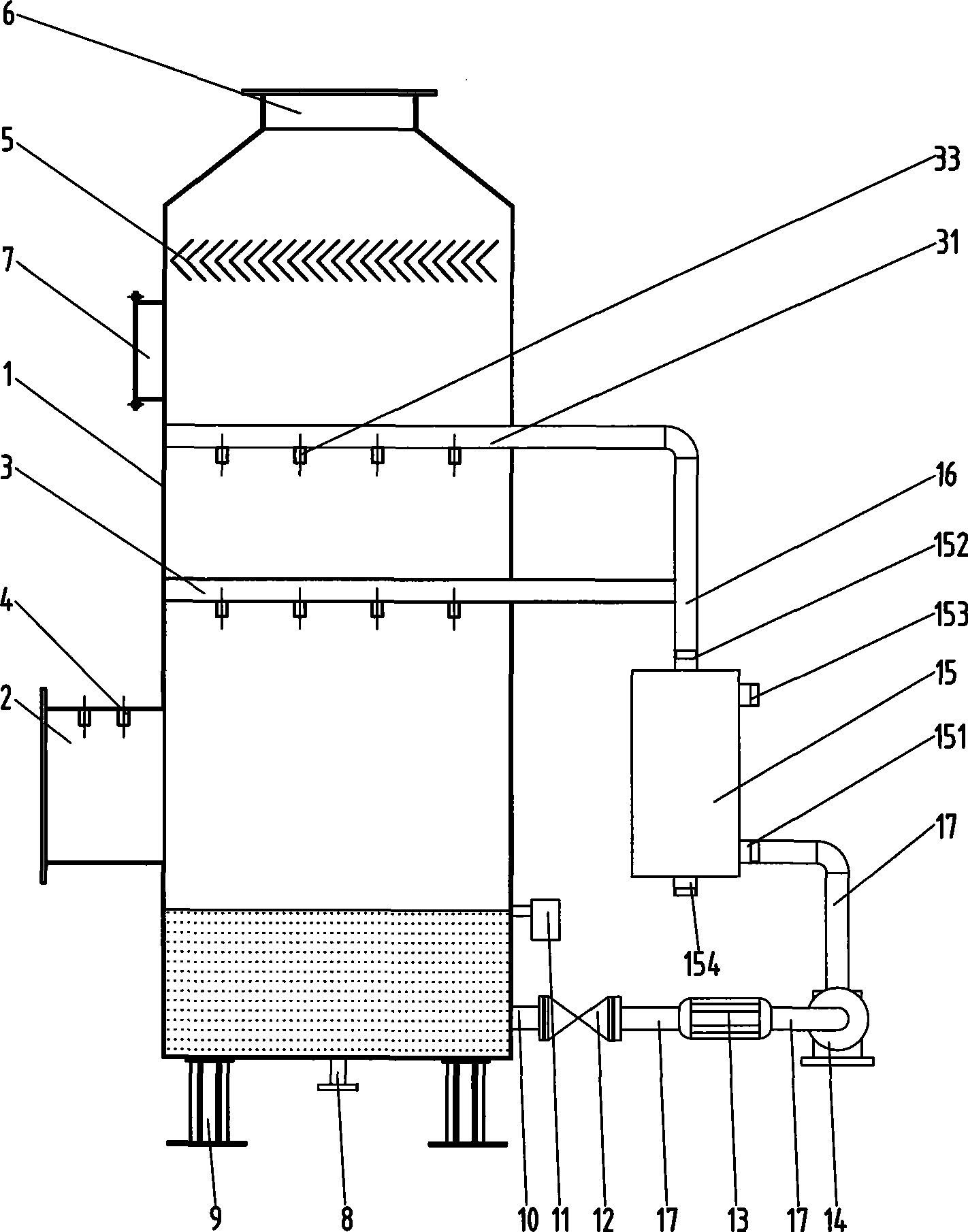

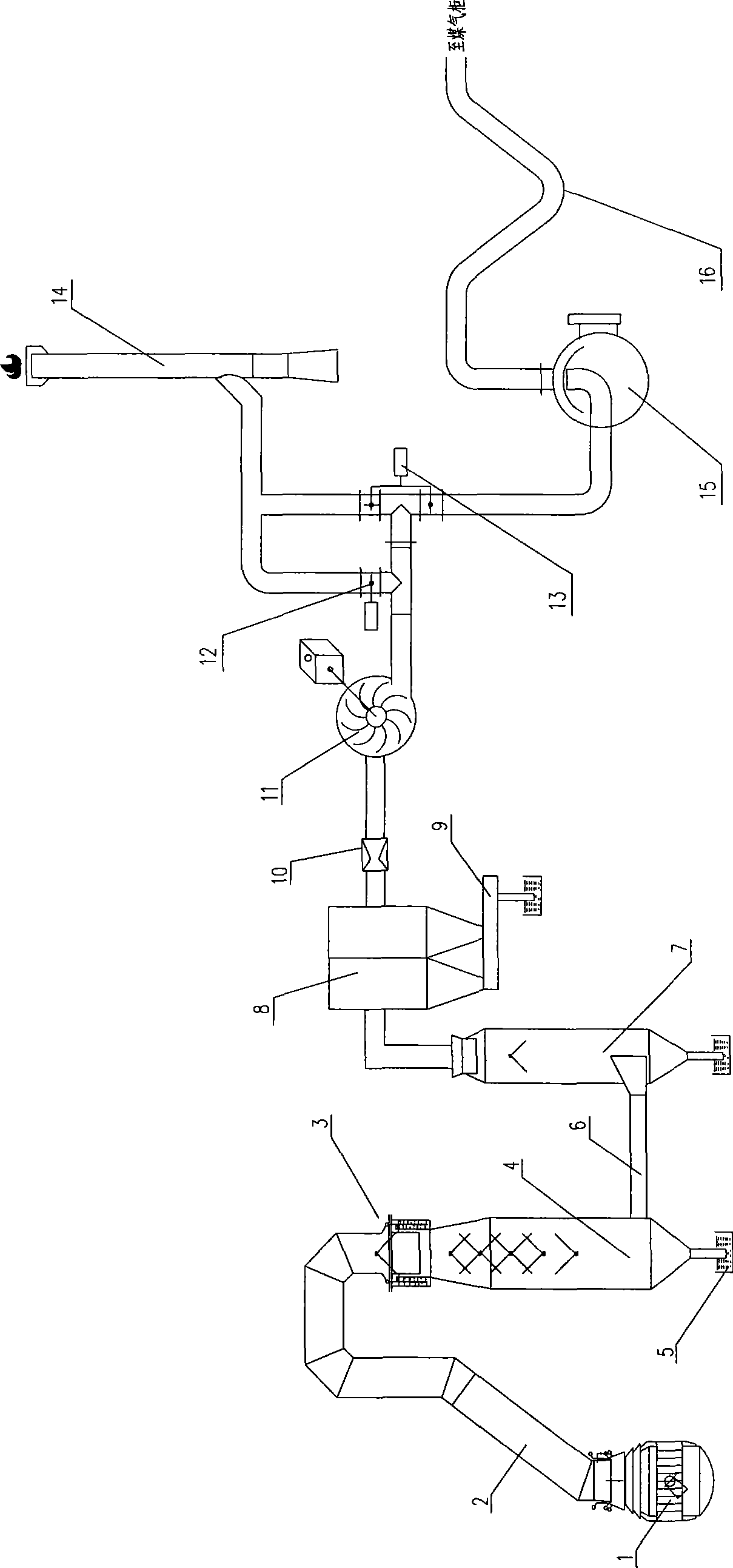

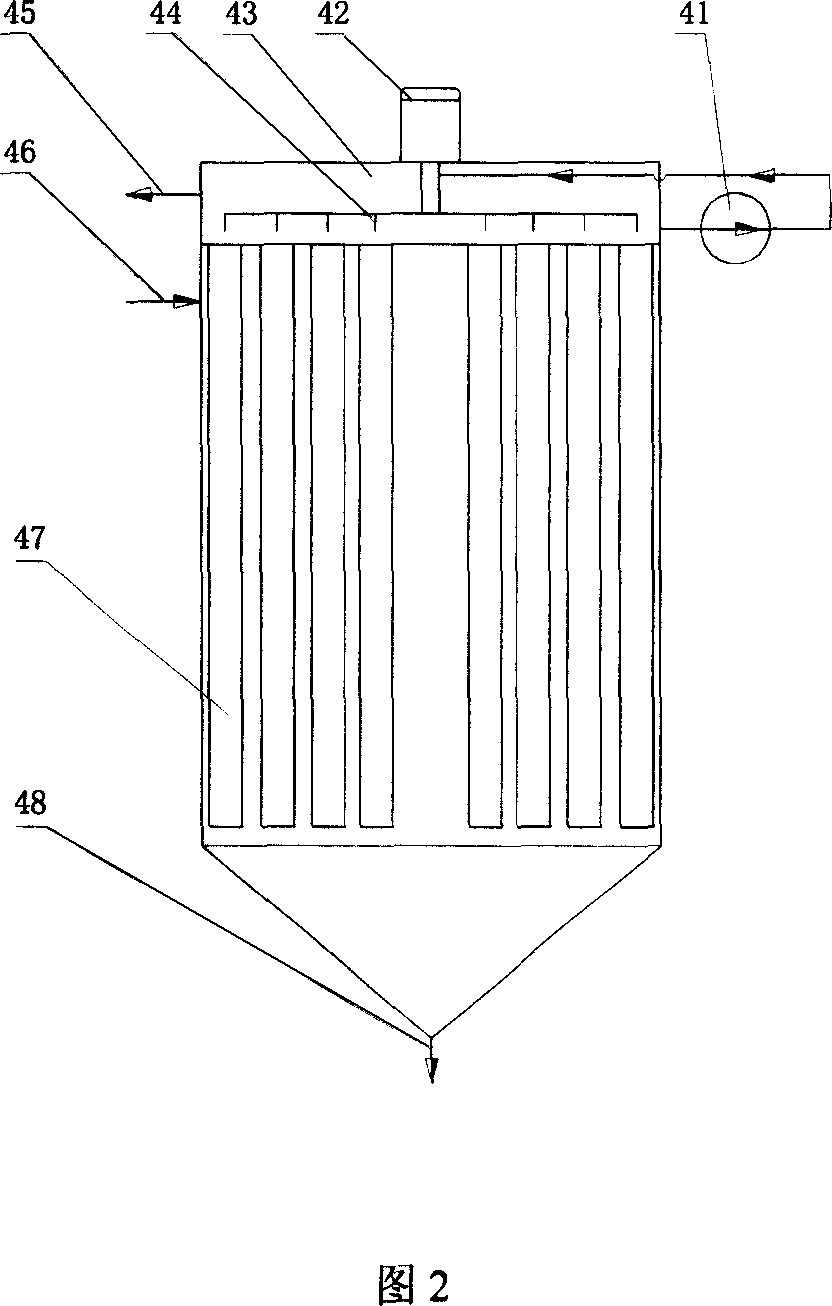

Converter gas purification and recovery process and system

InactiveCN101451079AImprove purification efficiencySolution to short lifeGas purification by liquid washingFiltrationFlue gas

The invention belongs to the technical field of gas purification and discloses a process and a system for purifying and reclaiming converter coal gas. The process comprises: cooling down high-temperature dust-laden flue gas generated by a converter during oxygen blast smelting to between 800 DEG C and 1,000 DEG C by a gasification cooling system; injecting dust-laden coal gas into a saturated spray tower through a water seal; carrying out heat mass exchange between the coal gas and water mist inside the saturated spray tower; removing most dust and dropping the removed dust into a dust hopper along with mechanical water so as to be fed into the water seal; meanwhile, cooling down the coal gas to 70 DEG C approximately, and injecting the coal gas into a sinter-plate filtration dust catcher for filter purification after the coal gas is dehydrated by a dehydration tower; and respectively reclaiming or dispersing the purified coal gas by a three-way switch valve according to the coal gas reclaiming conditions of the system. The process and the system have the advantages of high coal gas purification efficiency, low system operation resistance and energy consumption and long sinter-plate service life, and the dust concentration of the purified coal gas is less than 10mg / m<3> (under the standard condition); moreover, the process and the system are novel technology with high popularization value, energy conservation and environmental protection, and can be widely used in the converter coal gas purifying and reclaiming system.

Owner:CISDI ENG CO LTD

Catalyst loading component and loading method thereof

ActiveCN101596370AAchieve multiple contactsIncrease contact timeDistillation separationChemical/physical/physico-chemical processesGas phaseCatalytic distillation

The invention relates to a catalyst loading component and a loading method thereof for a catalytic distillation tower, comprising a catalyst basket and a bracket. The catalyst basket consists of a basket body, an upper cover and a bottom support, wherein the upper cover is mounted at the upper end of the basket body; the bottom support is mounted at the lower part of the basket body; the height of the basket body from the bottom support of the catalyst basket to the upper cover is 1.1-2 times of the height of the portiforium part of a cover hood in the catalytic distillation tower; the height from the bottom support to the lower basket body is 1.1-2 times of the height of a down-flow spout above a column plate in the catalytic distillation tower; the bracket is in a frame structure matched with the cover hood; and the bottom support of the catalyst basket is arranged on the bracket. The method is used for the catalytic distillation tower, realizes forcible redistribution of liquid in the tower, prolongs the flowing path of a gas phase and a liquid phase in a catalyst bed, enhances the holdup of liquid in a reaction area and ensures the mass exchange and catalytic effect. The loading method has simple process, convenient operation, improved efficiency, low cost and easy actualization and is helpful to fully exert the action of the catalyst.

