Method and device for regenerating liquid desiccant

A liquid dehumidification and regeneration device technology, which is applied in the direction of separation methods, chemical instruments and methods, spray evaporation, etc., can solve the problems of high-grade energy consumption, complex operation and maintenance, and large equipment structure, etc., and achieves the convenience of regeneration operation and device The effect of maintenance, dehumidification energy consumption reduction, mass transfer effect improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

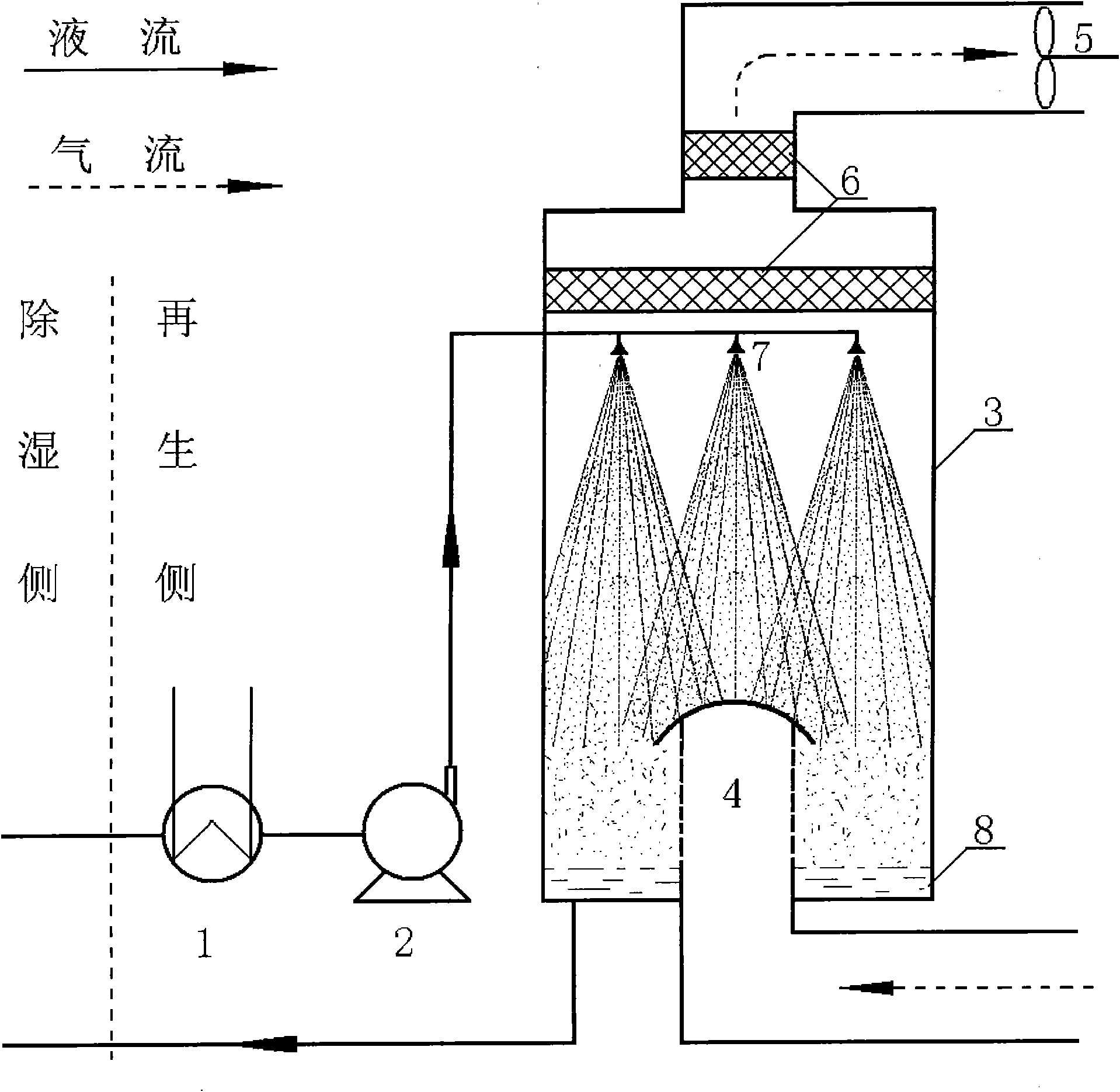

[0029] The embodiment flow process shown in accompanying drawing 1 is the flow process of countercurrent mode. The main structure of the device of this embodiment is a tank container (3), the length-to-diameter ratio is 2:1, and the top inside is provided with demisting parts (6) and atomizer (7) sequentially from top to bottom; the middle section is The liquid desiccant atomization and gas-liquid contact space, the bottom is a liquid storage space (8); the lower part is also provided with an air inlet distributor (4). The defogging parts are filled with structured metal fillers.

