Catalyst loading component and loading method thereof

A catalyst and filling technology, applied in chemical instruments and methods, separation methods, chemical/physical processes, etc., can solve problems such as damage to synergistic functions, influence of mass transfer exchange and reaction effects, and simultaneous satisfaction of catalytic rectification packing and filling methods. , to achieve the effect of reducing resistance, easy implementation and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The packing member and packing method of the present invention are implemented on a small-diameter cold mold tower.

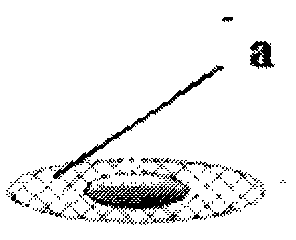

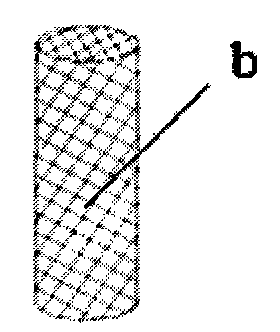

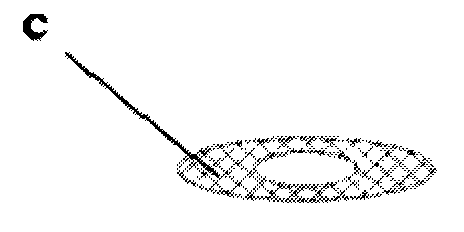

[0053] The selected small-diameter cold mold tower is made of plexiglass with an inner diameter of φ48×8mm, and the distance between the trays is 100mm. The vertical sieve plate cap is a cylindrical cap with a height of 45mm, an inner diameter of φ16mm, and a hole of φ2.5×50mm on the cap. A circular hole is opened in the center of the tray with a diameter of φ12mm. The cap is placed in the center of the tray, and four downcomers with an inner diameter of φ6mm are evenly distributed around the cap. Use catalyst component f of the present invention (packing structure is referring to image 3 ), the catalyst is a φ3×3mm θ wire mesh ring, and the filling height is 30mm. Air is the gas phase and water is the liquid phase. A cold mold experimental device is established for cold mold tests to investigate the hydrodynamic properties of the filling method.

[0...

Embodiment 2

[0056] The packing member and packing method of the present invention are implemented on a small-diameter cold mold tower.

[0057] The selected small-diameter cold mold tower is made of plexiglass with an inner diameter of φ24×8mm, and the spacing between the trays is 100mm. The vertical sieve plate cap is a cylindrical cap with a height of 35mm and an inner diameter of φ12mm. The opening on the cap is φ1.5× 40mm. A round hole is opened in the center of the tray, the hole diameter is φ8mm, the cap is placed in the center of the tray, and five downcomers with an inner diameter of φ3mm are evenly distributed around the cap. Use catalyst member f of the present invention, the catalyzer of filling in the member is φ 3mm spherical catalyst, and packing height is 20mm with air as gaseous phase, and water is liquid phase, set up cold mold experiment device and carry out cold mold test, investigate the fluid of this filling method mechanical properties.

[0058] The results of the ...

Embodiment 3

[0060] The packing member and packing method of the present invention are implemented on a small-diameter cold mold tower.

[0061] The selected small-diameter cold mold tower has an inner diameter of φ32×8mm plexiglass material, and the spacing between the trays is 100mm. The vertical sieve plate cap is a cylindrical cap with a height of 45mm, an inner diameter of φ12mm, and a hole of φ2×40mm on the cap. A circular hole is opened in the center of the tray with a diameter of φ10mm. The cap is placed in the center of the tray, and four downcomers with an inner diameter of φ3mm are evenly distributed around the cap. Using the catalyst component f of the present invention, the catalyst loaded in the component is a clover-type catalyst, and the filling height is 30mm. With air as the gas phase and water as the liquid phase, a cold model experimental device was established to carry out the cold model test to investigate the hydrodynamic properties of the filling method.

[0062] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com