A mold that can improve the yield of TV casings

A TV casing and yield technology, applied in the direction of coating, etc., can solve the problems affecting the TV casing yield and finished product speed, and achieve the effect of simple structure, reduced wear and convenient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

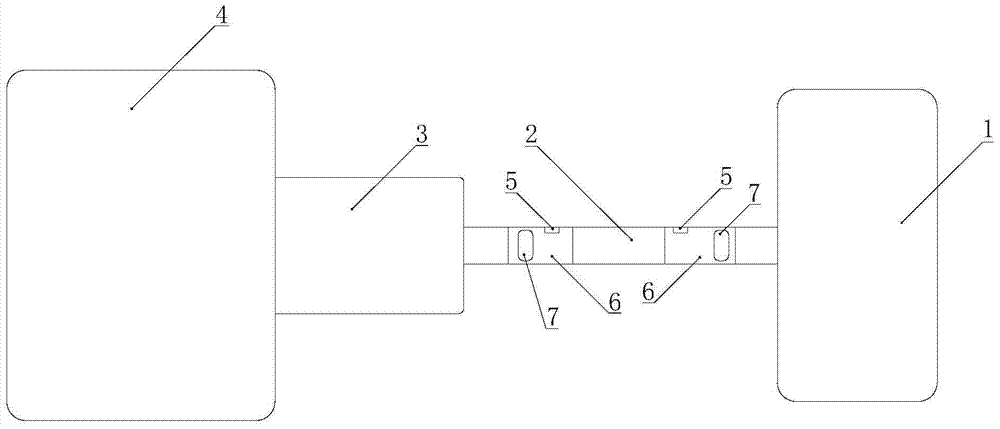

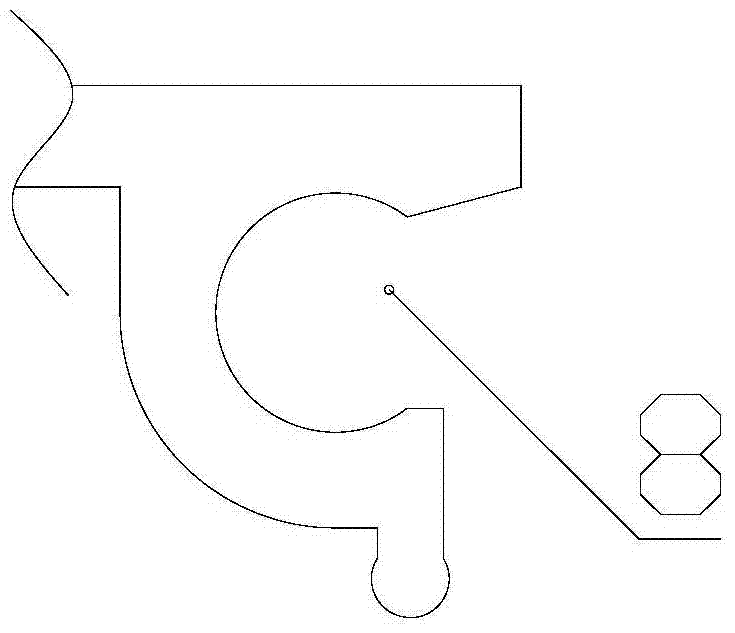

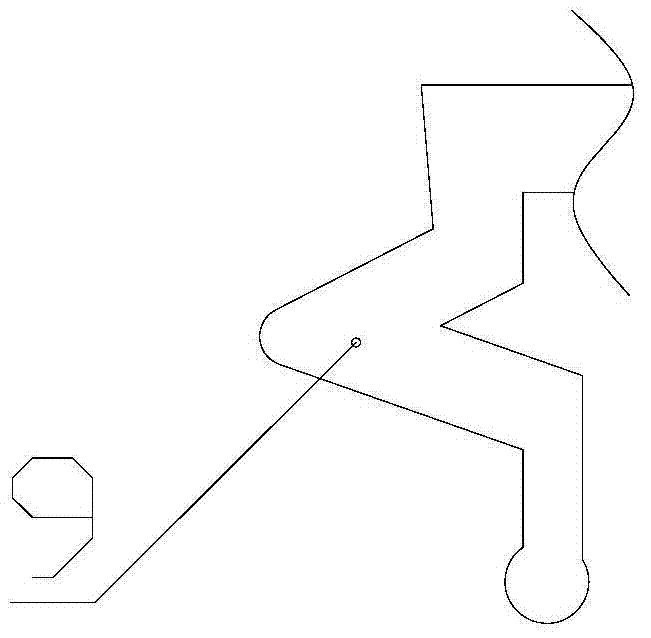

[0028] Corresponding reference characters indicate corresponding parts throughout the views of the drawings.

[0029] A mold that can improve the yield of TV casings, including a hot-melt mechanism 1 for melting raw materials into liquid, the hot-melt mechanism 1 is connected to an injection gun 3 through a pipeline 2, and the injection port of the injection gun 3 is connected to the TV casing for molding The mold 4 and the pipeline 2 are provided with a hydrogen gas inlet 5; the hydrogen gas structure is adopted, and the hydrogen gas can remove moisture in raw materials, thereby improving yield and speed.

[0030] The pipeline 2 is provided with more than two hydrogen chambers 6 communicating with the pipeline 2, the hydrogen inlet 5 is arranged on the hydrogen chamber 6, and the hot-melt mechanism 1 is connected to the injection gun 3 through more than two hydrogen chambers 6 in the pipeline 2 , as an implementation, the distance between two adjacent hydrogen chambers is 15m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com