Owner:PETROCHINA CO LTD

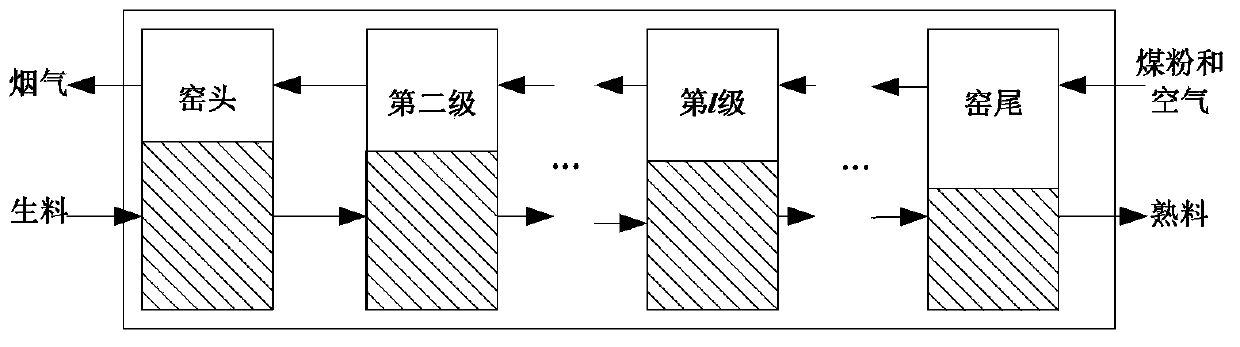

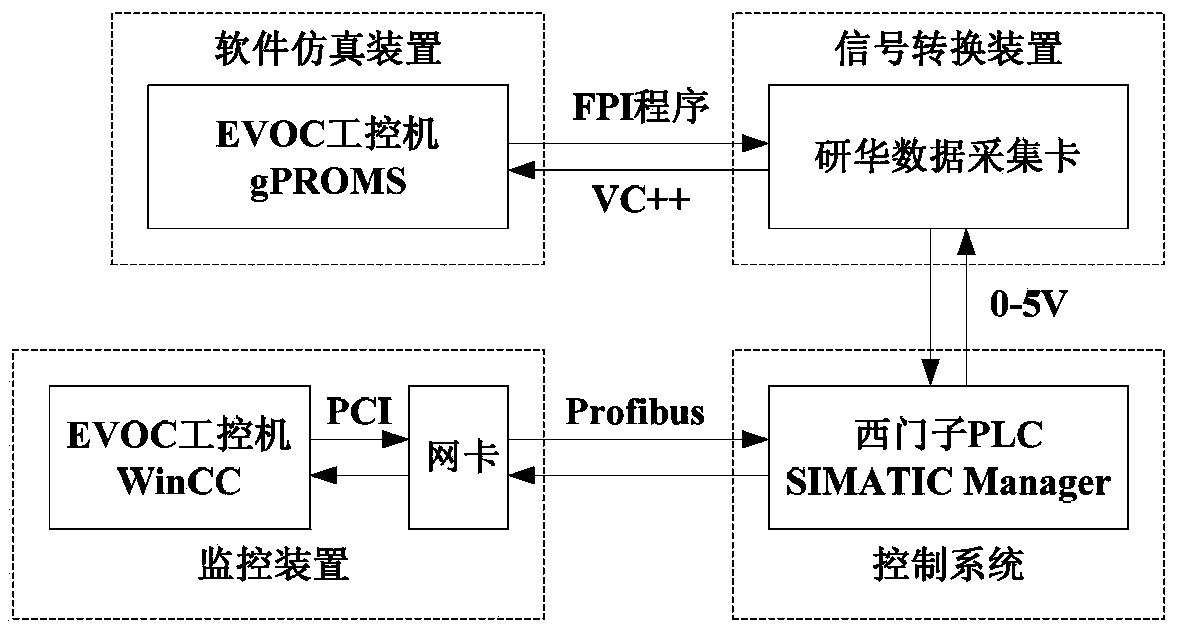

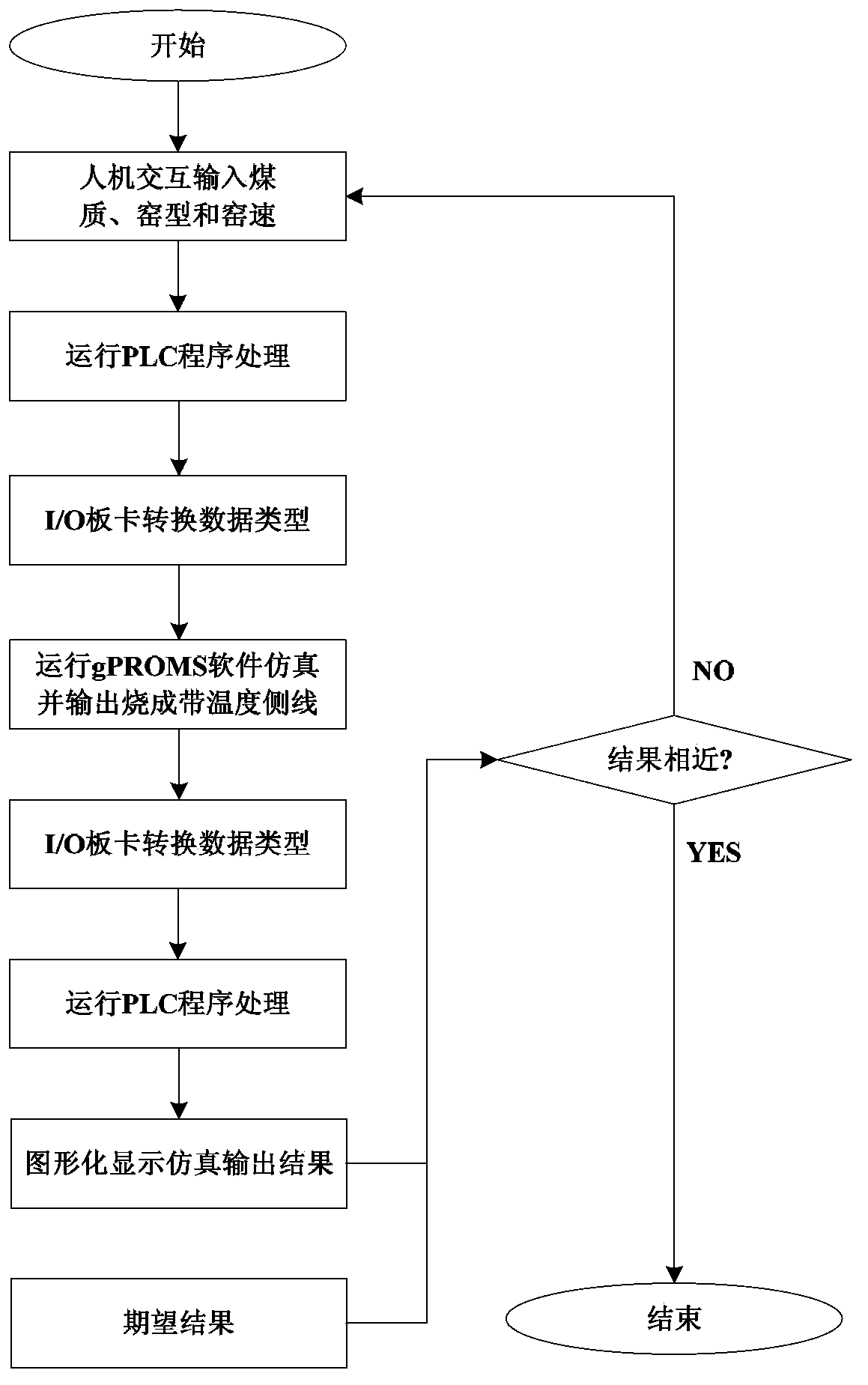

Semi-physical simulation platform and simulation method thereof used in cement clinker calcining process

ActiveCN103399779AImprove the speed of solvingImprove readabilityEnergy efficient ICTEnergy efficient computingProcess dynamicsSoftware emulation

The invention relates to a semi-physical simulation platform used in a cement clinker calcining process. According to the semi-physical simulation platform used in the cement clinker calcining process, a software simulation device, a signal conversion device, a control system and a monitoring device are connected in sequence. A simulation method of the semi-physical simulation platform comprises the steps that procedure parameters are input into a cement clinker calcining process dynamic model established by the monitoring device and sent to the control system; the procedure parameters are output by the control system to the signal conversion device, data conversion is carried out on the procedure parameters by the signal conversion device, and the procedure parameters are then output to a memory of the software simulation device to be stored; the software simulation device acquires virtual working condition parameters; the virtual working condition parameters output by the software simulation device are fed back to the control system by the signal conversion device; the virtual working condition parameters of the control system are received by the monitoring device and then are displayed through a human-computer interaction interface in an imaging mode. According to the modeling of the semi-physical simulation platform and the simulation method thereof used in the cement clinker calcining process, the dynamic variation rule of in-kiln gas-solid interphase energy and mass exchange is described from the view of mechanisms based on basic principles of mass conservation, energy conservation and macroscopic reaction kenitics.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

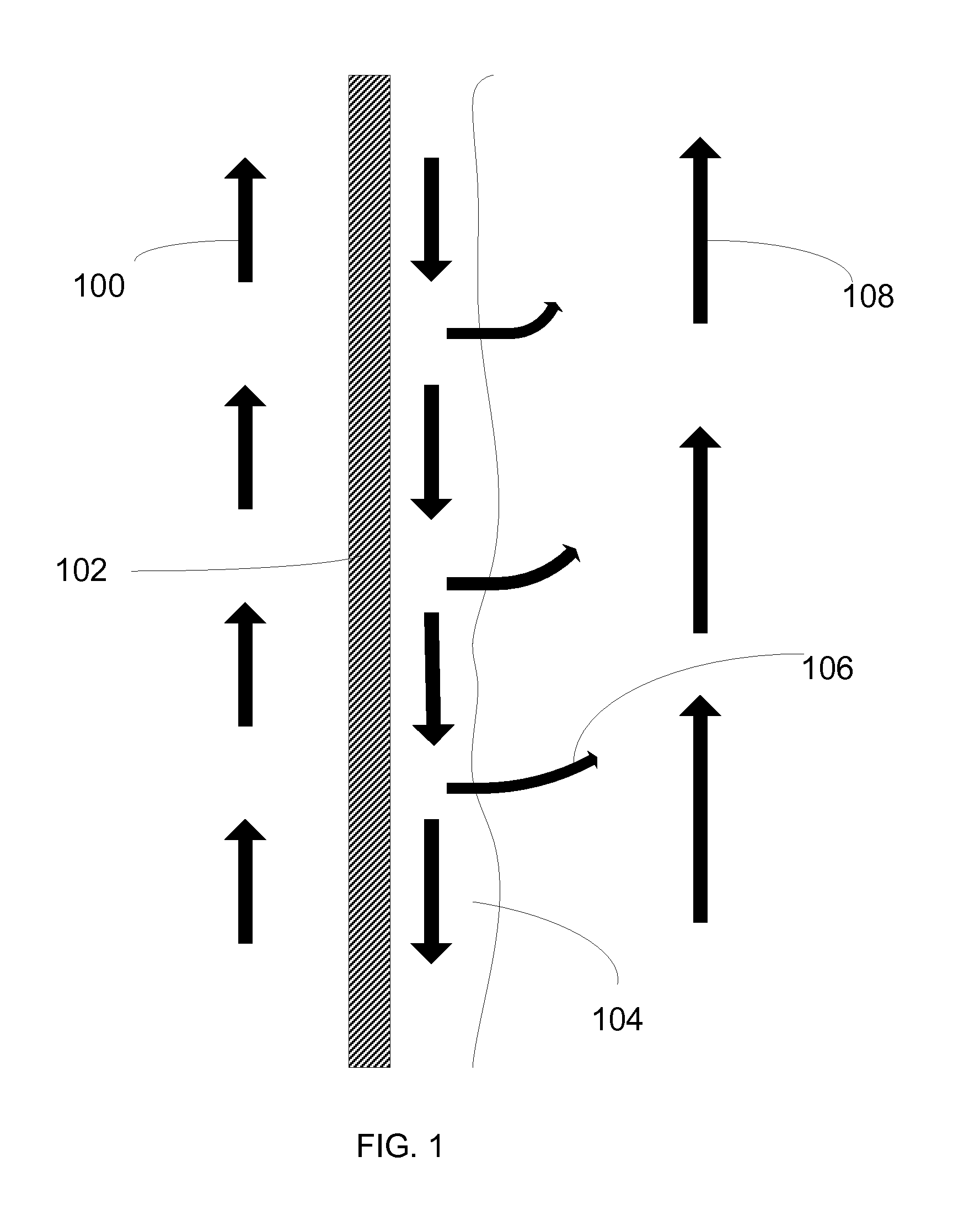

Vapor-liquid heat and/or mass exchange device

ActiveUS20130133346A1Increase desorptionImprove distributionHeat pumpsBoiler absorbersVapor liquidWorking fluid

The invention is directed toward a vapor-liquid heat and / or mass exchange device that can be used in an integrated heat and / or mass transfer system. To achieve high heat and mass transfer rates, optimal temperature profiles, size reduction and performance increases, appropriately sized flow passages with microscale features, and countercurrent flow configurations between working fluid solution, vapor stream, and / or the coupling fluid in one or more functional sections of the desorber are implemented. In one exemplary embodiment of the present invention, a desorber section utilizes a heating fluid flowing in a generally upward direction and a concentrated solution flowing in a generally downward direction with gravity countercurrent to the rising desorbed vapor stream. To further increase the efficiency of the system, various types of column configurations can be used. Additionally, the surfaces of the microchannels can be altered to better transfer heat.