[0030] The liquid desiccant used in this embodiment is an aqueous solution of lithium chloride, and the regeneration inlet concentration is 32.65%. The atomizer is a pressure nozzle. When the operating pressure is 0.65MPa and the operating liquid-gas ratio is 1.2, the atomizer can break the liquid desiccant into liquid particles with an average particle size of about 60μm. The solution is heated t...

Embodiment 2

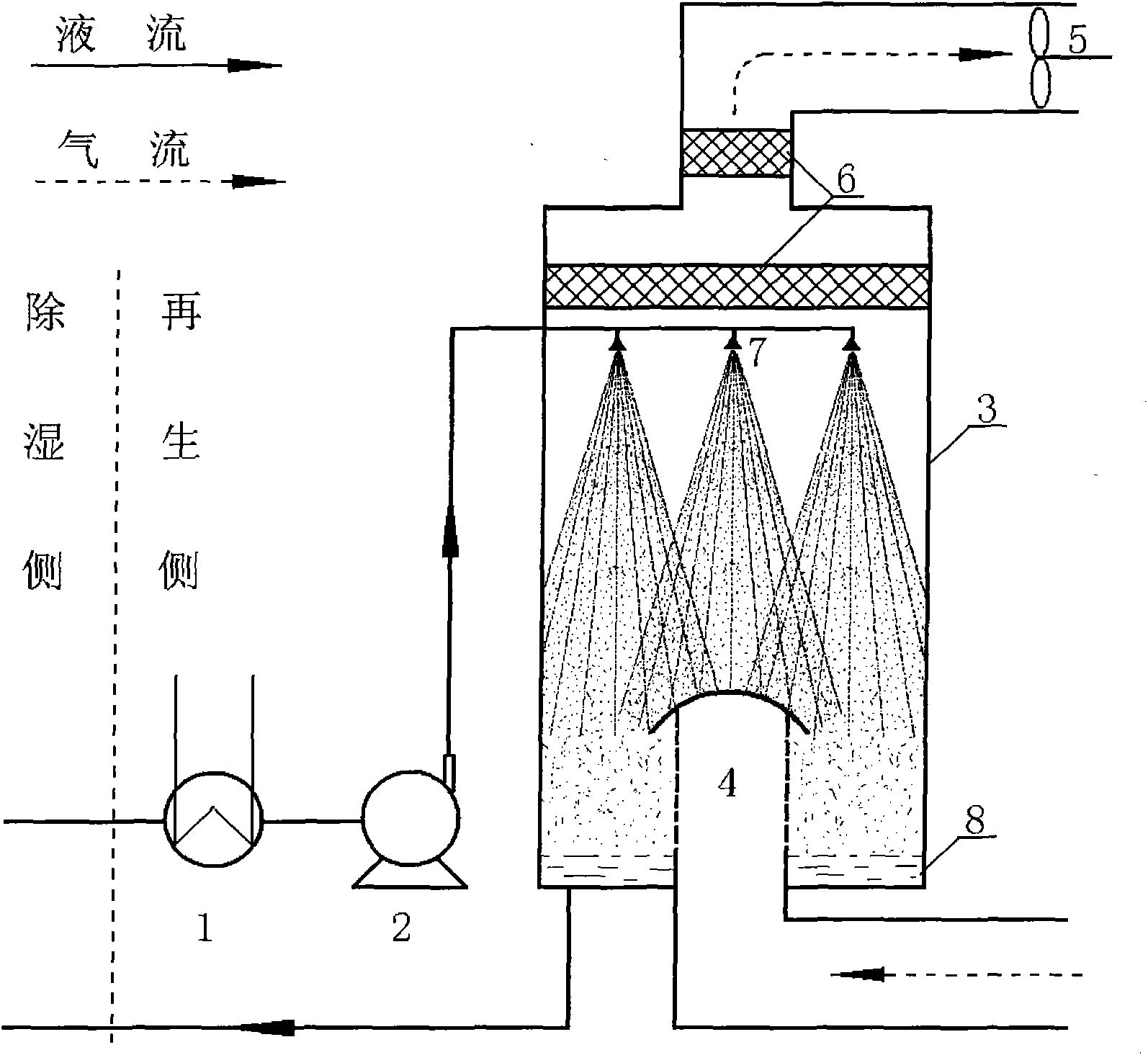

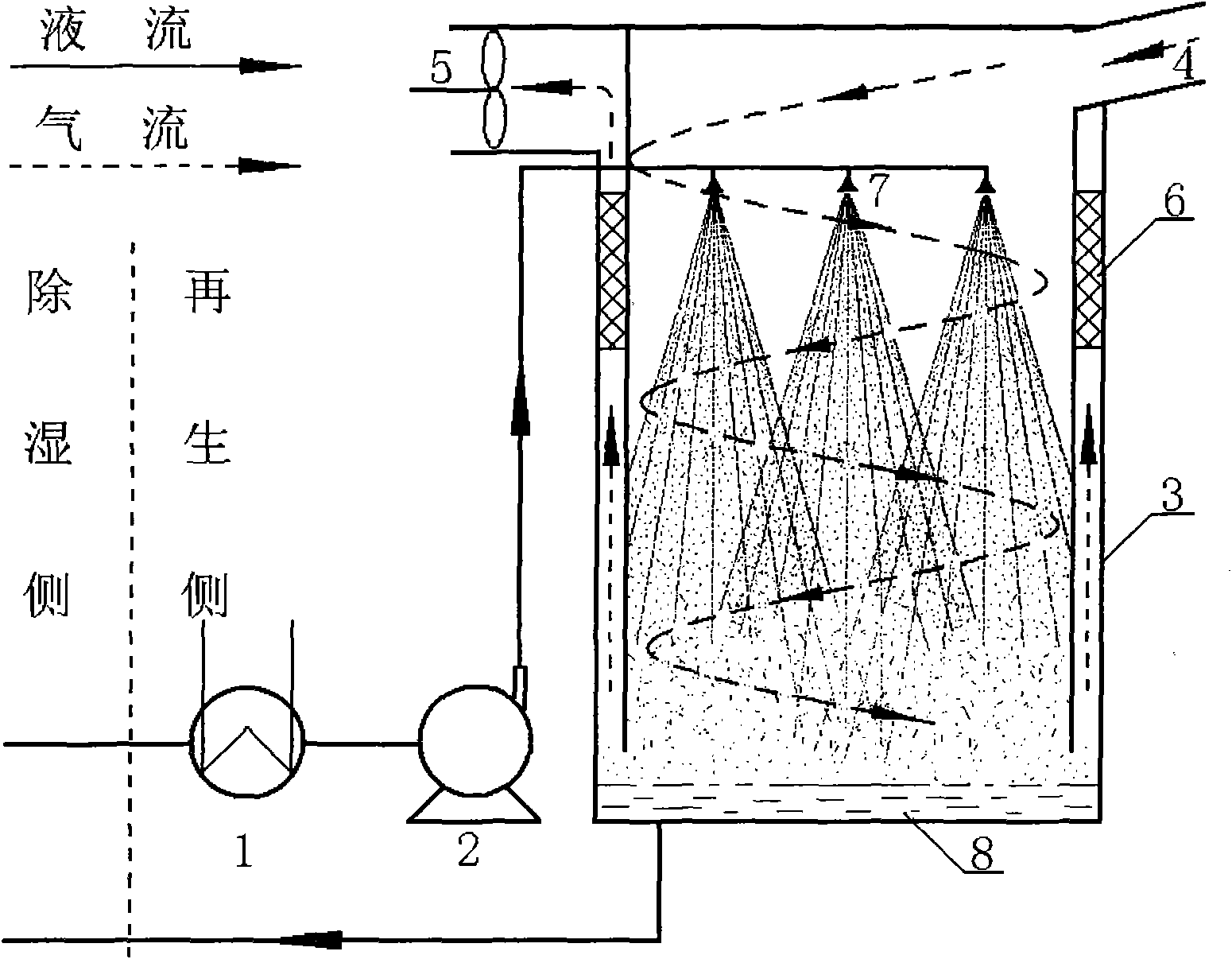

[0032] The embodiment process shown in accompanying drawing 2 is the flow process of downstream mode. The main structure of the device in this embodiment is a tank container (3) with a length-to-diameter ratio of 2:1. The wall of the tank container is designed with an interlayer as the regeneration air outlet channel. The top inside is an atomizer (7); the middle section is a space for liquid desiccant atomization and gas-liquid contact, and the bottom is a liquid storage space (8). After being heated by an external heat source (1), the liquid desiccant to be regenerated is delivered to the atomizer (7) in the tank container (3) through the solution pump (2). The air inlet distributor (4) is at an angle of 30° to the axial direction, and the airflow enters along the tangential direction of the barrel wall, and after contacting with the liquid desiccant inside the tank container (3) for heat and mass exchange, the air flows from the bottom of the tank container (3). Above the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com