Super-gravity heat exchange process

A supergravity and process technology, applied in the field of heat exchange technology, can solve the problems of inconvenient gas exchange, small amount of atomization, large water droplets, etc., and achieve the effect of saving resources, increasing the number of mutual contact, and increasing the relative speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

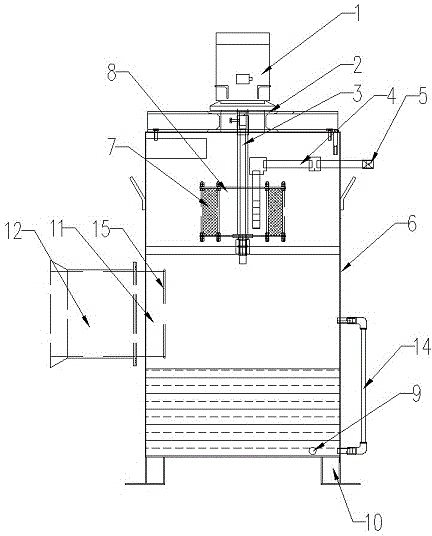

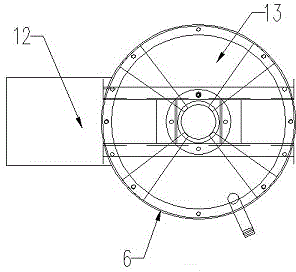

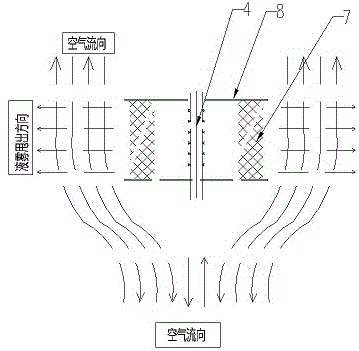

[0028] An embodiment, a high-gravity heat exchange process, the cooling liquid is sheared and dispersed by the high-gravity cooling liquid atomization device to form a high-speed moving water mist, which is in direct contact with the countercurrent spiral motion air generated by the heat exchange barrel 6 and the air inlet device Flow, by strengthening the heat transfer area between the cooling liquid and the air, increasing the relative velocity, and increasing the number of mutual contacts, the efficient heat and mass exchange between the cooling liquid and the air is realized.

[0029] The atomization steps of the supergravity coolant atomization device include:

[0030] 1) The high-gravity coolant atomization device rotates at high speed, the coolant is first refined through the coolant inlet device, and then evenly sprayed onto the filler of the high-gravity coolant atomization device for further crushing.

[0031] 2) The coolant is captured by the filler in a short time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com