Owner:GEORGIA TECH RES CORP

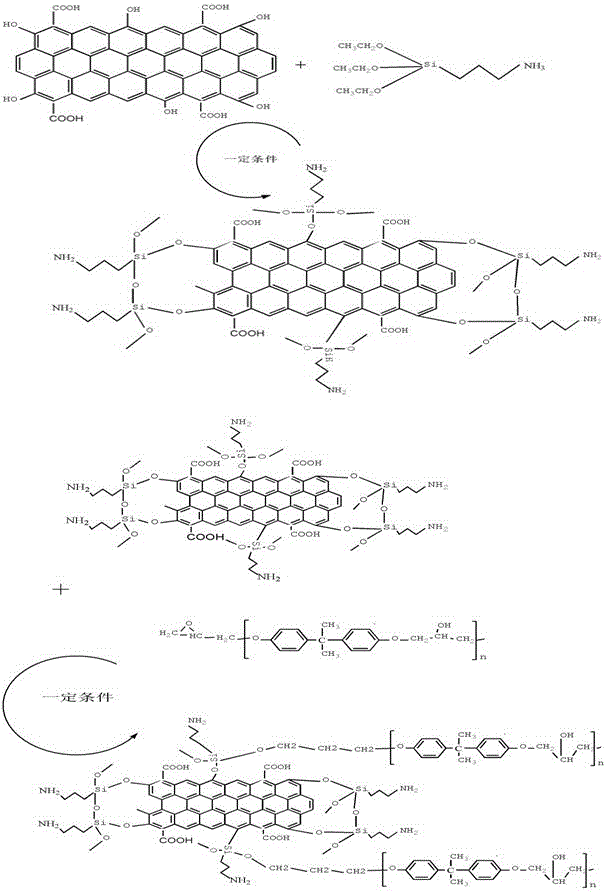

Preparation method of flame retardation graphene coating layer material

InactiveCN106497311AIncrease crosslink densityReduce energy consumptionFireproof paintsAnti-corrosive paintsEpoxyPorous carbon

The invention discloses a preparation method of a flame retardation graphene coating material, and relates to a preparation method of a coating. The method is characterized in that graphene oxide prepared through a Humeers hydrothermal technology is reduced by hydrazine hydrate, organosilane is used as a bridge to connect graphene with epoxy resin through chemical bonds, and a graphene and epoxy resin integrated coating material is synthesized through molecular design. The surface modifying organosilane avoids afresh stacking and aggregation of graphene flakes, so the heat stability and the tensile strength of the graphene and epoxy resin integrated coating material are substantially improved. The integrated functional material improves oxygen index of the tensile strength of the epoxy resin and reduces the heat release rate peak and the total heat release amount, because the integrated coating material can catalyze degradation of the epoxy resin to form a close and porous carbon layer covering the surface of polymer, prevent heat and mass exchange between a gas phase and a solid phase and delay further degradation of the internal material in order to reach the flame retardation purpose of the coating material.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

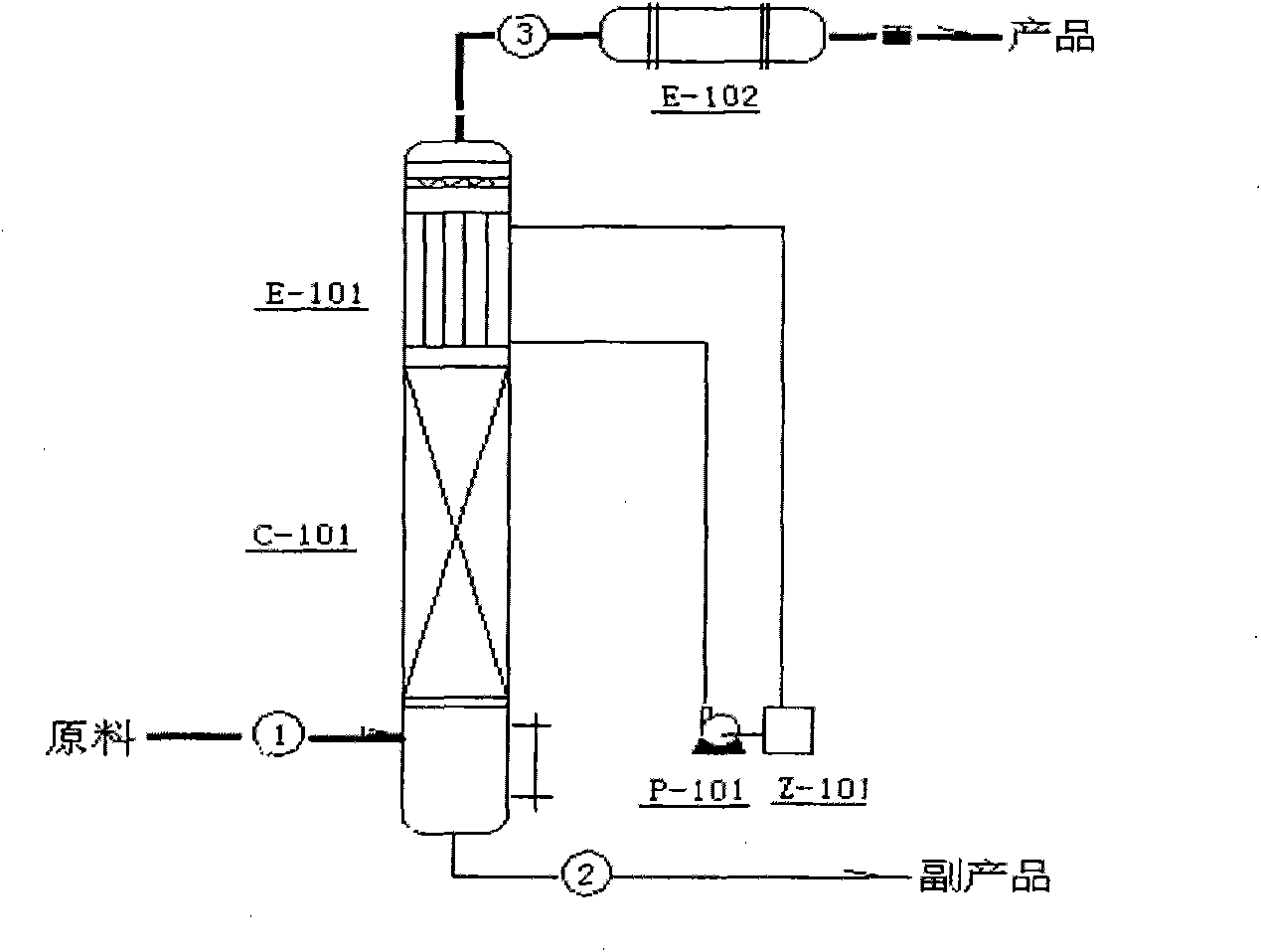

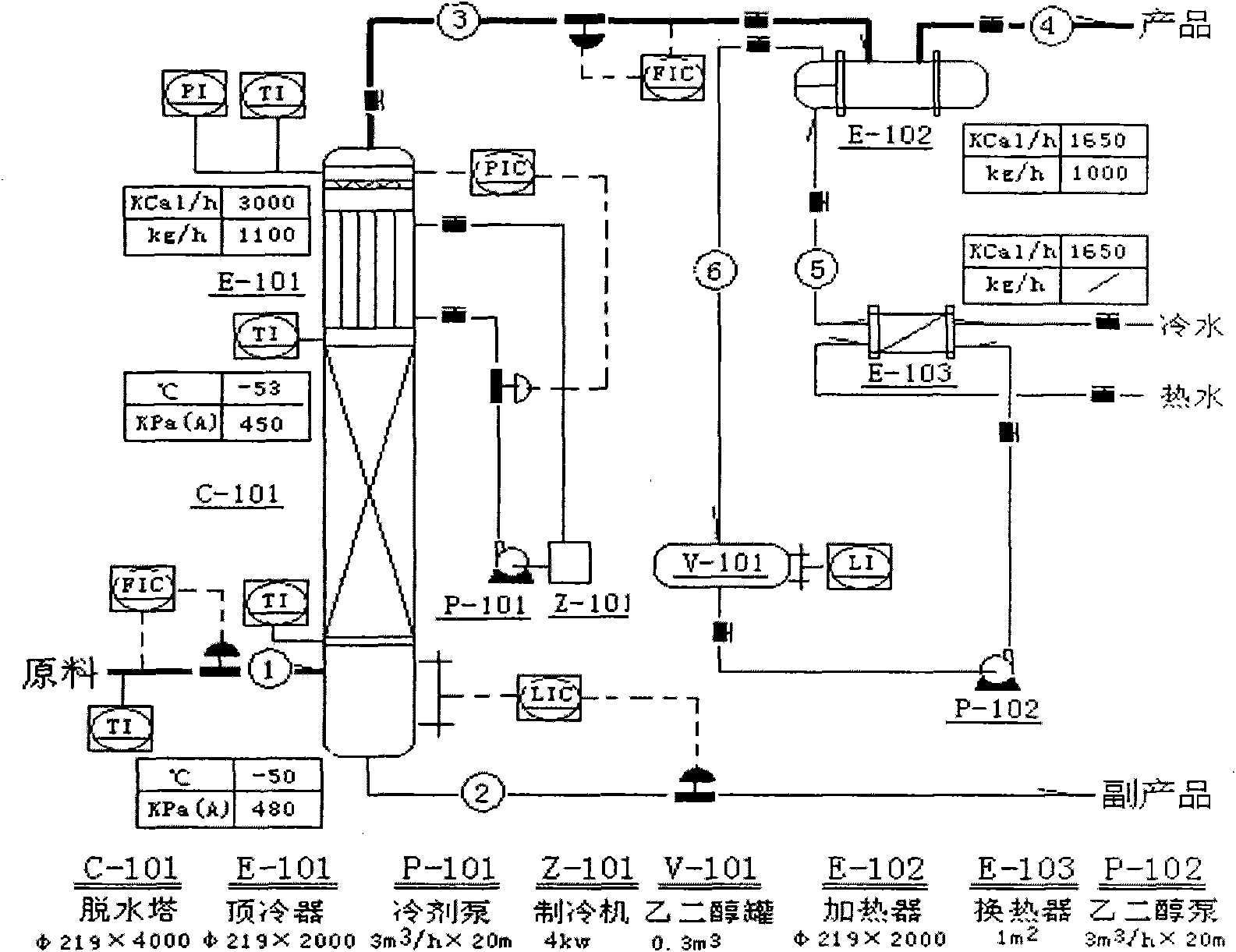

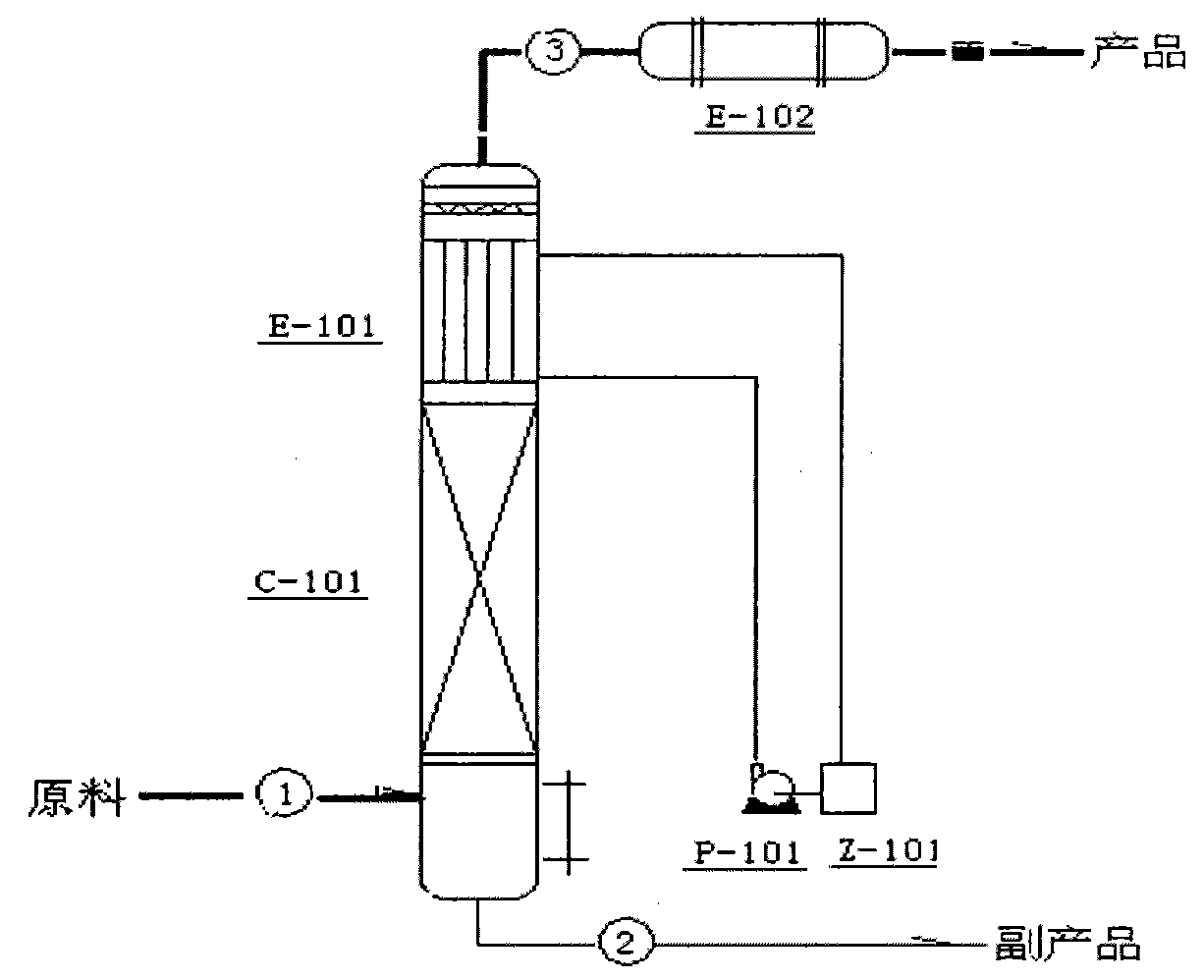

Method and system for preparing anhydrous hydrogen chloride gas

ActiveCN101774543ADeep dehydrationLow costChlorine/hydrogen-chloridePhysical chemistrySystem pressure

The invention discloses a method and a system for preparing an anhydrous hydrogen chloride gas. The method of the invention comprises that: a hydrous hydrogen chloride gas enters a dehydrating tower (C-101) from the bottom of the dehydrating tower (C-101) to flow upward; a cold hydrogen chloride liquid enters the dehydrating tower (C-101) from the top of the dehydrating tower (C-101) to flow downward and carries out heat and mass exchange with the hydrous hydrogen chloride gas flowing upward in the dehydrating tower (C-101), wherein the cold hydrogen chloride liquid flowing downward makes the temperature of the hydrous hydrogen chloride gas flowing upward reduced to below the dew point of the hydrogen chloride gas the liquid water content of which is 10*10-6 under the system pressure in the dehydrating tower (C-101); and then collecting the hydrogen chloride gas discharged from the tower top of the dehydrating tower (C-101) to obtain the anhydrous hydrogen chloride gas. The method of the invention does not introduce extra impurities, has deep dehydrating depth, saves materials, and has low cost and simple and convenient operation.

Owner:北京华宇同方化工科技开发有限公司

Island air water extracting device and water extracting method thereof

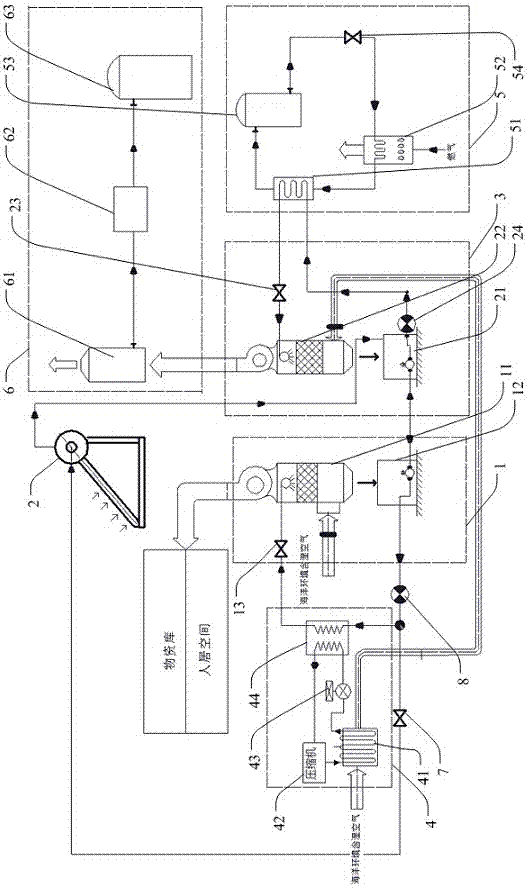

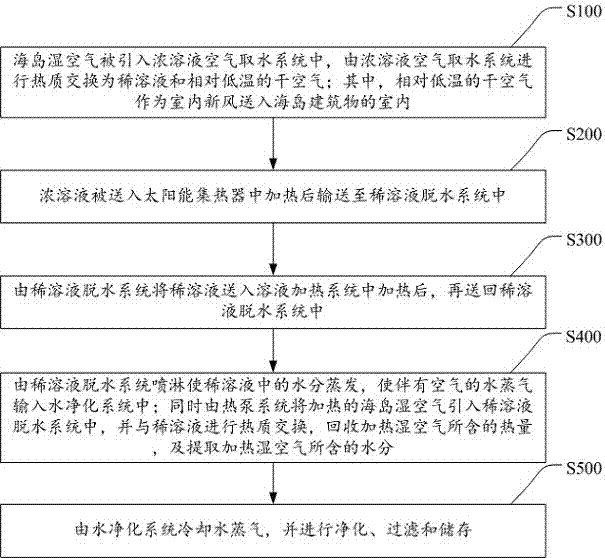

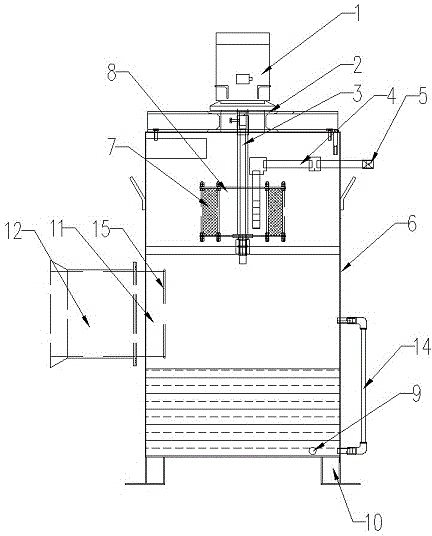

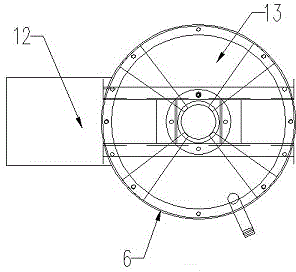

ActiveCN106906874AReduce energy consumptionImprove energy efficiencyHeat recovery systemsGeneral water supply conservationWater vaporEngineering

The invention discloses an island air water extracting device and a water extracting method thereof. The island air water extracting device comprises a concentrated solution air water extracting system, a solar thermal collector, a diluted solution dehydrating system, a heat pump system, a solution heating system and a water purifying system; island wet air is introduced into the concentrated solution air water extracting system to perform heat and mass exchange to obtain a diluted solution and relatively low-temperature dry air, wherein the air serves as indoor fresh air; the diluted solution is delivered into the solar thermal collector for heating and then is delivered into the diluted solution dehydrating system; after the diluted solution is delivered into the solution heating system and is heated by the diluted solution dehydrating system, the diluted solution evaporates to form water vapour, and the water vapour is delivered into the water purifying system; the water purifying system cools the water vapour, and the water vapour is purified, filtered and stored; meanwhile, the heated island wet air is introduced into the diluted solution dehydrating system by the heat pump system, so that the heat of the wet air is recycled, and the moisture in the wet air is extracted. According to the island air water extracting device and the water extracting method thereof, the air which is produced in a water extracting process is directly taken as the indoor fresh air, so that the air is utilized reasonably.

Owner:DONGGUAN UNIV OF TECH

Super-gravity heat exchange process

InactiveCN104567462AEfficient heat and mass exchangeHigh speedDirect contact heat exchangersEngineeringCooling fluid

The invention discloses a super-gravity heat exchange process which is characterized in that high-speed movement water mist is formed by cutting and dispersing cooling liquid through a super-gravity cooling liquid atomization device and is in direct contact with air capable of backflow spiral movement generated by a heat exchange barrel and an air inlet device to flow, and cooling liquid and air efficient heat and mass exchange is realized by increasing the cooling liquid and air heat transfer area, accelerating the relative speed and increasing the mutual contact number. According to the super-gravity heat exchange process, the high-speed movement water mist is formed by cutting and dispersing water by utilizing the super-gravity cooling liquid atomization device and is in direct contact with the air capable of backflow spiral movement generated by the heat exchange barrel and the air inlet device to perform unique flow behavior, and the cooling liquid and air efficient heat and mass exchange is realized through increasing the cooling liquid and air heat transfer area, accelerating the relative speed and increasing the mutual contact number, so that the heat and mass transfer effect is greatly improved; meanwhile, the number of the used cooling liquid is greatly reduced, and a large amount of resources are saved.

Owner:魏永阳

Freeze tolerant fuel cell power plant with a two-component mixed coolant

A freeze tolerant fuel cell power plant (10) includes at least one fuel cell (12), a coolant loop (42) having a porous water transport plate (44) secured in a heat and mass exchange relationship with the fuel cell (12) and a coolant pump (46) for circulating a coolant through the plate (44) and for transferring water into or out of the plate (44) with the coolant. A coolant heat exchanger (52) removes heat from the coolant, and an accumulator (66) stores the coolant and fuel cell product water and directs the product water out of the accumulator (66). The coolant is a two-component mixed coolant liquid circulating through the coolant loop (42) consisting of between 80 and 95 volume percent of a low freezing temperature water immiscible fluid component and between 5 and 20 volume percent of a water component.

Owner:INT FUEL CELLS

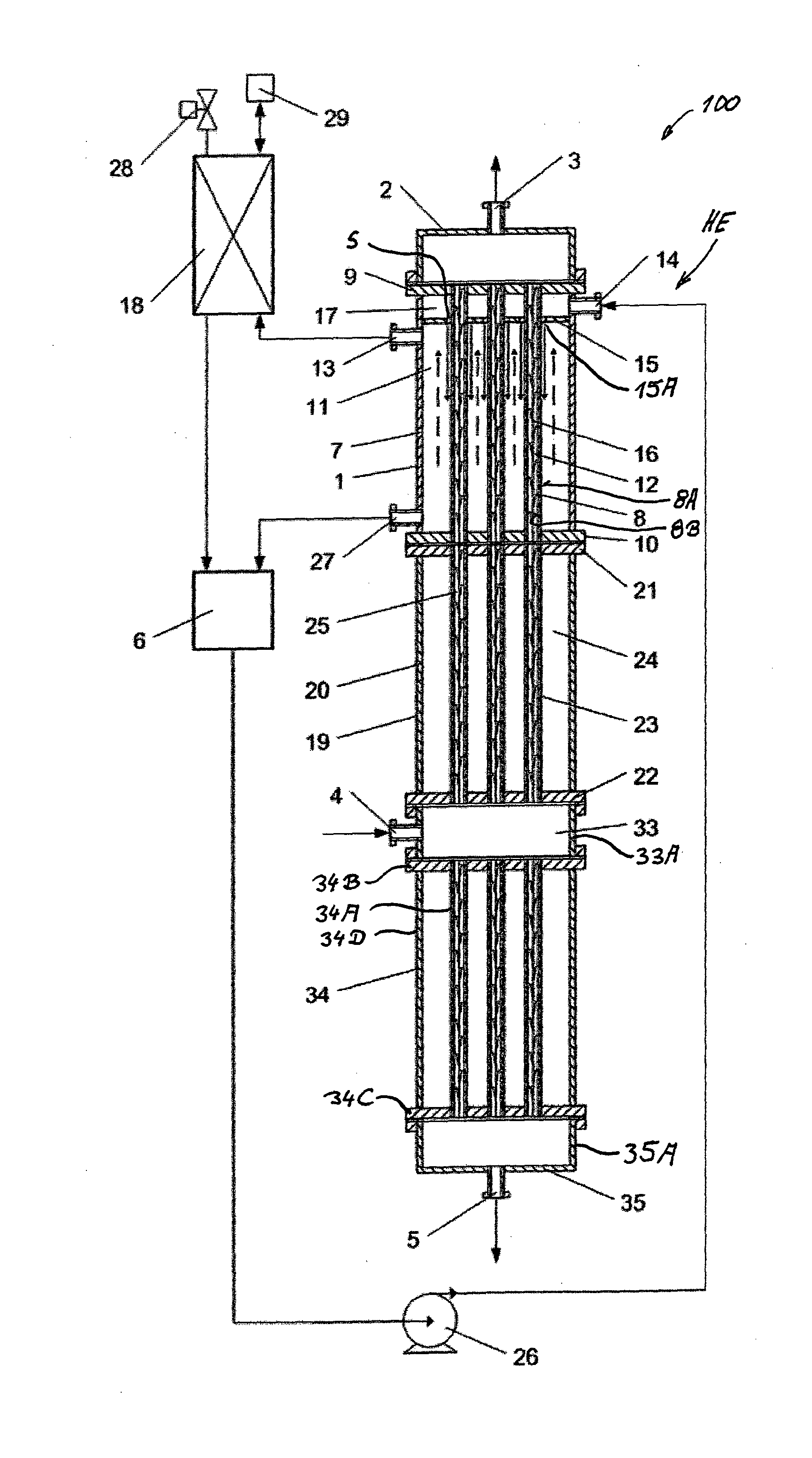

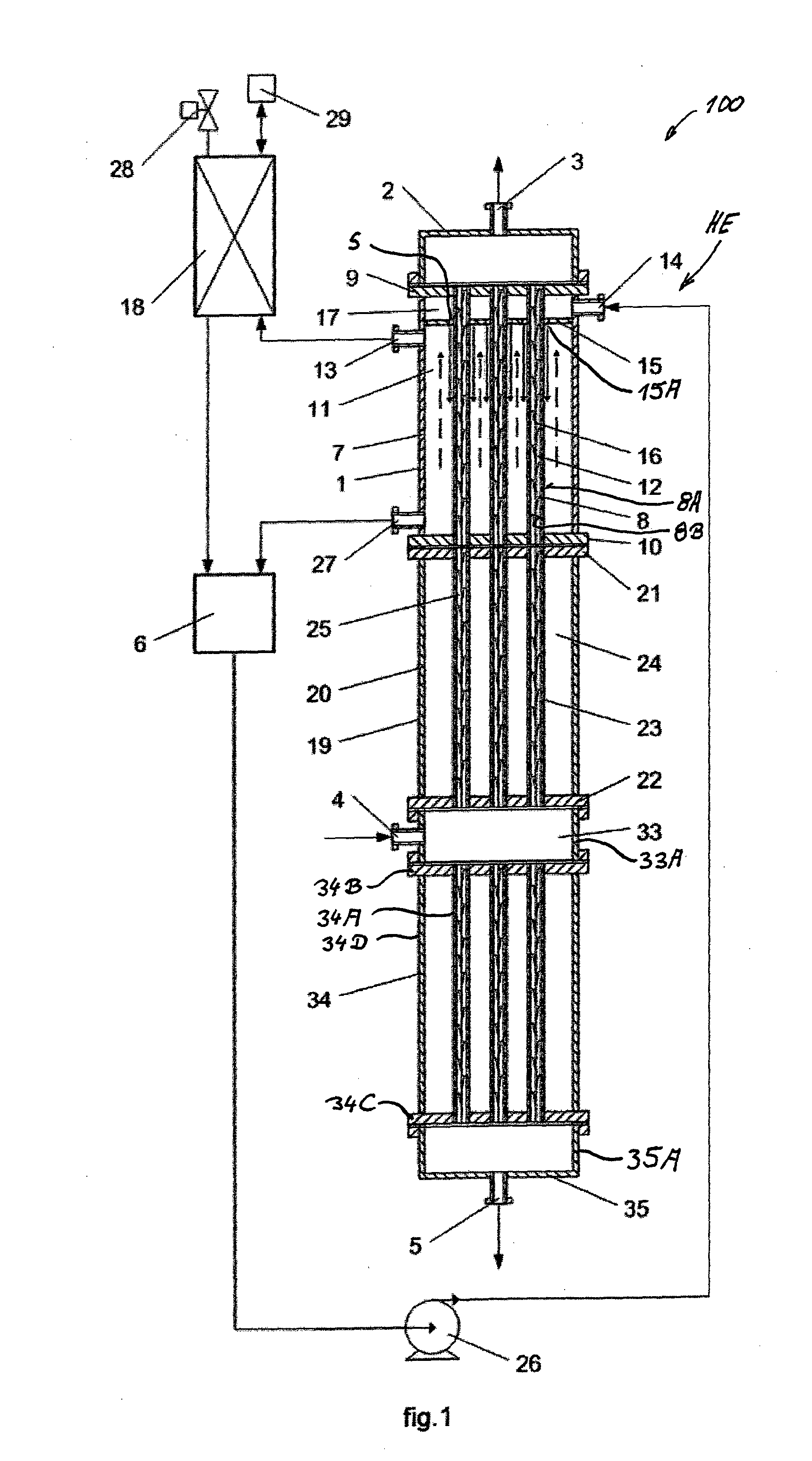

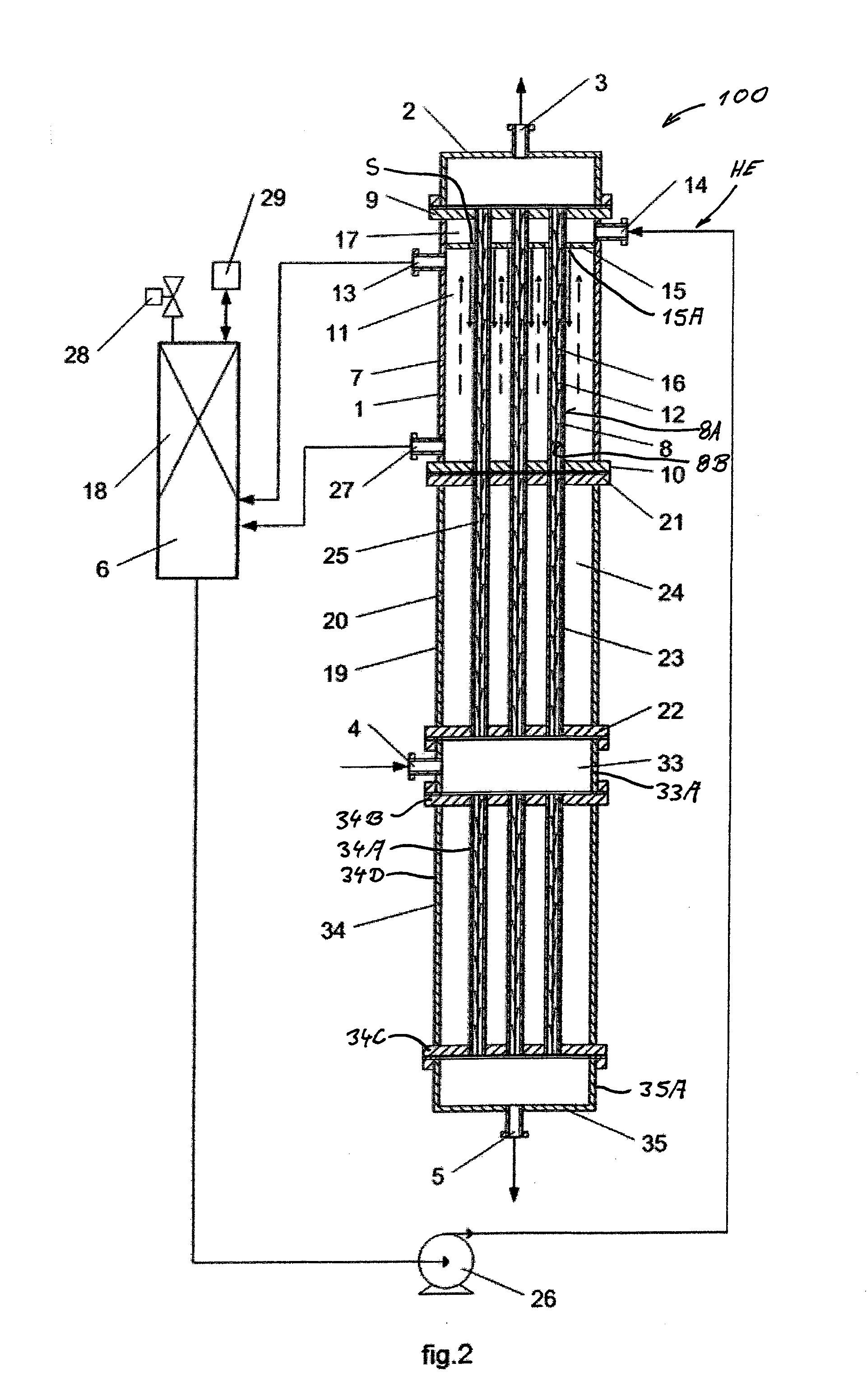

Rectification Tower with Internal Heat and Mass Exchange and Method for Separation of Multi-Component Mixtures into Fractions Using a Rectification Tower with an Internal Heat and Mass Exchange

InactiveUS20150090581A1Improve the situationIncrease heatDistillation regulation/controlDistillation in pipe stillsSteam condensationHeat carrier

A rectification column for multi-component mixture separation with internal heat and mass exchange, which ensures a heat and mass exchange in the film mode with internal reflux generation along the whole length of heat and mass exchange tubes and which allows for an increased efficiency, is proposed. The rectification column includes the rectifying / enriching section with the heat and mass exchange in its tubular and annular spaces being topped by a heat carrier distributor with a distributor chamber (17) on top of the heat carrier distributor in such a way that a higher pressure of fluid heat carrier in the distributor chamber (17) than in the annular space is allowed. The design of the distributor allows to separate an upper outlet for heat carrier vapors and a lower outlet for liquid heat carrier from the annular space completely from the fluid supply of fluid heat carrier in the distributor chamber. A feed-in device allows the multi-component mixture to enter the tubular spaces from below. A device for liquid phase (from the multi-component mixture) discharge from the rectification column. A heating medium vessel may be connected to the annular space and steam condenser of the heat carrier medium. One or more additional lower rectification section / s (19) with the heat and mass exchange in its tubular space of the tubes being aligned with the tubes may be provided directly below the enriching section. A steaming section, wherein the tubes and may be equipped with turbulators. The rectification column permits to extract intermediate fractions of the separated mixture with the help of appropriate devices installed below the enriching section.

Owner:SAIFUTDINOV ALBERT FARITOVICH +3

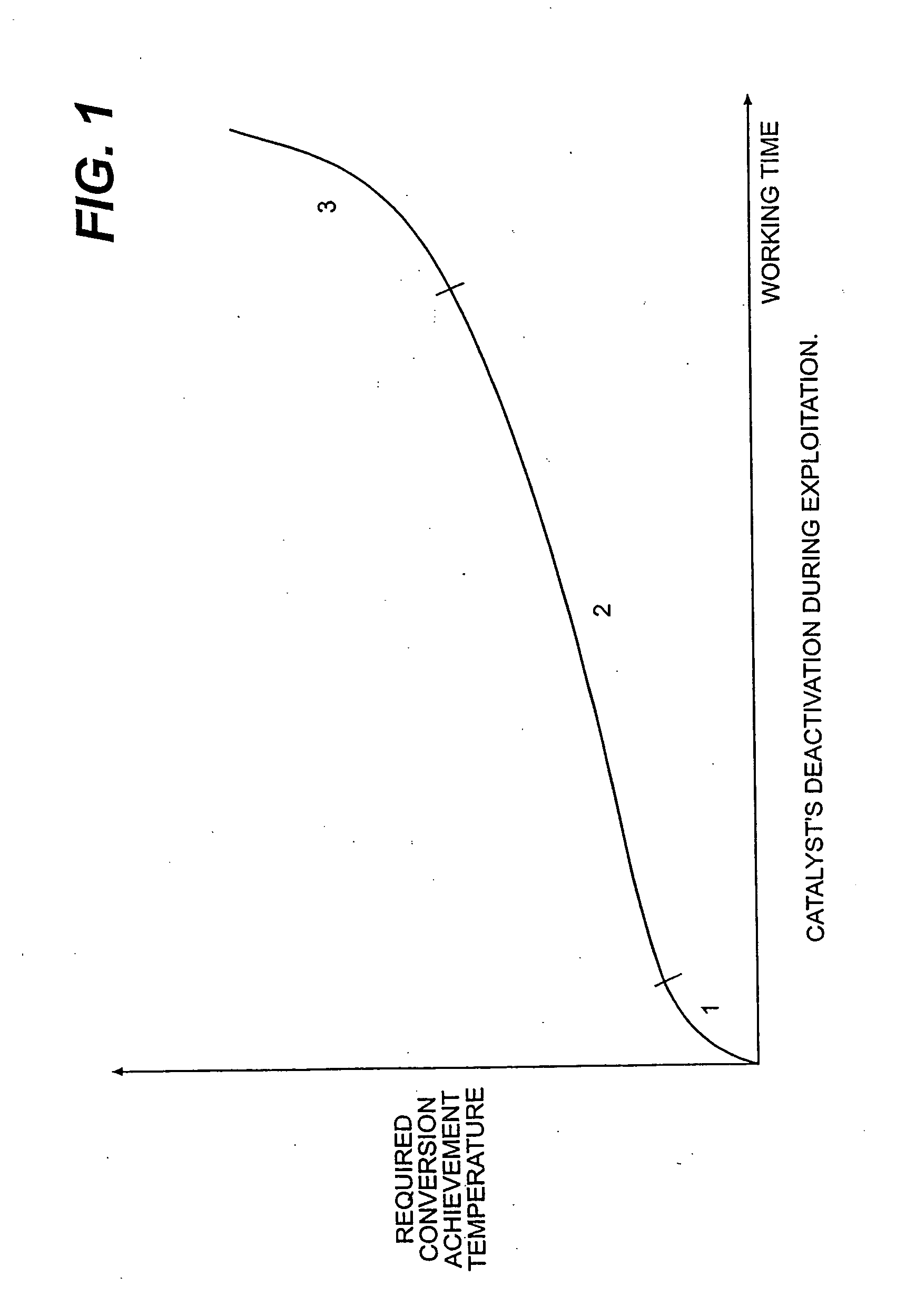

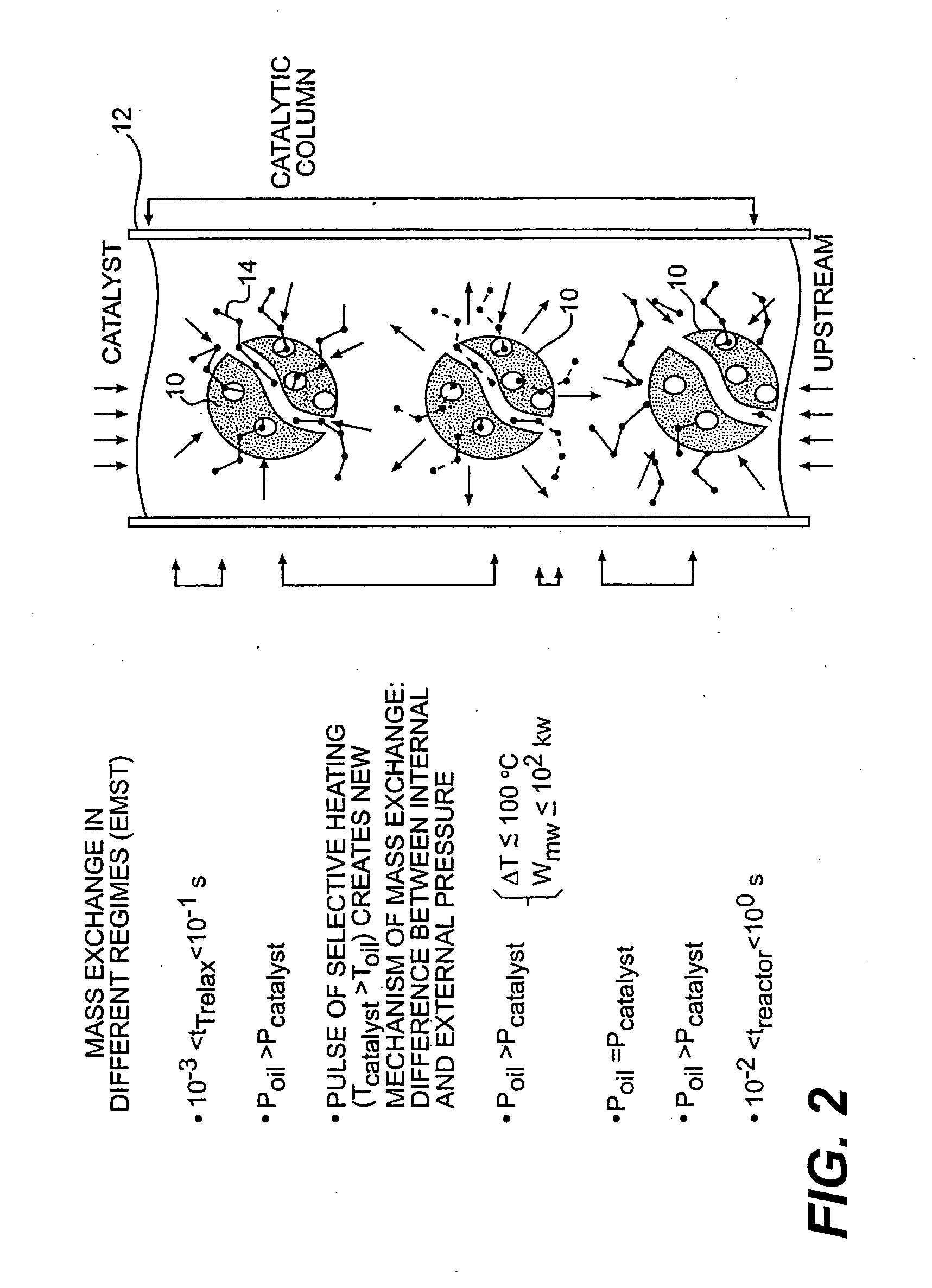

High frequency energy application to petroleum feed processing

InactiveUS20060073084A1Hydrocarbon oil cracking processHydrocarbonsElectromagnetic pulseElectromagnetic radiation

The present invention provides a method and apparatus for maintaining the active life of a catalyst in organic feed processing by applying a series of electromagnetic radiation pulses to the catalyst in a reactor. The pulsing of the catalyst selectively heats and cools the catalyst and can regulate the relative internal pressure of the catalyst particles to stimulate the acceleration of oil macromolecules mass-exchange through the catalyst pores and surface. This allows for the removal of cracked oil molecules from the particles. The application of electromagnetic pulses also regulates the activity of the catalyst. The electromagnetic radiation reduces the formation of coke on the catalyst and increases the life of the catalyst in the reactor. Further, the present invention provides a method and apparatus for removing water and salt from an organic feed. Water and salt is removed by applying a series of electromagnetic radiation pulses to the organic feed. A first pulse condenses water contained in the feed and induces salt to dissolve in the condensed water. A second pulse vaporizes a portion of the condensed water droplets to bring the droplets to the surface of the organic feed.

Owner:BURKITBAYEV SERIK M

Membrane device and process for mass exchange, separation, and filtration

A membrane device and processes for fabrication and for using are disclosed. The membrane device may include a number of porous metal membranes that provide a high membrane surface area per unit volume. The membrane device provides various operation modes that enhance throughput and selectivity for mass exchange, mass transfer, separation, and / or filtration applications between feed flow streams and permeate flow streams.

Owner:BATTELLE MEMORIAL INST

Dithane M-22 Z-78 closed loop circulating drying method and apparatus

InactiveCN1975303AReduce dissipationAvoid pollutionDrying solid materials with heatDrying gas arrangementsCycloneClosed loop

Drying methods of mancozeb closed cycle, the mancozeb was sent into the dryer, take heat and mass exchange with 140 degree C to 250 degree C nitrogen gas or carbon dioxide, separate in the cyclone separator and bag filter, dry goods was sent into cooler and unloaded after cooled to room temperature, the off-gas heat was recycled by recoverer, sent to the heater. Its installations comprises the dryer, cyclone separator, waste heat recoverer, the fan, spraying tower, heater and dry goods cooler, the air outlet was connected with the air inlet of the cyclone separator, its air outlet was connected with the hot end air inlet of the waste heat recoverer, the hot end air outlet was sequentially connected with spraying tower, demister and fan, the air outlet of the fan connects the cold end air inlet of the waste heat recoverer, the cold end air outlet of the waste heat recoverer connects the air inlet of dryer by the heater, the discharging mouth of cyclone separator links the dry goods cooler, which has discharge gate on it, the heater was set with heat medium inlet and outlet, the spraying tower was set with cooling water inlet and water outlet down, the bottom of the demister was also set with water outlet.

Owner:SOUTHEAST UNIV +1

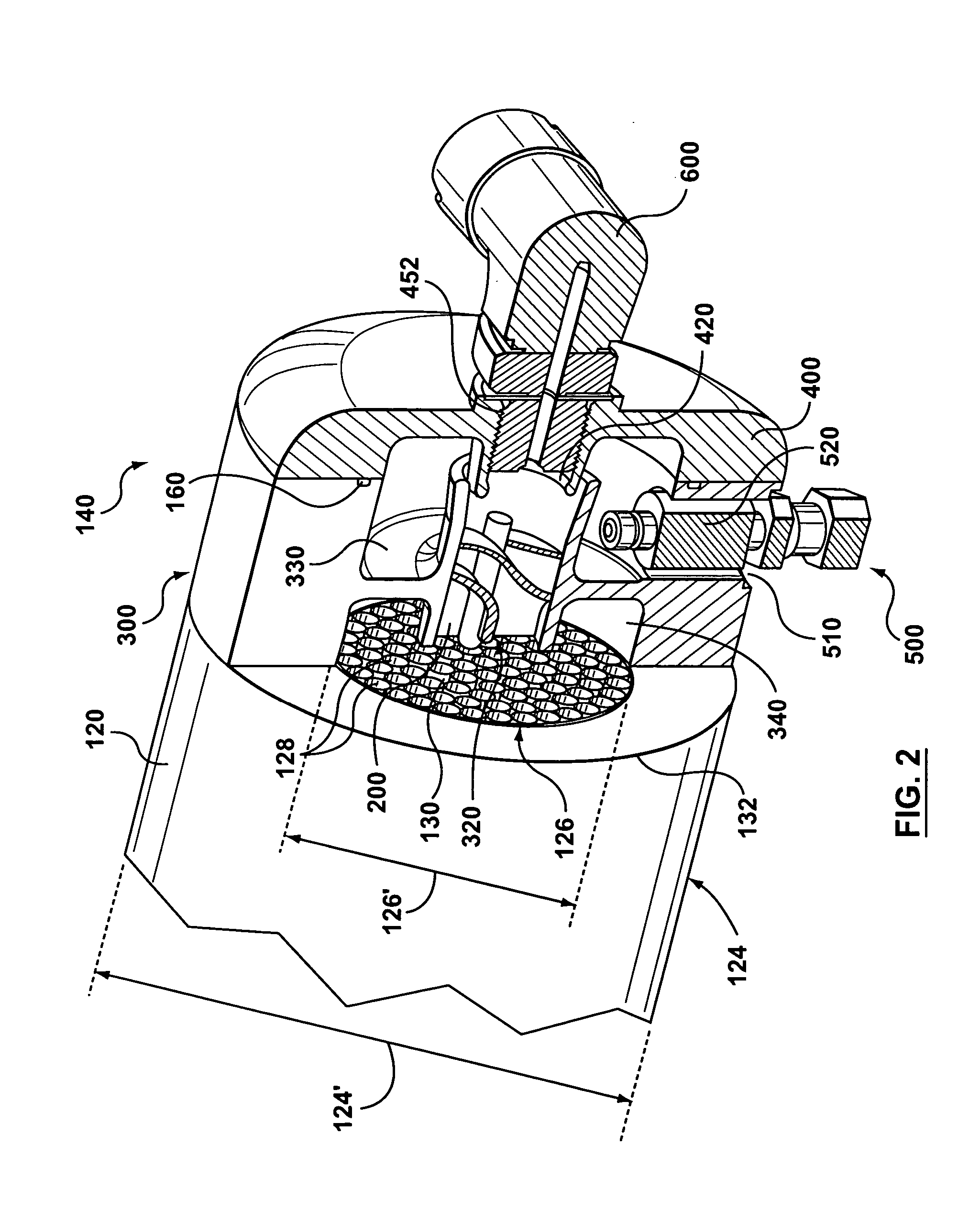

Energy and/or mass exchange apparatus having an integrated fluid separator

A liquid separator configured to separate liquid from a fluid stream. The separator includes a housing, a separation chamber disposed within the housing, a drain having a drain passageway for draining liquid from the separation chamber, an inlet chamber configured to receive the fluid stream, an inlet channel configured to communicate the fluid stream from the inlet chamber to the separation chamber, a swirler disposed within the inlet channel, and an outlet channel configured to communicate the fluid stream from a first outlet end positioned proximate the second inlet end, to a second outlet end remote from the separation chamber. Preferably, the separator also includes a separator mounting face proximate the inlet chamber, the mounting face configured for mounting the separator to a humidifier. The housing preferably includes a base and a cap which is removably mountable to the base.

Owner:HYDROGENICS CORP

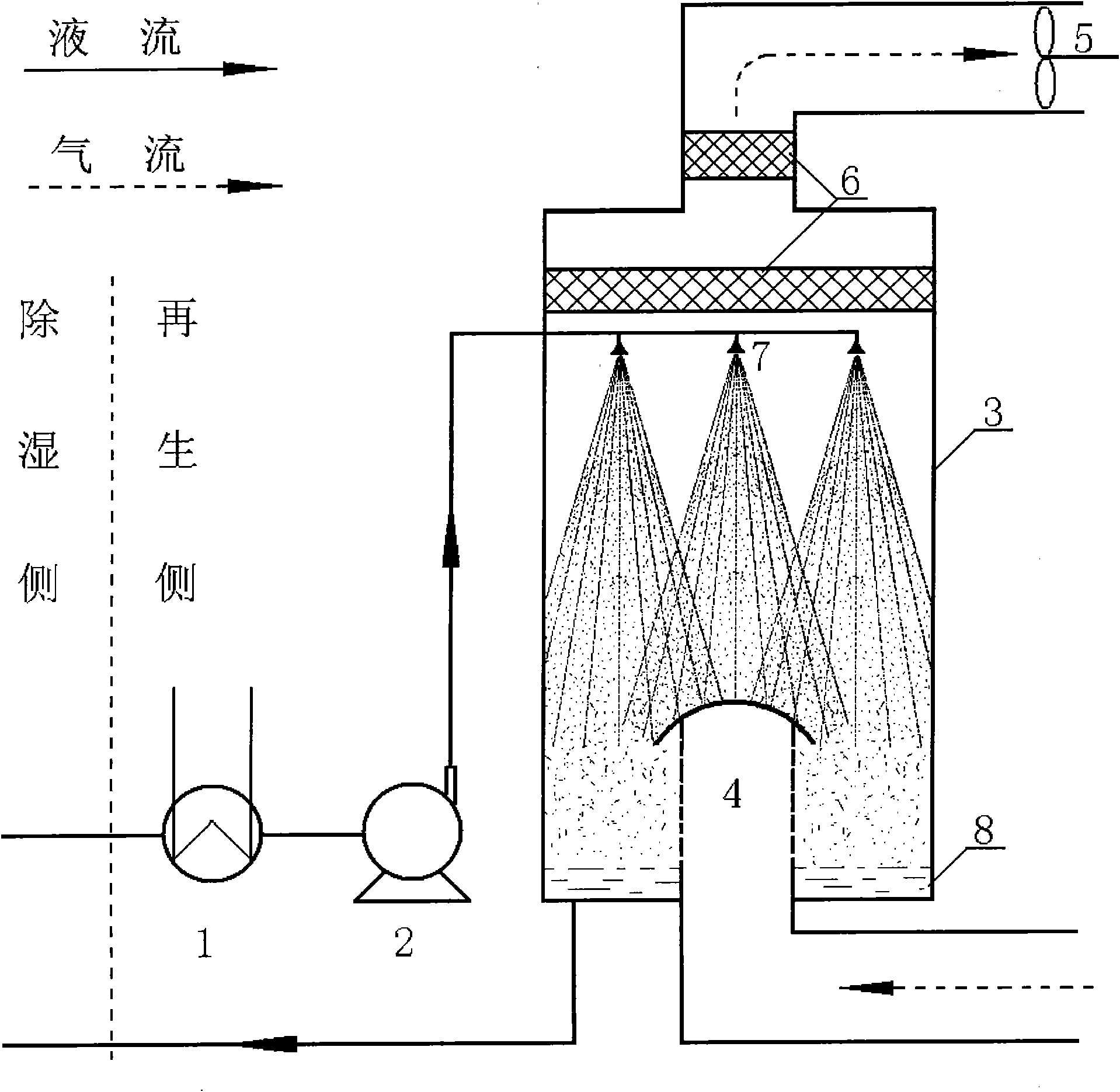

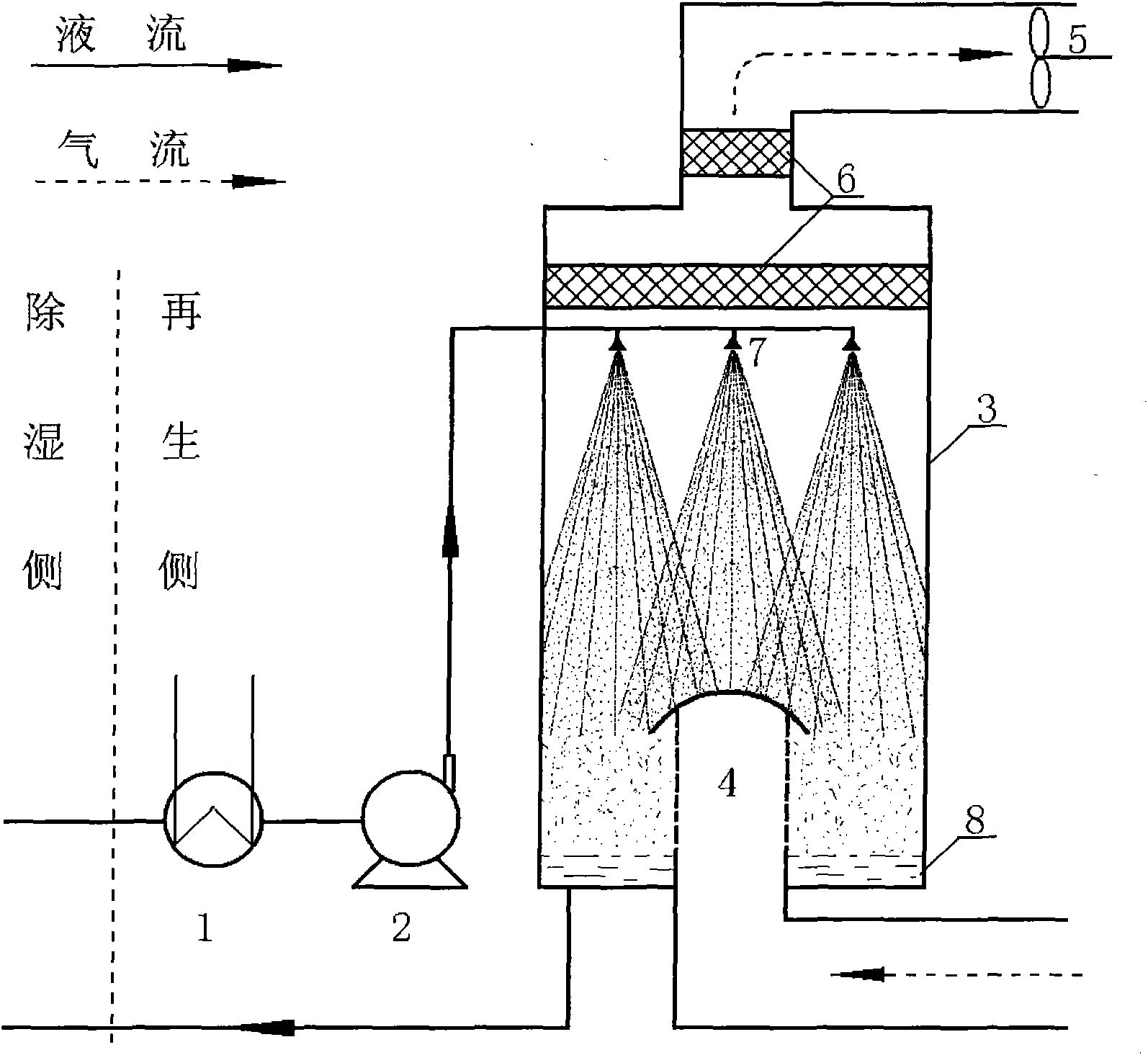

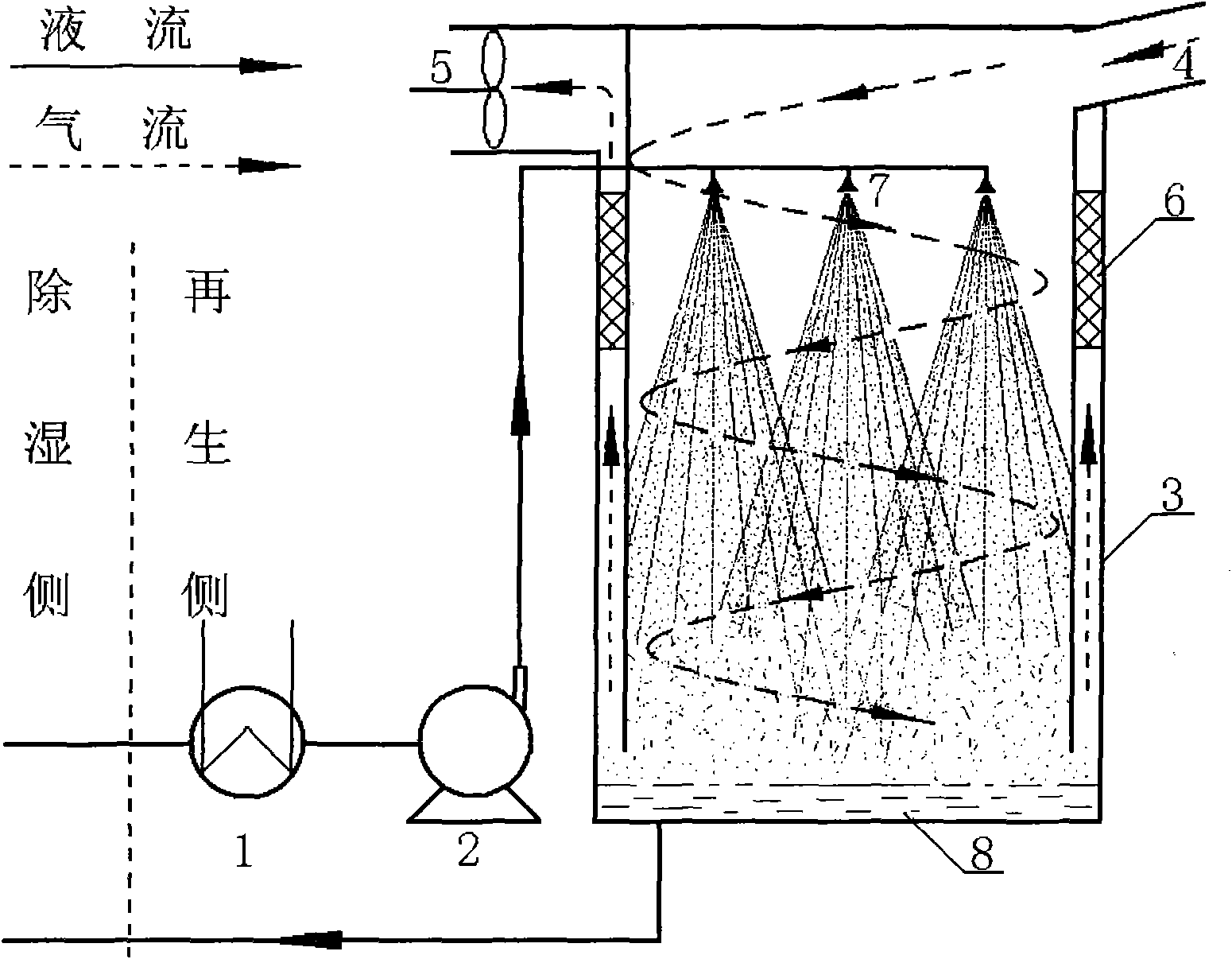

Method and device for regenerating liquid desiccant

InactiveCN101810935AOne-way concentration increaseReduce volumeDispersed particle separationEvaporation by sprayingEngineeringLiquid desiccant

The invention provides a method and a device for regenerating a liquid desiccant, which belongs to the field of air moisture adjustment. The device comprises an external heat source (1), a solution pump (2) and a pot-type container (3), wherein one end of the pot-type container (3) is provided with a regenerated air intake distributor (4) while the other end is connected with a draught fan (5); and a demisting component (6) and an atomizer (7) are arranged in the pot-type container (3). The method for regenerating the liquid desiccant comprises the following steps of: heating the liquid desiccant by the external heat source (1), and then delivering the heated liquid desiccant to the pot-type container (3) by the solution pump (2); atomizing the liquid desiccant by the atomizer (7) to form tiny fog drops; and performing heat and mass exchange on the fog drops and the air entering from the air intake distributor (4) to realize the regeneration of the liquid desiccant. The method and the device for regenerating the liquid desiccant significantly improve the regeneration effect, and the one-way solution process concentration change can be promoted by 1.5 to 3 percent; the heat utilization efficiency is high and reaches over 70 percent; and the device has a simple structure and is convenient to operate and maintain.

Owner:BEIJING UNIV OF CHEM TECH

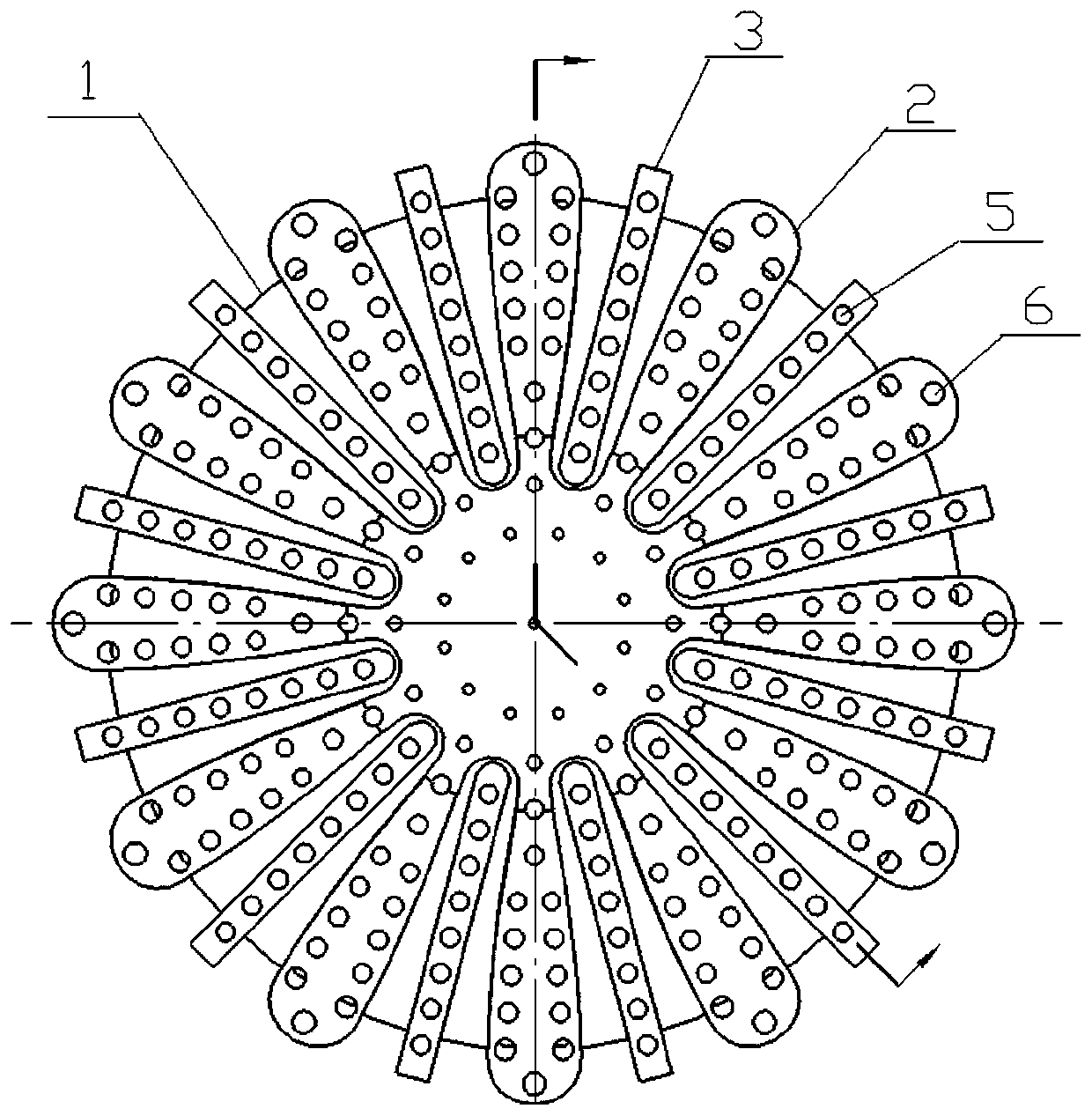

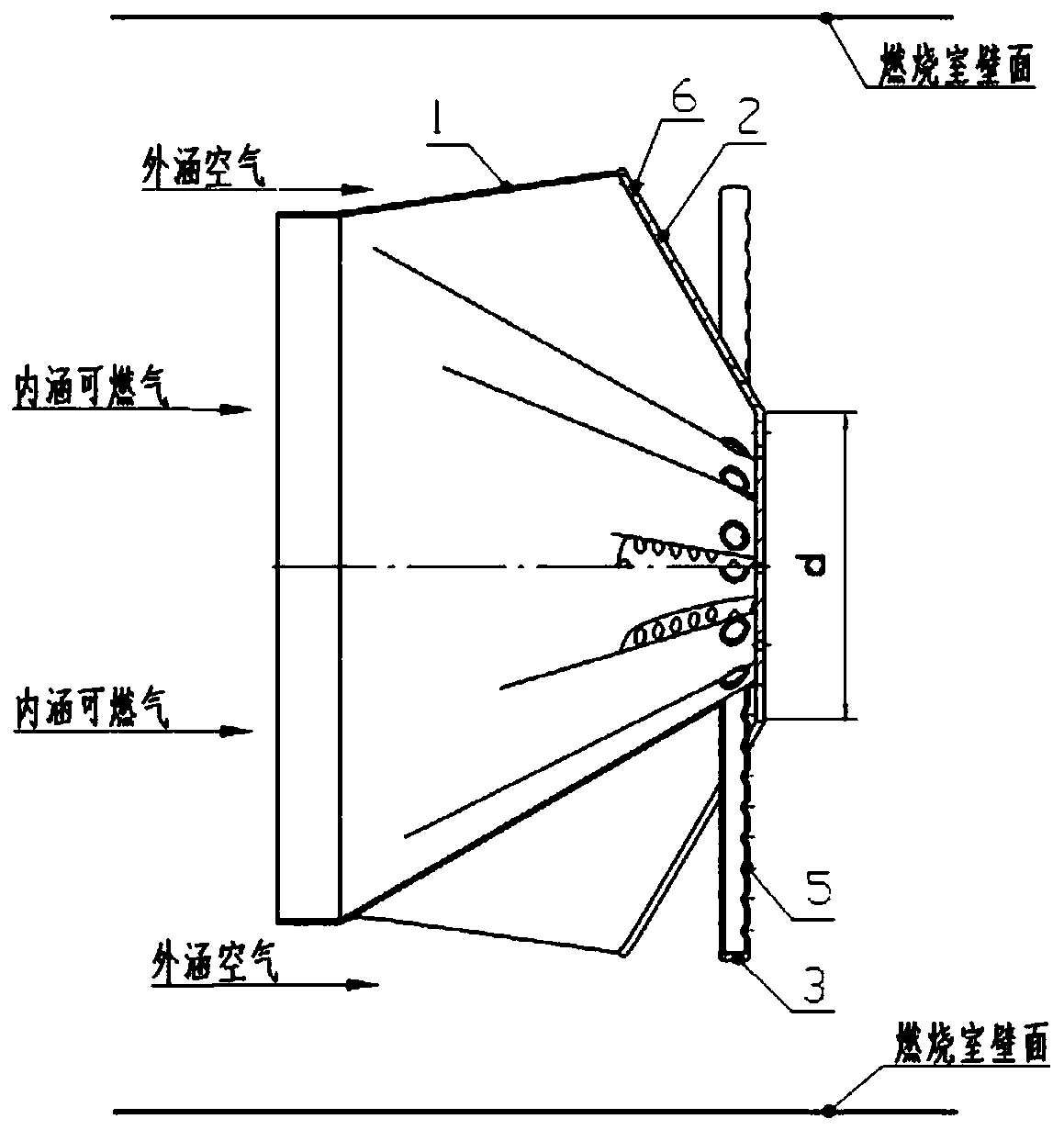

Mixing flame stabilizing device

PendingCN110939530AShorten the mixing distanceEfficient mixingContinuous combustion chamberRocket engine plantsCombustion chamberCombustible gas

The invention relates to the technical field of engines, and discloses a mixing flame stabilizing device. The mixing flame stabilizing device comprises a lobe mixer, a cover plate and turbulent flow columns, wherein a gas collecting cavity is formed between the cover plate and the lobe mixer; the turbulent flow columns are arranged at the position of an outer culvert air flow outlet of the lobe mixer; inner cavities of the turbulent flow columns communicate with the gas collecting cavity; the side walls of the turbulent flow columns and the cover plate are provided with spraying holes a and spraying holes b correspondingly; combustible gas is subjected to secondary flow dividing through the spraying holes a and the spraying holes b and then enters a combustion chamber to be mixed with air,the spraying pressure of the combustible gas is increased, accordingly, the penetrating capacity of the combustible gas in the gaseous environment is improved, and accordingly efficient mixing of twoair flows is achieved; and the turbulent flow columns are arranged at the position of the outer culvert air flow outlet of the lobe mixer, a large-scale radial vortex can be formed on the downstreamportion of the turbulent flow columns, outer culvert air is forced to flow in the circumferential direction of the turbulent flow columns at an outlet of the mixer, the mixing distance of the outer culvert air and inner culvert combustible gas is shortened, the mass exchange rate of the air and the combustible gas at an inner culvert outlet of the mixer is increased, and the mixing effect is improved.

Owner:XIAN AEROSPACE PROPULSION INST

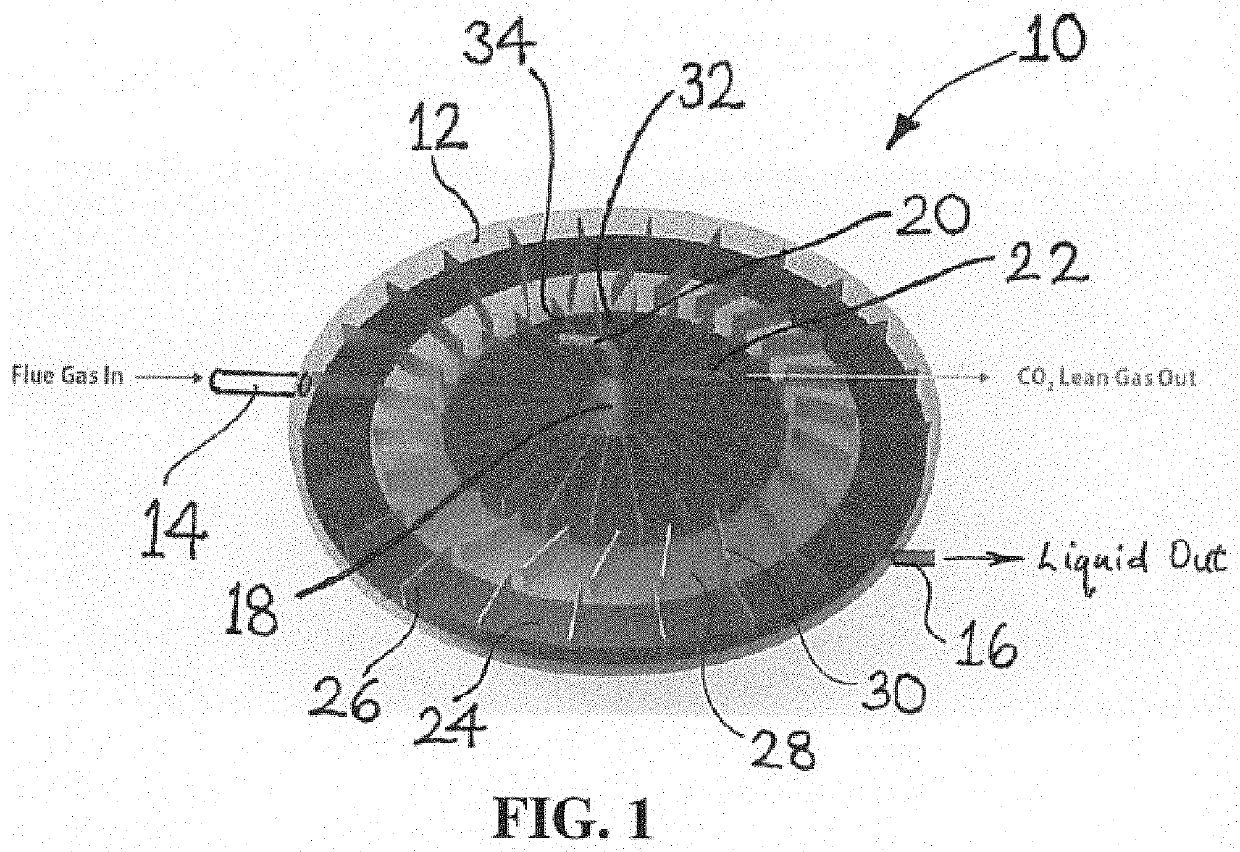

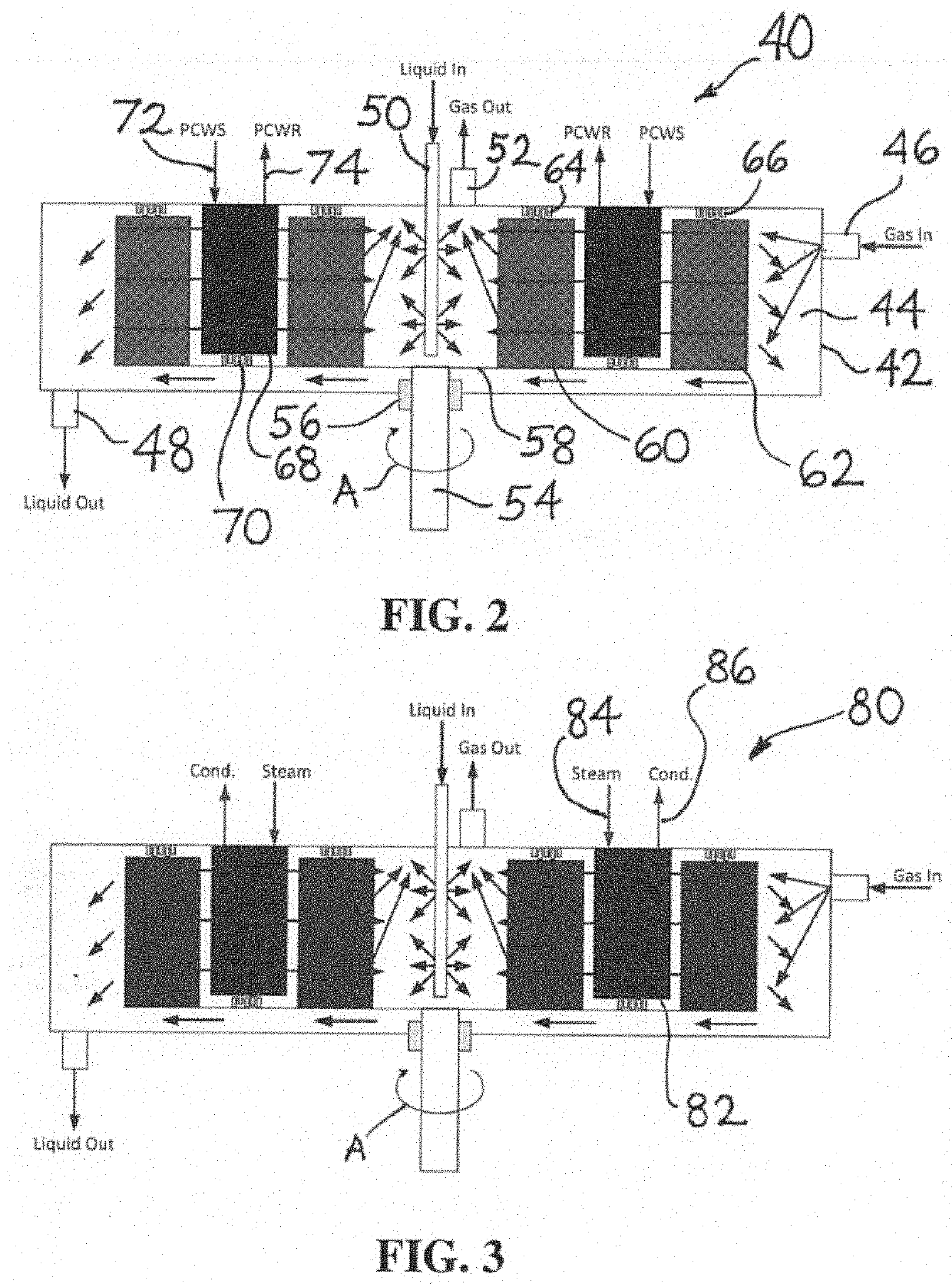

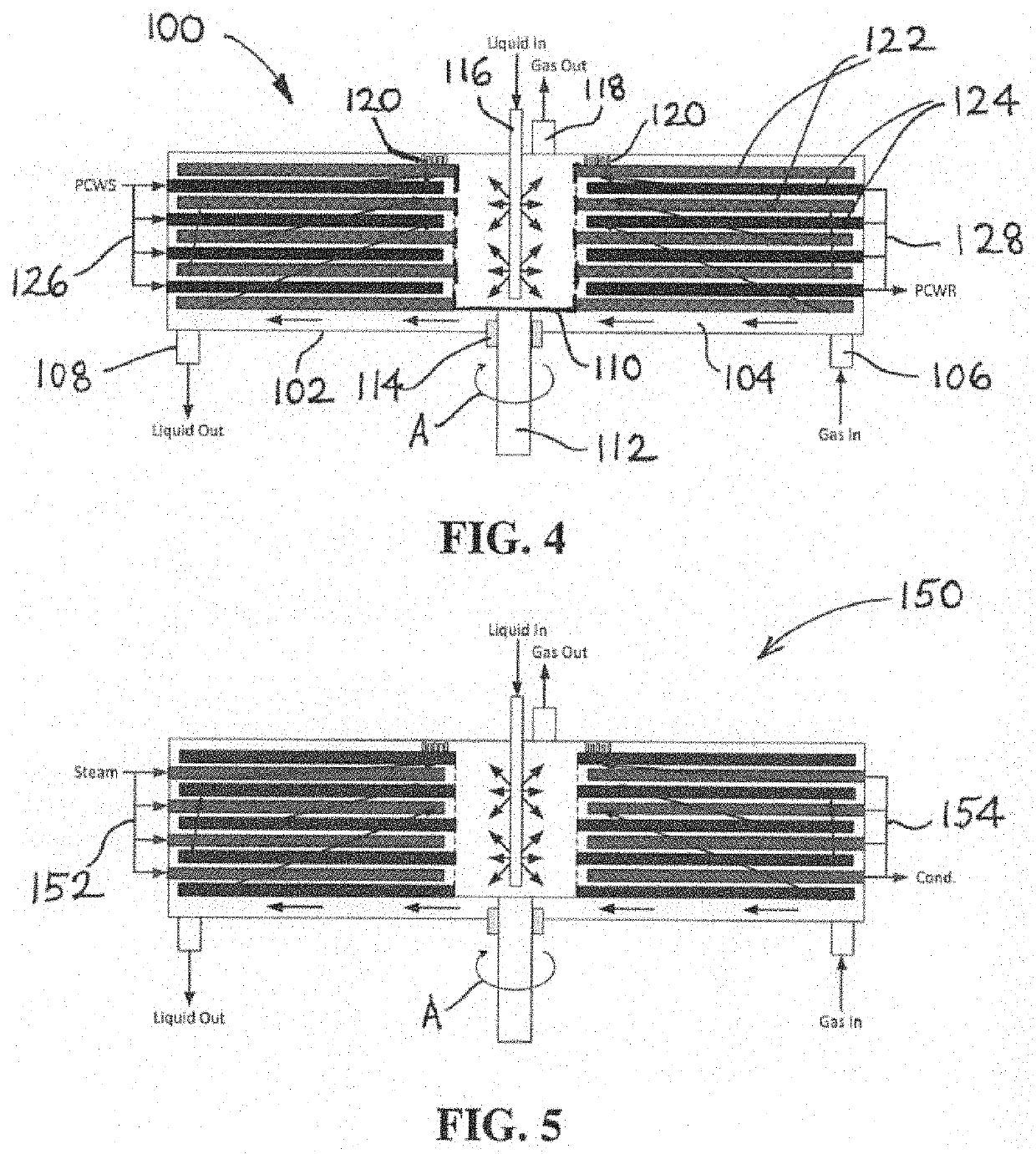

Rotating packed beds with internal heat transfer for absorption/regeneration applications

A gas-liquid contacting apparatus and method are described, in which at least one rotor assembly including packing is arranged in a contacting chamber containing at least one stator assembly including at least one heat exchanger arranged to thermally modulate the gas-liquid contacting so that each stator assembly is operatively arranged with each stator assembly to provide gas-liquid contacting at temperatures effective for mass exchange between the gas and liquid. The rotor and stator assemblies may be of annular shape, or may be of disk shape in a stacked array of rotor assemblies alternating with stator assemblies. Such apparatus and method are usefully employed for CO2 capture from CO2-containing flue gases such as combustion effluents from power generation plants.

Owner:RES TRIANGLE INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com